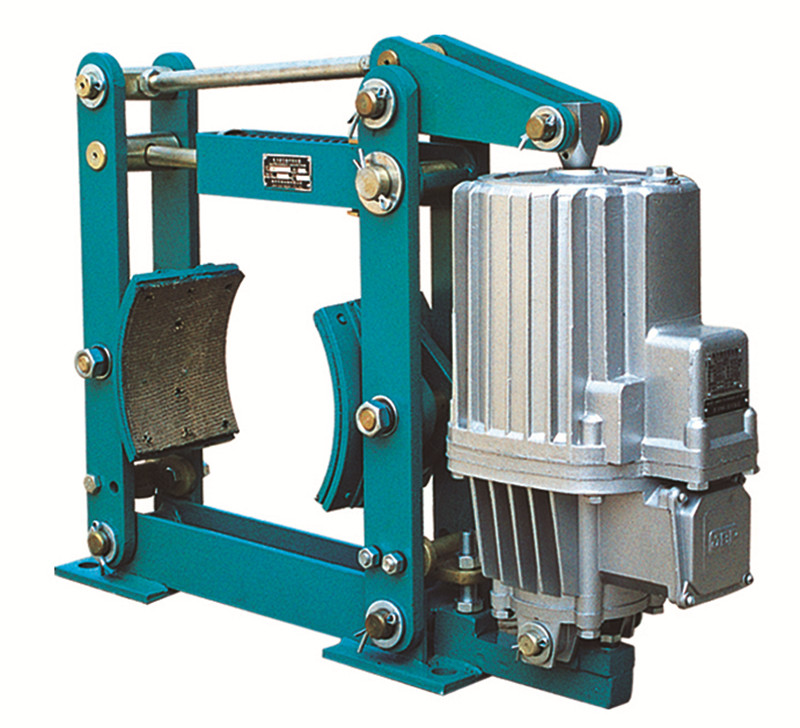

Golden hoop brand electric hydraulic thrusterWhat are the advantages of thrusters? For the maneuverability of the ship during navigation, omnidirectional thrusters are better than ducted thrusters and rotary thrusters. This is because although ducted thrusters have higher thrust in the forward direction, they have poorer thrust in the reverse direction and their maneuverability is not ideal; On the contrary, a rotary propeller can achieve good maneuverability, but its mechanism is complex, expensive, and easily damaged; And although the 360 ° rotary thruster does not have a rudder,However, it can completely convert the thrust of the propeller into the equivalent of rudder force to facilitate ship maneuvering, and the 360 ° rotary thruster has a large unit power thrust, and the reverse thrust and forward thrust are basically the same. Equipped with a fully rotating propeller can simplify the shape of the ship's stern, reduce ship resistance, and in the event of propeller failure, the entire machine can be lifted out of the engine room without the need for docking, greatly simplifying maintenance work and increasing the service life of the diesel engine.The classification of thrusters is that thrusters are the propulsion equipment of vehicles, which converts the power provided by the power device on the vehicle into thrust to propel the vehicle forward.According to different means of transportation, there are aviation thrusters, space thrusters, and ship thrusters.According to different principles, there are propeller propeller, jet propeller, Pump-jet and special propellerYT1 series electric hydraulic thruster:YT1-18ZB/2; YT1-25ZB/4; YT1-45Z/5; YT1-90Z/8; YT1-125Z/10; YT1-180Z/10; YT1-320Z/12; YT1-320Z/20; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12; YT1-320Z/12; YT1-350/12;YT1-350/20; YT1-350/35; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12BYT1 series electric hydraulic thrusters:BYT1-18ZB/2; BYT1-25ZB/4; BYT1-25ZC/4; BYT1-45Z/4; BYT1-45Z/5; BYT1-45Z/6; BYT1-90Z/6BYT1-90Z/8; BYT1-125Z/10; BYT1-180Z/8; BYT1-180Z/10; BYT1-180Z/12; BYT1-320Z/12BYT1-320Z/20; BYT1-25/4; BYT1-45/6; BYT1-90/8; BYT1-180/12ED series electric hydraulic thrusters:ED-23/5; ED-30/5; ED-50/6; ED-80/6; ED-121/6; ED-201/6; ED-301/6; ED-50/12; ED-80/12; ED-121/12; ED-201/12; ED-301/12; ED-630/12BED ZED series electric hydraulic thrusters:BED30/5; BED50/6; BED80/6; BED121/6; BED201/6; BED301/6; BED50/12; BED80/12; BED121/12BED201/12; BED301/12; BED630/12Our company produces various series of products called thruster brakes, mainly used for mechanical braking of mechanical driving devices in lifting, transportation, metallurgy, mining, ports, construction, etc. They have the advantages of smooth braking, safety and reliability, convenient maintenance, low power consumption, long service life, no noise, and high frequency. Our company is the first to pass the IS09001:2000 quality management system standard certification. Advanced process equipment, strong technical force, comprehensive testing methods, strict quality management system, reasonable product prices, and the service tenet of reputation first are the strong guarantees for our company's products to enter the market and win users.

time:2022-09-13

More

MWZ-315-630 series electromagnetic brakeTotal braking force=original braking force+self increasing force. When the balance increasing force brake operates, a self increasing braking force formed by the conversion of friction force into mechanical force needs to be generated. After the combination of the two braking forces, the total braking force can be increased by about 40%. Therefore, China's first "brake" has higher safety performance in dealing with heavy loads, steep slopes, and various dangerous road surfaces.YDWZ series electromagnetic brakeYDWZA series energy-saving long stroke brakeMWK type normally open electromagnetic brakeMWZ series electromagnetic brakeElectromagnetic long stroke thrusterDTZ series energy-saving DC (inverter) electromagnetic long stroke thrusterZWZ3 series DC electromagnetic brakeZWZA series DC electromagnetic brakeJZ energy-saving electromagnetic drum brakeYWZ2CK series pumping unit brakeHydraulic brakeYWZ series brakeYWZ3 series brakeYWZ4 series brakeYWZ5 series brakeYWZ12 series brakeYWZ8 series brakeYWZ9 series brakeYWZ10 series brakeYWZ13 series brakeDrive device1、 IntroductionThe electromagnetic power-off brake is a friction type brake that is electrically disengaged (released) and powered off by a spring. It is mainly used to form YEJ series electromagnetic braking three-phase asynchronous motors in conjunction with Y series motors.Widely used in metallurgy, construction, chemical industry, food, machine tools, packaging and other machinery, as well as in situations such as emergency braking during power outages. It has the advantages of compact structure, convenient installation, wide applicability, low noise, high working frequency, sensitive action, and reliable braking, making it an ideal automation execution component.The brake is composed of magnetic yoke, excitation coil, spring, brake disc, armature, gear sleeve, manual release device, installation screws, and other parts. When the brake coil is energized, the coil generates a magnetic field that attracts the armature towards the yoke, causing the armature to detach (release) from the brake disc; When the coil loses power, the magnetic flux disappears, and the armature is released. The spring applies pressure to the armature, compressing the friction plate on the brake disc, thereby generating braking torque to achieve the purpose of braking.YW.YWB.YWZ5.YWZE.YWZ6.YWZF series (2)The YW series electric hydraulic drum brake is widely used for deceleration and parking (maintenance) braking of various mechanisms in various lifting and transportation, port loading and unloading, metallurgical equipment, mining machinery, and engineering machinery.Compliant with standards:The connection dimensions and technical requirements of YW and YWB series brakes comply with JB/T6406-2006 standards, and the braking torque parameters comply with DIN15435 standards; The YW series is equipped with YTD series thrusters that meet the JB/T10603-2006 standard; The YWB series is equipped with Ed series thrusters that meet the DIN15430 standard; This series is suitable for new designs and matching selection of new hosts.The connection dimensions and braking torque parameters of YWZ5 and YWZE series brakes comply with GB6333-86 standard, and the technical requirements comply with JB/T6406-2006 standard; The YWZ5 series is equipped with YTD series thrusters that comply with the JB/T10603-2006 standard; The YWZE series is equipped with Ed series thrusters that comply with the DIN15430 standard.The connection dimensions and braking torque parameters of YWZ6 and YWZF series brakes comply with JB/ZQ4388-86 standards, and the technical requirements comply with JB/T6406-2006 standards; The YWZ6 series is equipped with YTD series thrusters that comply with the JB/T10603-2006 standard; YWZF is equipped with Ed series thrusters that comply with DIN15430 standard; This series is suitable for replacing old products such as YWZ, JCZ, JWZ, and TJ2 series

time:2022-09-13

More

Electric hydraulic drum brakes for cranes Electric hydraulic drum brakes for cranesThe installation and operation of crane brakes vary, and they are divided into three types: normally closed, normally open, and comprehensive. Most cranes use normally closed brakes. Normally closed brakes are closed during periods when the mechanism is not in operation. If you want the mechanism to work, you only need to release the brake to separate the friction pairs of the brake, and the mechanism can operate. The brakes used on cranes are divided into block brakes, belt brakes, disc brakes and cone brakes according to their shapes. The purpose of the crane braking device The braking device is an important component to ensure the safe and normal operation of the crane. The hinge point of the main swing of the electric hydraulic drum brake is equipped with self-lubricating bearings. Therefore, the transmission efficiency of the electric hydraulic drum brake is high, and the service life of the machine is long. Due to the self-lubricating bearing, the machine does not need lubrication during use, The main performance is very safe and reliable in use, and the braking is very smooth, and the mechanical movement frequency is very high.The electric hydraulic drum brake should use a 380V power supply, 50HZ, and the ambient temperature should be between minus 20 degrees Celsius to minus 50 degrees CelsiusThe company has rich professional design and manufacturing experience in Germany, combined with imported mechanical processing equipment, striving for excellence, customer and service: The success of enterprise operation depends on the recognition level of customers. We have the willingness and ability to mobilize all our resources to win the trust of customers. We will continue to use higher product performance and quality, faster market reaction speed, and stronger cost control ability, Strive for the success of our clients. We insist that any organization, process, or system established within the company must be based on providing customers with better quality services. In the work of mechanical equipment, it is always necessary to repeatedly perform repetitive movements. In order to provide better control, electro-hydraulic push rods are installed on the mechanical equipment. Electro hydraulic push rod is a control device for reciprocating movement, which can make production more safe. It is commonly used in metallurgy, mining, coal, power, machinery, grain, cement, nuclear power plant, environmental protection sewage treatment equipment and other industries, and is an indispensable universal power source.During the use of electro-hydraulic push rods, leakage is a common fault, and once this phenomenon occurs, it will first cause problems such as decreased equipment performance, damage to hydraulic components, waste of resources, and have a significant impact on daily work.Brake model classificationYWZ series brakes, YWZ3B series brakes, YWZ4 series brakes (matched with YT1 type thrusters), YWZ4B series brakes (matched with Ed type thrusters), YWZ5 series brakes, YWZ8 series brakes (matched with Ed type thrusters), YWZ9 series brakes (matched with Ed and YT1 type thrusters), YWZ10 series brakes (matched with Ed type thrusters), YWZ12 series brakes (matched with Ed type thrusters) YWZ13 series brake (matched with Ed type thruster)

time:2022-09-13

More

The coal mine monkey car detects the braking positive pressure of the wheel brake in real-time through an online detection device for the positive pressure of the wheel brake, and displays the braking positive pressure of the wheel brake in real-time through an electronic control device.Jiaozuo hydraulic brake; YWZ-100/18 hydraulic push rod brake; YWZ-150/25 hydraulic push rod brake; YWZ-200/25 hydraulic push rod brake; YWZ-200/25 hydraulic push rod brake; YWZ-300/45 hydraulic push rod brake; YWZ-400/45 hydraulic push rod brake; YWZ-400/90 hydraulic push rod brake; YWZ-400/125 hydraulic push rod brake; YWZ-500/125 hydraulic push rod brake; YT1-18ZB/2; YT1-25ZB/4; YT1-25ZC/4; YT1-45Z/4; YT1-45Z/5; YT1-45Z/6; YT1-45Z/6; YT1-90Z/6; YT1-90Z/8; YT1-125Z/10; YT1-180Z/8; YT1-180Z/8; YT1-180Z/10; YT1-180Z/12; YT1-320Z/12; YT1-320Z/20; Micro three-phase asynchronous motorYDT60-2; YDT80-2; YDT120-2; YDT140-2; YDT250-2; YDT400-2; YDT1100-2;Z series electric hydraulic block brakes: YWZ-100/18, YWZ-200/25, YWZ-300/25, YWZ-300/45, YWZ-300/90YWZ-400/45, YWZ-400/90, YWZ-500/125, YWZ-600/180YWZ5-630/121 YWZ5-500/201 YWZ5-500/121 YWZ5-500/80 YWZ5-400/121 YWZ5-400/80YWZ5-400/50 YWZ5-315/80 YWZ5-315/50 YWZ5-315/30 YWZ5-315/23 YWZ5-250/50YWZ5-250/30 YWZ5-250/23 YWZ5-200/30 YWZ5-200/23 YWZ5-160/23YMZ4-800/301 YMZ4-700/301 YMZ4-600/201 YMZ4-600/121 YMZ4-500/201YMZ4-500/121 YMZ4-400/121 YMZ4-400/80 YMZ4-400/50 YMZ4-300/80YMZ4-300/50 YMZ4-300/30 YMZ4-200/30 YMZ4-200/23 YMZ4-150/23 YMZ4-100/23YWZ2-100/23, YWZ2-200/23, YWZ2-200/30, YWZ2-200/40, YWZ2-300/30, YWZ2-300/50YWZ2-300/70, YWZ2-400/50, YWZ2-400/80, YWZ2-400/125, YWZ2-500/125, YWZ2-600/125YWZ3-160/18, YWZ3-200/25, YWZ3-250/25, YWZ3-250/45, YWZ3-315/45, YWZ3-315/90MYT3-315/8 MYT3-200E/8 MYT3-200-8 MYT3-125E/5 MYT3-125/5MYT3-70/5 MYT3-40/4 MYT3-22/4 TJ2-100 TJ2-200 TJ2-300TJ2-100, TJ2-200, TJ2-300 YW160-E23 YW200-E23 YW200-E30YW250-E23 YW250-E30 YW250-E50 YW250-E80 YW315-E23YW315-E30 YW315-E50 YW315-E80 YW400-E30 YW400-E50YW400-E80 YW400-E121 YW500-E50 YW500-E80 YW500-E121YW500-E201 YW630-E121 YW630-E201 YW630-E301 YW710-E121YW710-E201 YW710-E301 YW800-E301

time:2022-05-10

More

The coal mine monkey car detects the braking positive pressure of the wheel brake in real-time through an online detection device for the positive pressure of the wheel brake, and displays the braking positive pressure of the wheel brake in real-time through an electronic control device.Jiaozuo hydraulic brake; YWZ-100/18 hydraulic push rod brake; YWZ-150/25 hydraulic push rod brake; YWZ-200/25 hydraulic push rod brake; YWZ-200/25 hydraulic push rod brake; YWZ-300/45 hydraulic push rod brake; YWZ-400/45 hydraulic push rod brake; YWZ-400/90 hydraulic push rod brake; YWZ-400/125 hydraulic push rod brake; YWZ-500/125 hydraulic push rod brake; YT1-18ZB/2; YT1-25ZB/4; YT1-25ZC/4; YT1-45Z/4; YT1-45Z/5; YT1-45Z/6; YT1-45Z/6; YT1-90Z/6; YT1-90Z/8; YT1-125Z/10; YT1-180Z/8; YT1-180Z/8; YT1-180Z/10; YT1-180Z/12; YT1-320Z/12; YT1-320Z/20; Micro three-phase asynchronous motorYDT60-2; YDT80-2; YDT120-2; YDT140-2; YDT250-2; YDT400-2; YDT1100-2;Z series electric hydraulic block brakes: YWZ-100/18, YWZ-200/25, YWZ-300/25, YWZ-300/45, YWZ-300/90YWZ-400/45, YWZ-400/90, YWZ-500/125, YWZ-600/180YWZ5-630/121 YWZ5-500/201 YWZ5-500/121 YWZ5-500/80 YWZ5-400/121 YWZ5-400/80YWZ5-400/50 YWZ5-315/80 YWZ5-315/50 YWZ5-315/30 YWZ5-315/23 YWZ5-250/50YWZ5-250/30 YWZ5-250/23 YWZ5-200/30 YWZ5-200/23 YWZ5-160/23YMZ4-800/301 YMZ4-700/301 YMZ4-600/201 YMZ4-600/121 YMZ4-500/201YMZ4-500/121 YMZ4-400/121 YMZ4-400/80 YMZ4-400/50 YMZ4-300/80YMZ4-300/50 YMZ4-300/30 YMZ4-200/30 YMZ4-200/23 YMZ4-150/23 YMZ4-100/23YWZ2-100/23, YWZ2-200/23, YWZ2-200/30, YWZ2-200/40, YWZ2-300/30, YWZ2-300/50YWZ2-300/70, YWZ2-400/50, YWZ2-400/80, YWZ2-400/125, YWZ2-500/125, YWZ2-600/125YWZ3-160/18, YWZ3-200/25, YWZ3-250/25, YWZ3-250/45, YWZ3-315/45, YWZ3-315/90MYT3-315/8 MYT3-200E/8 MYT3-200-8 MYT3-125E/5 MYT3-125/5MYT3-70/5 MYT3-40/4 MYT3-22/4 TJ2-100 TJ2-200 TJ2-300TJ2-100, TJ2-200, TJ2-300 YW160-E23 YW200-E23 YW200-E30YW250-E23 YW250-E30 YW250-E50 YW250-E80 YW315-E23YW315-E30 YW315-E50 YW315-E80 YW400-E30 YW400-E50YW400-E80 YW400-E121 YW500-E50 YW500-E80 YW500-E121YW500-E201 YW630-E121 YW630-E201 YW630-E301 YW710-E121YW710-E201 YW710-E301 YW800-E301

time:2022-05-10

More

Product name of this design: hydraulic caliper disc brake for coal mine monkey car. Purpose of this appearance design product: This appearance design product is used for the braking of coal mine monkey cars or cableway hanging baskets. The key design points of this exterior design product are the shape of this exterior design. The image or photo that best illustrates the key points of this exterior design: a stereoscopic view. 5. Omitted view: The rear view is symmetrical with the main view, and there are no design elements in the bottom view, so it is omitted.

time:2022-05-10

More

Jiaozuo hydraulic brake; YWZ-100/18 hydraulic push rod brake; YWZ-150/25 hydraulic push rod brake; YWZ-200/25 hydraulic push rod brake; YWZ-200/25 hydraulic push rod brake; YWZ-300/45 hydraulic push rod brake; YWZ-400/45 hydraulic push rod brake; YWZ-400/90 hydraulic push rod brake; YWZ-400/125 hydraulic push rod brake; YWZ-500/125 hydraulic push rod brake; YT1-18ZB/2; YT1-25ZB/4; YT1-25ZC/4; YT1-45Z/4; YT1-45Z/5; YT1-45Z/6; YT1-45Z/6; YT1-90Z/6; YT1-90Z/8; YT1-125Z/10; YT1-180Z/8; YT1-180Z/8; YT1-180Z/10; YT1-180Z/12; YT1-320Z/12; YT1-320Z/20; Micro three-phase asynchronous motorYDT60-2; YDT80-2; YDT120-2; YDT140-2; YDT250-2; YDT400-2; YDT1100-2;Z series electric hydraulic block brakes: YWZ-100/18, YWZ-200/25, YWZ-300/25, YWZ-300/45, YWZ-300/90YWZ-400/45, YWZ-400/90, YWZ-500/125, YWZ-600/180YWZ5-630/121 YWZ5-500/201 YWZ5-500/121 YWZ5-500/80 YWZ5-400/121 YWZ5-400/80YWZ5-400/50 YWZ5-315/80 YWZ5-315/50 YWZ5-315/30 YWZ5-315/23 YWZ5-250/50YWZ5-250/30 YWZ5-250/23 YWZ5-200/30 YWZ5-200/23 YWZ5-160/23YMZ4-800/301 YMZ4-700/301 YMZ4-600/201 YMZ4-600/121 YMZ4-500/201YMZ4-500/121 YMZ4-400/121 YMZ4-400/80 YMZ4-400/50 YMZ4-300/80YMZ4-300/50 YMZ4-300/30 YMZ4-200/30 YMZ4-200/23 YMZ4-150/23 YMZ4-100/23YWZ2-100/23, YWZ2-200/23, YWZ2-200/30, YWZ2-200/40, YWZ2-300/30, YWZ2-300/50YWZ2-300/70, YWZ2-400/50, YWZ2-400/80, YWZ2-400/125, YWZ2-500/125, YWZ2-600/125YWZ3-160/18, YWZ3-200/25, YWZ3-250/25, YWZ3-250/45, YWZ3-315/45, YWZ3-315/90MYT3-315/8 MYT3-200E/8 MYT3-200-8 MYT3-125E/5 MYT3-125/5MYT3-70/5 MYT3-40/4 MYT3-22/4 TJ2-100 TJ2-200 TJ2-300TJ2-100, TJ2-200, TJ2-300 YW160-E23 YW200-E23 YW200-E30YW250-E23 YW250-E30 YW250-E50 YW250-E80 YW315-E23YW315-E30 YW315-E50 YW315-E80 YW400-E30 YW400-E50YW400-E80 YW400-E121 YW500-E50 YW500-E80 YW500-E121YW500-E201 YW630-E121 YW630-E201 YW630-E301 YW710-E121YW710-E201 YW710-E301 YW800-E301

time:2022-05-10

More

The brake is an essential and important component on a crane, and its braking performance directly affects the correctness of the operation and safety of each mechanism. Especially, the braking performance of the brake of the lifting mechanism and the luffing mechanism must be as reliable as possible. The brakes of the lifting mechanism and the luffing mechanism must be normally closed. For lifting hot metal, flammable, explosive and other dangerous goods, as well as lifting mechanisms that may cause significant danger or loss in the event of accidents during lifting, each set of driving device should be equipped with two sets of brakes.At present, there are three types of brakes commonly used in cranes, namely belt brake, block brake and disc brake. Common brakes for cranes and their characteristics

time:2022-05-10

More

Electric hydraulic arm disc brake YPZ2 seriesPZ2 series electric hydraulic arm disc brake:YPZ2-315I/23; YPZ2-315I/30; YPZ2-315I/50; YPZ2-315I/80; YPZ2-355I/23; YPZ2-355I/30; YPZ2-355I/50; YPZ2-355I/80; YPZ2-400I/30; YPZ2-400I/50; YPZ2-400I/80; YPZ2-450I/50; YPZ2-450I/80; YPZ2-450 II/50; YPZ2-450 II/121; YPZ2-450 II/201; YPZ2-500 II/50; YPZ2-500 II/80; YPZ2-500 II/121; YPZ2-500 II/201; YPZ2-560 II/50; YPZ2-560 II/80; YPZ2-560 II/121; YPZ2-560 II/201; YPZ2-630 II/80; YPZ2-630 II/121; YPZ2-630 II/201; YPZ2-710 II/121; YPZ2-710 II/201; YPZ2-630 III/201; YPZ2-630 III/301; YPZ2-710 III/201; YPZ2-710 III/301; YPZ2-800 III/201; YPZ2-800 III/301; YPZ2-900 III/201; YPZ2-900 III/301; YPZ2-1000 III/201; YPZ2-1000 III/301; YPZ2-1250 III/201; YPZ2-1250 III/301YPZ3 series electric hydraulic arm disc brake:YPZ3-315I/23; YPZ3-315I/30; YPZ3-315I/50; YPZ3-315I/80; YPZ3-355I/23; YPZ3-355I/30; YPZ3-355I/50; YPZ3-355I/80; YPZ3-400I/30; YPZ3-400I/50; YPZ3-400I/80; YPZ3-450I/50; YPZ3-450I/80; YPZ3-450 II/50; YPZ3-450 II/80; YPZ3-450 II/121; YPZ3-450 II/201; YPZ3-500 II/50; YPZ3-500 II/80; YPZ3-500 II/121; YPZ3-500 II/201; YPZ3-560 II/50; YPZ3-560 II/80; YPZ3-560 II/121; YPZ3-560 II/201; YPZ3-630 II/80; YPZ3-630 II/121; YPZ3-630 II/201; YPZ3-710 II/121; YPZ3-710 II/201; YPZ3-630 III/201; YPZ3-630 III/301; YPZ3-710 III/201; YPZ3-710 III/301; YPZ3-800 III/201; YPZ3-800 III/301; YPZ3-900 III/201; YPZ3-900 III/301; YPZ3-1000 III/201; YPZ3-1000 III/301; YPZ3-1250 III/201; YPZ3-1250 III/301Brake, thruster, electro-hydraulic brake, hydraulic brake, hydraulic thruster, ED electro-hydraulic thruster, ED thruster, explosion-proof thruster, disk brake, electromagnetic brake, brake shoe, brake accessories, brake manufacturer, brake price, Jiaozuo brake, Jiaozuo brake, Jiaozuo brake factory, Jiaozuo hydraulic brake factory, brake manufacturer, crane brake, Thruster brake, YT1 thruster, explosion-proof brake, windproof brake, electromagnetic brakeWe mainly produce YWZB, YWZ2, YWZ3, YWZ4, YWZ5, YWZ6, YWZ8, YWZ9, YWZ10, YWZ12, and YWZ13 series electric hydraulic block brakes. All kinds of explosion-proof brakes, TJ2 series new energy-saving electromagnet brakes, electric hydraulic arm disc brakes, mine explosion-proof electromagnetic starters and mine vacuum feed switches have complete specifications, reliable performance and superior quality. It sells well all over the country and is highly praised by users.Please pay attention to the failure causes and maintenance methods of the disc brake.The common faults of disc brake include air resistance, insufficient braking force and noise during braking. Here is a brief introduction to the causes and maintenance methods of the faults.1、 Air resistanceThe heating part of the disc brake is concentrated on a very narrow brake pad, and its unit pressure is larger than that of the drum brake. The brake pad is in direct contact with the piston of the caliper body, so the heat during braking is easily transferred to the brake fluid. In this way, the disc brake is prone to air lock. However, if corresponding measures are taken, the occurrence of air resistance can also be prevented.1. Prevent the boiling point of brake fluid from decreasingVegetable oil type brake fluid cannot meet the use requirements of disc brake, so synthetic brake fluid with high boiling point must be used. However, synthetic brake fluid has water absorption properties. Under certain usage conditions, the boiling point decreases rapidly. To prevent a significant decrease in the boiling point of brake fluid, the following measures are commonly adopted:(1) Regularly replace the brake fluid. 3 months or 5000km in summer; After 6 months of winter or 1000 kilometers of driving, the brake fluid will be updated soon.(2) Brake fluids with different properties cannot be interchanged or mixed.(3) Store brake fluid tightly. Automobile maintenance networkTo increase the temperature of the brake fluid, it is necessary to ensure that the piston can flexibly and automatically return to its original position to avoid slipping or biting of the brake due to rust or jamming. When the brake pads are excessively worn, the heat transmitted to the brake fluid will also rapidly increase. Therefore, worn brake pads should be replaced in a timely manner.2、 Insufficient braking forceWhen the braking force of the disc brake is insufficient, the following methods can be used to solve the problem:1. Change the brake pad materialA slightly softer brake pad material can be used to improve the friction coefficient and increase the braking force.2. Remove foreign objects from the debris removal groove of the brake padIf the debris discharge groove of the brake pad is covered by foreign objects, the effect of dust discharge and water scraping will be lost during braking, resulting in a decrease in braking force.3、 Noise during brakingWhen braking, if there is a "squeaking, squeaking" noise, the following methods can be used to eliminate it:1. Add an anti noise pad between the brake caliper piston and the brake lining to create a tilt on the piston. This ensures flexible contact between the brake pads and brake discs during braking, ensuring that there is no abnormal noise in the brake pads under normal wear and tear conditions.2. Choose a brake pad material that is softer and less dense.3. When braking, the brake pads may move to one side and there may be a knocking sound. This is due to the excessive gap between the brake pad and the caliper body, which can be eliminated by electroplating solder. However, it should be noted that the solder should be coated on the side opposite to the direction of travel to prevent failure under the action of braking force.4、 Damaged front wheel bearingsThe brake caliper body is generally installed behind the steering knuckle, which can relatively reduce the load on the front wheel bearings during braking. However, some models install the clamp body in front of the axle, which increases the synthetic load on the front wheel bearings and can easily cause premature damage to the front wheel bearings. Therefore, for wheels with this structure, timely adjustment and maintenance should be carried out.

time:2022-05-10

More

Electric hydraulic block brake YWZ3B-315/45The YWZ3B electric hydraulic block brake product model YWZ3B electric hydraulic block brake is an improved series of YWZ3 brakes, with better performance. Mainly used in mechanical equipment in fields such as mining, metallurgy, lifting, ports, and construction, it has the characteristics of stable braking, safety and reliability, convenient maintenance, low power consumption, long service life, and no noise.YWZ3-160/18, YWZ3-160/25, YWZ3-200/18, YWZ3-200/25, YWZ3-250/25, YWZ3-250/45, YWZ3-315/25, YWZ3-315/45, YWZ3-315/90, YWZ3-400/45, YWZ3-400/90, YWZ3-400/125, YWZ3-500/90, YWZ3-500/125, YWZ3-500/180, YWZ3B-160/18, YWZ3B-160/25, YWZ3B-200/18, YWZ3B-200/18 B-200/25, YWZ3B-250/25, YWZ3B-250/45, YWZ3B-315/25

time:2022-05-10

More

ED-201/6 Electric Hydraulic Thruster PriceYT1 series electric hydraulic thruster:YT1-18ZB/2; YT1-25ZB/4; YT1-45Z/5; YT1-90Z/8; YT1-125Z/10; YT1-180Z/10; YT1-320Z/12; YT1-320Z/20; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12; YT1-320Z/12; YT1-350/12;YT1-350/20; YT1-350/35; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12BYT1 series electric hydraulic thrusters:BYT1-18ZB/2; BYT1-25ZB/4; BYT1-25ZC/4; BYT1-45Z/4; BYT1-45Z/5; BYT1-45Z/6; BYT1-90Z/6BYT1-90Z/8; BYT1-125Z/10; BYT1-180Z/8; BYT1-180Z/10; BYT1-180Z/12; BYT1-320Z/12BYT1-320Z/20; BYT1-25/4; BYT1-45/6; BYT1-90/8; BYT1-180/12ED series electric hydraulic thrusters:ED-23/5; ED-30/5; ED-50/6; ED-80/6; ED-121/6; ED-201/6; ED-301/6; ED-50/12; ED-80/12; ED-121/12; ED-201/12; ED-301/12; ED-630/12BED ZED series electric hydraulic thrusters:BED30/5; BED50/6; BED80/6; BED121/6; BED201/6; BED301/6; BED50/12; BED80/12; BED121/12; BED201/12; BED301/12Electric hydraulic block brakes are widely used for deceleration or parking braking of mechanical drive devices such as lifting, metallurgy, mining, ports, docks, construction machinery, etc. Safe and reliable performance, smooth braking, and high action frequency.The main swing hinge point is equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use. Comply with standard installation dimensions and JB/ZQ4388-1997 standards.Operating conditions Environmental temperature: -20 ℃~+50 ℃ The relative air temperature should not exceed 90%. The surrounding working environment should not contain flammable, explosive, or corrosive gases. The altitude of the location of use should comply with GB755-2000. Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.Note: YWZ4B, YWZB, YWZB, YWZ8, and YWZ13 are interchangeable. YWZB matches the YT type thruster, while YWZ4B, YWZ8, and YWZ13 match the Ed type thruster.Electric hydraulic block brakes are widely used for deceleration or parking braking of mechanical drive devices such as lifting, metallurgy, mining, ports, docks, construction machinery, etc. Safe and reliable performance, smooth braking, and high action frequency.The main swing hinge point is equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use. Comply with standard installation dimensions and JB/ZQ4388-1997 standards.Operating conditions: Environmental temperature: -20 ℃~+50 ℃. The relative air temperature should not exceed 90%. The surrounding working environment should not contain flammable, explosive, or corrosive gases. The altitude of the location of use should comply with GB755-2000. Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products

time:2022-05-10

More

ZED AC DC dual purpose electric hydraulic thrusterThe ZEd series AC DC dual purpose electric hydraulic thruster is a patented product developed by our company based on the ED thruster. It uses advanced brushless motors and digital control circuits, suitable for DC220V and AC220V power supply systems; It has the characteristics of stable starting, low noise, anti-interference, energy-saving, and environmental protection. Widely used in previous occasions where frequency conversion was used to improve the system's performance, speed range and accuracy, and reduce costs.Environmental temperature -20-45 degrees CelsiusAir humidity not exceeding 90%, power on rate 0-100%Outdoor use, and the surrounding environment complies with relevant regulations in GB/T15957Structural features: This product consists of two parts: a controller and an electric hydraulic thruster

time:2022-05-10

More