Analysis of the Six Steps for Adjusting Hydraulic Brakes by Brake Manufacturers: Hydraulic brakes are one of the most important components in vehicles. Whenever there is a problem with the brakes, we need to promptly handle it. After replacing the brake friction pads, remaking the brake drum, or disassembling the brake base plate, the gap between the friction pads and the brake drum must be readjusted. The steps are as follows: 1) Remove the inspection hole cover on the brake drum, Loosen the fixing nut of the brake shoe support pin and the nut of the camshaft bracket fastening bolt. 2) Rotate the shoe support pin with the markings on the two pin ends facing inward. 3) By repeatedly twisting the screw shaft of the brake shoe support pin and adjusting arm, the brake friction plate and brake drum are fully fitted. At the adjusted position, slowly tighten the fastening nut of the bracket and the locking nut of the automatic shoe support pin to maintain the position of the brake shoe support pin unchanged (it is possible to press and hold the brake pedal to tighten all the bolts and nuts that have been adjusted on it, provided that the air pressure meets the regulations). 4) Loosen the worm shaft by 1/2-2/3 turns, and the brake drum should be able to rotate freely without colliding with the brake friction plate or other parts. The clearance position between the brake friction plate and the automatic drum: at the brake shoe support pin end, it is 0.25-0.40mm, and at the cam end, it is 0.40-0.55mm. The difference in clearance between the two shoes at the same end should not exceed 0.1mm. 5) After the adjustment is completed, compressed air is introduced into the brake chamber, and the stroke of the push rod should be 25-40mm. The rear wheel automatically adjusts the small worm shaft of the arm, and the stroke of the push rod changes by 5mm with each movement, while the front wheel is 4mm. 6) When the stroke of the push rod exceeds 40mm due to wear of the friction plate, local adjustment can be made (at this time, do not twist the support pin to avoid damaging the original good contact state). The method is to face the worm head of the adjustment arm, tighten the screw clockwise at two places on the front wheel (clearance decreases), loosen counterclockwise (clearance increases), tighten counterclockwise at two places on the rear wheel, and loosen clockwise. Attention, do not use the method of twisting the brake chamber push rod to change the ratio of the push rod for "adjustment". By adjusting through the six steps of appeal, we can ensure that the hydraulic brake performance on our vehicle meets the standard and ensure our safety during driving.

time:2023-06-23

More

The disc brake depends on your coupling type. If your coupling is a disc type, now it is indeed common to use YWZ series normally closed hydraulic block brakes. If your coupling is drum type, you should use the corresponding drum type normally closed hydraulic brake instead. Performance characteristics of the disc brake: compared with the drum brake, the working surface of the disc brake is flat and has heat transfer on both sides. The disc is easy to be cold cut when rotating, and is not prone to large deformation. The braking efficiency is stable. After a long time of use, the brake disc has enhanced its braking effect due to high temperature expansion; The drum brake has a single side heat transfer and a large temperature difference between the inside and outside, which leads to the brake drum being prone to deformation. At the same time, after prolonged braking, the brake drum expands due to its height, and the braking efficiency is weakened. In addition, the disc brake is simple in structure, convenient in maintenance, and easy to realize automatic adjustment of brake clearance. Working principle of ST3SH closed oil cylinder actual drawing disc brake: disc brake is mainly composed of brake disc, oil cylinder (air chamber), brake caliper, oil (air) pipe and other components, and hydraulic (air) power source. The disc brake is made of the end face of the rotating brake disc as the friction pair. The fixed support is equipped with a brake block composed of friction materials and its metal bottom plate. These brake blocks and their tensioning devices are installed in the clamping clamp shaped supports on both sides of the brake disc, called brake calipers. The brake disc is made of alloy steel and fixed to the wheels, rotating with the wheels. The oil cylinder (air chamber) is fixed on the bottom plate of the brake and does not move. The two friction plates on the brake caliper are installed on both sides of the brake disc. The piston of the oil cylinder (air chamber) is subjected to hydraulic (air) pressure from the oil (air) pipe, pushing the friction plate towards the brake disc for frictional braking, just like clamping a rotating plate with pliers, forcing the moving mechanism to stop moving. Advantages of embedded disc brake: simple structure, convenient installation, not easy to damage, pressure resistant, anti falling and anti knocking, long service life, generally only need to replace the brake pad, easy and simple to replace, using the magnet effect. After sales of Z9 with black background and white lettering: Our company promises a shelf life of one year. If any defects occur during this period, they will be replaced free of charge. Generally, the shell has been used for more than 10 years without any problems, so during use, only the brake pads need to be replaced, providing a good platform for customers to use in the future. Principle of normally closed brake: The embedded disc type normally closed pneumatic brake is different from the normally open brake in that the normally open brake is a ventilated holding brake, which means a ventilated brake. As soon as the brake is ventilated, the clamps on both sides are clamped. The normally closed brake, as shown in the figure, is always in a clamped state and released after being aerated. Therefore, in normal conditions, the normally closed brake is always in a braking state. Normally closed brake spring applies force to brake, and pneumatic drive releases. Advantages of disc brake: simple structure, easy installation, not easy to damage, resistant to pressure, falling and knocking, long service life, generally only need to replace the brake pad, easy and convenient replacement, using the magnet effect

time:2023-06-23

More

In a lifting machinery, there are many parts that occupy a very important role. We are familiar with bearings, wheel groups, couplings, hook groups, etc. However, what is easily overlooked is the brake, which is actually one of the very important roles. Without it, it is difficult for the equipment to stop normally. Let's take a look at it now. Brakes are not only used in lifting equipment, but also play a very important role in port loading and unloading, construction machinery, etc. However, some problems may also arise during use, which may affect its normal use. A common occurrence is brake failure. Let's take a look at the reasons for this situation. There are many reasons for this phenomenon. This situation is prone to occur when the hydraulic oil inside the brake master cylinder is lacking. In addition, when the leather ring experiences aging, deformation, or blockage of the compensation hole, braking failure may also occur. This can happen when the brake shoe is worn due to long-term use, air enters the brake system, the brake gap is too large, and the system temperature is too high.

time:2023-06-23

More

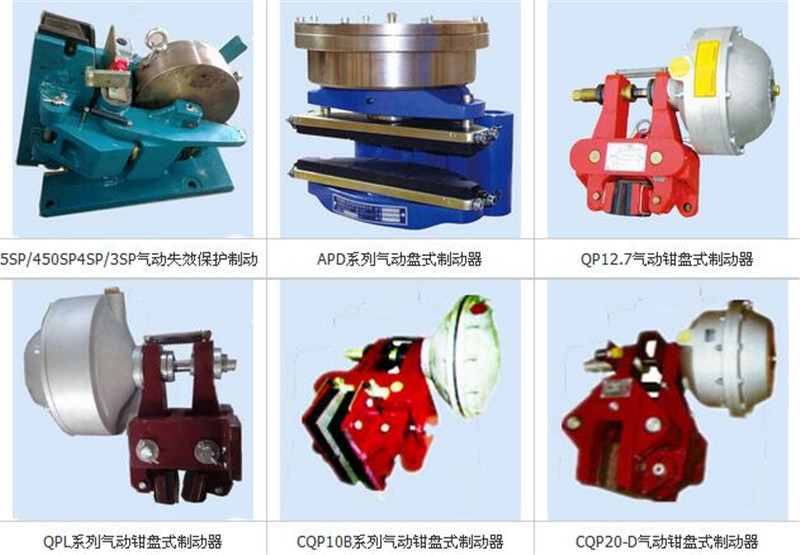

Pneumatic disc brake is also called air pressure disc brake. In addition to the common fan type, there are also vertical and horizontal types. The horizontal mounted disc brake provides approximately 2 times the braking force corresponding to the vertical mounted type. Equipped with retractable spring pads to ensure braking balance, there is also an optional brake disc thickness of 10mm-20mm.The representative model of the vertical type of pneumatic disc brake is DBG type, which is an economical brake, providing stable, effective and adjustable braking force. Vertical installation saves space, and the open friction surface has excellent heat dissipation. Easy to replace friction components, free of asbestos, with optional brake disc thickness of 10mm-20mm. Resistant to water, oil, and dust.The representative models of horizontal pneumatic disc brake are DBH type and DBH-F type. It is especially suitable for safety protection. It is braked by brake spring and opened by filling air. When there is a power outage and the air pressure is low, automatic braking is applied, and the responsiveness of the connection release is good. The simple yet sturdy structure has good reliability and a long service life.Both vertical and horizontal models can be selected based on disc thickness and diameter

time:2023-06-23

More

Pneumatic disc brake is also called air pressure disc brake. In addition to the common fan type, there are also vertical and horizontal types. The horizontal mounted disc brake provides approximately 2 times the braking force corresponding to the vertical mounted type. Equipped with retractable spring pads to ensure braking balance, there is also an optional brake disc thickness of 10mm-20mm.The representative model of the vertical type of pneumatic disc brake is DBG type, which is an economical brake, providing stable, effective and adjustable braking force. Vertical installation saves space, and the open friction surface has excellent heat dissipation. Easy to replace friction components, free of asbestos, with optional brake disc thickness of 10mm-20mm. Resistant to water, oil, and dust.The representative models of horizontal pneumatic disc brake are DBH type and DBH-F type. It is especially suitable for safety protection. It is braked by brake spring and opened by filling air. When there is a power outage and the air pressure is low, automatic braking is applied, and the responsiveness of the connection release is good. The simple yet sturdy structure has good reliability and a long service life.Both vertical and horizontal models can be selected based on disc thickness and diameter

time:2023-06-23

More

The electric hydraulic thruster consists of two parts: the driving motor and the body. The body is composed of a cover, cylinder, piston, impeller, and shaft.When powered on, the motor drives the impeller on the transmission shaft and rotating shaft to rotate, generating pressure inside the piston. Under the influence of this pressure, oil is sucked into the lower part of the piston from the upper part, forcing the piston to be fixed on it. The push rod and crossbeam quickly rise, and the load spring is mechanically compressed by the lever (the push rod or brake has a load spring) to generate mechanical motion.When the power is cut off, the impeller stops rotating, and the piston rapidly drops under the action of spring force and its own gravity, forcing oil to flow back into the upper part of the piston and then return to its original position through a lever mechanism.Electric hydraulic thrusters are often used in conjunction with brake frames and are widely used for braking various transmission devices.Design characteristics of electric hydraulic thrustersThe shell is made of cast aluminum alloy, with light weight and beautiful appearance;The motor is a non oil immersed structure, with B or F insulation (according to user requirements), good heat resistance, and long service life;The motor junction box cover is sealed, and the cable stuffing box is used for incoming lines, which is firm and reliable. The electrical casing protection level reaches IP55;The surface of the motor shaft and push rod is plated with hard chromium, greatly extending the service life of the sealing components;There is a balance chamber on one side of the cylinder body, which allows the push rod to be installed in any direction from 0 to 180 °, thereby expanding its range of use;All sealing components of the Ed series He bearings are made of world-renowned products, with reliable sealing and long service life;The Ed series fasteners are made of stainless steel, which is beautiful and durable.

time:2023-06-21

More

When using brakes, regular replacement and maintenance are required. Many people may say that when the wear is severe, in fact, when the brake disc breaks, it also needs to be replaced with a new one. The brake cracks generated during the use of brake discs are mainly caused by two reasons: first, cracks on the friction surface; The other is a crack on the brake. Due to repeated heating and cooling; The fine cracks on the friction surface propagate from the thin layer near the friction surface. Under high-speed braking or forced movement, the brake will produce cracks. Among the factors that affect the strength characteristics of brake discs, the heat of the friction surface is the main factor, while the influence of pressure or centrifugal force is relatively small. At high temperatures, the material strength of brake discs shows a sudden decrease trend. Here, the strength of the brake disc is evaluated based on temperature, thermal stress, and braking frequency.

time:2023-06-21

More

When using brakes, regular replacement and maintenance are required. Many people may say that when the wear is severe, in fact, when the brake disc breaks, it also needs to be replaced with a new one. The brake cracks generated during the use of brake discs are mainly caused by two reasons: first, cracks on the friction surface; The other is a crack on the brake. Due to repeated heating and cooling; The fine cracks on the friction surface propagate from the thin layer near the friction surface. Under high-speed braking or forced movement, the brake will produce cracks. Among the factors that affect the strength characteristics of brake discs, the heat of the friction surface is the main factor, while the influence of pressure or centrifugal force is relatively small. At high temperatures, the material strength of brake discs shows a sudden decrease trend. Here, the strength of the brake disc is evaluated based on temperature, thermal stress, and braking frequency.

time:2023-06-21

More

In order to ensure the uninterrupted operation of the hydraulic brake, it is necessary to frequently protect and protect it: 1. Lubricant is often added to the movable parts of the electromagnetic brake. 2. Regularly check the length of the armature stroke. Because during the operation of the brake, the travel length of the armature will increase due to wear on the moving surface. When the length of the armature stroke cannot reach the normal value, it is necessary to adjust it to reproduce the small gap between the moving surface and the turntable. If the stroke length of the armature increases above the normal value, it may greatly reduce the suction force. 3. If a worn brake surface is replaced, the small gap between the brake surface and the rotary table should be adjusted appropriately from the beginning. 4. Regularly check the tightening degree of the bolts, especially tighten the bolts of the electromagnet, the bolts of the electromagnet and the shell, the bolts of the magnetic yoke, the bolts of the electromagnet coil, and the wiring bolts. 5. Regularly check the mechanical wear status of movable components and remove dust, burrs, and dirt from the surface of electromagnetic components.

time:2023-06-21

More

The electric hydraulic thruster is a part that needs continuous work, so its maintenance should be carried out according to a certain time. The use and maintenance of the hydraulic brake is a very important work. Only when the equipment is in good condition can it play its due role. Once there is a problem with serious consequences, the following steps will be taken to understand its maintenance: (1) Each shift will check whether the thruster works normally and whether there is oil leakage, Is the quantitative oil level maintained, and whether there is insufficient stroke or smoke from the brake shoes. (2) Check the oil once every 6 months. When the oil deteriorates or mixes with people or debris, the oil should be changed. When refueling, pull the upper and lower push rods several times to exhaust air and add enough oil. The oil level should not exceed the plug hole of the oil level indicator; (3) The hydraulic oil used for Jiaozuo hydraulic brakes is selected as follows: 10 # transformer oil is used when the ambient temperature is 0-20 ℃, 20 # transformer oil is used when the temperature is 20-45 ℃, and 25 # transformer oil is used when the temperature is -15-0 ℃. Through the understanding of the maintenance steps of the electric hydraulic thruster, it can be seen that the main loss areas are the thruster, oil, and hydraulic oil. Therefore, we should pay attention to these maintenance points.

time:2023-06-21

More

When using the electric hydraulic brake, it is necessary to carry out daily maintenance and upkeep. 1. Keep the electric hydraulic brake assembly, especially the surface of the brake disc and brake lining, clean, and make the entire Jiaozuo brake operate freely, flexibly, reliably, and clean. 2. Regularly observe the stock of brake fluid in the oil pool. When the liquid level is below the marking line, clean brake fluid of the original brand should be added in a timely manner, so that its height is millimeters higher than the marking line. Never mix other brands of brake fluid. After adding, the air nozzle should be opened for exhaust before tightening for use. 3. Regularly check the thickness of the brake disc (usually over kilometers). When the thickness of the worn brake disc is less than the specified value, the brake disc must be replaced. 4. During use, the surface of the brake lining should not be contaminated with grease or brake fluid, and the thickness of the lining should be checked regularly. If the thickness is less than the specified value, the dynamic lining should be replaced. When there is oil leakage at the piston of the master cylinder and slave cylinder, the sealing ring must be replaced. Special attention should be paid to the fact that new sealing rings must be soaked in brake fluid for at least an hour before being replaced. They cannot be assembled and used after being taken out. When cleaning the oil cylinder or piston, it is necessary to use a sprinkling solution, and gasoline or other mineral oils are not allowed.

time:2023-06-21

More

When the electric hydraulic thruster is powered on, the electric motor drives the rotor shaft and the impeller on the rotor shaft to rotate, generating pressure inside the piston. Under this pressure, oil is sucked from the upper part of the piston to the lower part of the piston, forcing the piston and the push rod and crossbeam fixed on it to rise rapidly. By mechanically compressing the load spring through a lever (if the thruster or brake is equipped with a load spring), mechanical motion is generated.When the power is cut off, the impeller stops rotating, and the piston rapidly descends under the force of the load spring and its own gravity, forcing oil to flow back into the upper part of the piston. At this time, it still returns to its original position through the lever mechanism. Electric hydraulic thrusters are often used in conjunction with brake frames and are widely used for braking various transmission devices.Characteristics of electric hydraulic thrusters:With the continuous use of various electrical equipment in daily life, it has brought many conveniences to everyone, especially for machines and equipment equipped with drive and control devices, which are not only widely used, but also very convenient in the process of use. During this period, the electric hydraulic thruster is a compact layout of driving and control equipment that integrates motors, centrifugal pumps, and oil cylinders, and is widely used. Therefore, the main characteristics of the electric hydraulic thruster are as follows:1. The layout of the electric hydraulic thruster is simple and the volume is relatively small, which will reduce the occupied area of the thruster. Therefore, there are many categories and professions to use, and the application is sensitive.2. Electric hydraulic thrusters are usually manufactured using aluminum alloy materials, which have outstanding anti-corrosion features and excellent underwater impact force, making their use more convenient, convenient, and agile.

time:2023-06-21

More