MYT1 series electric hydraulic thrusterMYT1-18ZB/2; MYT1-25ZB/4; MYT1-45Z/5; MYT1-90Z/8; MYT1-125Z/10; MYT1-180Z/10; MYT1-320Z/12; MYT1-320Z/20; MYT1-25/4; MYT1-45/6; MYT1-90/8; MYT1-180/12YTD series electric hydraulic thrusterYTD-300-60, YTD-500/60, YTD800-60, YTD1250-600, YTD2000-600, YTD3000-600Hydraulic thruster manufacturer 13803910788The above electric hydraulic thrusters are matched with brake models: YWZ, YWZB, YWZ2, YWZ3B, YWZ4B, YWZ5, YWZ8, YWZ9, YWZ13, YW, YWL and other series of hydraulic brakes.Manufacturer of Jiaozuo hydraulic thrusterThe pump is composed of components such as rotor 1, stator 2, blades 3, oil distribution plate, and end cover; The inner surface of the stator is a cylindrical hole; There is eccentricity between the rotor and stator; The blades can slide flexibly in the slots of the rotor. Under the centrifugal force during rotor rotation and the pressure oil flowing into the blade root, the top of the blades is tightly attached to the inner surface of the stator, forming sealed working cavities between two adjacent blades, oil distribution plates, stator, and rotor; When the rotor rotates in a counterclockwise direction, the blade on the right side of the figure extends outward, and the volume of the sealing working chamber gradually increases, creating a vacuum. Therefore, oil is sucked in through the suction port 6 and the window on the oil distribution plate 5; On the left side of the figure; The blades retract inward, and the volume of the sealing chamber gradually decreases. The oil in the sealing chamber is pressed out through another window of the oil distribution plate and the oil pressure port 1 and output to the system; This type of pump absorbs and presses oil once during each rotation of the rotor, hence it is called a single acting pump; The rotor is subjected to radial hydraulic imbalance force, so it is also known as a non balanced pump, and its bearing load is relatively large; By changing the eccentricity between the stator and rotor, the displacement of the pump can be changed, so these pumps are variable displacement pumps.YT1 series hydraulic thruster:YT1-18ZB/2 Hydraulic Pusher YT1-25ZB/4 Hydraulic Pusher YT1-25ZC/4 Hydraulic Pusher YT1-45Z/4 Hydraulic Pusher YT1-45Z/5 Hydraulic Pusher YT1-45Z/6 Hydraulic Pusher YT1-90Z/6 Hydraulic Pusher YT1-90Z/8 Hydraulic Pusher YT1-125Z/10 Hydraulic Pusher YT1-180Z/8 Hydraulic Pusher YT1-180Z/10 Hydraulic Pusher YT1-180Z/12 Hydraulic Pusher YT1-320Z/12 Hydraulic Pusher YT1-320Z/20 Hydraulic Pusher YT1-25/4 Hydraulic Pusher YT1-45/6 fluids Pressure thruster YT1-90/8 Hydraulic thruster YT1-125/10 Hydraulic thruster YT1-180/12 Hydraulic thrusterYT1CJ-125/10, YT1CJ-180/12, YT1CJ-125Z/10YT1CJ-125/10, YT1CJ-180/12, YT1CJ-125Z/10YT1CJ-125/10, YT1CJ-180/12, YT1CJ-125Z/10

time:2022-05-07

More

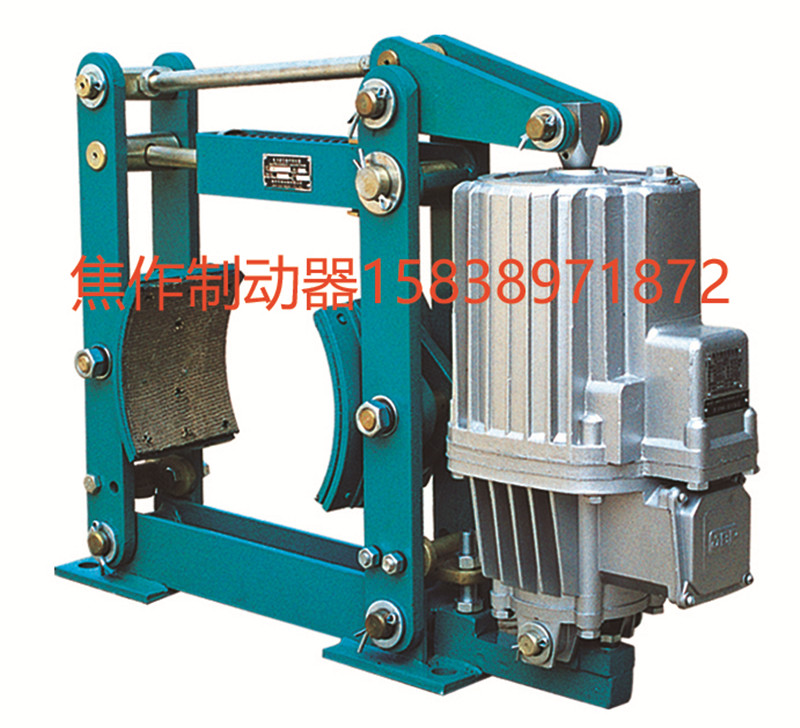

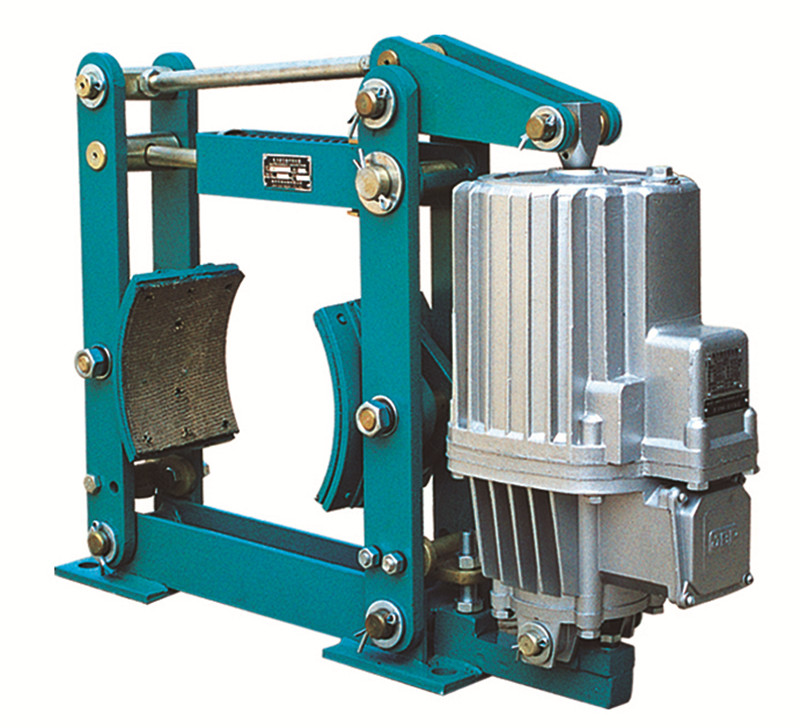

Holding brake hydraulic push rod brake YWZ4-300/50YWZ4-300/E50 Electric Hydraulic Brake Manufacturer YWZ4-200/23YWZ4-300/E50YWZ4-300/E80 Electric Hydraulic Brake Manufacturer YWZ4-300/E80YWZ4-400/E50 Electric Hydraulic Brake Manufacturer YWZ4-400/E50YWZ4-400/E80 Electric Hydraulic Brake Manufacturer YWZ4-400/E80YWZ4-400/E121 Electric Hydraulic Brake Manufacturer YWZ4-400/E121YWZ4-500/E80 Electric Hydraulic Brake Manufacturer YWZ4-500/E80YWZ4-500/E121 Electric Hydraulic Brake Manufacturer YWZ4-500/E121YWZ4-600/E121 Electric Hydraulic Brake Manufacturer YWZ4-600/E121YWZ4-600/E201 Electric Hydraulic Brake Manufacturer YWZ4-600/E201YWZ4-700/E201 Electric Hydraulic Brake Manufacturer YWZ4-700/E201YWZ4-700/E301 Electric Hydraulic Brake Manufacturer YWZ4-700/E301YWZ4-800/E301 Electric Hydraulic Brake Manufacturer YWZ4-800/E301YWZ4B-100/18 Electric Hydraulic Brake Manufacturer YWZ4B-100/18YWZ4B-150/25 Electric Hydraulic Brake Manufacturer YWZ4B-150/25YWZ4B-200/25 Electric Hydraulic Brake Manufacturer YWZ4B-200/25YWZ4B-300/25 Electric Hydraulic Brake Manufacturer YWZ4B-300/25YWZ4B-300/45 Electric Hydraulic Brake Manufacturer YWZ4B-300/45YWZ4B-400/45 Electric Hydraulic Brake Manufacturer YWZ4B-400/45YWZ4B-400/90 Electric Hydraulic Brake Manufacturer YWZ4B-400/90YWZ series electric hydraulic block brakes: YWZ-100/18, YWZ-200/25, YWZ-300/25, YWZ-300/45, YWZ-300/90, YWZ-400/45, YWZ-400/90, YWZ-500/125, YWZ-600/180. YWZ2CJ-200/40, YWZ2CJ-300/30, YWZ2CJ-300/40, hydraulic brake, Wenner hydraulic brake, hydraulic brake manufacturer YWZ2CJ-300/50, YWZ2CJ-300/70, YWZ2CJ-300/80, hydraulic brake, Wenner hydraulic brake, hydraulic brake manufacturer. Xinhe ZWZA-700, YWZ2-300/30, YWZ10-630/T1250, DYTZWII500, YWZ2-400/50, YWZ10-710/D301, DYTP3000-100/90, YWZ3BCJ-500/180, YWZ13-250/D30, YT1CJ-180Z/12, YWZ4BCJ-200/E30, YWCJ-250/30, YTD2-500/60, YWB-710/301, YW-400/Q3260, YWZ3-710/320, YWZ13-200/E23,YWZ3B-160/18, YWZ3B-500/125, YWZ3B-160/25YWZ3B-500/90, YWZ3B-200/18, YWZ3B-400/125YWZ3B-200/25, YWZ3B-400/90, YWZ3B-250/25YWZ3B-400/45, YWZ3B-250/45, YWZ3B-315/90YWZ4-100/18, YWZ4-100/23, YWZ4-150/25, YWZ4-150/25, YWZ4-200/23YWZ4-150/30, YWZ4-300/30, YWZ4-300/50YWZ4-400/50, YWZ4-400/80, YWZ4-400/121 YWZ4-500/80, YWZ4-500/201, YWZ4-600/121 YWZ4-600/201, YWZ4-700/201 YWZ4-800/201/YWZ4-800/301, YWZ4-800/320YWZ4-700/180, YWZ4-600/180, YWZ4-600/90YWZ4-500/180, YWZ4-500/125, YWZ4-500/90YWZ4-400/125, YWZ4-400/90, YWZ4-400/45YWZ4-300/45, YWZ4-300/25, YWZ4-200/25

time:2022-05-07

More

YWZ8-400/80 electric hydraulic brake YWZ8-400/E121YWZ8-400/D50, YWZ8-400/D50, YWZ8-300/D50, YWZ8-300/D30, hydraulic brakeYWZ8-200/D30, YWZ8-200/D23, YWZ8-500/D121, YWZ8-400/D121, hydraulic brakeYWZ8-400/D80, YWZ8-600/D201, YWZ8-600/D121, YWZ8-500/D201, hydraulic brakeYWZ8-700/D301, YWZ8-700/D201, YWZ8-600/D301, YWZ8-400/E50, hydraulic brakeYWZ8-300/E80, YWZ8-300/E50, YWZ8-200/E30, YWZ8-300/E30, hydraulic brakeYWZ8-200/E23, YWZ8-200/E23, YWZ8-500/E121, YWZ8-400/E121, hydraulic brakeYWZ8-400/E80, YWZ8-600/E201, YWZ8-600/E121, YWZ8-500/E201, hydraulic brakeYWZ8-700/E301, YWZ8-700/E201, YWZ8-600/E301, YWZ8-800/E301/12, hydraulic brakeYWZ8-800/E301, hydraulic brakeYWZ8 series hydraulic brake1、 Main features1. Safe and reliable use, smooth braking, and high action frequency.2. The braking torque is directly displayed.3. Asbestos free gaskets and brake pads adopt a plug-in type, which is safe and reliable, and easy and fast to replace.2、 Usage conditions1. Environmental temperature: -25~+50 ℃2. AC 380V/50Hz power supply.3. The altitude of the location of use complies with GB755-20004. The relative humidity of the air at the place of use shall not exceed 90%5. There should be no flammable, explosive or corrosive gases around.YWZ4B series electric hydraulic block brake:YWZ4B-100/23; YWZ4B-150/23; YWZ4B-200/23; YWZ4B-200/30; YWZ4B-300/30; YWZ4B-300/50;YWZ4B-300/80; YWZ4B-400/50; YWZ4B-400/80; YWZ4B-400/121; YWZ4B-500/121; YWZ4B-600/121;YWZ4B-600/201; YWZ4B-700/201; YWZ4B-700/301; YWZ4B-800/301YWZ5 series electric hydraulic block brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50;YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80;YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121;YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50;YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201;YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12YWZ9 series electric hydraulic block brake:YWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50; YWZ9-300/30;YWZ9-300/50; YWZ9-300/80; YWZ9-315/30; YWZ9-315/50; YWZ9-315/80; YWZ9-400/50;YWZ9-400/80; YWZ9-400/121; YWZ9-500/80; YWZ9-500/121; YWZ9-500/201; YWZ9-600/121;YWZ9-600/201; YWZ9-600/301; YWZ9-630/121; YWZ9-630/201; YWZ9-6

time:2022-05-07

More

YWZ8-400/E50, YWZ8-400/D50, YWZ8-300/D50, YWZ8-300/D30, hydraulic brakeYWZ8-200/E30, YWZ8-200/D23, YWZ8-500/D121, YWZ8-400/D121, hydraulic brakeYWZ8-400/E80, YWZ8-600/D201, YWZ8-600/D121, YWZ8-500/D201, hydraulic brakeYWZ8-700/D301, YWZ8-700/D201, YWZ8-600/D301, YWZ8-400/E50, hydraulic brakeYWZ8-300/E80, YWZ8-300/E50, YWZ8-200/E30, YWZ8-300/E30, hydraulic brakeYWZ8-200/E23, YWZ8-200/E23, YWZ8-500/E121, YWZ8-400/E121, hydraulic brakeYWZ8-400/E80, YWZ8-600/E201, YWZ8-600/E121, YWZ8-500/E201, hydraulic brakeYWZ8-700/E301, YWZ8-700/E201, YWZ8-600/E301, YWZ8-800/E301/12, hydraulic brakeYWZ8-800/E301, hydraulic brakeYWZ8 series hydraulic brake1、 Main features1. Safe and reliable use, smooth braking, and high action frequency.2. The braking torque is directly displayed.3. Asbestos free gaskets and brake pads adopt a plug-in type, which is safe and reliable, and easy and fast to replace.2、 Usage conditions1. Environmental temperature: -25~+50 ℃2. AC 380V/50Hz power supply.3. The altitude of the location of use complies with GB755-20004. The relative humidity of the air at the place of use shall not exceed 90%5. There should be no flammable, explosive or corrosive gases around.

time:2022-05-07

More

YWZ5-500/201 Electric Hydraulic Block BrakeSpecific model:YT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various friction pads, brake pads, couplings, brake wheels, brake discs, and non-standard brakes according to user needsProduct model: YWZ8-400/E80 hydraulic brakeYT1CJ-45/6 hydraulic thrusterYW500-E201YW Hydraulic BrakeYWZ3B-710/180YWZ3 series hydraulic brakeTJ2-200/200 Electromagnetic BrakeYWZ10-630/201 Hydraulic BrakeMYT3-70 Hydraulic PusherMWZ315-630 Electromagnetic Block BrakeYWZ9-250/50 hydraulic brakeBED301/6 explosion-proof hydraulic thruster YW500-E121YW hydraulic brakeYWZ12-500/121S hydraulic brakeYWZ9-250/E50 hydraulic brakeYWZ5-500/121 hydraulic brakeYWZ4B-400/90YWZ4 hydraulic brakeYWZ3B-250/25YWZ3 series hydraulic brakeYWZ2-300/30YWZ series hydraulic brakeMYT3-80 Hydraulic PusherMYTD2-1250/50 hydraulic thrusterED-70/5 hydraulic thruster YW-500/201 hydraulic brakeYWK250-300YWK electric hydraulic brakeTJ2A-300 energy-saving electromagnetic block brakeHydraulic push rod brakeED-301/12 hydraulic thrusterYWZ-150/25YWZ series hydraulic brakeYWZ4-200/30YWZ4 hydraulic brakeYWZ5-630/E201 Hydraulic BrakeYWZ10-630/121 hydraulic brakeYWB-710/301 Hydraulic Brake ED-1250/120 Hydraulic Pusher_ ZWZ3-500/500ZWZ3-400/400YW630-E1250YW Hydraulic BrakeYWZ10-630/E121 Hydraulic BrakeYWZ5-250/E23 Hydraulic BrakeYWZ3B-160/25YWZ3 series hydraulic brakeMYTD2-2000/120 Hydraulic PusherYT1CJ-45Z/6 hydraulic thrusterJCZ-300/25H electromagnetic brakeYWP-400/121 Hydraulic BrakeAnd we can design and manufacture various non-standard products according to user requirements, which are widely used in lifting, mining, mechanical metallurgy, electricity, railways, water conservancy, ports, chemical engineering, and docks.Our factory has obtained the special equipment type test certificate issued by the National Lifting Machinery Quality Supervision and Inspection Center. It was rated as a contract abiding and credit worthy enterprise in Henan Province and a contract abiding and credit worthy enterprise in Jiaozuo City.Our factory adheres to the principle of quality and customer satisfaction. Think of the user's thoughts, be anxious about the user's anxieties. Our factory will sincerely cooperate with friends from all walks of life to seek common development with high-quality products, discounted prices, and thoughtful services.

time:2022-05-06

More

Electric hydraulic block brakes: YWL series electric hydraulic block brakes, YWZ3B series electric hydraulic brakes, YWZ4B series electric hydraulic brakes, YWZ5 series electric hydraulic brakes, YWZ8 series electric hydraulic brakes, YWZ9 series electric hydraulic brakes, YWZ12 series electric hydraulic actuators, YWZ13 series electric hydraulic brakes, YWZB series electric hydraulic brakes, and YW series electric hydraulic brakes.Electric hydraulic thrusters: Ed series electric hydraulic thrusters, YT1 series electric hydraulic thrusters.Explosion proof electric hydraulic thruster: BEd series explosion-proof electric hydraulic thruster, BYT1 explosion-proof electric hydraulic thruster.Electromagnetic block brake: MW series electromagnetic block brakeElectric hydraulic arm disc brake: YPZ2 series electric hydraulic arm disc brake, YPZ3 series electric hydraulic arm disc brake.Pneumatic caliper disc brake: QP12.7 series pneumatic caliper disc brakeDC electromagnetic iron block brake: ZWZ series DC electromagnetic iron block brake, ZWZ3 series DC electromagnetic iron block brake, ZWZ3A DC electromagnetic iron block brake.Hydraulic wheel brake: YLBZ hydraulic wheel brakeEnergy saving electromagnetic block brake: JZ energy-saving electromagnetic block brakeElectric hydraulic brakeYWZB YWZ3B YWZ4B YWZ5 YWZ8 YWZ9 YWZ12 YWZ13 YW YWL TYWZ2 YWPElectromagnetic block brakeJZ (TJ2A) MW (Z) ZWZAZWZ2 ZWZ3ADCW3Electromagnetic failure protection disc brake5SE 561SE 560SE 56SEDCPZ12.7 4SE 3SE ST1SE ST2SE 450SEHydraulic failure protection disc brake5SH 4SH 3SH 450SH ST1SH ST2SH ST3SH ST4SHSB (YQP) SBDST5SH ST10SHST16SHST25SHST25SH-AST40SH904SHSBBElectro hydraulic arm disc brakeYPZ2 I, II, IIIYPZ2 IV, V, VIPneumatic caliper disc brake QP12.7 5SP4SP3SP450SPPDADP60M-ADP61M-ADP62MHydraulic direct acting disc brake DADH75ADH60ADH90ADH120DADH80DADH90DADH120DADH103DADH195Electric hydraulic thrusterYT1 EdMYT1 hydraulic thruster motor modelBO62Z YDT80-2 ASF82A ASF102A B112Z A028012A028022 three-phase asynchronous motorExplosion proof electric hydraulic thrusterBYT1 BEDOur company adheres to the business philosophy of "conducting oneself in the world and creating a win-win situation together". Our products now serve hundreds of large enterprises and tens of thousands of small and medium-sized enterprises in China, involving industries such as machinery, metallurgy, ports, docks, electricity, railways, water conservancy, chemical engineering, etc. We have successfully designed and manufactured specialized transmission equipment with advanced international industry standards for multiple large enterprises and many key construction projects in China. Our high-quality products and after-sales service beyond contracts have been widely recognized and praised by users. At present, our products are undertaking heavy responsibilities and serving society in multiple industries related to national construction and development.Gratitude to friends, return to society, integrity to the world, and jointly build the future. We sincerely welcome friends from all walks of life to visit and cooperate with us

time:2022-05-06

More

How to adjust the brake of the crown block brakeThe brake is the brake or brake we talk about everyday. It is a Machine element that stops or decelerates moving parts in machinery.So what are the types of brakes? There are two types of brakes: hydraulic brakes and block brakes.The function of the brake is obvious and crucial, so what happens when the brake malfunctions?Below, we will analyze the common troubleshooting of hydraulic brakes.Hydraulic braking equipment transfers braking force by converting pedal force into hydraulic energy. Its transmission organization is simple, but the braking torque generated by the brake is linearly related to pedal force. If the adhesion between the tire and the road surface is met, the braking force experienced by the car is linearly related to pedal force. This function is called brake pedal feeling (commonly known as foot feeling), so the driver can directly feel whether various working conditions of the automobile brake equipment are normal, so as to quickly diagnose. Common faults in hydraulic braking systems include: ineffective braking, such as brake bite.1、 Brake failure1. Appearance: When the car is moving, quickly press the brake pedal to the bottom, and the car cannot immediately slow down or park. Its brakingThe deceleration is small and the braking interval is too long.2. Reason:(1) Excessive pedal free travel.(2) Lack of brake fluid in the brake master cylinder, or blockage of the compensation hole, aging, swelling, deformation, or overturning of the master cylinder cup and ring.(3) The brake master cylinder piston and cylinder body are excessively worn and loose, resulting in oil leakage, poor sealing of the return valve, and broken tension spring of the outlet valve.(4) The brake wheel cylinder cup is aged, swollen, and the piston is stuck, resulting in excessive wear and loose oil leakage between the wheel cylinder piston and the cylinder body.(5) The brake shoes are severely worn, and the brake clearance is too large or reversed.(6) The brake drum is out of round, grooved or worn too thin, the brake shoe surface has oil, burns and hardens, and rivets are exposed.(7) When air enters the hydraulic braking system or the temperature of the braking system is too high, the brake fluid in the pipeline vaporizes, forming an air lock.(8) The oil pipe is concave, the joint is loose and leaking, and the brake hose is aged, cracked, or blocked.YWZ4 series electric hydraulic block brake:YWZ4-100/18; YWZ4-150/25; YWZ4-160/25; YWZ4-200/25; YWZ4-200/45; YWZ4-300/25; YWZ4-300/45; YWZ4-300/90; YWZ4-400/45; YWZ4-400/90; YWZ4-400/125; YWZ4-500/90; YWZ4-500/125; YWZ4-500/180; YWZ4-600/180; YWZ4-700/180; YWZ4-800/180; YWZ4-800/320YWZ3B series electric hydraulic block brake:YW160-E23 electric hydraulic drum brake shoeYWZ3B-160/18; YWZ3B-160/25; YWZ3B-200/18; YWZ3B-200/25; YWZ3B-250/25; YWZ3B-250/45; YWZ3B-315/25; YWZ3B-315/45; YWZ3B-315/90; YWZ3B-400/90; YWZ3B-400/125; YWZ3B-500/90; YWZ3B-500/125; YWZ3B-500/180; YWZ3B-630/125; YWZ3B-630/180; YWZ3B-630/320; YWZ3B-710/180; YWZ3B-710/320; YWZ3B-800/320YWZ4B series electric hydraulic block brake:YWZ4B-100/23; YWZ4B-150/23; YWZ4B-200/23; YWZ4B-200/30; YWZ4B-300/30; YWZ4B-300/50; YWZ4B-300/80; YWZ4B-400/50; YWZ4B-400/80; YWZ4B-400/121; YWZ4B-500/121; YWZ4B-600/121; YWZ4B-600/201; YWZ4B-700/201; YWZ4B-700/301; YWZ4B-800/301YWZ5 series electric hydraulic block brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50; YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201; YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12YWZ9 series electric hydraulic block brake:YW160-E23 electric hydraulic drum brake shoeYWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50; YWZ9-300/30; YWZ9-300/50; YWZ9-300/80; YWZ9-315/30; YWZ9-315/50; YWZ9-315/80; YWZ9-400/50; YWZ9-400/80; YWZ9-400/121; YWZ9-500/80; YWZ9-500/121; YWZ9-500/201; YWZ9-600/121; YWZ9-600/201; YWZ9-600/301; YWZ9-630/121; YWZ9-630/201; YWZ9-630/301; YWZ9-700/201; YWZ9-700/301; YWZ9-710/201; YWZ9-710/301; YWZ9-800/301/12The brake is the brake or brake we talk about everyday. It is a Machine element that stops or decelerates moving parts in machinery.So what are the types of brakes? There are two types of brakes: hydraulic brakes and block brakes.The function of the brake is obvious and crucial, so what happens when the brake malfunctions?Below, we will analyze the common troubleshooting of hydraulic brakes.Hydraulic braking equipment transfers braking force by converting pedal force into hydraulic energy. Its transmission organization is simple, but the braking torque generated by the brake is linearly related to pedal force. If the adhesion between the tire and the road surface is met, the braking force experienced by the car is linearly related to pedal force. This function is called brake pedal feeling (commonly known as foot feeling), so the driver can directly feel whether various working conditions of the automobile brake equipment are normal, so as to quickly diagnose. Common faults in hydraulic braking systems include: ineffective braking, such as brake bite.1、 Brake failure1. Appearance: When the car is moving, quickly press the brake pedal to the bottom, and the car cannot immediately slow down or park. Its brakingThe deceleration is small and the braking interval is too long.2. Reason:(1) Excessive pedal free travel.(2) Lack of brake fluid in the brake master cylinder, or blockage of the compensation hole, aging, swelling, deformation, or overturning of the master cylinder cup and ring.(3) The brake master cylinder piston and cylinder body are excessively worn and loose, resulting in oil leakage, poor sealing of the return valve, and broken tension spring of the outlet valve.(4) The brake wheel cylinder cup is aged, swollen, and the piston is stuck, resulting in excessive wear and loose oil leakage between the wheel cylinder piston and the cylinder body.(5) The brake shoes are severely worn, and the brake clearance is too large or reversed.(6) The brake drum is out of round, grooved or worn too thin, the brake shoe surface has oil, burns and hardens, and rivets are exposed.(7) When air enters the hydraulic braking system or the temperature of the braking system is too high, the brake fluid in the pipeline vaporizes, forming an air lock.(8) The oil pipe is concave, the joint is loose and leaking, and the brake hose is aged, cracked, or blocked.

time:2022-05-06

More

The YWH series electric hydraulic drum brake is widely used for deceleration and parking (maintenance) braking of various mechanisms in various lifting and transportation, port loading and unloading, metallurgical equipment, mining machinery, and engineering machinery.Compliant with standards:The connection dimensions and braking torque parameters of the YWH series brake comply with the JB/T6406-2006 standard and DIN15435 standard; Equipped with Ed series thrusters that comply with DIN15430 standard. This series is mainly suitable for places with small installation space, where YW, YWZ2, YWZ4 and other forms cannot be arranged.Main features:Interlocking type equal back distance device (patented technology) and automatic tile following device can always maintain equal back distance of both sides of the tiles without adjustment, completely avoiding the phenomenon of one brake pad floating against the brake wheel due to uneven back distance.The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use.The brake spring is arranged inside the square tube and equipped with a ruler, making it very convenient for users to read the braking torque value, eliminating the trouble of measurement and calculation.The brake pad is a card mounted integral molding structure, which is very convenient and fast to replace. There are different materials of brake pads available for users to choose from, including semi metal (asbestos free) hard and semi hard, soft (asbestos free) brake pads.The matching series of thruster products are sensitive in action and have a long service life.Basic parameters:Product models: YWH160, YWH200, YWH250, YWH300, YWH315, YWH400, YWH500Applicable wheel diameter: 160-500mmBraking torque: 80-4000NmPerformance description:The product has the advantages of reliable performance, no pollution, no noise, high wear resistance, and long service life. Our company's brake accessories such as friction pads, friction blocks, brake shoes, brake pads, clutch pads, etc. are suitable for use in various types of mechanical brakes such as automobiles, motor vehicles, textile machinery, marine machinery, engineering machinery, etc., mainly for industrial and agricultural machinery such as forklifts, bulldozers, excavators, loaders, tractors, harvesters, etc, There are over 2000 types of products that can provide you with high-quality mechanical accessories. At the same time, the company has developed environmentally friendly friction products that can be applied in various fields. They have low density, good bending strength, high rotational burst strength, stable friction coefficient, low wear rate, and smooth connection during installation and use. Their comprehensive performance meets the requirements of supporting enterprises. The company can design and develop various specifications of friction materials according to customer requirements (samples and drawings)The enterprise has become a domestic producer of heavy-duty vehicles, medium-sized vehicles, sedans, and micro cars by introducing advanced production processes from Japan and German distribution technology through the import of raw materials; Various specifications of (non) asbestos mechanical brake pads, clutch pads, mechanical friction pads, brake pads, brake bands, lining pads, copper based friction pads, paper based friction pads, motor friction rings, brake pads, various types of cork friction plates, asbestos friction plates, (non) asbestos friction plates, and semi metal friction plates, including industrial machinery, engineering machinery, mining machinery, oil drilling rigs, ship machinery, agricultural machinery, and electric bicycles, Electromagnetic friction discs and various non-standard friction materials can be customized. Our company strictly adheres to the corporate tenet of "good management, quality, reasonable price, and excellent service", and always adheres to treating product quality as the life of the enterprise. Since its establishment for over a decade, the company has provided products and services to over 300 customers both domestically and internationally, with customers spread throughout the country. It has established long-term partnerships with multiple large enterprises, and its products are exported to Southeast Asia, the Americas, Japan and other countries and regions, deeply favored by users.Add self-lubricating bearings to all brake closing positions. 8.2 Check if the microswitch is triggered when lever 11 is not in the manual release position (i.e. screw 4 is fully released). 9. Brake friction pad wear display. Microswitch 14 can display the time when the brake friction pad needs to be replaced. In order to accurately display the wear of the brake friction pad, when the brake is replaced with a new friction pad and in the braking state, place the microswitch contact (located at the triggering point) at a distance of 14mm from the plate 15, and tighten the microswitch fastening screw with a sleeve plate (4). M8, display of manual release status. Microswitch 16 can indicate whether the brake is manually released or active. The lever 11 is in a manual release state. The contact of microswitch 16 (at the triggering point position) contacts the outer contour of manual lever 11 and tighten the fastening screw.

time:2022-05-06

More

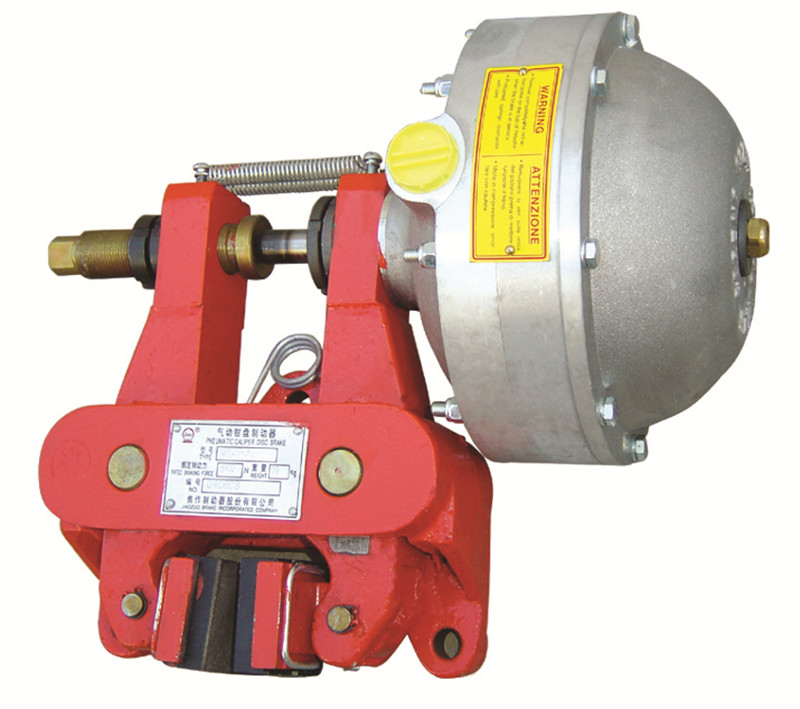

Provided by QP12.7-A, QP15, QP20, QP25.4, QP30-C and other pneumatic caliper disc brake manufacturersPneumatic caliper disc brakeAll power sources do not need to be set separately and can be used in conjunction with existing air compression stations. Speed control valves are installed in the gas supply line, and the braking time can be adjusted steplessly.2、 Usage conditionsEnvironmental temperature: -40 ℃~60 ℃;Working air pressure: 5-7bar;Installation method: Horizontal installation. Pneumatic caliper disc brake QP30-DThe pneumatic caliper Disc brake frame and cylinder are composed of two parts (see the structure diagram).When cylinder 1 is filled with pressure air, piston rod 5 rapidly contracts into the cylinder under the action of air pressure,The left and right brake arms, under the action of the reset spring 4, drive the friction block 12 to quickly open (i.e. release the brake). When the cylinder stops supplying air and quickly deflates through the control valve, the piston rod 5 quickly extends under the internal spring of the cylinder, pushing the left and right brake arms to drive the friction block 12 to close (i.e., the holding brake).2、 Installation of disc brake·Firstly, check the brake surface of the brake disc and brake pad for oil sludge or other stains.·Install the G3/8 "(cast iron rod cylinder) or 1/2" (cast aluminum cylinder) connector on the air inlet of cylinder 1, connect the air pipe with a hose, and the air source should be free of oil, water, and other impurities·During installation, pressure air is first introduced to retract piston rod 5 into the cylinder. Then, the friction block 12 is installed into the brake disc in the direction perpendicular to the brake disc. Then, the base 9 is fixed horizontally on the rigid base so that it is in line with the thickness of the brake disc. The installation position dimensions are shown in the structural diagram3、 Disc brake commissioning·Adjust the air pressure value to a range of 5-7 bar.·For normal work, the first step is to test the brake several times and check if there are any abnormalities in the brake.·The retraction distance of the friction block can be adjusted by rotating the adjustment rod 6 to change the size of the working stroke. When rotating the adjustment rod, pressure air is first introduced to retract the piston rod, and then adjusted.Pneumatic inlaid disc brake includes QP12.7-A, QP12.7-B, CQP12.7-A, CQP12.7-B, QP127-C, QPL12.7A-A, QPL12.7A-B, CQPL12.7A-A, CQPL12.7A-B, QPL12.7-B, CQPL12.7-B, QP30-D, QP25.4-D, CQP30-D, CQP25.4-D, CQP20-D, CQP10B-A, CQP10B-B, CQP10B-F, CQP10B-A, CQP10B-B, CQP10B-F, CQP20B-A, CQP20B-B, CQP20B-F, CQP38B-A, CQP38B-A Specifications such as 8B-B, CQP38B-F, CQPL38B-A, CQPL38B-B, etc. Each brake disc diameter can be adjusted for four levels of braking torque. The matching air bag uses imported aluminum alloy air bags, which are reliable and stable in performance and have good sealing performance, Small in size and light in weight, it can be classified into A type, B type, C type, D type, and F type according to performance requirements4、 Disc brake maintenanceWhen the friction plate is worn and the working stroke increases to 8mm, it is necessary to immediately adjust lever 6 to readjust the working stroke by about 4mm. Otherwise, the brake will fail. After adjustment, the nut 7 should be tightened. When the friction block 12 is worn to about 6mm, the wear block needs to be replaced. The replacement steps are as follows:1. Cylinder, 2. Right brake arm, 3. Return spring, 5. Piston rod, 6. Adjusting rod, 7. Nut, 8. Left brake arm, 9. Base, 10. Brake block, 11. Spring steel wire, 12. Friction plateThe working principle of pneumatic brakes is to input pressurized gas into the air bag of the pneumatic brake, thereby pushing the piston to move in a straight line, and achieving the braking function by compressing the brake wheel with the friction block of the brake. The pneumatic brake is connected by air pressure, released by a reset spring, and the disc slides along the axis with air pressure to contact the friction plate. Discs, friction plates, etc. are assembled onto the wheel hub to form an integrated structure. The friction plate can be disassembled by unscrewing the adjusting nut, and the exchange is simple. Pneumatic brakes are constructed by installing a tapered shaft sleeve with a wedge onto the shaft, with friction plates that can be exchanged while maintaining the mechanical equipment in its original state. The heat generated by friction is dissipated by a cooling plate installed on a disc with a hub. The friction plate is a double cut split type, which can be exchanged by using a screwdriver to remove the countersunk screw through the hole of the hub disc. Pneumatic brakes have good heat dissipation and can be widely used in industries such as packaging machinery, wire and cable equipment, thin paper, and corrugated paper.Pneumatic brakes, also known as ventilated brakes, mean that there is a fully inflated air that applies pressure to the socket to achieve braking effect, which is widely used in industry. When it comes to pneumatic brakes, they are also divided into normally closed brakes and normally open brakes. Normally closed brakes keep their sockets open when they are not working, and when they are ventilated during operation, they brake and form a brake.

time:2022-04-16

More

YWZB-200/25 Hydraulic Brake Jiaozuo Brake Factory Co., LtdDetailed description:YWZB series electric hydraulic block brakeProduct Introduction:Electric hydraulic block brakes are widely used for deceleration or parking braking of mechanical drive devices such as lifting, metallurgy, mining, ports, docks, construction machinery, etc.Compliant with standards:The installation dimensions of the YWZB series electric hydraulic block brake comply with the JB/ZQ4388-1997 standard.Main features:The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and do not require lubrication during use;There are two types of installation methods for brake pads according to user needs: riveted and plug-in (please specify when ordering).Usage conditions:Environmental temperature -20 ℃~+50 ℃;Power supply: 380V, 50HZ;Relative humidity: should not exceed 90%;There should be no flammable, explosive, or corrosive gases in the surrounding working environment;The altitude of the location of use complies with GB755-2000;Outdoor rain and snow erosion or corrosive gases and media should use anti-corrosion products.YWZB, YWZ4B, YWZ8, and YWZ13 are interchangeable. YWZB is matched with YT type thrusters, while YWZ4B, YWZ8, and YWZ13 are matched with ED type thrusters. YWZ8 and YWZ13 have equal backlash devices. The YWZ13 spring is located on the side and arranged in the spring tube. It is equipped with a brake torque scale and can be equipped with a pad automatic wear compensation device.YWZ-100/18; YWZ-150/25; YWZ-160/25; YWZ-200/25; YWZ-200/45; YWZ-300/25; YWZ-300/45; YWZ-300/90; YWZ-400/45; YWZ-400/90; YWZ-400/125; YWZ-500/90; YWZ4-500/125; YWZ4-500/180; YWZ4-600/180; YWZ4-700/180; YWZ4-800/180; YWZ4-800/320

time:2022-04-16

More

Which manufacturer is reliable in making brakes in JiaozuoThe former Jiaozuo Brake Co., Ltd. is a company integrating electric hydraulic brake, electromagnet brake, ypz series disc brake, qp12.7 series disc brake, windproof iron wedge series brake, wind turbine brake, hydraulic failure protection disc brake, pneumatic failure protection disc brake, electric failure protection disc brake, explosion-proof brake, yt series thruster, ed series thruster The research and development, manufacturing, sales, and service of series products such as explosion-proof thrusters are integrated into a brake production enterprise. The company has 6 engineers, 22 intermediate engineering and technical personnel, and 50 technical personnel, providing users with the design and manufacturing of national standard and non-standard products. The company has advanced equipment and 180 production equipment, with an annual production of 60000 sets of various brakes, thrusters, and electromagnets.The various series of brakes produced by the company are mainly used for mechanical braking of mechanical driving devices in lifting, transportation, metallurgy, mining, ports, construction, etc. They have the advantages of smooth braking, safety and reliability, convenient maintenance, low power consumption, long service life, no noise, and high frequency. Our company is the first to pass the ISO 9001.2000 quality management system standard certification. Advanced process equipment, strong technical strength, comprehensive testing methods, strict quality management system, reasonable product prices, and reputation are the strong guarantees for the company's products to enter the market and win users.Tel: 15838971872Brake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various brakes, brake pads, brake wheels, and brake discs, and customized non-standard brakes according to user needsTel: 15838971872Various arm disc brakes, various electromagnetic, hydraulic and pneumatic caliper disc brakesVarious electromagnetic block type stop washers, hydraulic brakes, pneumatic, drum brakes,Various windproof iron wedges, hydraulic wheel edges, hydraulic top rail brakes. And we can design and manufacture various non-standard products according to user requirements, which are widely used in lifting, mining, mechanical metallurgy, electricity, railways, water conservancy, ports, chemical engineering, and docks.Our factory has obtained the special equipment type test certificate issued by the National Lifting Machinery Quality Supervision and Inspection Center. It was rated as a contract abiding and credit worthy enterprise in Henan Province and a contract abiding and credit worthy enterprise in Jiaozuo City.

time:2022-04-16

More

YLBZ25-160 wheel brake padYLBZ25-160, YLBZ40-150, YLBZ40-160, YLBZ40-180, YLBZ63-200Wheel brake padsYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesYLBZ series wheel edge brakeDP series motor disc brakeCustomized various brake wheels and discs, and customized non-standard brakes according to user needs

time:2022-04-16

More