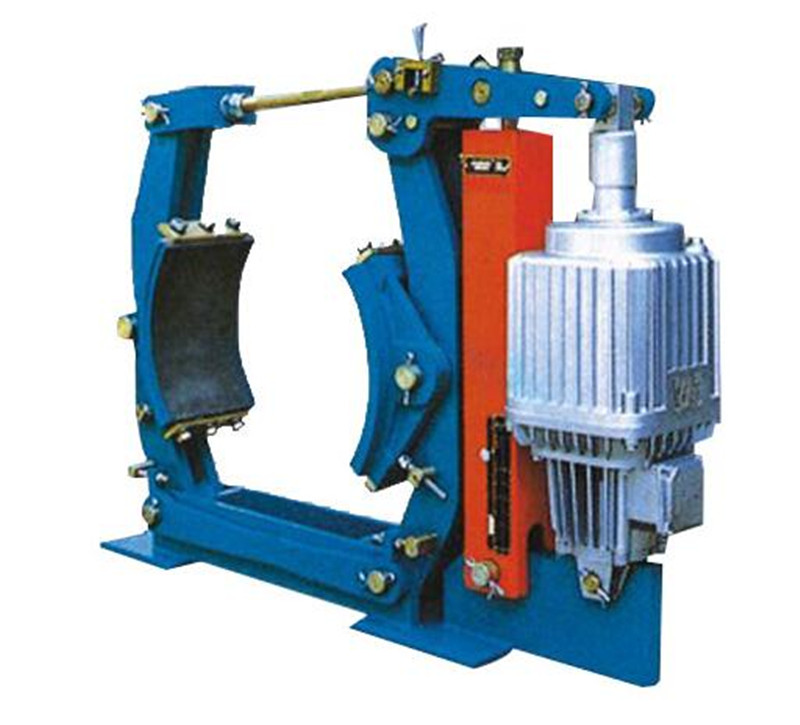

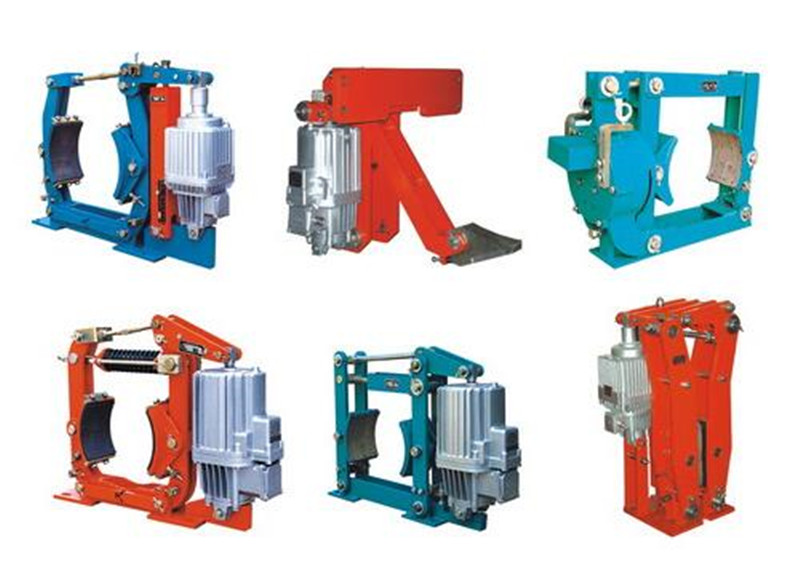

Special holding brake brake brake for crane, winch, belt conveyorSpecific model:YT1, ED, YTD, MYT1, MYT3 series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW, YWL series electric hydraulic brakesQP, CQP series pneumatic caliper disc brakesDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeDDMZ-10 DDMZ-40 DDMZ-20 DDMZ-80 DDMZ-160 DDMZ-250 DDMZ-320 DDMZ-500 DDMZ-1000Customized various brakes, brake wheels, brake discs, foot pumps, electro-hydraulic push rods, couplings, hydraulic stations, brake pads, and customized non-standard brakes according to user needs.Electric hydraulic drum brakes are widely used for deceleration and parking (maintenance) braking in various lifting and transportation, port loading and unloading, metallurgical equipment, mining machinery, and engineering machinery.main features 1. Safe and reliable performance, smooth braking, and high action frequency;2. The main hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use;3. The interlocking equal back distance device and automatic tile following device can always maintain equal back distance of both sides of the tiles without adjustment, completely avoiding the phenomenon of one side of the brake pad floating against the brake wheel due to uneven back distance;4. The brake pad is a card mounted integral shaped structure, which is very convenient and fast to replace. There are different materials of brake pads available for users to choose from, such as semi metal (asbestos free) hard and semi hard, soft (asbestos containing, asbestos free).Additional devices1. Manual release device;2. Releasing (opening) or closing (closing) limit switch can display whether the brake is normally released or closed;3. The automatic compensation device for brake pad wear can achieve five levels of automatic compensation for pad setback and braking torque when pad wear occurs;4. The limit switch for pad wear can achieve signal attention when the brake pad is worn to its limit (note: automatic compensation device must be equipped during application);5. Using a thruster with a lowering delay valve to drive, the delayed closure of the brake can be achieved.special requirementsAccording to user requirements, we can produce various explosion-proof and non-standard products.

time:2022-02-10

More

Which company is good for electric hydraulic drum brakes? Jiaozuo Brake Factory produces electric hydraulic drum brakes, electric hydraulic thrusters, disc brakes, electromagnetic iron block brakes, pneumatic brakes and other industrial brakes. The products have safe and reliable performance, smooth braking, high smoothness of action and long service life.Specific model:YT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various brake wheels and discs, and customized non-standard brakes according to user needs.

time:2022-02-10

More

Genuine gold hoop electric hydraulic brake electric hydraulic thrusterElectric hydraulic brake, electric hydraulic thruster, disc brake, electromagnetic brake and other industrial brakes. Tel: 15838971872YT1 series electric hydraulic thruster:YT1-18ZB/2; YT1-25ZB/4; YT1-45Z/5; YT1-90Z/8; YT1-125Z/10; YT1-180Z/10; YT1-320Z/12; YT1-320Z/20; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12; YT1-320Z/12; YT1-350/12;YT1-350/20; YT1-350/35; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12ED series electric hydraulic thrusters:ED-23/5; ED-30/5; ED-50/6; ED-80/6; ED-121/6; ED-201/6; ED-301/6; ED-50/12; ED-80/12; ED-121/12; ED-201/12; ED-301/12; ED-630/12YWZ series electric hydraulic block brake:YWZ-100/18; YWZ-150/25; YWZ-160/25; YWZ-200/25; YWZ-200/45; YWZ-300/25; YWZ4-300/45; YWZ4-300/90; YWZ4-400/45; YWZ4-400/90; YWZ4-400/125; YWZ4-500/90; YWZ4-500/125; YWZ4-500/180; YWZ4-600/180; YWZ4-700/180; YWZ4-800/180; YWZ4-800/320YWZ3B series electric hydraulic block brake: YWZ9-200/E23 electric hydraulic drum brake with low priceYWZ3B-160/18; YWZ3B-160/25; YWZ3B-200/18; YWZ3B-200/25; YWZ3B-250/25; YWZ3B-250/45; YWZ3B-315/25; YWZ3B-315/45; YWZ3B-315/90; YWZ3B-400/90; YWZ3B-400/125; YWZ3B-500/90; YWZ3B-500/125; YWZ3B-500/180; YWZ3B-630/125; YWZ3B-630/180; YWZ3B-630/320; YWZ3B-710/180; YWZ3B-710/320; YWZ3B-800/320Low price of YWZ9-200/E23 electric hydraulic drum brakeYWZ4B series electric hydraulic block brake: YWZ9-200/E23 electric hydraulic drum brake with low priceYWZ4B-100/23; YWZ4B-150/23; YWZ4B-200/23; YWZ4B-200/30; YWZ4B-300/30; YWZ4B-300/50; YWZ4B-300/80; YWZ4B-400/50; YWZ4B-400/80; YWZ4B-400/121; YWZ4B-500/121; YWZ4B-600/121; YWZ4B-600/201; YWZ4B-700/201; YWZ4B-700/301; YWZ4B-800/301YWZ5 series electric hydraulic drum brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50; YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201; YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12YWZ9 series electric hydraulic block brake:YWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50

time:2022-02-10

More

Differences between YWZ6 electric hydraulic brake and YWZ8 electric hydraulic brakeThe installation dimensions of YWZ6 electric hydraulic brake and YWZ8 electric hydraulic brake are the same. Jiaozuo Brake Factory produces electric hydraulic brake, thruster, disc brake, electromagnetic iron block brake, pneumatic caliper brake, wind brake and other industrial brakes. The product performance is safe and reliable, braking is stable, action rate is high, and service life is long.Main products:1. YWZB, YWZ3, YWZ4, YWZ5, YWZ6, YWZ8, YWZ9, YWZ10, YWZ12, YWZ13 series electric hydraulic pad brakes2. YW series electric hydraulic tile brake3. YWL series electric hydraulic tile brake4. EYWZ series two-stage hydraulic block brake5. TWZ (B) series normally open operated pad brake6. JZ, MW, MWZ, ZWZA, ZWZ3, ZWZ3A series electromagnetic pad brakes7. YPZ2 series electric hydraulic arm disc brake8. YFX series electric hydraulic windproof iron wedge brake9. YLBZ series hydraulic wheel edge brake10. ED, YT1 series electric hydraulic thrusters11. BED and BYT1 series explosion-proof electric hydraulic thrusters12. TYWZ series hydraulic tile brake13. DCPZ series electromagnetic caliper disc brake14. QP12.7 series pneumatic caliper disc brake15. TYWZ2 series foot hydraulic block brake16. SE, SH, SP series failure disc protection brakes17. SBD series hydraulic failure protection disc brake18. DYT series electric hydraulic push rod electric push rod

time:2022-02-10

More

Electric hydraulic thruster Jiaozuo Brake General FactoryThe ED series electric hydraulic thrusters, YT1 series electric hydraulic thrusters, BED series electric hydraulic thrusters, and BYT1 series electric hydraulic thrusters can operate up to 720 times per hour. Comply with JB/ZQ4388-86 standard;YT1 series electric hydraulic thruster:YT1-18ZB/2; YT1-25ZB/4; YT1-45Z/5; YT1-90Z/8; YT1-125Z/10; YT1-180Z/10; YT1-320Z/12; YT1-320Z/20; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12; YT1-320Z/12; YT1-350/12;YT1-350/20; YT1-350/35; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12ED series electric hydraulic thrusters:ED-23/5; ED-30/5; ED-50/6; ED-80/6; ED-121/6; ED-201/6; ED-301/6; ED-50/12; ED-80/12; ED-121/12; ED-201/12; ED-301/12; ED-630/12The thruster mainly consists of three parts: electric motor, centrifugal pump, and hydraulic cylinder. The motor shaft is hollow and connected to the square shaft through a coupling. The end of the square shaft is equipped with a centrifugal impeller. When the push rod acts, the square shaft slides up and down in the hollow motor shaft and transmits torque.When energized, the electric motor drives the impeller to rotate, generating oil pressure to push the piston push rod up rapidly. When the rated stroke is completed and the specified oil pressure is reached, the piston rapidly drops under the action of external load and returns to its starting position.5 Technical parameters and external installation dimensions6. Installation adjustment and usage requirements6.1 Installation of thrusters6.1.1 Firstly, check if the model on the nameplate of the thruster matches the requirements.6.1.2 When the thruster leaves the factory, there is no working oil and it cannot be used directly. When using it, first add pure hydraulic oil from the oil filling hole (5) to the oil level hole (3). Pay attention to pulling the push rod up and down several times during the oil filling process to eliminate air and fill the oil cylinder with oil, and then tighten the plug.6.1.3 The thruster is used for vertical or inclined installation not exceeding ± 15 °, with the connecting rod (7) facing upwards.6.1.4 After installation, the thruster should be able to swing as a whole during operation, and the push rod is not allowed to bear radial force.6.1.5 The thruster is equipped with qualified motors that have obtained explosion-proof certificates.When wiring the thruster motor, it is necessary to carefully compare the wiring with the motor nameplate.6.1.7 The diameter of the motor inlet cable should match the hole of the rubber pad, ensuring that there is no gap between the silicone rubber pad and the cable and outlet, otherwise the explosion-proof performance will be lost.6.1.8 The thruster is equipped with grounding screws, and users should ground it according to relevant regulations when using it. Do not open the cover with electricity!!!6.2 Use of thrusters6.2.1 Before use, it should be checked according to Article 5.1, and once it is correct, it can be put into use.6.2.2 Regularly check whether the thruster works normally, whether there is oil leakage, and maintain a certain amount of oil.6.2.3 Check the oil every six months, and change the oil when it deteriorates or gets mixed with debris (see 5.1.2).6.2.4 Based on the temperature of the surrounding medium, it is recommended to select hydraulic oil according to the following table:When the thruster is in operation, the lower end of the piston should be kept at a certain distance (generally not less than 5mm) from the cylinder bottom, otherwise it will affect normal operation.7. Usage and Maintenance7.1 Before use, it should be checked according to Article 6.1, and once it is correct, it can be put into use.7.2 Regularly check the operation of the thruster, whether there is any oil leakage, and maintain a fixed amount of oil.Warning: It is strictly prohibited to set up oil collection pits. Strengthen inspections and promptly handle any oil spills or leaks that are discovered.7.3 Check the oil every six months, and when the oil deteriorates or gets mixed with debris, the oil should be changed (see Article 6.1.2).8. Storage and transportation8.1 When storing thrusters, they should be kept dry to prevent moisture and sharp changes in ambient temperature.8.2 During transportation, it is necessary to prevent rain and not use a rope to cover the push rod for transportation.

time:2022-02-10

More

Which electric hydraulic thruster is more durable? YT1, ED, MYT1, MYT3, YTD series electric hydraulic thrusters have safe and reliable performance, high action rate, and long service life.Our company produces various series of brakes, mainly used for mechanical braking of mechanical driving devices in lifting, transportation, metallurgy, mining, ports, construction, etc. They have the advantages of smooth braking, safety and reliability, convenient maintenance, low power consumption, long service life, no noise, and high frequency. Our company is the first to pass the ISO 9001.2000 quality management system standard certification. Advanced process equipment, strong technical strength, comprehensive testing methods, strict quality management system, reasonable product prices, and reputation are the strong guarantees for the company's products to enter the market and win users.Tel: 15838971872Brake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various brake wheels and discs, and customized non-standard brakes according to user needs

time:2022-02-10

More

Which product of hydraulic disc brake is reliableOur company has taken the lead in passing the IS09001:2000 quality management system standard certification. Our factory has various sophisticated processing equipment required for production, excellent technical equipment, strong technical force, advanced technology, complete testing methods, and a strict quality management system. The product quality is stable and reliable, and we have an annual production capacity of over 10000 sets of various brakes and actuators.The pursuit of quality and endless service is the consistent tenet of the company. The company has established strict service measures: pre-sales and during sales are completed by a nationwide sales network, and after-sales is implemented by the company's after-sales service department. Thus, users can receive comprehensive pre-sales, in sales, and after-sales services.Our factory has an exquisite technical team, advanced production equipment, scientific management level, strict testing methods, and good after-sales service.The products sell well all over the country: various electromagnetic, hydraulic, pneumatic, failure protection brakes, various arm disc brakes, various electromagnetic, hydraulic, pneumatic caliper disc brakes, various electromagnetic, hydraulic, pneumatic, drum brakes, various wind proof iron wedges, hydraulic wheel edges, hydraulic top rail brakes. And we can design and manufacture various non-standard products according to user requirements, which are widely used in lifting, mining, mechanical metallurgy, electricity, railways, water conservancy, ports, chemical engineering, and docks. Our factory has obtained the special equipment type test certificate issued by the National Lifting Machinery Quality Supervision and Inspection Center. Rated as a contract abiding and trustworthy enterprise in Henan ProvinceThe products produced and sold cover nearly thirty provinces and cities in China. The company is committed to building itself into an enterprise in the brake and related product industry with its team, rigorous management, and advanced equipment. The company adheres to using corporate culture to enhance its core competitiveness and establish a good social image in its development.Tel: 15838971872Main products: electric hydraulic wind proof iron wedge brake supplier, Jiaozuo ED series electric hydraulic thruster market price, electric hydraulic block brake market price, Henan electric hydraulic arm disc brake market price, EYWZ series electric hydraulic block brake supplier, YWL series electric hydraulic block brake supplier, YWZ8 series electric hydraulic block brake supplier, YWZ9 series electric hydraulic block brake supplier YWZ13 series electric hydraulic block brake supplier, YWZ3B electric hydraulic block brake supplier, YWZ5 electric hydraulic block brake supplier, YWZB electric hydraulic block brake supplier, electric hydraulic block brake distributor, YW electric hydraulic block brake supplier, YT1 series electric hydraulic thruster supplierMain products:1. YWZB, YWZ3, YWZ4, YWZ5, YWZ8, YWZ9, YWZ10, YWZ12, YWZ13 series electric hydraulic pad brakes2. YW series electric hydraulic tile brake3. YWL series electric hydraulic tile brake4. EYWZ series two-stage hydraulic block brake5. TWZ (B) series normally open operated pad brake6. JZ, MW, MWZ, ZWZA, ZWZ3, ZWZ3A series electromagnetic pad brakes7. YPZ2 series electric hydraulic arm disc brake8. YFX series electric hydraulic windproof iron wedge brake9. YLBZ series hydraulic wheel edge brake10. ED, YT1 series electric hydraulic thrusters11. BED and BYT1 series explosion-proof electric hydraulic thrusters12. TYWZ series hydraulic tile brake13. DCPZ series electromagnetic caliper disc brake14. QP12.7 series pneumatic caliper disc brake15. TYWZ2 series foot hydraulic block brake16. SE, SH, SP series failure disc protection brakes17. SBD series hydraulic failure protection disc brake18. DYT series electric hydraulic push rod electric push rod

time:2022-02-10

More

Electric hydraulic brakes are mainly supplied and used in lifting equipment, mining equipment, coal mining equipment, construction equipment, metallurgical equipment, double beam cranes, bridge erecting machines, winches, lifting winches, steel mills, smelters and other equipmentMain products or services: ED YT1 electric hydraulic thruster, YWZ electric hydraulic brake, SE disc brake. Our main products are: YT1, ED, YTD. series electric hydraulic thruster JZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brake YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brake QP, CQP series pneumatic caliper disc brake. DCPZ series electromagnetic caliper disc brake YPZ series arm disc brake SBD series safety brake SH, ST series hydraulic failure protection brake DADH series hydraulic direct brake SE series electromagnetic failure protection brake YFX, YDGZ, YLBZ, series wind proof brake SP series pneumatic failure protection brake, DP series motor disc brake additionally customized various brake wheels, brake discs, customized various non-standard brakes according to user needs, Hydraulic wheel edge, hydraulic top rail brake. And we can design and manufacture various non-standard products according to user requirements, which are widely used in lifting, mining, mechanical metallurgy, electricity, railways, water conservancy, ports, chemical engineering, and docks. Our factory has obtained the special equipment type test certificate issued by the National Lifting Machinery Quality Supervision and Inspection Center. It was rated as a contract abiding and trustworthy enterprise in Henan Province and a contract abiding and trustworthy enterprise in Jiaozuo City, Henan Jiaozuo brake manufacturer. Our company produces various brakes, such as hydraulic brake, hydraulic thruster, caliper disc brake, electromagnet brake, etcOverview:Scope of application: electric hydraulic hydraulic brake is mainly used for mechanical braking or deceleration of various mechanical drives in wind turbine generator high speed shaft brake, hoisting and transportation, port loading and unloading, cable, sling equipment and other industries.Design features:Adopting a floating installation design, installation and debugging are faster and more convenient than fixed and swinging. High performance friction materials with good temperature resistance and stable friction performance. Linkage reset design ensures equal brake opening clearance and convenient adjustment. It has a display function, which can display the working status and provide interlocking protection. An automatic compensation device for brake pad wear can be installed. Realize automatic pad wear, tile retreat, and infinite compensation for braking torque. In terms of volume, the structure is compact.Warning: It is strictly prohibited to set up oil collection pits. Strengthen inspection, and immediately handle YWZ4 network diagram once oil spill or oil leakage is foundThe YWZ4B brake models mainly include:YWZ4B-100/23 electric hydraulic block brake, YWZ4B-150/23 electric hydraulic block brakeYWZ4B-200/23 electric hydraulic block brake, YWZ4B-200/30 electric hydraulic block brakeYWZ4B-200/40 electric hydraulic block brake, YWZ4B-300/30 electric hydraulic block brakeYWZ4B-300/40 electric hydraulic block brake, YWZ4B-300/50 electric hydraulic block brakeYWZ4B-300/70 electric hydraulic block brake, YWZ4B-300/80 electric hydraulic block brakeYWZ4B-400/50 electric hydraulic block brake, YWZ4B-400/70 electric hydraulic block brakeYWZ4B-400/80 electric hydraulic block brake, YWZ4B-400/121 electric hydraulic block brakeYWZ4B-500/121 electric hydraulic block brake, YWZ4B-500/201 electric hydraulic block brakeYWZ4B-600/121 electric hydraulic block brake, YWZ4B-600/201 electric hydraulic block brakeYWZ4B-700/201 electric hydraulic block brake, YWZ4B-700/301 electric hydraulic block brakeYWZ4B-800/301 Electric Hydraulic Block BrakeWhen installing a crane, a lifting point can be set above the I-beam, and the handle chain hoist can be hung onto the I-beam. Then, the electric hoist can be lifted. The advantage of using a chain hoist for lifting is that it is lightweight and easy to move, while others are safer than ropes and have brakes. The crane should stand in the same plane as the hand chain wheel and pull the hand chain, so that the hand chain wheel rotates clockwise to lift the weight; Pull the chain in the opposite direction, and the heavy object can slowly descend. When lifting heavy objects, it is prohibited for personnel to do any work or walk under them to avoid accidents. The skills and progress of cranes are mainly reflected in the increase of the service life of the equipment and the enhancement of the carrying capacity of Overhead crane. These two aspects are highly valued by Dongguan cranes. In response to the needs of shopping malls and the requirements for transaction development, it can be said that a lot of effort has been spent on improving. Through repeated experimental comments and tests, new products have been produced. Compared to previous products, the functionality is better and stronger. Moreover, in terms of load-bearing capacity, in order to satisfy the need for some overweight items in daily life to be able to load and unload well with a double beam crane, Dongguan cranes are also constantly innovating in this regard. And there is also progress in repair skills, which can achieve fast and good repair operations for various cranes without delaying any engineering work, and it is indeed responsible. In addition to putting in a lot of effort on the electric and hydraulic brakes of cranes, the services in various aspects are becoming more comprehensive, the scope of operation is broader, and the shopping malls they face are larger. The quality of employees is also constantly improving. The innovation of skills not only reflects the increasing recognition of the entire social market in industry, but also reflects the firm attitude of the entire enterprise towards its own work. This responsibility and attitude make customers more confident in purchasing

time:2021-04-15

More

Manufacturer of SBD250-A hydraulic disc brakeThe safety disc brake is a mechanical brake set on the last shaft (drum shaft) of the transmission mechanism, which is generally only used on important mechanisms with lifting properties (crane lifting mechanism, boom pitching mechanism, downward inclined belt conveyor, etc.). Since the 1980s, with the rapid development of lifting and loading and unloading machinery towards large-scale and ultra large-scale, specialized and efficient, as well as semi-automatic and automated directions, the application of safety brakes has been rapidly developed. At present, safety brakes have been widely used in large-scale port specialized loading and unloading machinery, and large-scale specialized lifting equipment (such as power station gantry cranes, casting cranes, cable cranes, etc.) and inclined belt conveyors are being promoted and applied.The safety disc brake in China was almost blank before the mid-1990s. After the mid-1990s, the rapid improvement of the manufacturing level of large and special port handling machinery in China and the rapid growth of market demand promoted the rapid development of safety brakes in China. In just over a decade, China's safety brake technology has approached or reached international level, and the variety of products is also constantly increasing. SBD250-A means the rated clamping force is 250kn, SBD80-B hydraulic disc brake with brake opening limit switch, type A safety brake SBD250-C hydraulic disc brake, brake disc diameter is 1600mm, SBD250-C hydraulic disc brake is 30mm behind the disc, SBD125-A hydraulic disc brakeCall to inquire about the ordering marks, installation diagram, technical parameters, and external dimension table of the safety brake. SBD100-A Hydraulic Disc Brake SBD HDSBD-B series safety brake: SBD250-A hydraulic disc brakeSBD80-BSBD160-BInstallation type: I type II SBD250-A hydraulic disc brake SBD160-B hydraulic disc brakeSBD80-BSBD160-BSBD250-CSBD365-CSBD425-CPlease call for the model meaning, outline and installation dimensions of SBD80-B hydraulic disc brake, installation diagram and order marks. SBD160-A hydraulic disc brake SBD160-B hydraulic disc brakeSBD250-C hydraulic disc brakeThe series brake is a disc brake that operates in the way of wheel brake and realizes bilateral braking. By simultaneously applying braking force to the brake disc through two symmetrical points, the radial force generated on the shaft is compensated. The TEXU series brakes adopt a unique design that combines dual brake heads, dual spring components, and single thruster interlocking. When the brake is applied, the spring force is evenly applied to the brake arm through the hinge point connection. At this point, the lever arm simultaneously acts axially, and the brake arms on both sides act simultaneously through the pin shaft. The final friction plate tightly acts on the brake disc. The brake adopts an equal torque device to maintain the same clearance between the four friction plates and the brake disc. The automatic wear compensation device of TEXU series brakes will automatically adjust the brake release clearance when the friction plate wears and the brake release clearance increases. Product features: patented design of spring on brake electro-hydraulic push rod for brake release. A single hydraulic push rod can achieve symmetrical braking, ensuring that the motor shaft and reducer shaft are no longer subjected to radial force during braking. This reduces the width of the brake, greatly shortening the length of the coupling between the motor and reducer. The entire transmission system's structure is more compact, and smaller discs achieve greater braking force, reducing coupling vibration and other related issues, Extending the service life of various components of the transmission system, the automatic wear compensation device compensates accurately and reliably, and the equidistant device automatically aligns the friction plate with high temperature and wear resistance. SIBRE CB series compact disc brake CB series compact disc brake is gradually completed according to the continuous progress and improvement of industrial technology for many years. On the running mechanism of various cranes and material factory equipment. This type of brake works safely and reliably, with a compact structure. Suitable for various traveling mechanisms of lifting and transportation equipment. The SIBRE SHI series safety brake consists of two parts: a disc spring component and a hydraulic piston. The SHI brake is mainly used as an emergency brake and can be used horizontally or vertically. After the friction plate is worn, the brake release clearance can be readjusted through manual compensation. After applying adhesive to the friction lining, it is riveted onto the friction lining. Special friction discs are used for special projects. Product features: Disc spring set with an ultra long service life>2 million times. Single set brake with a large braking force of 440kN and an adjustable patented product with a single sealing ring design. The braking force will not be transmitted to the piston, completely solving the problem of oil leakage. The friction plate has a large contact area with the brake disc, and is made of asbestos free copper based powder metallurgy material

time:2021-04-15

More

YWZ9 series electric hydraulic block brakeThe installation dimensions of the electric hydraulic block brake comply with the GB6333-86 standard, and the technical requirements comply with the JB6406-2006 electric hydraulic block brake standard. Main characteristics of hydraulic brakes: The main swing hinge points of hydraulic brakes are equipped with self-lubricating bearings, which have high transmission efficiency and do not require lubrication during use; The main performance is safe and reliable, with smooth braking and high action frequency. The brake has an interlocking equal distance device, which always maintains equal distance between the two pads during use, avoiding the phenomenon of one brake pad floating against the brake wheel due to uneven distance; The brake spring is arranged inside the spring tube and is equipped with a brake torque scale on one side, making adjustment convenient and intuitive; The asbestos free brake pad and brake pad of the brake adopt a plug-in type, which is safe and reliable, and easy and fast to replace. Service conditions for hydraulic brakes: The ambient temperature of the hydraulic brake is -20 ℃~+50 ℃; Power supply: 380V, 50HZ; Relative humidity: should not exceed 90%; There should be no flammable, explosive, or corrosive gases in the surrounding working environment; The altitude of the location of use complies with GB755-2000; Outdoor rain and snow erosion or corrosive gases and media should use anti-corrosion productsYWZ9 series electric hydraulic block brake:YW160-E23 electric hydraulic drum brake shoeYWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50; YWZ9-300/30; YWZ9-300/50; YWZ9-300/80; YWZ9-315/30; YWZ9-315/50; YWZ9-315/80; YWZ9-400/50; YWZ9-400/80; YWZ9-400/121; YWZ9-500/80; YWZ9-500/121; YWZ9-500/201; YWZ9-600/121; YWZ9-600/201; YWZ9-600/301; YWZ9-630/121; YWZ9-630/201; YWZ9-630/301; YWZ9-700/201; YWZ9-700/301; YWZ9-710/201; YWZ9-710/301; YWZ9-800/301/12YWZ9 seriesInspection of brake usage process:a. Inspect each hinge joint to see if there is any wear, and the wear of the pin shaft generally does not exceed 5% of the original diameter,If there is wear, it will affect the opening of the brake. b. The lever and spring should be updated if cracks are found. c. The surface temperature of the brake disc should not exceed 300 ℃, otherwise it will affect the braking effect. If there are 0.5mm deep cracks on the surface of the brake disc, it should be re polished. d. During the brake braking process, whether the brake spring is released smoothly, whether there is any jamming between the lower seat of the spring and the inner wall of the spring tube, the spring rod and the upper end of the spring tube. e. After the brake is operated for a long time, the hydraulic oil will become turbid, and a new hydraulic oil (DB-25 transformer oil, usually about a year) needs to be replaced. Before replacing the new hydraulic oil, it is necessary to wait for the oil to completely cool before opening the oil filling plug, Otherwise, the hydraulic oil heated during operation may splash and cause injury. Under normal usage conditions, the thruster operates 5 million times under a 60% intermittent working system, requiring major repairs or complete machine replacement. Note: For maintenance of the brake actuator, please refer to the actuator user manual. Please refer to the user manual for the maintenance of the thruster. User ManualThe brake voltage does not meet the requirements, the wiring phase is not checked, and the frequency does not meet the requirements. Mechanical jamming occurs and the company is contacted to maintain the motor heating Temperature rise, forced cooling or higher ambient temperature. Replace with other products suitable for the environment. After identifying the cause, contact the motor and the company if the oil level is insufficient. Add sufficient oil. Mechanical jamming occurs. Contact the company for maintenance. After connecting to the power supply, push the spring to adjust the length. Adjust the spring according to regulations. The spring does not move to the specified value. After oil injection, the push rod is not fully vented and pulled several times. The power pressure is lower than 85% of the guaranteed normal power supply After searching for the cause, contact the motor company for insufficient fuel, add sufficient fuel, internal leakage, and do not contact the company for insufficient maintenance thrust Low oil viscosity repair mechanical resistance and contact the company for maintenance. Under low temperatures, the oil is not used according to regulations. The connecting bolts of the oil are not tightened or the tightening force is tight or the surrounding tightening force is uneven. The sealing gasket is damaged. The motor shaft oil seal is damaged. The sealing component is replaced. The smoothness of the piston rod is damaged. The replacement is damaged. The oil seal at the piston rod is damaged. The replacement is damaged. Excessive oil injection is eliminated. The thruster does not operate. Find the cause Afterwards, contact the company to adjust the length of the spring according to regulations. The spring brake cannot be opened to the specified value. The hinge joint of the spring length is not strong,1. The brake has good thermal stability. This is because the brake disc has no friction boosting effect on the friction pad, and also because the size of the brake friction pad is not long, and its working surface area is only 12% to 6% of the brake disc area, so the heat dissipation is good2. The brake water has good stability. Because the unit pressure of the brake pad on the disc is high, it is easy to squeeze out water, and at the same time, it is easy to shake off water under the action of centrifugal force. In addition, the pad has a wiping effect on the disc, so after water is released, it can only be restored to normal after one or two brake applications; The drum brake, on the other hand, requires more than ten brake applications to restore normal braking efficiency.3. Good braking stability. The braking torque of the disc brake has a linear relationship with the piston thrust and friction coefficient of the brake cylinder. In addition, there is no self increasing effect. Therefore, the braking torque increases slowly during braking. Compared with the drum brake, it can ensure high braking stability.4. The braking torque is independent of the forward and backward movement of the car.5. Under the condition of outputting the same braking torque, the mass and size of the disc brake is smaller than that of the drum brake.6. Disc type friction pads are easier to replace after wear than drum type friction pads, with a simpler structure and easier maintenance.7. The gap between the brake disc and the friction pad is small (0.05-0.15mm), which shortens the operating time of the oil cylinder piston and makes it possible to increase the force transmission ratio of the brake drive mechanism.8. The thermal expansion of the brake disc will not cause a loss of brake pedal travel like the thermal expansion of the brake drum, which also simplifies the design of the automatic gap adjustment device.9. Easy to form a multi loop brake drive system, ensuring good reliability and safety, ensuring that all wheels of the car can brake uniformly and stably at any speed.electric hydraulic block brake Product Introduction: Electric hydraulic block brake is widely used for reducing hydraulic pressure or parking brake of mechanical driving devices such as lifting, metallurgy, mining, ports, docks, construction machinery, etc.

time:2021-04-14

More

Our factory is a modern company dedicated to the R&D, production, sales and service of industrial brakes. It is a member of the Overhead crane Branch of China Heavy Machinery Industry Association, the Transmission Parts Branch of China Heavy Machinery Industry Association, and the Construction Crane Machinery Branch of China Construction Machinery Industry Association. All kinds of production and testing equipment are complete. The main products are: electric hydraulic drum brakes, electromagnet brakes, The company has an annual production capacity of 45000 sets of electric hydraulic disc brakes, pneumatic disc brakes, electric hydraulic thrusters and other products of more than 20 series and more than 400 varieties and specifications. The products are widely used in lifting, mining, machinery, metallurgy, power, railway, water, port, wharf, chemical industry and other industries.Welcome to inquire about procurement, contact Manager Niu 13803910788The production of lifting equipment accessories, hydraulic components, mechanical and electrical accessories, electric push rods, YT1 series hydraulic thrusters, and YWZ series hydraulic brakes are all standard equipment accessories issued by the Ministry of Heavy Machinery Industry. YWZ, YWZ4, YWZ5, YWZ8, YWZ9, YWZ13 series hydraulic push rod brakes are essential safety braking devices in mechanical driving equipment, widely used in lifting, transportation, metallurgy, mining, railway, port, construction, water conservancy, power and other driving machinery. They have the advantages of smooth braking, high action frequency, low power consumption, no noise, long service life, safety and reliability, and convenient maintenance, It is currently an ideal product that has emerged to replace the old electromagnetic brakes and hydraulic electromagnetic brakes both domestically and internationally

time:2021-04-14

More

ED-23/5, ED-30/5, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-50/6, ED-80/6, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-121/6, ED-201/6, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters,ED-301/6, ED-50/12, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-80/12, ED-121/12, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters,ED-201/12, ED-301/12, electric hydraulic thrusters, electric hydraulic thruster prices, electric hydraulic thruster manufacturers

time:2021-04-14

More