How to install the hoist mechanism actuator of the craneHow to install the hoist mechanism actuator of the craneBrake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various explosion-proof brakes, non-standard brakes, brake pads, brake wheels, brake discs, and customized non-standard brakes according to user needsTel: 15838971872Various arm disc brakes, various electromagnetic, hydraulic and pneumatic caliper disc brakesVarious electromagnetic block type stop washers, hydraulic brakes, pneumatic, drum brakes,

time:2022-04-07

More

How to install the hoist mechanism actuator of the craneHow to install the hoist mechanism actuator of the craneBrake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various explosion-proof brakes, non-standard brakes, brake pads, brake wheels, brake discs, and customized non-standard brakes according to user needsTel: 15838971872Various arm disc brakes, various electromagnetic, hydraulic and pneumatic caliper disc brakesVarious electromagnetic block type stop washers, hydraulic brakes, pneumatic, drum brakes,

time:2022-04-07

More

How to install the hoist mechanism actuator of the craneHow to install the hoist mechanism actuator of the craneBrake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various explosion-proof brakes, non-standard brakes, brake pads, brake wheels, brake discs, and customized non-standard brakes according to user needsTel: 15838971872Various arm disc brakes, various electromagnetic, hydraulic and pneumatic caliper disc brakesVarious electromagnetic block type stop washers, hydraulic brakes, pneumatic, drum brakes,

time:2022-04-07

More

How to install the hoist mechanism actuator of the craneHow to install the hoist mechanism actuator of the craneBrake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various explosion-proof brakes, non-standard brakes, brake pads, brake wheels, brake discs, and customized non-standard brakes according to user needsTel: 15838971872Various arm disc brakes, various electromagnetic, hydraulic and pneumatic caliper disc brakesVarious electromagnetic block type stop washers, hydraulic brakes, pneumatic, drum brakes,

time:2022-04-07

More

How to install the hoist mechanism actuator of the craneHow to install the hoist mechanism actuator of the craneBrake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various explosion-proof brakes, non-standard brakes, brake pads, brake wheels, brake discs, and customized non-standard brakes according to user needsTel: 15838971872Various arm disc brakes, various electromagnetic, hydraulic and pneumatic caliper disc brakesVarious electromagnetic block type stop washers, hydraulic brakes, pneumatic, drum brakes,

time:2022-04-07

More

How to install the hoist mechanism actuator of the craneHow to install the hoist mechanism actuator of the craneBrake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various explosion-proof brakes, non-standard brakes, brake pads, brake wheels, brake discs, and customized non-standard brakes according to user needsTel: 15838971872Various arm disc brakes, various electromagnetic, hydraulic and pneumatic caliper disc brakesVarious electromagnetic block type stop washers, hydraulic brakes, pneumatic, drum brakes,

time:2022-04-07

More

How to install the hoist mechanism actuator of the craneHow to install the hoist mechanism actuator of the craneBrake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various explosion-proof brakes, non-standard brakes, brake pads, brake wheels, brake discs, and customized non-standard brakes according to user needsTel: 15838971872Various arm disc brakes, various electromagnetic, hydraulic and pneumatic caliper disc brakesVarious electromagnetic block type stop washers, hydraulic brakes, pneumatic, drum brakes,

time:2022-04-07

More

How to install the hoist mechanism actuator of the craneHow to install the hoist mechanism actuator of the craneBrake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various explosion-proof brakes, non-standard brakes, brake pads, brake wheels, brake discs, and customized non-standard brakes according to user needsTel: 15838971872Various arm disc brakes, various electromagnetic, hydraulic and pneumatic caliper disc brakesVarious electromagnetic block type stop washers, hydraulic brakes, pneumatic, drum brakes,

time:2022-04-07

More

The working principle of an electric hydraulic brake is as follows: 1. Overview of the braking system. The brake is the brake. It is a Machine element that stops or decelerates the moving parts in the machine. Commonly known as brakes or brakes. The brake mainly consists of a brake frame, brake components, and control devices, etcComposition. Some brakes are also equipped with automatic adjustment devices for brake component clearances. In order to reduce braking torque and structural dimensions, the brake is usually installed on the high-speed shaft of the equipment, but it is not safeLarge equipment with high integrity requirements (such as mine hoists, elevators, etc.) should be installed on the low-speed shaft near the working part of the equipment. Some brakes have been standardized and serialized, and have been replaced byManufactured by the factory for selection. One piece brake shoe brake is a brake that relies on the brake pads pressed against the brake wheels to achieve braking. A single brake block has a large and uneven pressure on the brake wheel axle, so an additional pair of brake blocks is usually used to counteract the pressure exerted by the brake blocks on the brake wheel axle. There are two types of block brakes: externally locked and internally tensioned External block brake: It is divided into short stroke block brake and long stroke block brake according to the length of the control device stroke. The magnet of the short stroke block brake is directlyMounted on the brake arm. During operation, the moving iron core rotates around the pin shaft to achieve brake release; When the magnet is powered off, it is tightly closed by the main spring. This type of brake has a compact structure and fast tightening and releasing actions, butHigh impact force. Long travel block brakes can generate a large release force through the brake lever system, but the braking action is slow and suitable for large brakes Internally tensioned block brake: The brake block is located inside the brake wheel, and is opened by the pedal, pull rod, and convex block to compress the inner surface of the brake wheel and tighten the brake. If the pedal is released, it will springPull the spring back to the brake block and release the brake. This type of brake can also be operated by hydraulic or pneumatic pressure. The internal tension block brake has a compact structure and good dust resistance, which can be used for installation in the field of spaceIt is widely used in various vehicles. Block brake pads This standard is applicable to external double block brakes. According to the connection method between the brake pad (referred to as the brake pad) and the brake pad, and whether there is a counterbore at the end of the brake pad hinge hole, there are four types: B1 type: the rivet hole on the brake pad is connected by adhesive method to the brake pad, and the end of the brake pad hinge hole is not counterbore; B1C type: without rivet holes on the brake pad, connected to the pad by bonding, and the end of the brake pad hinge hole has a countersunk hole; B2 type: There are rivet holes on the brake pad, which are connected to the brake pad by riveting. The end of the brake pad hinge shaft also has no countersunk holes; B2C type: There are rivet holes on the brake pad, which are connected to the brake pad by riveting. The end of the brake pad hinge also has a countersunk hole 2 disc brake disc brake is a hydraulic actuator used in the braking system of mine hoists. The accurate name should be: normally closed rear oil cylinder disc brake, which is currently widely usedThe rear mounted oil cylinder is used. When the hoist is started, the hydraulic station outputs pressure oil to open the brake, and the hoist starts working. When the working brake is applied, the hydraulic station increases or decreases according to the working conditionsUnder low pressure, the brake will provide opposite braking force. In an accident state, the hydraulic station pressure returns to residual pressure, and the brake will lift with high braking force in a short period of timeThe DHD series brakes are friction disc brakes (hereinafter referred to as brakes) that apply spring pressure during electromagnetic disengagement (release) and power outage. It can be paired with electric power to form a new typeBrake motors can also be used in mechanical transmission systems to achieve fast parking and accurate positioning, and can be used in situations such as safe (emergency) braking during power outages. This type of brake has a structureIt has the advantages of simplicity, wide adaptability, low noise, and reliable braking, and is widely used in various mechanical transmission devices. It is an ideal executive component in industrial modernization. livingThe automation of production technology requires ultra-thin power-off brakes (safety brakes) to meet the needs of various machinery such as robots and motors for different purposes with their excellent characteristics. Structural features: 1. Compact structure. Although the axial size of the power loss brake is small, the braking torque is large enough. 2. The quick response and power loss brake uses a spring device to form braking torque, and the spring reset time is the braking response time. 3. Long service life and power loss brake use new friction materials, which determine the performance of high service life. The brake can work reliably under the following conditions: 1. The relative humidity of the surrounding air is not more than 85% (20 ± 5 ℃); 2. There is no gas or dust in the surrounding medium that is sufficient to corrode metals and damage insulation. 3. The brake is equipped with Class B insulation around it, with voltage fluctuations not exceeding+5% and -15% of the rated voltage. Its working mode is continuous operation. 4. During installation, the matching accuracy between the transmission shaft and the brake should be ensured. 5. The brake disc of the brake must be used without oil stains. Structure and working principle: The brake is composed of a magnetic yoke, excitation coil, spring, brake disc, armature, spline sleeve, installation screws, etc. The brake is installed on the flange plate (or motor) of the equipmentRear end extension; The transmission shaft is connected to the spline sleeve and the brake disc. When the excitation coil of the brake is connected to the rated voltage (DC), the electromagnetic force attracts the armature, causing it to detach (release) from the brake disc. At this time, the transmission shaft is carrying the brake discNormally running or starting, when the transmission system separates or loses power, the brake also loses power. At this time, the spring exerts pressure on the armature, forcing the brake disc to generate force between the armature and the flange plateFriction torque makes the transmission shaft stop quickly. When the heat dissipation environment of the brake is poor and the transmission shaft operates continuously for a long time, if conditions permit, the brake can be operatedAfterwards, maintain the voltage conversion to 70% -80% of the rated voltage to reduce heating.fifteen billion eight hundred and thirty-eight million nine hundred and seventy-one thousand eight hundred and seventy-twoThe working principle of an electric hydraulic brake is as follows: 1. Overview of the braking system. The brake is the brake. It is a Machine element that stops or decelerates the moving parts in the machine. Commonly known as brakes or brakes. The brake mainly consists of a brake frame, brake components, and control devices, etcComposition. Some brakes are also equipped with automatic adjustment devices for brake component clearances. In order to reduce braking torque and structural dimensions, the brake is usually installed on the high-speed shaft of the equipment, but it is not safeLarge equipment with high integrity requirements (such as mine hoists, elevators, etc.) should be installed on the low-speed shaft near the working part of the equipment. Some brakes have been standardized and serialized,And byHigh impact force. Long travel block brakes can generate a large release force through the brake lever system, but the braking action is slow and suitable for large brakes Internally tensioned block brake: The brake block is located inside the brake wheel, and is opened by the pedal, pull rod, and convex block to compress the inner surface of the brake wheel and tighten the brake. If the pedal is released, it will springPull the spring back to the brake block and release the brake. This type of brake can also be operated by hydraulic or pneumatic pressure. The internal tension block brake has a compact structure and good dust resistance, which can be used for installation in the field of spaceIt is widely used in various vehicles. Block brake pads This standard is applicable to external double block brakes. According to the connection method between the brake pad (referred to as the brake pad) and the brake pad, and whether there is a counterbore at the end of the brake pad hinge hole, there are four types: B1 type: the rivet hole on the brake pad is connected by adhesive method to the brake pad, and the end of the brake pad hinge hole is not counterbore; B1C type: without rivet holes on the brake pad, connected to the pad by bonding, and the end of the brake pad hinge hole has a countersunk hole; B2 type: There are rivet holes on the brake pad, which are connected to the brake pad by riveting. The end of the brake pad hinge shaft also has no countersunk holes; B2C type: There are rivet holes on the brake pad, which are connected to the brake pad by riveting. The end of the brake pad hinge also has a countersunk hole 2 disc brake disc brake is a hydraulic actuator used in the braking system of mine hoists. The accurate name should be: normally closed rear oil cylinder disc brake, which is currently widely usedThe rear mounted oil cylinder is used. When the hoist is started, the hydraulic station outputs pressure oil to open the brake, and the hoist starts working. When the working brake is applied, the hydraulic station increases or decreases according to the working conditionsUnder low pressure, the brake will provide opposite braking force. In an accident state, the hydraulic station pressure returns to residual pressure, and the brake will lift with high braking force in a short period of timeThe DHD series brakes are friction disc brakes (hereinafter referred to as brakes) that apply spring pressure during electromagnetic disengagement (release) and power outage. It can be paired with electric power to form a new typeBrake motors can also be used in mechanical transmission systems to achieve fast parking and accurate positioning, and can be used in situations such as safe (emergency) braking during power outages. This type of brake has a structureIt has the advantages of simplicity, wide adaptability, low noise, and reliable braking, and is widely used in various mechanical transmission devices. It is an ideal executive component in industrial modernization. livingThe automation of production technology requires ultra-thin power-off brakes (safety brakes) to meet the needs of various machinery such as robots and motors for different purposes with their excellent characteristics. Structural features: 1. Compact structure. Although the axial size of the power loss brake is small, the braking torque is large enough. 2. The quick response and power loss brake uses a spring device to form braking torque, and the spring reset time is the braking response time. 3. Long service life and power loss brake use new friction materials, which determine the performance of high service life. The brake can work reliably under the following conditions: 1. The relative humidity of the surrounding air is not more than 85% (20 ± 5 ℃); 2. There is no gas or dust in the surrounding medium that is sufficient to corrode metals and damage insulation. 3. The brake is equipped with Class B insulation around it, with voltage fluctuations not exceeding+5% and -15% of the rated voltage. Its working mode is continuous operation. 4. During installation, the matching accuracy between the transmission shaft and the brake should be ensured. 5. The brake disc of the brake must be used without oil stains. Structure and working principle: The brake is composed of a magnetic yoke, excitation coil, spring, brake disc, armature, spline sleeve, installation screws, etc. The brake is installed on the flange plate (or motor) of the equipmentRear end extension; The transmission shaft is connected to the spline sleeve and the brake disc. When the excitation coil of the brake is connected to the rated voltage (DC), the electromagnetic force attracts the armature, causing it to detach (release) from the brake disc. At this time, the transmission shaft is carrying the brake discNormally running or starting, when the transmission system separates or loses power, the brake also loses power. At this time, the spring exerts pressure on the armature, forcing the brake disc to generate force between the armature and the flange plateFriction torque makes the transmission shaft stop quickly. When the heat dissipation environment of the brake is poor and the transmission shaft operates continuously for a long time, if conditions permit, the brake can be operatedAfterwards, maintain the voltage conversion to 70% -80% of the rated voltage to reduce heating.

time:2022-04-07

More

Mining explosion-proof hydraulic thruster BED121/6bed201/6Dedicated to coal mines, cranes, and mining machineryBEd-121/12, BEd-201/12, BEd-301/12Manufacturer's prices for BEd30/5, BEd50/6, BEd80/6, BEd80/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd121/6, BEd201/6, BEd301/6, BEd30/5 explosion-proof electric hydraulic thrustersManufacturer prices for BEd121/12, BEd201/12, BEd301/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd-30/5, BEd-50/6, BEd-80/6, BEd-80/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd-121/6, BEd-201/6, BEd-301/6, BEd-30/5 explosion-proof electric hydraulic thrustersManufacturer prices for BEd-121/12, BEd-201/12, BEd-301/12 explosion-proof electric hydraulic thrustersThe BED series explosion-proof electric hydraulic thrusters are mainly used as driving devices for electric hydraulic drum brakes, and can also achieve rapid movements such as reciprocating, circular, and swinging through levers. They are suitable for industries such as lifting, transportation, metallurgy, mining, ports, and construction; Its explosion-proof performance complies with the provisions of GB3836.2-2000 "Explosion proof Electrical Equipment and Explosion proof Electrical Equipment for Explosive Atmospheres" d ". The explosion-proof signs are" dI "and" DIICT4 ", which are respectively used in coal mines and IIA, IIB, IIC (Class I, II, Class B, Class II, Class C, Class II) temperature groups T1-T4 combustible gases or explosive mixtures formed by steam and airBYWZ5 explosion-proof electric hydraulic brake has complete models, low prices, excellent quality, complete certificates, fast delivery, Cash on delivery and door-to-door delivery.The order is packaged in wooden boxes and straw ropes, with a one-year shelf life.Shandong BYWZ5 explosion-proof brake price, BYWZ5 explosion-proof brake manufacturer direct sales, Shandong explosion-proof brake production.Shanxi BYWZ5 explosion-proof brake quotation, BYWZ5 explosion-proof brake low price supply, Shanxi explosion-proof brake manufacturer.The main sales regions for explosion-proof brakes are Henan, Hebei, Shandong, Shanxi, Zhejiang, Chongqing, Gansu, Xinjiang, and Urumqi.Dedicated to coal mines, cranes, and mining machinery

time:2022-04-07

More

Jiaozuo Hydraulic Safety Disc Brake FactoryProduct Introduction of Jiaozuo Hydraulic Safety Disk Brake Factory:Brakes:Electric hydraulic brake, electric hydraulic drum brake, electromagnetic block brake, electric hydraulic windproof iron wedge brakeSafety wind brake electromagnetic failure protection disc brake electric hydraulic arm disc brake wind electric yaw brakeWind power spindle brake Pneumatic caliper disc brake Hydraulic failure protection Brake electromagnetic failure protection BrakeHydraulic direct acting disc brake electromagnetic caliper disc brake pneumatic failure protection brake hydraulic direct acting brakeMotor disc brakePusher:Electric hydraulic thruster explosion-proof electric hydraulic thrusterBrake pads:1. Ordinary materials (resistant to high temperature of 400 degrees)2. High wear-resistant materials (4-8 times the service life of ordinary materials)3. Special wear-resistant material (8-12 times the service life of ordinary materials)4. Explosion proof materials5. Copper based material (resistant to high temperature of 800 degrees)6. Anticorrosive materialsNon standard products:1. YQP series: YQP50 YQP100 YQP160 YQP250 YQP315 YQP400 YQP3652. SB series: SB50 SB100 SB160 SB250 SB3653. YPZ series: YPZ2-I YPZ2-II YPZ2-III YPZ2-IV YPZ2-V YPZ2-VI P2-III4. QP series: QP12.7 QPL12.7-A QP25.4 QP30 QP405. YP series: YP1 YP2 YP3 YP11 YP21 YP31 YP416. Yaw series: (0.8 MW, 1.5 MW, 2 MW) DADH75 DADH80 DADH90 DADH103 DADH120 DADH1957. ADP series: ADP (H) 60 ADP (H) 90 ADP (H) 1208. SE series: 3SE (P) 4SE (P) 5SE (P) 450SE 56SE9. ST series: ST1SH ST2SH ST3SH ST4SH ST5SH ST10SH ST25SH ST25SH-A ST40SH ST3SH-A10. Wheel edge: YLBZ25-160 YLBZ40-160 YLBZ40-180 YLBZ40-200 YLBZ40-150 YLBZ63-180 YLBZ63-200YLBZ63-210 YLBZ100-20011. Copper based: FSH30 BSFA70 HB3012. Drilling rig: BSC90 ZWPS65-113. Wind power high-speed shaft: (0.8 MW, 1.5 MW, 2 MW)According to your needs, choose temperature resistance, wear resistance, select materials, provide drawings, or provide technical requirements to design friction coefficients according to production requirements.

time:2022-04-07

More

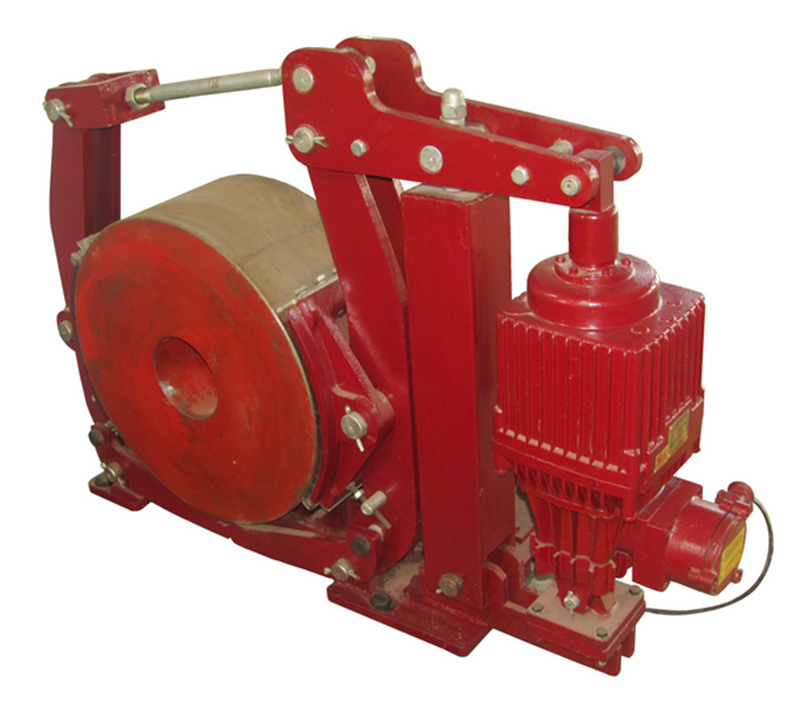

YWZ, YWZ2, YWZ3, YWZ4, YWZ5, YWZ9 series hydraulic block brakes are mainly used for mechanical braking of driving devices in lifting, transportation, metallurgy, mining, port, and construction machinery. They have the advantages of smooth braking, safety and reliability, convenient maintenance, low power consumption, long service life, and no noise.① The WYZ series can operate up to 720 times per hour. Comply with JB/ZQ4388-86 standard;② The WYZ2 series can operate up to 1200 times per hour, meeting the JB/ZQ4388-86 standard;③ The YWZ3 series can operate up to 720 times per hour, meeting the GB6333-86 standard;④ The YWZ4 series can operate up to 1200 times per hour, meeting the JB/ZQ4388-86 standard;⑤ The YWZ5 series can operate up to 1200 times per hour, meeting the GB6333-86 standard;2、 Usage conditions1. Environmental temperature -20 ℃~+50% (changed to YH-10 aviation hydraulic oil below the thruster)2. The relative humidity of the air shall not exceed 90%3. Generally used for three-phase AC power supply, 50HZ, 380V;4. The sea height meets the GB755-87 standard;5. In the absence of explosion hazards, and in the absence of gases and discharge dust in the medium that are sufficient to corrode metals and damage insulation;6. YZW and YZW3 use the YTI series thrusters, which are generally suitable for vertical work with a tilt of no more than ± 15 °Our company has always adhered to the business philosophy of "integrity builds brand, quality wins users". Provide users with comprehensive pre-sales, in sales, and after-sales services. Customer satisfaction is the eternal pursuit of all employees of our brake company! Over the years since entering the market, the products produced and sold have covered nearly thirty provinces and cities in China. The company is committed to building itself into an enterprise in the brake and related product industry with its team, rigorous management, and advanced equipment. The company adheres to using corporate culture to enhance its core competitiveness and establish a good social image in its development. Sincerely welcome new and old users to visit and patronize! Main products: electric hydraulic arm disc brake, pneumatic disc brake, hydraulic failure protection brake, electromagnetic failure protection brake, wheel edge brake, electric hydraulic wind proof iron wedge brake, ZWZ3 series electromagnetic DC drum brake, YWZB series electric hydraulic drum brake, YWZ3B series electric hydraulic drum brake, YWZ4 series electric hydraulic drum brake, YWZ5 series electric hydraulic drum brake, YWZ8 series electric hydraulic drum brake, YWZ9 series electric hydraulic drum brake, YWZ10 series electric hydraulic drum brake, YWZ13 series electric hydraulic drum brake, YWL series electric hydraulic drum brake, YWP series electric hydraulic drum brake, YW-E series electric hydraulic two-stage drum brake, YW series electric hydraulic drum brake, YW series pneumatic drum brake, ED series electric hydraulic thruster, The YT1 series electric hydraulic thrusters, BED series electric hydraulic thrusters, and BYT1 series electric hydraulic thrusters can operate up to 720 times per hour. Comply with JB/ZQ4388-86 standard;Main application scope: metallurgy, petrochemicals, large pumps, cable cars, mining machines, conveyor belts, port machines, track machines, heavy machinery, blowers, generator sets, etc. SIBRE drum gear couplings are divided into two major series: AGC and ZKES. The design of the AGC series refers to relevant Chinese standards and has the ability to replace the domestic GIICL series; The ZKES series adopts European design standards and has designed tooth shapes, which are more compact in structure compared to the AGC series and suitable for occasions with special requirements for installation dimensions and positions. The AGC series drum gear coupling is suitable for high-speed and low-speed shaft couplings of various industrial heavy-duty transmissions, such as steel mills, mines, lifting and transportation industries, and is also suitable for shaft transmission of various machinery such as petroleum, chemical, and general machinery. The main technical features of the AGC series include the ability to compensate for radial, axial, and angular deviations, with a large angle compensation of up to 1.5. It is characterized by compact structure, small Radius of gyration, large bearing capacity, high transmission efficiency, low noise and long maintenance cycle.

time:2022-04-07

More