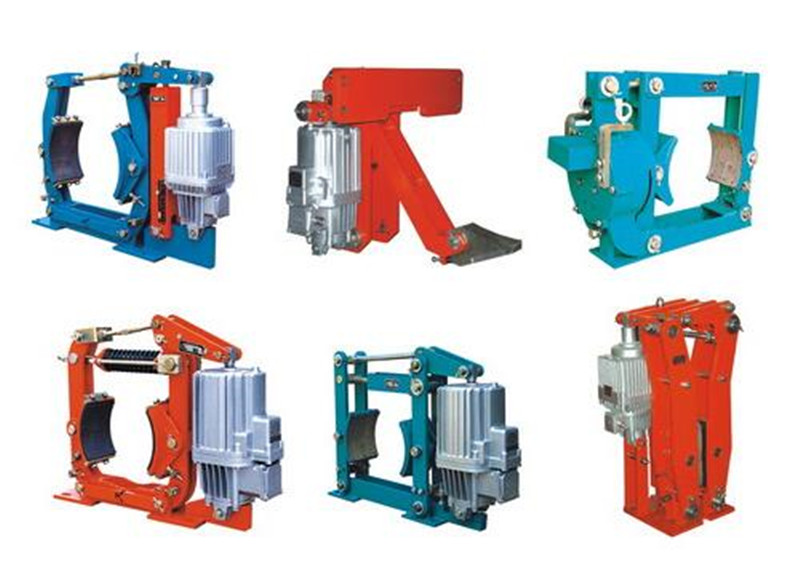

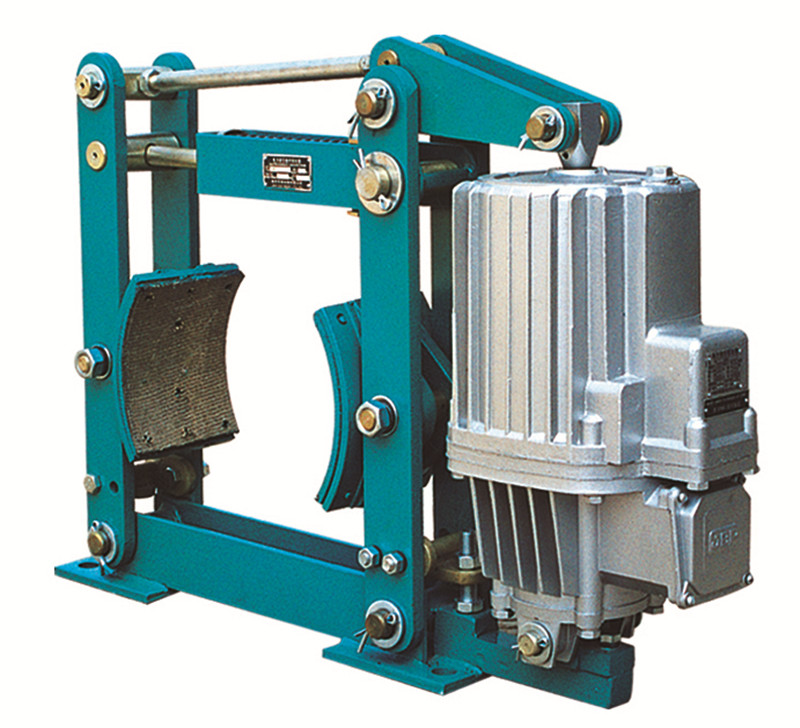

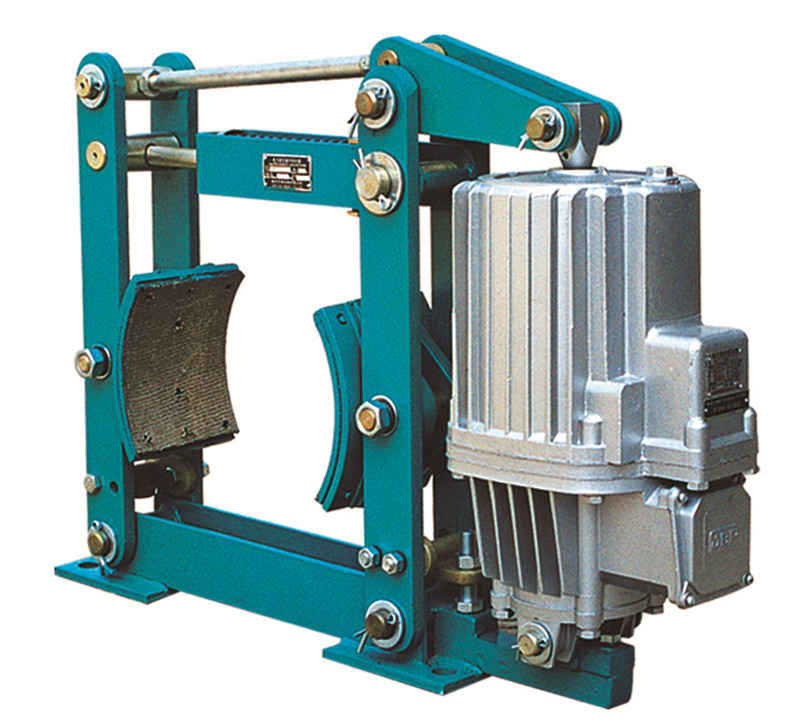

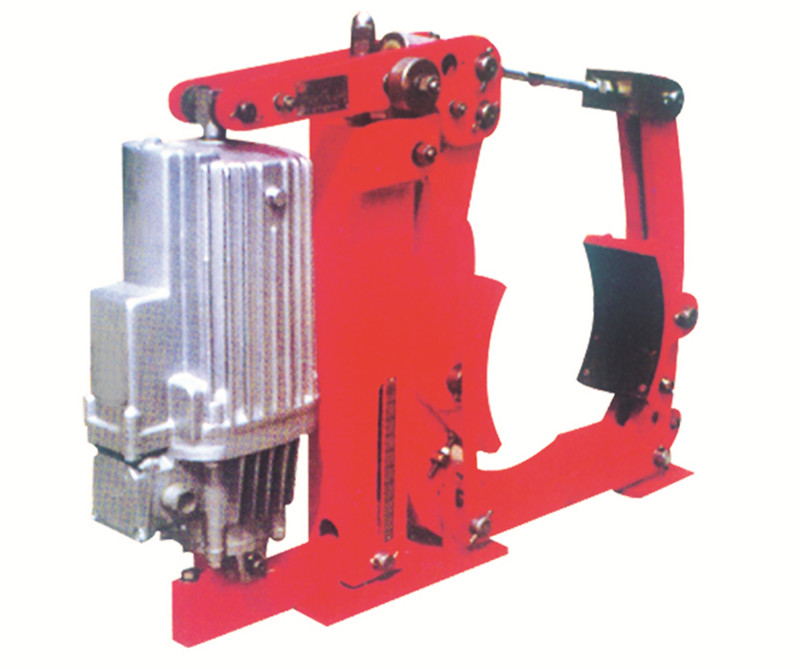

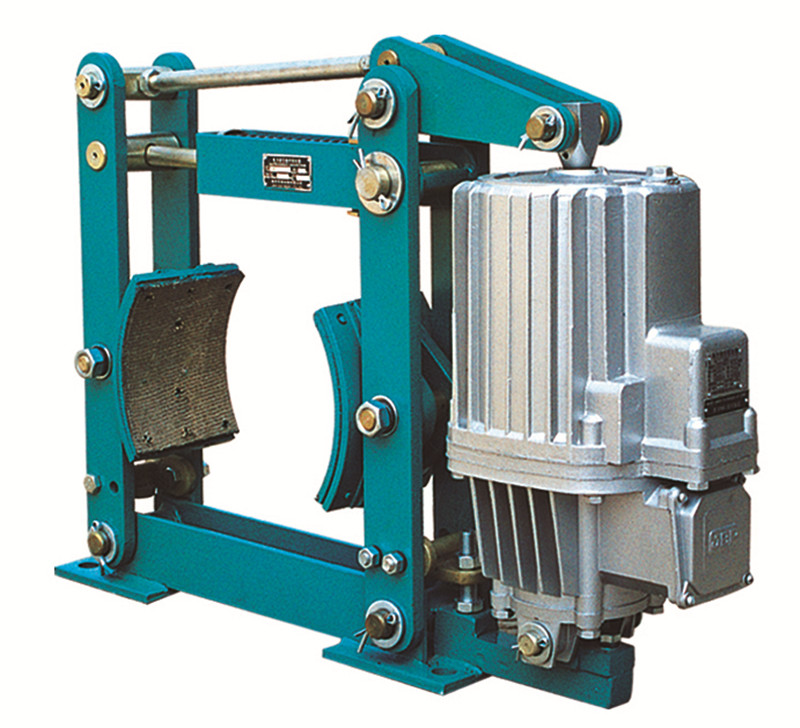

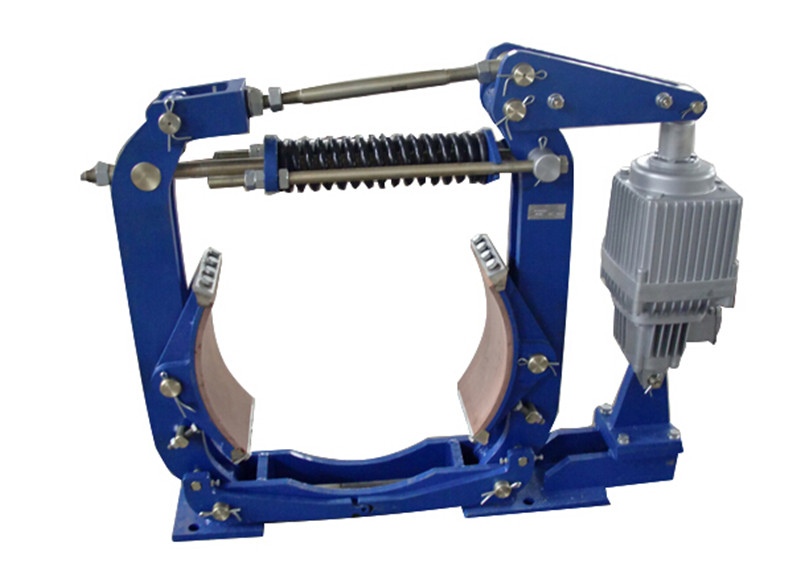

Crane brake price Belt mechanism actuator price Winch brake priceOur company has a complete range of brake models, with safe and reliable product performance, smooth braking, high action smoothness, and long service life.Brake products are widely used for deceleration and braking of fixed operating mechanisms such as lifting, transportation, metallurgy, mining, ports, construction, water conservancy, electricity, steel, bulk loading and unloading, as well as tension control of machinery such as cables, paper making, and steel platesDomain.Main products:1. YWZB, YWZ3, YWZ4, YWZ5, YWZ8, YWZ9, YWZ10, YWZ12, YWZ13 series electric hydraulic pad brakes2. YW series electric hydraulic tile brake3. YWL series electric hydraulic tile brake4. EYWZ series two-stage hydraulic block brake5. TWZ (B) series normally open operated pad brake6. JZ, MW, MWZ, ZWZA, ZWZ3, ZWZ3A series electromagnetic pad brakes7. YPZ2 series electric hydraulic arm disc brake8. YFX series electric hydraulic windproof iron wedge brake9. YLBZ series hydraulic wheel edge brake10. ED, YT1 series electric hydraulic thrusters11. BED and BYT1 series explosion-proof electric hydraulic thrusters12. TYWZ series hydraulic tile brake13. DCPZ series electromagnetic caliper disc brake14. QP12.7 series pneumatic caliper disc brake15. TYWZ2 series foot hydraulic block brake16. SE, SH, SP series failure disc protection brakes17. SBD series hydraulic failure protection disc brake18. DYT series electric hydraulic push rod electric push rodOur company adheres to serving society with high-quality products and reasonable prices, promotes the spirit of diligence, dedication, and innovation, adheres to the sales philosophy of customers, and takes high service quality and customer-centric as the long-term development strategy of the enterprise. We strive to provide customers with fast services and more products.

time:2022-02-08

More

ED series electric hydraulic thrusters:Ed-23/5 electric hydraulic thruster ed-30/5 electric hydraulic thruster ed-40/4 electric hydraulic thrusterEd-50/6 electric hydraulic thruster ed-70/5 electric hydraulic thruster ed-80/6 electric hydraulic thrusterEd-121/6 electric hydraulic thruster ed-201/6 electric hydraulic thruster ed-301/6 electric hydraulic thrusterEd-50/12 electric hydraulic thruster ed-80/12 electric hydraulic thruster ed-121/12 electric hydraulic thrusterEd-201/12 electric hydraulic thruster ed-301/12 electric hydraulic thruster ed-630/12 electric hydraulic thrusterMain technical parametersMotor 1/2 three-phase AC asynchronous motor, in accordance with the regulations of (g 755-87), insulation level: f levelUsage conditions:Continuous operation s1, continuous operation s2, load duration fc=60%Rated voltage is 380V three-phase, frequency is 50HzThe altitude level of the location of use complies with the (GB755-87) standardThe ambient temperature should be within the range of -20 ℃ to 40 ℃, and the relative humidity of the air should not exceed 90%Vertical installation: piston connection block facing upwards, horizontal installation: marked label facing upwards: (ed630/12 male suitable for vertical installation)

time:2022-02-10

More

How much do you know about electric hydraulic drum brakes?A typical drum brake mainly consists of components such as the base plate, brake drum, brake shoes, wheel cylinder (brake cylinder), return spring, and positioning pin.The base plate is installed in a fixed position on the axle, which is fixed and fixed. It is equipped with brake shoes, wheel cylinders, return springs, and positioning pins to withstand the rotational torque during braking.Each drum has a pair of brake shoes with friction lining on them. The brake drum is installed on the wheel hub and is a component that rotates with the wheel. It is made of cast iron and has a shape resembling a round drum.When the vehicle brakes, the wheel cylinder piston pushes the brake shoe to compress the brake drum, causing the brake drum to experience friction and decelerate, forcing the wheels to stop rotating.The structure of the rear wheel drum brake is shown in the following figure, which is a wheel cylinder non balanced brake.In the brake, the rotating component is the brake drum, which is connected to the wheel with bolts and rotates with the wheel;The fixed part is the brake base plate 10, which is installed on the flange of the rear vehicle bridge end. The brake base plate is equipped with brake parts such as brake shoes 3 and wheel brake cylinder assembly 9.In the brake drum, the lower ends of the brake shoes 3 on both sides and the brake friction plate 12 are inserted into the corresponding grooves of the brake base plate 10, and the upper end is tightly against the piston of the wheel brake cylinder 9. Adjacent to the upper support point is the support point of the hand brake push rod 2, which is stuck in the push rod 2.The upper part of the brake shoe is tightened by springs 5 and 4, and the lower part is tightened by springs 8. The brake shoe is pressed against the brake base plate 10 through the limit screw, limit spring seat 6, and limit spring.When braking, press the brake pedal and the brake fluid pressure enters the wheel brake cylinder 9, causing the piston to move outward, pushing the brake shoe 3 and brake friction plate 12 outward to tightly press on the brake drum, causing the wheel to slow down until it stops rotating.When applying the hand brake, pull the hand brake handle, pull the hand brake cable forward on the hand brake lever 7, and use the lever action of the push rod 2 to push the left and right brake shoes apart and press them towards the brake drum;When the handbrake handle gets stuck, the brake shoe tightly presses against the brake drum, becoming the parking brake of the car.The gap between the brake shoe and the brake drum is automatically adjusted through the adjustment wedge 1 installed on the push rod 2. The lower end of the adjustment wedge is equipped with an adjustment spring 13, and the adjustment spring pulls the adjustment wedge to automatically adjust the gap. (The article is sourced from the internet)

time:2022-02-10

More

Henan Jiaozuo brake manufacturer Jiaozuo brake manufacturer Hydraulic brake manufacturer Pusher manufacturer Disk brake manufacturerVarious windproof iron wedges, hydraulic wheel edges, hydraulic top rail brakes. And we can design and manufacture various non-standard products according to user requirements, which are widely used in lifting, mining, mechanical metallurgy, electricity, railways, water conservancy, ports, chemical engineering, and docks.Our factory has obtained the special equipment type test certificate issued by the National Lifting Machinery Quality Supervision and Inspection Center. It was rated as a contract abiding and credit worthy enterprise in Henan Province and a contract abiding and credit worthy enterprise in Jiaozuo City.Specific model:YT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various brake wheels and discs, and customized non-standard brakes according to user needsCustomized hotline: 15838971872

time:2022-02-08

More

ED electric hydraulic thruster manufacturers produce electric hydraulic brake, electric hydraulic thruster, disc brake, electromagnetic iron block brake, pneumatic caliper brake, windproof iron wedge brake, pneumatic brake and other industrial brakes, with safe and reliable performance, smooth braking, high action rate and long service lifeApplication of ED hydraulic thrusterThe ED series electric hydraulic thrusters are mainly used as operating components for the YWZ4, YWZ5, YWZ8, YWZ9, and YWZP series electric hydraulic block brakes, widely used in industries such as lifting and transportation, metallurgy, mining, ports, and construction.Normal working conditionsMotor 1/2 three-phase AC asynchronous motor, in accordance with (G 755-87) regulations, insulation level: F levelUsage conditions:Continuous operation S1, continuous operation S2, load duration FC=60%Rated voltage is 380V three-phase, frequency 50HzThe altitude level of the location of use complies with the GB755-87 standardThe ambient temperature should be within the range of -20 ℃ to 40 ℃, and the relative humidity of the air should not exceed 90%Vertical installation: piston connection block facing upwards, horizontal installation: marked label facing upwards: (ED630/12 male is suitable for vertical installation)Main technical parametersModel rated thrust(N) Rated stroke(mm) Action stroke brake spring force(N) Rated frequency(Hz) Input power(W) Rated voltage(V) Rated current(A) High operating frequency weight (kg)Rising and fallingShort stroke thruster deviation ± 20%ED23/5 220 50 0.35 0.35 180 50 165 380 0.52 2000 10ED30/5 300 50 0.35 0.35 270 50 200 380 0.46 2000 14ED50/6 500 60 0.45 0.39 460 50 210 380 0.48 2000 14ED80/6 800 60 0.32 0.34 750 50 330 380 1.42 2000 24ED121/6 1250 60 0.4 0.42 1200 50 330 380 1.44 2000 39ED201/6 2000 60 0.5 0.32 1900 50 450 380 1.45 2000 39ED301/6 3000 60 0.58 0.32 2700 50 550 380 1.46 1500 40purposeContinuously work S1 and continue working S3, and the ambient temperature of chicken feathers reaches+50 ℃.The rated current in the table refers to the line terminal current during rated operation, but if the power supply is at a non rated value, it will inevitably cause a corresponding change in the rated current. Environmental temperature: -20 ℃~+50 ℃, hydraulic oil: DB-25 (SY1351-77) When it is below -20 ℃, YH-10 hydraulic oil can be used without a heater. When using DB-25 hydraulic equipment, a heater must be installed. The travel time is measured at an ambient temperature of 20 ℃.Main technical parametersModel A B C D E F G H K L M N O P Q R S T UED23/5 286 50 26 12 20 16 20 160 80 40 200 16 85 55 75 100 20ED30/5 370 50 34 15 16 25 16 18 160 80 80 40 197 16 85 55 75 100 20ED50/6 435 60 36 18 20 30 20 23 195 97 120 60 254 22 85 55 75 100 20ED80/6 450 60 36 18 20 30 23 195 97 120 60 254 22 85 55 75 100 20ED50/12 515 120 36 18 20 30 20 23 195 97 120 60 254 22EN80/12 530 120 36 18 20 30 20 23 195 97 120 60 254 22EN121/6 645 60 38 25 25 40 25 35 240 112 90 40 260 25 130 80 120 147 35EN201/6 645 60 38 25 40 25 35 240 112 90 40 260 25 130 80 120 147 35EN301/6 645 60 38 25 25 40 25 35 240 112 90 40 260 25 130 80 120 147 35

time:2022-02-08

More

Price of regular electric hydraulic brakesPrice of electric hydraulic brake Price of electric hydraulic thruster Price of disc brake Price of pneumatic brake Price of electromagnet brakeOur company has taken the lead in passing the IS09001:2000 quality management system standard certification. Our factory has various sophisticated processing equipment required for production, excellent technical equipment, strong technical force, advanced technology, complete testing methods, and a strict quality management system. The product quality is stable and reliable, and we have an annual production capacity of over 10000 sets of various brakes and actuators.The pursuit of quality and endless service is the consistent tenet of the company. The company has established strict service measures: pre-sales and during sales are completed by a nationwide sales network, and after-sales is implemented by the company's after-sales service department. Thus, users can receive comprehensive pre-sales, in sales, and after-sales services.Our factory has an exquisite technical team, advanced production equipment, scientific management level, strict testing methods, and good after-sales service.The products sell well all over the country: various electromagnetic, hydraulic, pneumatic, failure protection brakes, various arm disc brakes, various electromagnetic, hydraulic, pneumatic caliper disc brakes, various electromagnetic, hydraulic, pneumatic, drum brakes, various wind proof iron wedges, hydraulic wheel edges, hydraulic top rail brakes. And we can design and manufacture various non-standard products according to user requirements, which are widely used in lifting, mining, mechanical metallurgy, electricity, railways, water conservancy, ports, chemical engineering, and docks. Our factory has obtained the special equipment type test certificate issued by the National Lifting Machinery Quality Supervision and Inspection Center. Rated as a contract abiding and trustworthy enterprise in Henan ProvinceMain products:1. YWZB, YWZ3, YWZ4, YWZ5, YWZ8, YWZ9, YWZ10, YWZ12, YWZ13 series electric hydraulic pad brakes2. YW series electric hydraulic tile brake3. YWL series electric hydraulic tile brake4. EYWZ series two-stage hydraulic block brake5. TWZ (B) series normally open operated pad brake6. JZ, MW, MWZ, ZWZA, ZWZ3, ZWZ3A series electromagnetic pad brakes7. YPZ2 series electric hydraulic arm disc brake8. YFX series electric hydraulic windproof iron wedge brake9. YLBZ series hydraulic wheel edge brake10. ED, YT1 series electric hydraulic thrusters11. BED and BYT1 series explosion-proof electric hydraulic thrusters12. TYWZ series hydraulic tile brake13. DCPZ series electromagnetic caliper disc brake14. QP12.7 series pneumatic caliper disc brake15. TYWZ2 series foot hydraulic block brake

time:2022-02-08

More

■ QP, CQP, DCPZ series caliper disc brakeCaliper disc brake is an advanced product that not only has the advantages of disc brake, but also has wide adaptability and unique advantages. This product has a simple structureSingle, small in size, light in weight, high in reliability, easy to use, suitable for various disc diameters, easy to install, debug, and maintain. Widely applicable for lifting and transportationDeceleration and braking of fixed operating mechanisms such as transportation, metallurgy, mining, ports, construction, bulk loading and unloading, as well as tension control of machinery such as cables, paper making, and steel platesDomain.main features Compact structure, small size, light weight, high reliability, and convenient installation and use.Sensitive action and flexible control.● QP series pneumatic caliper disc brake meets the installation performance requirements of foreign similar products. Matched with imported air bags, reliable performance and long service life.The brake pad adopts a pressure spring clamp type, with a unique structure and convenient and fast replacement.A display device can be installed to visually display the working status of the brake.All power sources do not need to be set separately and can be used in conjunction with existing air compression stations. Speed control valves are installed in the gas supply line, and the braking time can be adjusted steplessly.● Normally closed design: spring braking, pneumatic release.Normally open design: pneumatic braking, spring release, and braking force can be flexibly changed with air pressure.OverviewThe QP (CQP) series pneumatic caliper disc brakes are mainly used in lifting, transportation, metallurgy, mines, and portsThe braking and deceleration of various mechanisms in machinery such as machinery and construction.Usage conditionsEnvironmental temperature: -5 ℃~40 ℃● Working air pressure: 5-7bar for QP series;The CQP series is ≤ 7bar.Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.The air source should be free of oil, water, and other impurities.Main featuresThe QP series adopts spring braking and pneumatic release; The CQP series is pneumatic braking with spring release.The overall structure is simple, small in size, and lightweight.Asbestos free brake pads, green and environmentally friendly.The installation of the brake pad adopts a spring clamp type, which is convenient and fast to replace.● The brake pad is easy to adjust after being worn.Each disc diameter of the QP series brake can be adjusted for four levels of braking torque.All power sources do not need to be set separately and can be connected to the existing air compression station for grid use. They can be added to the gas supply lineEquipped with a speed control valve, the braking time can be adjusted steplessly.Note: 1. It can produce pneumatic caliper disc brakes with different disc thicknesses and installation sizes.2. The specific model and structural dimensions reserve the right to change.

time:2022-02-08

More

Production and sales of YWZ-YWZ13, YW, YWL series electric hydraulic brakes, ZWZ, TJ2A series electromagnet brakes, YPZ series disc brake Ed thruster, YT1 series electric hydraulic thruster, BYT1 series explosion-proof electric hydraulic thruster, pneumatic thruster and hydraulic devices. At present, the product has more than 30 series and over 500 specifications, with an annual production capacity of 60000 sets. Our company is a member unit of the Crane Association and the Construction Machinery Industry Association, and has obtained the brake "Product Quality Approval Certificate", "Type Test Approval Certificate", and "Special Equipment Type Test Qualification Certificate" issued by the National Center for Quality Supervision, Inspection and Testing of Lifting and Transportation Machinery Products. And passed the ISO: 9000 and GB/T19001-2000 Quality Management System Certification of the China Fangyuan Certification Committee. In 2004, it was awarded the title of High Quality Product in Henan Province. Obtained the National Industrial Product Production License (Explosion proof Electrical Appliances) in April 2008

time:2022-02-08

More

1. Check whether the electric hydraulic thruster works normally, whether there is oil leakage, and whether there is oil leakage. Always keep a certain amount of oil.2. Check the oil at least once every six months. When the oil deteriorates or becomes mixed with impurities, and the viscosity increases, the oil should be changed. If the oil selection is not appropriate, a separate selection should be made.3. Check if the motor wiring is in good condition and if the protective device is appropriate and reliable.4. When the thruster is in operation, the lower end of the piston should be kept at a certain distance from the cylinder bottom (generally not less than 5mm). Otherwise, it will affect normal operation.5. Check that the insulation resistance is not lower than 1M Ω. If it is lower than 1M Ω, the drive motor should be dried and qualified before installation and use.6. The diameter of the motor inlet cable should match the bottom hole of the rubber pad, ensuring that there is no gap between the rubber pad cable and the outlet, otherwise the explosion-proof performance will be lost.7. After connecting the power supply, check the junction box for debris and remove dust.8. Ground screws are installed inside the junction box to ensure reliable grounding.9. All explosion-proof parts shall not have cracks or defects that affect explosion-proof performance, otherwise they shall not be used.When removing and installing explosion-proof parts, attention should be paid to protecting the explosion-proof surfaces, and all explosion-proof surfaces should not be damaged or corroded. During assembly, parts should be coated with 204-1 anti rust oil on the explosion-proof surface.

time:2022-02-08

More

BYWZ5 explosion-proof electric hydraulic brake brake telephone 138 0391 0788Consulting and ordering model: BYWZ5-160/23 BYWZ5-200/23BYWZ5-250/23 BYWZ5-250/50BYWZ5-315/23 BYWZ5-315/50 BYWZ5-315/50 BYWZ5-315/80BYWZ5-400/50 BYWZ5-400/80 BYWZ5-400/121BYWZ5-500/80 BYWZ5-500/121 BYWZ5-500/201BYWZ5-630/121 BYWZ5-630/201 BYWZ5-630/301BYWZ5-710/201 BYWZ5-710/301 BYWZ5-800/301/201BYWZ9 explosion-proof electric hydraulic brakeConsulting and ordering model: BYWZ9-160/23 BYWZ9-200/23BYWZ9-250/23 BYWZ9-250/50BYWZ9-315/23 BYWZ9-315/50 BYWZ9-315/50 BYWZ5-315/80BYWZ9-400/50 BYWZ9-400/80 BYWZ9-400/121BYWZ9-500/80 BYWZ9-500/121 BYWZ9-500/201BYWZ9-630/121 BYWZ9-630/201 BYWZ9-630/301BYWZ9-710/201 BYWZ9-710/301 BYWZ9-800/301/201Dedicated to coal mines, cranes, and mining machineryBEd-121/12, BEd-201/12, BEd-301/12Manufacturer's prices for BEd30/5, BEd50/6, BEd80/6, BEd80/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd121/6, BEd201/6, BEd301/6, BEd30/5 explosion-proof electric hydraulic thrustersManufacturer prices for BEd121/12, BEd201/12, BEd301/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd-30/5, BEd-50/6, BEd-80/6, BEd-80/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd-121/6, BEd-201/6, BEd-301/6, BEd-30/5 explosion-proof electric hydraulic thrustersManufacturer prices for BEd-121/12, BEd-201/12, BEd-301/12 explosion-proof electric hydraulic thrustersThe BED series explosion-proof electric hydraulic thrusters are mainly used as driving devices for electric hydraulic drum brakes, and can also achieve rapid movements such as reciprocating, circular, and swinging through levers. They are suitable for industries such as lifting, transportation, metallurgy, mining, ports, and construction; Its explosion-proof performance complies with the provisions of GB3836.2-2000 "Explosion proof Electrical Equipment and Explosion proof Electrical Equipment for Explosive Atmospheres" d ". The explosion-proof signs are" dI "and" DIICT4 ", which are respectively used in coal mines and IIA, IIB, IIC (Class I, II, Class B, Class II, Class C, Class II) temperature groups T1-T4 combustible gases or explosive mixtures formed by steam and airBYWZ5 explosion-proof electric hydraulic brake has complete models, low prices, excellent quality, complete certificates, fast delivery, Cash on delivery and door-to-door delivery.The order is packaged in wooden boxes and straw ropes, with a one-year shelf life.Shandong BYWZ5 explosion-proof brake price, BYWZ5 explosion-proof brake manufacturer direct sales, Shandong explosion-proof brake production.Shanxi BYWZ5 explosion-proof brake quotation, BYWZ5 explosion-proof brake low price supply, Shanxi explosion-proof brake manufacturer.The main sales regions for explosion-proof brakes are Henan, Hebei, Shandong, Shanxi, Zhejiang, Chongqing, Gansu, Xinjiang, and Urumqi.Dedicated to coal mines, cranes, and mining machineryfifteen billion eight hundred and thirty-eight million nine hundred and seventy-one thousand eight hundred and seventy-two

time:2022-02-08

More

Production and sales of YWZ-YWZ13, YW, YWL series electric hydraulic brakes, ZWZ, TJ2A series electromagnet brakes, YPZ series disc brake Ed thruster, YT1 series electric hydraulic thruster, BYT1 series explosion-proof electric hydraulic thruster, pneumatic thruster and hydraulic devices. At present, the product has more than 30 series and over 500 specifications, with an annual production capacity of 60000 sets. Our company is a member unit of the Crane Association and the Construction Machinery Industry Association, and has obtained the brake "Product Quality Approval Certificate", "Type Test Approval Certificate", and "Special Equipment Type Test Qualification Certificate" issued by the National Center for Quality Supervision, Inspection and Testing of Lifting and Transportation Machinery Products. And passed the ISO: 9000 and GB/T19001-2000 Quality Management System Certification of the China Fangyuan Certification Committee. In 2004, it was awarded the title of High Quality Product in Henan Province. Obtained the National Industrial Product Production License (Explosion proof Electrical Appliances) in April 2008

time:2022-02-08

More

Jiaozuo Brake Group Co., LtdThe company is the standing director unit of China Heavy Machinery Industry Association and the vice chairman unit of the Transmission Parts Special Committee. It has won the honors of "China Machinery Industry Enterprise", "Henan High tech Enterprise", "Henan Top 100 Enterprise in Product Quality Management", and is the undertaker of national key projects, three major satellite launch bases such as Xichang, and the Three Gorges, Gezhouba Our company's brake products are used for national key engineering projects such as the Yellow River Xiaolangdi and other large-scale hydropower hub projects, as well as the launch towers of Shen-5, Shen-6, and Shen-7 spacecraft, the lifting platform of the Beijing Olympic Bird's Nest Stadium, and the lifting platform of the main venue of the Shanghai World Expo.The company has advanced production equipment in the industry, and has more than ten fully automatic production lines, semi-automatic production lines, automatic Assembly line, and painting lines that are Vanguard International Semiconductor Corporation in the world and in China. At present, it has an annual production capacity of 50000 sets of industrial brakes, 50000 sets of wind power brakes, and 100000 sets of ABS.The company has a huge marketing and comprehensive market service network system, with nearly 100 sales personnel, 6 distributors, and 36 offices forming a sound sales network and after-sales service system. The sales network is spread throughout the country, and the after-sales service is in place, providing users with high-quality pre-sales, in sales, and after-sales services in a timely and comprehensive manner.The company is one of the first batch of post doctoral research and development base units in Henan Province, with strong technical development strength, a provincial technical center and a nationally recognized laboratory, and a scientific and technological research and development team of more than 300 people. The company has established a scientific and technological research and development team with Zhengzhou University, Wuhan University of Technology, Taiyuan University of Science and Technology, Shenyang University of Technology, Henan Polytechnic University, Beijing Lifting and Transportation Machinery Design and Research Institute, Tianjin Planning and Design Institute of Automobile Industry of the Ministry of Machinery Industry and other institutions of higher learning Scientific research institutions have established an industry university research consortium, which has developed proprietary technology and various new products, obtained various scientific and technological achievements, and established extensive technical cooperation relationships with foreign scientific research institutions. The company has 42 national patents and 29 proprietary technologies. The company has drafted and participated in the development of 6 industry standards, 1 national standard being drafted, 3 industry standards being drafted, 15 products winning awards, and more than 30 products winning provincial and municipal awards.The company operates in accordance with modern enterprise systems and adheres to management innovation, creating an internal market-oriented management model and a corporate culture system that creates value for customers, wealth for society, profits for enterprises, and benefits for employees. It is a banner for the development of national industry in the industry, and is following the path of new industrialization and sustainable development in domestic and foreign market competition, Striving towards the goal of "Century Golden Hoop, World Golden Hoop", and making unremitting efforts to build a strong and internationally operated enterprise.Brake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various brake wheels and discs, and customized non-standard brakes according to user needsfifteen billion eight hundred and thirty-eight million nine hundred and seventy-one thousand eight hundred and seventy-two

time:2022-02-08

More