Grinding method for disc brakesThe disc brake shall grind each brake shoe to make the contact area reach more than 60% of the total brake shoe area. The grinding method is as follows:1. Ensure that the brake disc is clean before grinding.2. Predict the oil pressure value when sticking the brake shoe.3. Predict the thickness of each brake shoe (brake block). To ensure the contact area of the brake shoe, reduce the grinding time, and ensure that the center line of the brake shoe and the brake cylinder is vertical after installation, the brake shoe can be removed first, and the brake shoe can be planed based on the contact surface between the brake shoe and the sliding sleeve until it is flat, and then assembled onto the brake.4. Start the main motor for grinding the brake shoe (do not hang steel wire ropes or lift containers), and the positive pressure for grinding should generally not be too high, slightly 0.2-0.4 Pa lower than the oil pressure for grinding the brake shoe. The grinding of brake shoes should be carried out at low speed. When grinding, it is necessary to always pay attention to the temperature of the brake disc not exceeding 80 ℃ (measured with a temperature gauge) to avoid damaging the surface roughness of the brake disc. When the temperature exceeds the limit, stop grinding and wait for cooling before running. Operate intermittently in sequence until the contact area of the brake shoe meets the requirements.

time:2023-06-26

More

The brake manufacturer explains the function of the small hole in the brake friction block1. Heat removal, air exchange, and cooling: The brake disc rotates at high speed and uses air exchange to dissipate heat, cooling the brake device.2. Slag discharge: During braking, friction produces powder that can be discharged from the hole.3. Drainage: It is very important to drain the brakes when driving on rainy days.4. Lightweight effect.

time:2023-06-26

More

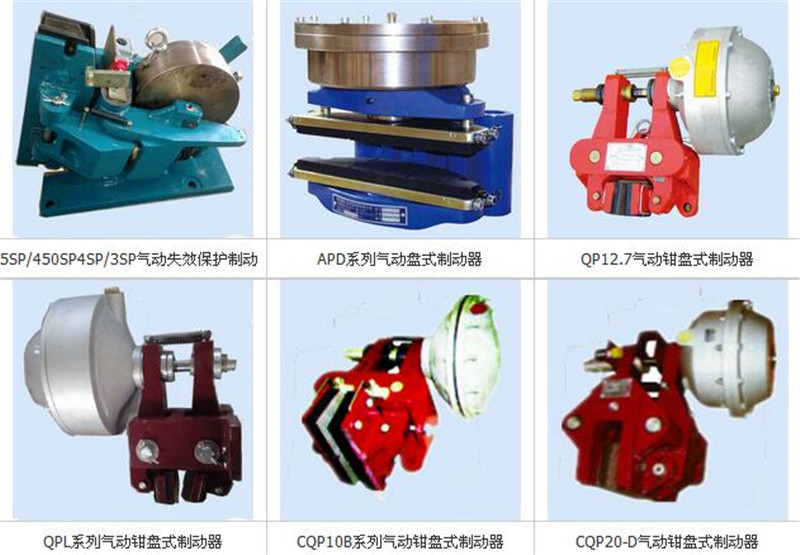

Disc brake is a kind of brake that is realized by friction between discs. There are two types of disc brake: full disc brake and point disc brake. It is hydraulically controlled. Click to enlarge the picture. The main parts are brake disc, slave cylinder, brake caliper, oil pipe, etc. The brake disc is made of alloy steel and fixed to the wheels, rotating with the wheelsThe fixed component is installed on the fixed component, and the brake disc is connected to the rotating component. When braking, the fixed component is pressed onto the brake disc, utilizing friction to achieve braking.structure type The structure of fixed components in massage wipes can be divided into two types: clamp disc type and full disc type1. The structural principle of the full disc brake: the rotating elements and fixed elements of the friction pair in the full disc brake are both disc shaped. When braking, the friction surfaces of the two discs are in full contact, and the working principle is like a friction clutch.2. The structure principle of the caliper disc brake: the fixed element of the caliper disc brake is the brake pad, which is installed in the brake caliper that is connected with the axle and cannot rotate around the axle axis. The contact area between the brake pad and the brake disc is very small. Fixed clamp typeStructural features: The brake caliper does not move, and there are hydraulic cylinders on both sides of the brake discPerformance characteristics: There are no sliding parts except for pistons and brake pads, with good stiffness and easy manufacturing. It can adapt to different circuit driving requirements, but it is large in size, difficult to arrange, and generates a lot of heatSliding clamp typeStructural features: The brake caliper can perform axial sliding, and there is a hydraulic cylinder on the inner side of the brake discSwing clamp type1 arm disc YPZ mesh structure features: the brake caliper is hinged with the fixed seat, and there is a hydraulic cylinder on the inner side of the brake disc1. AdvantagesGood thermal stability, while drum brakes exhibit mechanical decayGood water stability, mud and water are easily thrown away from the brake discThe braking torque is independent of the direction of motionEasy to construct dual circuit system, reliable and safeSmall size, low quality, and good heat dissipationUniform pressure distribution and uniform pad wearReplacing the pads is simple and easy2 DisadvantagesDifficult to prevent debris from getting onto the work surfaceWhen used as a parking brake, the driving mechanism is complexBooster needs to be installed in the brake drive mechanismThe pad has a small working area, fast wear, and low lifespan.Short braking coordination timeEasy to achieve automatic gap adjustmentSBD250 overhaul1. Use a dial gauge to detect that the cross-sectional runout error of the brake disc is greater than 0.06mm. The surface of the brake disc has obvious wear steps and strained grooves, which can be processed and repaired2. Check that the wear limit thickness of the brake disc is 8mm. If the thickness exceeds the limit, replace it with a new oneWhen the thickness of the brake shoe friction plate is less than 7mm (including the bottom plate), the friction plate must be replaced, and the left and right wheels must be replaced in sets (4 friction plates, 4 spring plates)4. Check the brake caliper body. If any oil leakage is found, replace it with a new piston sealing ring

time:2023-06-26

More

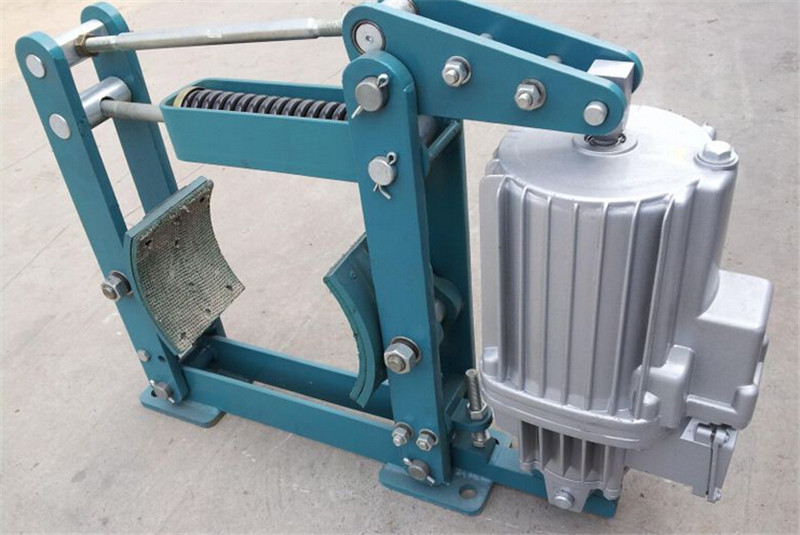

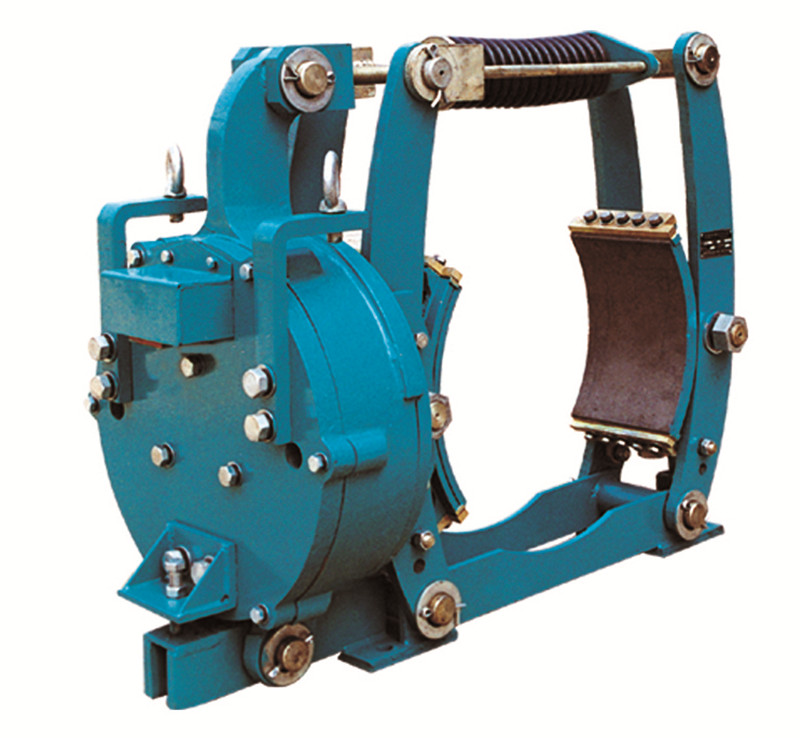

Electric hydraulic thruster ED Electric hydraulic thrusterEd23/5, Ed30/5, Ed50/6, Ed80/6, Ed121/6, Ed201/6, Ed23/5, Ed30/5, Ed50/6, Ed80/6, Ed121/6, Ed201/6, Ed301/6Mainly used as an operating component for the YWZ4, YWZ5, YWZ8, YWZ9, YWL.YW.YWZP series electric hydraulic block brakes. It is widely used in industries such as lifting transportation, metallurgy, mining, port electric hydraulic block brake ports, and construction.Electric hydraulic thruster ED-23/5, thrust 220N, stroke 50mm, 380V, 165W; Electric hydraulic thruster; Ed-30/5 thrust 300N stroke 50mm 380V 200W; ED23 network image; Electric hydraulic thruster; Ed-50/6 thrust 500N stroke 60mm 380V 210W; Jiaozuo Gongli Brake Co., Ltd. Electric hydraulic thruster; Ed-80/6 thrust 800N stroke 60mm 380V 330W;Jiaozuo Gongli Brake Co., Ltd; Electric hydraulic thruster; Ed-121/6 thrust 1250N stroke 60mm 380V 330W;Jiaozuo Gongli Brake Co., Ltd; Electric hydraulic thruster; Ed-201/6 thrust 2000N stroke 60mm 380V 450W;Jiaozuo Gongli Brake Co., Ltd. Electric hydraulic thruster; Ed-301/6 thrust 3000N stroke 60mm 380V 550W;Electric hydraulic thrusterWarning: The thruster should be reliably grounded according to electrical specifications! Attention: When wiring, cut off the power supply and erect a sign at the power switch that reads "Someone is working, do not switch on",Until the wiring is completed.When wiring, remove the cover of the thruster junction box (there is a wiring diagram on the reverse side), and connect the three-phase power line (phase sequence is not required) and grounding wire as required. Then cover the junction box cover and tighten the screws (see Figure 4). Note: The protection level of the thruster is IP65. The cable should enter the junction box through a stuffing box (the stuffing box needs to be provided by the user). YT1-45/6 YT1-90/8 Electric Hydraulic Pusher ED Full Drawing YT1-320Z/12 YT1-320Z/20 Electric Hydraulic Pusher

time:2023-06-26

More

Durable electric hydraulic thruster Ed121/6 Ed201/6 Ed301/6, including motor, hydraulic cylinder, impeller, push rod, and piston; The motor is located below the hydraulic cylinder, which is divided into a lower impeller chamber and an upper working chamber. The impeller is located in the impeller chamber and is connected to the motor rotor shaft. The push rod and the piston connected to the push rod are located in the working chamber. The piston is externally equipped with a cylinder liner, which is combined with the hydraulic cylinder body as a whole; The front and back of the impeller are equipped with blades, and the upper end of the impeller is equipped with valve blocks. The valve blocks are located on both sides of the impeller, forming a double oil inlet with the upper wall of the impeller chamber, and the cylinder liner and hydraulic cylinder form a double oil return port. The electric hydraulic thruster of this utility model adopts a dual circuit structure, which reduces the blade diameter, reduces shaft power, increases the service life of the motor and blades, reduces the power of the motor, and achieves energy-saving purposes. Durable electric hydraulic thruster Ed121/6 Ed201/6 Ed301/6 Electric hydraulic thruster Ed50/6 Ed80/6 Ed30/6 23/5It is also a common fault that the brake cannot be opened. Firstly, check whether the coil of the brake is burnt out. If the coil is burnt out, it needs to be replaced and wired again. Secondly, check if the friction plate of the brake has experienced excessive surface temperature and brake wheel adhesion due to frequent braking. If this is the case, the brake wheels should be cleaned with gasoline and the friction plates should be replaced. The ED model parameters and appearance diagram should be provided

time:2023-06-26

More

A Brief Discussion on the Forms and Causes of Cracks in Brake Discs by Brake ManufacturersOne reason why brake discs need to be replaced is due to cracks. There are two forms of cracks; One type is cracks generated on the friction surface; Another type is cracks that occur on the heat dissipation ribs.Due to repeated heating and cooling; Fine cracks on the friction surface begin to develop and propagate near the thin layer of the friction surface. Therefore, cracks occur under high-speed braking or strong braking conditions. Cracks occur on the heat dissipation ribs, which are subjected to tensile, compressive, and bending effects caused by thermal expansion. This type of crack occurs during high-speed braking, strong braking, or prolonged braking.

time:2023-06-26

More

Brake manufacturers explain the situation of brake parts being scrappedThe parts of the brake should be scrapped in one of the following situations:1. Cracks.2. The thickness of the brake pad or friction pad is worn to 50% of the original thickness.3. The spring undergoes plastic deformation.4. The wear of the small shaft or shaft hole diameter reaches 5% of the original diameter.

time:2023-06-26

More

Structural purpose of electric hydraulic brake. Electric hydraulic brake is a Machine element that stops or decelerates moving parts in machinery. Commonly known as brakes or brakes. The brake mainly consists of a brake frame, brake components, and control devices.1. Although the axial size of the compact and power-off brake is small, the braking torque is sufficient.2. The quick response and power loss brake uses a spring device to form braking torque, and the spring reset time is the braking response time3. The use of new friction materials in life loss braking determines the performance of high life.

time:2023-06-23

More

The performance characteristics of the pneumatic hydraulic disc brake. Compared with the drum brake, the working surface of the disc brake is flat and heat transfer occurs on both sides. When the disc rotates, it is easy to cool and is not prone to large deformation. The braking efficiency is relatively stable. After a long time of use, the brake disc has enhanced its braking effect due to high temperature expansion; The drum brake has a single side heat transfer and a large temperature difference between the inner and outer sides, which makes the brake drum prone to deformation. At the same time, after prolonged braking, the brake drum expands due to high temperature, and the braking efficiency is weakened. In addition, the disc brake is simple in structure, convenient in maintenance, and easy to realize automatic adjustment of brake clearance.The disadvantage of the disc brake is that the friction plate acts directly on the disc, without automatic friction amplification, and the braking efficiency is low. Therefore, if the brake actuating pipeline pressure required for the hydraulic braking system is high, additional power auxiliary devices must be installed; When also used for parking brake, the added parking brake transmission device is more complex than the drum brake, so it is applied on the rear wheels.Flower white green, with a diameter of 5-7 millimeters; Petals nearly ovoid, approximately 2 millimeters in length and width, stamen anthers oblong, introverted; Filament length 2-4 millimeters; The ovary has 2 ovules per locule, attached to the top of the central axis. Capsule subglobose, approximately 8 mm in diameter, light red; One seed per chamber, terminal, elliptic, about 6 mm long, about 4 mm in diameter, Aril orange red, full of seeds. The flowering period is from June to July, and the fruit ripening period is from September to October.

time:2023-06-23

More

The working principle of the disc brake is that when braking, the oil is pressed into the inner and outer wheel cylinders (wheel cylinders), and its piston presses the two brake blocks against the brake disc under the hydraulic action to produce Friction torque and brake. At this point, the edge of the rectangular rubber sealing ring in the wheel cylinder groove undergoes slight elastic deformation under the action of piston friction. When releasing the brake, the piston and brake block rely on the force of the sealing ring and the force of the spring to return.The advantages of disc brakes are as follows:1. The heat dissipation of disc brakes is better than that of drum brakes, and it is less likely to cause brake failure when continuously stepping on the brakes;2. The thermal expansion of the brake disc along the thickness direction is extremely small, and the change in size after heating does not increase the stroke of the brake pedal;3. The disc brake system has a fast response and can perform high-frequency braking actions, which is more in line with the requirements of the ABS system;4. Disc brakes do not have the frictional assistance effect of drum brakes, so the braking force of the left and right wheels is relatively average;5. Due to the better drainage of the brake disc, it can reduce the situation of poor braking caused by water or sediment;6. Compared to drum brakes, disc brakes have a simple structure, are easier to achieve automatic clearance adjustment, and are easy to maintain.

time:2023-06-23

More

The resistance torque applied by an electromagnetic brake to stop or decelerate mechanical components is called the braking torque.The braking torque of an electromagnetic brake is the basis for designing and selecting the brake, and its size is determined by the mechanical type and working requirements. The performance of the friction materials (brake components) used on the brake directly affects the braking process, and the main factors affecting its performance are the working temperature and temperature rise rate.

time:2023-06-23

More

Introduction to hydraulic brakes:Hydraulic brakes, also known as brakes. It is a Machine element that stops or decelerates the moving parts in the machine. Commonly known as brakes or brakes. The brake mainly consists of a brake frame, brake components, and control devices. Some brakes are also equipped with automatic adjustment devices for brake component clearances.In order to reduce braking torque and structural dimensions, brakes are usually installed on the high-speed shaft of equipment, but large equipment with high safety requirements (such as mine hoists, elevators, etc.) should be installed on the low-speed shaft near the working part of the equipment. Some brakes have been standardized and serialized, and are manufactured by factories for selection.Working principle of electric hydraulic brake:The electric hydraulic brake is composed of electric motors, centrifugal pumps, oil cylinder pistons, and other components. When the mechanism is working, the electric motor 1 is energized, driving the centrifugal pump impeller 5 to rotate under the action of centrifugal force; The high-pressure oil is pumped out and flows into the lower chamber of piston 6, pushing the piston and push rod 2 to rise together. At this time, square shaft 3 rises along the shaft sleeve, and the brake release lever releases the brake.The impeller of a centrifugal pump adopts radial blades, which can pump high-pressure oil to make the piston move regardless of the direction of current, i.e. the direction of motor rotation. When the mechanism is not working, the electric motor 1 is powered off, the impeller stops rotating, the oil pressure in the lower chamber of the piston decreases, and the tension of the main spring causes the brake to close and brake. At the same time, the piston quickly resets under the gravity of the piston and push rod.

time:2023-06-23

More