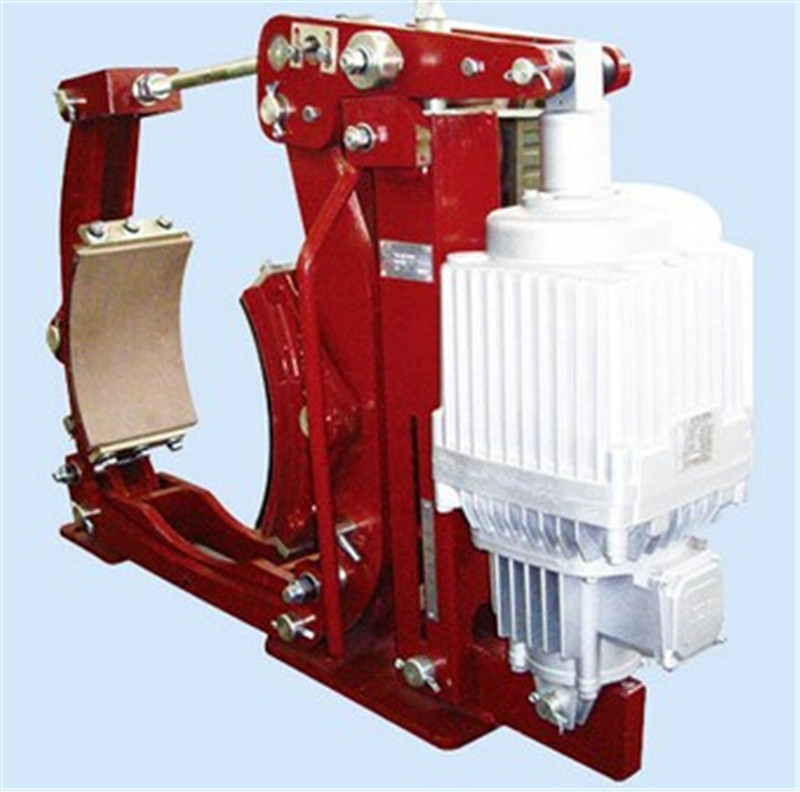

SB, SBD Series Safety BrakesApplication: Hydraulic safety (emergency) brake is a high-power braking device used on low-speed shafts (drum shafts), which can be widely usedWidely used for emergency safety braking of low-speed shafts in large and medium-sized cranes, port loading and unloading machinery, and boom lifting mechanisms. mineWork braking and emergency safety braking of winches, hoists, and high-power inclined belt conveyors, as well as lifting of cable cars and cablesThe safety braking of the driving mechanism of the machine, and the safety (emergency) braking of the low-speed shaft of the lifting mechanism of special cranes such as casting cranes.Application:Hydraulic safety (emergency) brakes are high power brakingdevices which can be widely used as emergency safetybrakeOn low speed shifts for the lifting control and picking mechanism of variable large and middle crane, port handlingMachinery They are also applied for the same purpose format winder, lift, elevators, belt conveyors, cablecars,Foundry and cable cranes and so on■ Normally closed design, safe and reliable; Special disc spring force braking requires an additional hydraulic drive release device.Sensitive action and short closing (closing) time.It can be equipped with an opening limit switch and a pad wear limit switch for interlocking protection and fault display (controlled by PLC)System time).High performance asbestos free hard friction lining, stable friction coefficient, no damage to the brake disc, and insensitive to water medium and salt spray (seawater).Reasonable sealing structure design and imported famous brand seals. Good effect and long service life.Flexible installation position, easy to use, adjust, and maintain.main features Main feature:Normally closed design, safe and reliable; Specially designed disc springs appliedSwift actions and short braking timeEquipped with release limit switch and lining wear limit switch can achieve interlocking protection and failureIndication by PLCBrake lining is madefrom non asbestos hard material, which has high and stable frictionperformance, and it isInsensitive to water, salt and other environmental agentsExcellent sealing of the brake long service lifeCovenant of installation and ease of maintenance● Safety brakes.The braking force is high, just like the working brake.In case of overspeed, it is used for emergency braking, and under normal circumstances, the static brake response time is short.Large installation tolerance, brake disc end face runout: maximum ± 0.2mm. The verticality deviation of the base relative to the disc: ± 0.4 ‰.This series includes the following types of brakes:All SE series. Electromagnetic release. When working, it is necessary to have a supporting power supply (see specific parameters in the supporting power supply).All SH series - mainly ST series. Hydraulic release. Equipped with a hydraulic station during operation.All SP series. Pneumatic release (5bar)Note: ST1SE and ST2SE are only suitable for use as safety brakes. It can also be used as a working brake when the frequency of use is very low.According to the different needs of users, the following devices can be installed:● Display of pad wear (achieved by displaying the wear line in the switch or pad).● Brake display (achieved through display switches).● Manual release display (achieved through display switch)● Special applicationsSintered liner for very high disc temperature, special liner (without sparks, etc.)● Special discs (thickness, diameter, material, etc.).SBD160-B safety brake - winch brake shoeSBD160-B safety brake - winch brake shoe3SH, 450SH, 4SP, 5SP16. The hydraulic connection of the brake 16.1 The brake must be connected to a hydraulic source (mineral fluid), which provides a pressure of 80 bars at a low pressure and 100 bars at a high pressure.16.2 The brake is connected to the hydraulic source through oil hole 05 (Prague standard pipe thread).17. The exhaust of the hydraulic circuit requires the hydraulic cylinder to exhaust in order for the brake to operate correctly.17.1 Connect the brake oil hole to a suitable hydraulic source.17.2 Install the hose on the exhaust screw 06, with the hose end immersed in a liquid container.17.3 Gently loosen the exhaust screw (hexagonal, 8A/F)17.4 Supply fluidWhen stopping the exhaust from the hose, tighten the exhaust screw.18. Connection of cylinder brake18.1 An air supply needs to be connected to the air inlet joint of the brake using a gas pipe. (Air inlet size Z1/4)18.2 The required air pressure for this brake shall not be less than 5 bar low and up to 7 bar high18.3 Adjust the brake according to 2.1 and 2.3.SBD series safety brake SBD-A SBD-B SBD-c safety brake usage conditions: ambient temperature: -25-+40 ° relative humidity: 90 ° SBD-A: model SBD-A SBD-A SBD-A SBD-A SBD-A SBD-A ordering mark: SBD-A-30 I RL represents the rated clamping force of kn. The diameter of the A-type safety brake disc installed with an opening limit switch is 30mm after the discPlease call 13803910788 to inquire about the ordering marks, installation diagrams, technical parameters, and overall dimensions of the safety brake.SBD-B series safety brake: SBD80-B SBD-B installation type: I type II SBD80-B SBD-B SBD-C SBD-C SBD-C model meaning, appearance and installation dimensions, installation diagram, and ordering marks. Please call to request. SBD series safety brakes produce SBD safety brakes with good quality, excellent effect, and low price.There is stock supply, reasonable price, good quality, good specifications: standard color: bright material: steel. All products in our factory have a one-year warranty and are delivered to our doorstep for packaging to ensure that all products arrive intact and flawless.Main features: Safe, reliable, sensitive action, short closing (closing) time. Good effect and long lifespan. The installation position is flexible, easy to use, adjust, and maintain.Specific model:YT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various brake wheels and discs, and customized non-standard brakes according to user needs.

time:2022-04-05

More

QP, CQP, DCPZ series caliper disc brakeCaliper disc brake is an advanced product that not only has the advantages of disc brake, but also has wide adaptability and unique advantages. This product has a simple structureSingle, small in size, light in weight, high in reliability, easy to use, suitable for various disc diameters, easy to install, debug, and maintain. Widely applicable for lifting and transportationDeceleration and braking of fixed operating mechanisms such as transportation, metallurgy, mining, ports, construction, bulk loading and unloading, as well as tension control of machinery such as cables, paper making, and steel platesDomain.main features Compact structure, small size, light weight, high reliability, and convenient installation and use.Sensitive action and flexible control.● QP series pneumatic caliper disc brake meets the installation performance requirements of foreign similar products. Matched with imported air bags, reliable performance and long service life.The brake pad adopts a pressure spring clamp type, with a unique structure and convenient and fast replacement.A display device can be installed to visually display the working status of the brake.All power sources do not need to be set separately and can be used in conjunction with existing air compression stations. Speed control valves are installed in the gas supply line, and the braking time can be adjusted steplessly.● Normally closed design: spring braking, pneumatic release.Normally open design: pneumatic braking, spring release, and braking force can be flexibly changed with air pressure.OverviewThe QP (CQP) series pneumatic caliper disc brakes are mainly used in lifting, transportation, metallurgy, mines, and portsThe braking and deceleration of various mechanisms in machinery such as machinery and construction.Usage conditionsEnvironmental temperature: -5 ℃~40 ℃● Working air pressure: 5-7bar for QP series;The CQP series is ≤ 7bar.Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.The air source should be free of oil, water, and other impurities.Main featuresThe QP series adopts spring braking and pneumatic release; The CQP series is pneumatic braking with spring release.The overall structure is simple, small in size, and lightweight.Asbestos free brake pads, green and environmentally friendly.The installation of the brake pad adopts a spring clamp type, which is convenient and fast to replace.● The brake pad is easy to adjust after being worn.Each disc diameter of the QP series brake can be adjusted for four levels of braking torque.All power sources do not need to be set separately and can be connected to the existing air compression station for grid use. They can be added to the gas supply lineEquipped with a speed control valve, the braking time can be adjusted steplessly.Note: 1. It can produce pneumatic caliper disc brakes with different disc thicknesses and installation sizes.2. The specific model and structural dimensions reserve the right to change.Due to the simple structure, stable operation, convenient installation, no noise, good linearity, and no empty space of pneumatic brakesDue to its characteristics of high torque, fast heat dissipation, light weight, easy adjustment, and high temperature resistance under high loads, it is widely used in transmission systems of various industrial machinery such as wire and cable equipment, packaging machinery, printing machinery, textile machinery, wire and cable mechanical winding machines, machine tools, and other equipment. The pneumatic brake can perform functions such as cutting, combining, inching, reversing, and shifting. It adopts a voltage of DC24V, and the voltage fluctuation cannot exceed the rated voltage of plus or minus 5%. The friction surface must not be contaminated with any oil stains or various impurities that can affect the normal operation of the disc brake. When installing the air pressure disc brake, axial positioning should be carried out, the air gap should be adjusted to the specified value, and the coaxiality of the split shaft installation should be maintained within a range of no more than 0.1mm, in order to maintain the normal operation and characteristics of the pneumatic brake.Compared with the drum brake, the working surface of the disc brake is flat and has heat transfer on both sides. The disc is easy to be cold cut when rotating, and is not prone to large deformation. The braking efficiency is stable. After a long time of use, the brake disc has enhanced its braking effect due to high temperature expansion; The drum brake has a single side heat transfer and a large temperature difference between the inside and outside, which leads to the brake drum being prone to deformation. At the same time, after prolonged braking, the brake drum expands due to its height, and the braking efficiency is weakened. In addition, the disc brake is simple in structure, convenient in maintenance, and easy to realize automatic adjustment of brake clearance.Pneumatic brakes are widely used as actuators in mechanical transmission systems such as machine tools, motors, packaging machinery, printing machinery, papermaking machinery, textile machinery, office equipment, metallurgical machinery, tobacco machinery, automated production equipment, and woodworking machinery, to complete functions such as clutch, direction change, speed change, braking, and positioning.Entry labels: ScienceDue to the simple structure, stable operation, convenient installation, no noise, good linearity, and no empty space of pneumatic brakesDue to its characteristics of high torque, fast heat dissipation, light weight, easy adjustment, and high temperature resistance under high loads, it is widely used in transmission systems of various industrial machinery such as wire and cable equipment, packaging machinery, printing machinery, textile machinery, wire and cable mechanical winding machines, machine tools, and other equipment. The pneumatic brake can perform functions such as leaving, combining, inching, reversing, and shifting. It adopts a voltage of DC24V, and the voltage fluctuation cannot exceed the rated voltage of plus or minus 5%. The friction surface must not be contaminated with any oil or other debris that can affect the normal operation of the disc brake. When installing the air pressure disc brake, axial positioning should be carried out, the air gap should be adjusted to the specified value, and the coaxiality of the split shaft installation should be maintained within a range of no more than 0.1mm, in order to maintain the normal operation and characteristics of the pneumatic brake.Compared with the drum brake, the working surface of the disc brake is flat and has heat transfer on both sides. The disc is easy to be cold cut when rotating, and is not prone to large deformation. The braking efficiency is stable. After a long time of use, the brake disc has enhanced its braking effect due to high temperature expansion; The drum brake has a single side heat transfer and a large temperature difference between the inside and outside, which leads to the brake drum being prone to deformation. At the same time, after prolonged braking, the brake drum expands due to its height, and the braking efficiency is weakened. In addition, the disc brake is simple in structure, convenient in maintenance, and easy to realize automatic adjustment of brake clearance.Pneumatic brakes are widely used as actuators in mechanical transmission systems such as machine tools, motors, packaging machinery, printing machinery, papermaking machinery, textile machinery, office equipment, metallurgical machinery, tobacco machinery, automated production equipment, and woodworking machinery, to complete functions such as clutch, direction change, speed change, braking, and positioning.Entry labels:science

time:2022-04-05

More

What oil is added to YT1 electric hydraulic thrusterWhat oil is added to YT1, ED, MYT1.YTD electric hydraulic thrusters, BD-25 hydraulic oil anti-wear hydraulic oil 46, transformer oil can also be added to aviation oil, etc. Jiaozuo Brake Factory produces electric hydraulic thrusters, electric hydraulic brakes, disc brakes, pneumatic brakes, electromagnetic iron block brakes and other industrial brakes, with safe and reliable performance, smooth braking, high action rate and long service life.Brake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof Brakes

time:2022-04-05

More

ED electric hydraulic thruster replaces YT1-45Z/6 thrusterED series electric hydraulic thrusters:ED-23/5; ED-30/5; ED-50/6; ED-80/6; ED-121/6; ED-201/6; ED-301/6; ED-50/12; ED-80/12; ED-121/12; ED-201/12; ED-301/12; ED-630/12ED25, ED45, ED90BED ED series electric hydraulic thrusters:BED30/5; BED50/6; BED80/6; BED121/6; BED201/6; BED301/6; BED50/12; BED80/12; BED121/12BED201/12; BED301/12; BED630/12YT1-25/4, YT1-45/6, YT1-90/8, YT1-125/10, YT1-180/12YT1-25/4, YT1-45/6, YT1-90/8, YT1-125/10, YT1-180/12YT1-18ZB/2, YT1-25ZB/4, YT1-25ZC/4, YT1-45Z/4YT1-45Z/5, YT1-45Z/6, YT1-90Z/6, YT1-90Z/8YT1-125Z/10, YT1-180Z/8, YT1-180Z/10YT1-180Z/12, YT1-320Z/12, YT1-320Z/20YT1-25/4, YT1-45/6, YT1-90/8, YT1-125/10, YT1-180/12YT1-18Z/2, YT1-25Z/4, YT1-25ZB/4, YT1-18/2YT1-90/6, YT1-45/5, YT1-45/4, YT1CJ-18Z/2

time:2022-04-05

More

BED301/12 explosion-proof electric hydraulic thruster BED301/6ED series electric hydraulic thrusters:ED-23/5; ED-30/5; ED-50/6; ED-80/6; ED-121/6; ED-201/6; ED-301/6; ED-50/12; ED-80/12; ED-121/12; ED-201/12; ED-301/12; ED-630/12BED ED series electric hydraulic thrusters:BED30/5; BED50/6; BED80/6; BED121/6; BED201/6; BED301/6; BED50/12; BED80/12; BED121/12BED201/12; BED301/12; BED630/12

time:2022-04-01

More

Replacement method for electric hydraulic drum brakesYWZ5 series electric hydraulic drum brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ4-500/121, YWZ4-600/201 electric hydraulic block brakeProduct modelNumber of boxes packedpriceYMZ4-800/301 Electric Hydraulic Brake 1 InquiryYMZ4-700/301 Electric Hydraulic Brake 1 InquiryYMZ4-600/201 Electric Hydraulic Brake 1 InquiryYMZ4-600/121 Electric Hydraulic Brake 1 InquiryYMZ4-500/201 Electric Hydraulic Brake 1 InquiryYMZ4-500/121 Electric Hydraulic Brake 1 InquiryYMZ4-400/121 Electric Hydraulic Brake 1 InquiryYMZ4-400/80 Electric Hydraulic Brake 1 InquiryYMZ4-400/50 Electric Hydraulic Brake 1 InquiryYMZ4-300/80 Electric Hydraulic Brake 1 InquiryYMZ4-300/50 Electric Hydraulic Brake 1 InquiryYMZ4-300/30 Electric Hydraulic Brake 1 InquiryYMZ4-200/30 Electric Hydraulic Brake 1 InquiryYMZ4-200/23 Electric Hydraulic Brake 1 InquiryYMZ4-150/23 Electric Hydraulic Brake 1 InquiryYMZ4-100/23 Electric Hydraulic Brake 1 InquiryProduct Details:YWZ-400/90, YWZ-500/125, YWZ-600/180 electric hydraulic block brakesYWZ series electric hydraulic block brake:YWZ-100/18 electric hydraulic block brake, YWZ-200/25 electric hydraulic block brake, YWZ-300/25 electric hydraulic block brake, YWZ-300/45 electric hydraulic block brake, YWZ-300/90 electric hydraulic block brake, YWZ-400/45 electric hydraulic block brake, YWZ-400/90 electric hydraulic block brake, YWZ-500/125 electric hydraulic block brake, YWZ-600/180 electric hydraulic block brakeYWZ series electric hydraulic block brake:YWZ-100/18, YWZ-200/25, YWZ-300/25, YWZ-300/45, YWZ-300/90, YWZ-400/45, YWZ-400/90, YWZ-500/125, YWZ-600/180

time:2022-04-01

More

Brake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof Brakes1. Brake drum. The working surface of the inner wall of the brake drum will experience severe wear after long-term braking use. Its roundness has changed, and the coaxiality between its inner working surface and its installation positioning surface has also changed. As a result, various faults may occur when the car is braking, such as poor braking effect, noise, vibration, etc. Therefore, timely repairs must be carried out. As for the repair method to be used, it can be determined based on the wear and tear situation. When the wear of the inner wall working surface is not very severe, and the changes in its roundness and coaxiality of the positioning reference are not too large, the method of honing can be used to solve it. Usually, the roundness of the inner wall working surface reaches 0 5 mm, with a coaxiality of 0 2 mm requires hole lining repair. The common damages of brake drums in operation include wear and grooving of the friction surface, as well as deformation and loss of roundness. These damages will directly affect braking efficiency. Therefore, the working surface of the brake drum must be flat and smooth, and have good contact with the friction plate. Minor scratches, small grooves, and slight mechanical damage on the outer shoulder are allowed without affecting the quality of use. The roundness error can be measured with a dedicated bow inner diameter gauge, and the radius error exceeds 0 13 mm, or severe grooves caused by exposed shoe rivets, should be polished on a lathe or brake drum polishing machine according to the actual wear situation. If the brake drum of a car experiences cracks, severe deformation, or wear, and the inner diameter exceeds the limit, it should be replaced. The repaired brake drum should undergo a static balance check, and its static imbalance should not exceed 200 g • cm. When grooves appear on the working surface of the brake drum, or its roundness and radial total runout (i.e. the deviation from the hub axis) exceed the usage requirements, it will seriously affect the braking efficiency of the car and should be repaired in a timely manner. General requirements for brake drum lining: Position the outer ring of the wheel hub bearing (to ensure coaxiality after lining). After lining, the inner diameter of the brake drum shall not exceed the basic size by 4 mm, and the cylindricity shall not exceed 0 10mm, with a radial runout of no more than 0 10 mm. If the inner diameter of the brake drum is worn beyond the specified limit, it should be replaced with a new one.2. Brake shoe friction lining. When the brake shoe friction lining is severely worn, or the surface of the friction lining is severely contaminated or burned by oil, a new shoe should be replaced. When replacing, both left and right wheels must be carried out simultaneously, and friction linings of the same manufacturer, brand, and material must be selected and installed. When the new shoe after replacement does not fit well with the brake drum, it should be ground until it meets the requirements. The general requirement is to ensure that the bonding area between the shoe and the brake drum is greater than 60% of the total area of the friction lining. The brake shoe return spring should be checked for its free length. If it exceeds 5% of its standard length or if there is a gap between the coils, it should be replaced. If the brake shoe tendon is warped or deformed, it will interfere with the bolt (nut) of the brake clearance adjustment device, and with the groove of the brake cylinder piston and brake support plate. This will affect the free opening and return of the brake shoe friction lining assembly. If this situation occurs, it can be repaired using cold correction methods. If the brake shoe base plate undergoes deformation, it can also be repaired using cold correction methods. For cracks in the brake shoe bottom plate welds caused by deformation or other reasons, the verticality shall not exceed 0 At 25 mm, welding repair and correction can be carried out; If the damage is too severe and cannot be repaired, it should be replaced. The tension spring of the brake shoe must maintain a certain amount of elasticity. If there is a severe decrease in elasticity, it often causes the brake tendon to detach from the groove of the brake support plate and become stuck, causing the brake to not be released. Therefore, it is necessary to replace springs with severely reduced elasticity in a timely manner. During driving, due to the frequent application of braking to the car, the brake drum and brake shoe friction plate will experience varying degrees and types of wear or deformation. To ensure driving safety, it is necessary to repair it. Within the allowable range of repair dimensions, the brake drum is often processed using ordinary lathes or specialized machine tools. At present, there are two ways to process brake friction pads. One is to remove them from the vehicle and fix them on a specialized fixture for grinding or turning. Although this method can improve processing quality, save labor hours, and is suitable for division of labor and flow operations, due to the limitations of current overhaul and maintenance technology in China, the brake shoes processed in this way often cannot meet the assembly requirements of vehicles, thereby affecting braking efficiency in the early stages of driving. Another method is to machine the brake shoe friction plates on the machine. As it is positioned and processed based on actual conditions, it is more suitable for the assembly requirements of the brake. Although this method requires more labor, it is flexible and convenient for general repair shops or workshops to use. The equipment processed using the second method is mostly self-made, which can be divided into integral and separate types from the perspective of the overall structure. The latter is to install the moving tool head and feed mechanism on a small car, while the tool holder and positioning device are fixed on the front or rear axle of the car; The former institutions are installed as a whole on the car. There are two types of integrated brake shoe polishing machines: manual and electric, while the separate types are mostly electric.

time:2022-04-01

More

ED hydraulic thruster ED-121/6, ED121/6 usageThe ED series electric hydraulic thrusters are mainly used as operating components for the YWZ4, YWZ5, YWZ8, YWZ9, and YWZP series electric hydraulic block brakes, widely used in industries such as lifting and transportation, metallurgy, mining, ports, and construction.Normal working conditionsMotor 1/2 three-phase AC asynchronous motor, in accordance with (G 755-87) regulations, insulation level: F levelUsage conditions:Continuous operation S1, continuous operation S2, load duration FC=60%Rated voltage is 380V three-phase, frequency 50HzThe altitude level of the location of use complies with the GB755-87 standardThe ambient temperature should be within the range of -20 ℃ to 40 ℃, and the relative humidity of the air should not exceed 90%Vertical installation: piston connection block facing upwards, horizontal installation: marked label facing upwards: (ED630/12 male is suitable for vertical installation)Main technical parametersModel rated thrust(N) Rated stroke(mm) Action stroke brake spring force(N) Rated frequency(Hz) Input power(W) Rated voltage(V) Rated current(A) High operating frequency weight (kg)Rising and fallingShort stroke thruster deviation ± 20%ED23/5 220 50 0.35 0.35 180 50 165 380 0.52 2000 10ED30/5 300 50 0.35 0.35 270 50 200 380 0.46 2000 14ED50/6 500 60 0.45 0.39 460 50 210 380 0.48 2000 14ED80/6 800 60 0.32 0.34 750 50 330 380 1.42 2000 24ED121/6 1250 60 0.4 0.42 1200 50 330 380 1.44 2000 39ED201/6 2000 60 0.5 0.32 1900 50 450 380 1.45 2000 39ED301/6 3000 60 0.58 0.32 2700 50 550 380 1.46 1500 40purposeContinuously work S1 and continue working S3, and the ambient temperature of chicken feathers reaches+50 ℃.The rated current in the table refers to the line terminal current during rated operation, but if the power supply is at a non rated value, it will inevitably cause a corresponding change in the rated current. Environmental temperature: -20 ℃~+50 ℃, hydraulic oil: DB-25 (SY1351-77) When it is below -20 ℃, YH-10 hydraulic oil can be used without a heater. When using DB-25 hydraulic equipment, a heater must be installed. The travel time is measured at an ambient temperature of 20 ℃.Main technical parametersModel A B C D E F G H K L M N O P Q R S T UEN23/5 286 50 26 12 20 16 20 160 80 40 200 16 85 55 75 100 20EN30/5 370 50 34 15 16 25 16 18 160 80 80 40 197 16 85 55 75 100 20EN50/6 435 60 36 18 20 30 20 23 195 97 120 60 254 22 85 55 75 100 20EN80/6 450 60 36 18 20 30 23 195 97 120 60 254 22 85 55 75 100 20EN50/12 515 120 36 18 20 30 20 23 195 97 120 60 254 22EN80/12 530 120 36 18 20 30 20 23 195 97 120 60 254 22EN121/6 645 60 38 25 25 40 25 35 240 112 90 40 260 25 130 80 120 147 35EN201/6 645 60 38 25 40 25 35 240 112 90 40 260 25 130 80 120 147 35EN301/6 645 60 38 25 25 40 25 35 240 112 90 40 260 25 130 80 120 147 35

time:2022-04-01

More

ED-23/5, ED-30/5, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-50/6, ED-80/6, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-121/6, ED-201/6, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters,ED-301/6, ED-50/12, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-80/12, ED-121/12, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters,ED-201/12, ED-301/12, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrustersED-23/5, ED-30/5, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-50/6, ED-80/6, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-121/6, ED-201/6, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters,ED-301/6, ED-50/12, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-80/12, ED-121/12, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters,ED-201/12, ED-301/12, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters

time:2022-04-01

More

Supply YPZ2-W550/E30 electric hydraulic horizontal disc brakeElectric hydraulic brakeYWZB YWZ3B YWZ4B YWZ5 YWZ8 YWZ9 YWZ12 YWZ13 YW YWL TYWZ2 YWPElectromagnetic block brakeJZ (TJ2A) MW (Z) ZWZAZWZ2 ZWZ3ADCW3Electromagnetic failure protection disc brake5SE 561SE 560SE 56SEDCPZ12.7 4SE 3SE ST1SE ST2SE 450SEHydraulic failure protection disc brake5SH 4SH 3SH 450SH ST1SH ST2SH ST3SH ST4SHSB (YQP) SBDST5SH ST10SHST16SHST25SHST25SH-AST40SH904SHSBBElectric hydraulic arm disc brake Horizontal disc brakeYPZ2 I, II, IIIYPZ2 IV, V, VIYPZ2-W550/E30Pneumatic caliper disc brake QP12.7 5SP4SP3SP450SPPDADP60M-ADP61M-ADP62MHydraulic direct acting disc brake DADH75ADH60ADH90ADH120DADH80DADH90DADH120DADH103DADH195Electric hydraulic thrusterYT1 EdMYT1 hydraulic thruster motor modelBO62Z YDT80-2 ASF82A ASF102A B112Z A028012A028022 three-phase asynchronous motorExplosion proof electric hydraulic thrusterBYT1 BED

time:2022-03-29

More

Product model: YWZ8-400/E80 hydraulic brakeYT1CJ-45/6 hydraulic thrusterYW500-E201YW Hydraulic BrakeYWZ3B-710/180YWZ3 series hydraulic brakeTJ2-200/200 Electromagnetic BrakeYWZ10-630/201 Hydraulic BrakeMYT3-70 Hydraulic PusherMWZ315-630 Electromagnetic Block BrakeYWZ9-250/50 hydraulic brakeBED301/6 explosion-proof hydraulic thruster YW500-E121YW hydraulic brakeYWZ12-500/121S hydraulic brakeYWZ9-250/E50 hydraulic brakeYWZ5-500/121 hydraulic brakeYWZ4B-400/90YWZ4 hydraulic brakeYWZ3B-250/25YWZ3 series hydraulic brakeYWZ2-300/30YWZ series hydraulic brakeMYT3-80 Hydraulic PusherMYTD2-1250/50 hydraulic thrusterED-70/5 hydraulic thruster YW-500/201 hydraulic brakeYWK250-300YWK electric hydraulic brakeTJ2A-300 energy-saving electromagnetic block brakeHydraulic push rod brakeED-301/12 hydraulic thrusterYWZ-150/25YWZ series hydraulic brakeYWZ4-200/30YWZ4 hydraulic brakeYWZ5-630/E201 Hydraulic BrakeYWZ10-630/121 hydraulic brakeYWB-710/301 Hydraulic Brake ED-1250/120 Hydraulic Pusher_ ZWZ3-500/500ZWZ3-400/400YW630-E1250YW Hydraulic BrakeYWZ10-630/E121 Hydraulic BrakeYWZ5-250/E23 Hydraulic BrakeYWZ3B-160/25YWZ3 series hydraulic brakeMYTD2-2000/120 Hydraulic PusherYT1CJ-45Z/6 hydraulic thrusterJCZ-300/25H electromagnetic brakeYWP-400/121 Hydraulic Brake

time:2022-03-29

More

ED thrusterEd series electric hydraulic thrusters1、 ED thruster overview Ed series electric hydraulic thruster is a very compact drive control device integrating motor, centrifugal pump and oil cylinder. It is widely used as the drive device of various block brakes and disc brakes, and can also be used for the drive control of various industrial valves, gates, directional swing and rotation (<90 °) devices (mechanisms) and clamping devices. 2、 The design feature of the thruster is that the outer shell is made of cast aluminum alloy, with light weight and beautiful appearance; The motor is of non oil immersed structure, with Class B or F insulation (according to user requirements). Good heat resistance and long service life; The motor junction box cover is equipped with a seal and uses a cable stuffing box for incoming lines, which is firm and reliable. The electrical casing protection level reaches IP55;The surface of the motor shaft and push rod are plated with hard chromium treatment, greatly extending the service life of the sealing element; The oil cylinder shell is equipped with a balance chamber on one side, which can allow the thruster to be installed in any direction from 0 to 180 °, thereby expanding its range of use; All seals and bearings of the Ed series adopt world products, with reliable sealing and long service life; The Ed series fasteners are made of stainless steel material, which is beautiful and durable. 3、 Selection of installation method for vertical installation: the piston rod connecting block faces upwards; Horizontal installation and any position in the middle: the main parameter label faces upwards; All push rod connection blocks of thrusters can rotate. The Ed50-Ed301 fixed seat can rotate 90 °, while the Ed23-Ed30 fixed seat can also provide 90 ° rotation, but the installation height dimension A is increased by 8mm; Regardless of the installation position, the piston rod cannot withstand any force to avoid affecting its effectiveness and lifespan. 4、 Additional devices can be installed according to user needs to meet different work needs; Rising or falling valve: the rising valve "H", the falling valve "S" or the rising and falling valves "H, S" can extend the rising and Fall time steplessly, and the adjustable value can reach 10-20 times of the rated value. The valve is adjusted externally. The rising and Fall time time of the thruster with valve will be extended, the short stroke will be extended by 0.1-0.2s, and the long stroke will be extended by 0.2-0.4s; Brake spring: It generates braking force, and the spring force listed in the technical parameters is 1/3 of the rising stroke (2/3 of the falling stroke); Return spring: The working principle is the same as C-spring, but the return spring force is relatively small; Cushion spring: (only applicable to short stroke) mainly regulates the braking process. The non periodic transient process of buffering braking ensures smooth braking. It replaces the connecting block of the push rod and is installed on the piston rod without changing the stroke of the pusher. Heater: In areas with ambient temperatures below -20 ℃, additional heaters can be installed according to user needs. The heaters are AC200V or AC110V voltage, and should be specified when ordering. The temperature control and adjustment method is chosen by the user themselves; Travel switch: According to user requirements, the pusher can be equipped with a mechanical travel switch.The ED series electric hydraulic thruster is mainly used as an operating component for the YWZ4, YWZ5, YWZ8, YWZ9, and YWZP series electric hydraulic block brakes. It is widely used in industries such as lifting and transportation, metallurgy, mining, ports, and construction.Normal working conditions: 1/2 three-phase AC asynchronous motor, in accordance with the regulations of (G 755-87), insulation level: Class F, brake usage conditions: continuous operation S1, continuous operation S2, load duration FC=60%Rated voltage is 380V three-phase, frequency 50HzThe altitude level of the location of use complies with the GB755-87 standard. The ambient temperature should be within the range of -20 ℃ to 40 ℃, and the relative humidity of the air should not exceed 90%Vertical installation: piston connection block facing upwards, horizontal installation: marked label facing upwards: (ED630/12 male is suitable for vertical installation)

time:2022-03-29

More