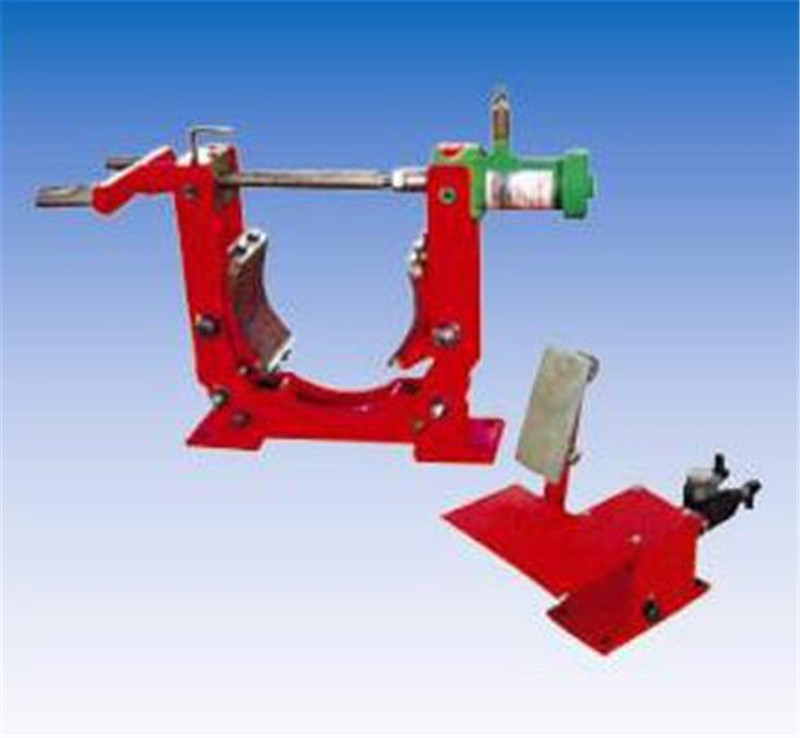

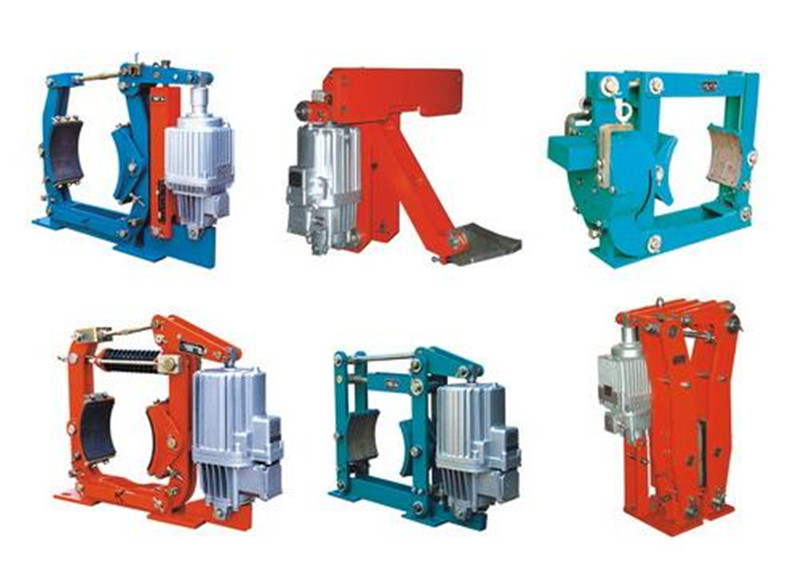

Winch mechanism actuator brake bracketThe winch mechanism actuator is a hydraulically operated normally closed brake that can be widely used in lifting and transportation machinery to stop the lifting speed of objects and absorb the inertia of motion or rotary mechanism motion massThe brake mainly consists of a vertical plate frame, a brake shoe, an adjustment rod, a spring, and a base. The brake shoe is connected to the vertical plate frame, and the vertical plate frame is connected to the base by a shaft pin. The supporting side can be equipped with an electromagnet, and the main spring is installed above the vertical plate frame. The top of the adjustment rod is similar to the stopping gear of the electromagnet. In order to increase the friction coefficient between the brake shoe and the surface of the brake wheel, a replaceable asbestos brake band is installed on the brake shoeWhen the operated electromagnet of the winch mechanism is powered off, the brake compresses the spring to maintain the braking state. When the electromagnet is energized and closed, it releases the brake, allowing the mechanism to operate. When the winch mechanism brake is used, sometimes there are situations where the brake is adjusted tightly to hold the rated load brake, but the brake wheel will soon produce smoke from the brake belt, making the motor rotation appear difficult and the sound dull; Although the brake wheels are not heating up and the motor rotates properly, they cannot hold the net, even under light loads. The situation where the winch mechanism actuator is "too loose to hold or too tight to open" often occurs in crane operators after maintenance. The main reason is that: (1) the relative error between the sleeve center of the brake wheel and the center of the brake pad is too large (not allowed to exceed 3mm). This is because there was an error in the installation of the gearbox after maintenance, which caused the position of the brake wheel to be changed, resulting in a case where the brake shoe could not be opened due to one side breaking through the shoe. When the brake wheel is aligned at the center of two brake shoes, this fault can be eliminated. (2) The centerline of the brake shoe and brake wheel is tilted. When the installation position of the reducer and the sliding lever system (brake frame) of the winch mechanism actuator is incorrect, it can cause partial contact between the brake shoe and the brake wheel, causing the closed shoe to not hold the brake wheel tightly. In this case, if the brake shoes are tightened slightly, there will be a phenomenon where the brake shoes cannot be completely released from the brake wheels, and the winch mechanism actuator will cause high heat to be generated by friction on the brake wheels. When the brake shoe is released, the inclination or unevenness between the brake shoe and the brake wheel shall not exceed one thousandth of the width of the brake wheel. (3) Due to severe wear and tear on the various pin shafts and shaft holes of the brake, the ineffective stroke (empty stroke) for adjusting the electromagnet is increased, while the effective stroke is reduced. (4) After the brake wheel is worn, it causes errors during reprocessing. (5) Due to improper adjustment of the winch, the brake solenoid stroke is too small. This situation often occurs when only adjusting the pull rod without adjusting the upright rod. (6) The processing size of the newly replaced adjustment rod is incorrectElectric hydraulic brakeYWZB YWZ3B YWZ4B YWZ5 YWZ8 YWZ9 YWZ12 YWZ13 YW YWL TYWZ2 YWPElectromagnetic block brakeJZ (TJ2A) MW (Z) ZWZAZWZ2 ZWZ3ADCW3Electromagnetic failure protection disc brake5SE 561SE 560SE 56SEDCPZ12.7 4SE 3SE ST1SE ST2SE 450SEHydraulic failure protection disc brake5SH 4SH 3SH 450SH ST1SH ST2SH ST3SH ST4SHSB (YQP) SBDST5SH ST10SHST16SHST25SHST25SH-AST40SH904SHSBBElectro hydraulic arm disc brakeYPZ2 I, II, IIIYPZ2 IV, V, VIElectric hydraulic thrusterYT1 EdExplosion proof electric hydraulic thrusterBYT1 BEDZ-Z9 series brake

time:2021-05-02

More

Manufacturer of hydraulic brake for port craneHydraulic brakes, as the name suggests, play a role in speed control and braking in various devices that use them. The concept of control should be fully reflected in the brakes. All movements, planned goals, must find results on the brakes. There are many manufacturers producing brakes, and according to the different functions of the site, many series of brakes have also been derived. With the promotion of design and technology personnel, they are gradually improving and progressing. The following will gradually introduce the history and evolution of each series of brakes, as well as the new models and functional features.Main characteristics of hydraulic brakes for lifting cranes1. The automatic tile following device and interlocking backhaul equalization device (patented technology) can always maintain equal backhaul of both sides of the tiles without adjustment, completely avoiding the phenomenon of one brake pad floating against the brake wheel due to uneven backhaul2. Its main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and long service life, so there is no need for lubrication during use.3. The brake springs arranged in the square tube are all equipped with scales, so users can easily read the braking torque value, which can reduce the trouble of measurement and calculation.4. The brake pad is a card mounted integral shaped structure, which is very convenient and fast to replace. It is also equipped with different materials such as semi metal (non asbestos) hard and semi hard, soft (including asbestos, non asbestos) brake pads for users to freely choose from.5. This new type of armature follower device can always maintain a good fit between the armature and the magnetic yoke. The disc brake will gradually replace the drum brake, mainly due to the advantages and disadvantages of the disc brake and drum brake. The disc brake has a large and stable braking force under the hydraulic assistance. The hydraulic brake of the crane has good braking performance on various roads. Its braking efficiency is far higher than that of the drum brake. Moreover, the air directly passes through the Disc brake disc, so the heat dissipation of the disc brake is very good. However, compared with the drum brake, the structure of the disc brake is more complex, with higher requirements for the brake caliper and Plumbing, and its cost is higher than that of the drum brake. Compared with the disk brake, the brake efficiency and heat dissipation of the drum brake are much worse. The stability of the brake force of the drum brake is poor. The brake force varies greatly on different roads, and it is not easy to control. Moreover, due to poor heat dissipation, drum brakes exhibit thermal decay. Of course, drum brakes are not entirely useless. Their major applications are in the manufacturing of CNC machine tools, as stepper motors do not require conversion and can directly convert digital pulse signals into angular displacement. Therefore, they are considered ideal actuators for CNC machine tools. The output torque of early stepper motors was relatively small and could not meet the needs. In use, a hydraulic pulse motor was formed together with a hydraulic torque amplifier. With the development of stepper motor technology, the hydraulic brake of lifting cranes has become an irreplaceable executive component that can be used alone in the system. For example, the stepping motor is used as the drive motor of the CNC milling machine feed Servomechanism. In this application, the hydraulic brake stepping motor of the crane can complete two tasks at the same time, one is to transmit torque, the other is to transmit information. The stepper motor can also be used as the driving motor for the synchronous system of the CNC worm wheel grinding machine. The brake is a type of brake applied to the traveling crane (i.e. lifting equipment). When it is necessary to stop working, the equipment is subjected to certain resistance to stop mechanical operation. Its use is directly related to the safety of personnel and equipment, so personnel working on the use of service brakes must have a detailed understanding.The hydraulic brake and service brake of a crane are equivalent to the brake pads on a car. When the car needs to stop, the brake pads fail, causing the car to fly out and collide with pedestrians, resulting in a traffic accident. The same applies to the use of the traveling crane. When it is necessary to stop, the brake needs to be activated to stop the traveling crane. Proper use of brakes during driving is not only beneficial for ensuring driving safety, but also for saving fuel, reducing tire wear, and preventing damage to machinery componentsZ-Z9 series brake

time:2021-05-02

More

The difference between energized electromagnetic brake and deenergized electromagnetic brakeThe electromagnetic brake is divided into two types: energized electromagnetic brake and deenergized electromagnetic brake (electromagnetic deenergized brake or non excitation action brake). The energized electromagnetic brake must be powered on before it can operate, while the deenergized electromagnetic brake brakes after being powered off. Both use DC24V direct current. Many customers are not aware of the differences between them. Here, Hangzhou Mingte Transmission will introduce the differences between them.The working principle of an electrified electromagnetic brake is: when the magnetic coil is used, the electromagnetic force attracts the brake pad, and the brake disc is released using the brake pad. At this time, the transmission shaft runs or starts normally with the brake disc. When the current of the electromagnetic brake is cut off, the brake pad will disengage from the brake disc, Friction torque will be produced between the brake disc and the brake pad and flange, and the transmission shaft will be used to stop quickly.The working principle of a power off electromagnetic brake is: its structure is to use coil springs to press the brake pads, and use its friction force to generate braking torque. When the excitation coil is energized, the armature that presses against the brake pad compresses the coil coil, which is attracted by the excitation iron core, and the brake is in a released state. If the excitation current is cut off, the spring pressure of the coil spring will cause the armature to press against the brake pad, and the brake will act.The purpose, application fields, and characteristics of the powered electromagnetic brake and the powered electromagnetic brake are relatively similar, with small size, easy and simple installation, fast response speed, no no-load torque, environmental protection, and no noise. They are widely used in various mechanical rotation systems for starting, cutting, inching, positioning, variable speed, reversing, and other functionsElectromagnetic block brake:ZWZA-400; ZWZA-500; ZWZA-600; ZWZA-700; ZWZA-800;ZWZ2 series DC electromagnetic block brake:ZWZ2-160/100; ZWZ2-160/200; ZWZ2-200/100; ZWZ2-200/200; ZWZ2-200/300; ZWZ2-250/200; ZWZ2-250/300; ZWZ2-315/200; ZWZ2-315/300ZWZ3A series DC electromagnetic block brake:ZWZ3A-400/400; ZWZ3A-400/500; ZWZ3A-500/400; ZWZ3A-500/500; ZWZ3A-500/600; ZWZ3A-630/500; ZWZ3A-630/600; ZWZ3A-630/700; ZWZ3A-710/600; ZWZ3A-710/700; ZWZ3A-710/800; ZWZ3A-800/700; ZWZ3A-800/800TJ2 series AC electromagnetic block brake:TJ2-100/100; TJ2-200/100; TJ2-200/200; TJ2-300/200; TJ2-300/300JZ series energy-saving electromagnetic block brake:JZ-100; JZ-200; JZ-300; JZ-400; JZ-500; JZ-600MW series energy-saving AC electromagnetic block brake:MW-100; MW-160; MW-200; MW-250; MW-315; MW-400; MW-500; MW-630; MW-710; MW-800MWZ series energy-saving DC electromagnetic block brake:MWZ-100; MWZ-160; MWZ-200; MWZ-250; MWZ-315; MWZ-400; MWZ-500; MWZ-630; MWZ-710; MWZ-800In order to ensure the uninterrupted operation of the electromagnetic brake, it is necessary to regularly maintain and maintain it:1. Frequently add lubricant to the movable part of the electromagnetic brake.2. Regularly check the length of the armature stroke. Because during the operation of the brake, the travel length of the armature will increase due to wear on the moving surface. When the length of the armature stroke cannot reach the normal value, adjustments must be made to restore the small gap between the brake surface and the rotary table. If the stroke length of the armature increases above the normal value, it may greatly reduce the suction force.TJ200 ordinary electromagnet

time:2021-05-02

More

The working principle of the electric hydraulic push rod brake is that this series of hydraulic push rod brakes consists of two parts: a brake frame and a matching yt1 electric hydraulic thruster. When powered on, the electric hydraulic thruster acts, and its push rod quickly rises, and the brake shoe is opened (released) through the action of a lever; When the power is cut off, the push rod of the electric hydraulic thruster rapidly descends under the action of spring force and closes the brake shoe (holding brake) through lever action. Installation and adjustment of the brake: Vertical installation: Loosen nuts 4 and 5 to make the main spring in a free state, loosen nuts 6 and 8, rotate screw 7 to open the brake arm, and then install the brake on the spring base of brake wheel joint 9- spring seat. 10- Horizontal installation of spring frame scale machine: When the brake wheel is already installed between the motor and other components, loosen nuts 4, 5, 6, 7, and 8, turn the screw to remove screws 3 and 7, and lower the brake arm. Install from the side south onto the brake wheel. The adjustment of the working stroke of the actuator ensures that the working stroke of the actuator is ideal as long as the brake shoe has a small backlash. Therefore, it is necessary to adjust its installation height h1. The adjustment method is to loosen nuts 6 and 8 (as shown in the figure), rotate screw 7, and ensure that the installation size of h1 meets the requirements of Table 1. After adjustment, tighten nuts 6 and 8. Loosen the nut 4 for adjusting the braking torque, clamp the square end of the screw, turn the nut 5 to make the square spring seat within the groove of the spring frame, and tighten the nuts 4 and 5 after adjustment. When the brake shoe is opened, adjust bolt 1 to ensure that the back distance on both sides is basically consistent. The nut for fixing the brake shoe (as shown in the figure) should be appropriately tightened in the exterior diagram of YWZ13, so that the brake shoe and brake wheel can be aligned. Regularly check the working condition of the brake during use and maintenance. During the inspection, the following items shall be emphasized: whether the components of the brake can move normally and whether the adjusting nuts are fastened. Whether the components of the thruster are normal and whether the hydraulic oil is sufficient. Is there any oil leakage or seepage. Check if the insulation of the incoming wires is good. The size h1 shall not be less than the small dimensions listed in Table 1. If it exceeds the requirements, it must be adjusted immediately, otherwise the braking effect will be lost. Check whether the brake shoe rests on the brake wheel normally, whether the friction surface is in good condition, and whether there is greasy dirt. When the thickness of the brake pad reaches the values in Table 2, the brake pad should be replaced. The temperature of the brake wheel should not exceed 200 ℃. If cracks are found on the lever and spring, they should be replaced. Chapter 2: Brake Manual (Reference) 1 Introduction 1.1 Project Background and Purpose The popularization of automobiles has been accompanied by an increase in energy consumption, and nowadays, automobiles have become an essential tool in people's daily lives. The electric hydraulic block brake consists of two parts: an electric hydraulic thruster and a block brake frame. It involves mechanical, Fluid mechanics, hydraulic, electromagnetic and other disciplines. Its working principle is to convert the electrical energy of the driving device into mechanical energy, and through the rotation of the impeller, the liquid flow in the cylinder forms a high and low pressure chamber to push the piston upward, thereby transforming the vertical movement into left and right swing of the brake arm through the lever mechanism, and completing the brake release. The main auxiliary function of the product is the automatic equalizing device for backtracking. The technical working principle is to rigidly connect the equidistant device to the brake arm, and maintain the automatic equalizing of backtracking on both sides when the brake arm is opened through the transmission pairs of the left and right connecting plates. The technical research results of this project carried out by our company are at the domestic advanced level, especially in the key technical indicators of temperature rise and rise Fall time. Under the background of energy-efficient efforts, the requirements for energy saving of cars are increasing. The emergence of Compact car just adapts to the development of the times. The displacement is only 2.0. Compared with other types of household cars, Compact car are obviously economical in terms of energy saving and other costs. In order to meet the requirements of the times, the graduation design of Compact car is proposed. It is required to complete the development and design of the braking system on the basis of mutual cooperation among the same group of personnel. The aim is to cultivate the practical work ability to comprehensively apply the learned and basic theoretical knowledge in product system development and design. On the basis of collecting and analyzing relevant data, it is required to reasonably determine the braking mode and system layout scheme of Compact car, design and calculate the strength and fatigue life of main parts, draw system assembly drawings and parts drawings, and prepare design calculation instructions. 1.2 Research status at home and abroad Since the birth of automobiles, vehicle braking systems have played a crucial role in vehicle safety.The electric hydraulic block brake project involves machinery, Fluid mechanics, hydraulics and other disciplines. The working principle of the YWZ9 electric hydraulic block brake is mainly to convert the electrical energy of the driving device into mechanical energy, and through the rotation of the impeller, the liquid flow in the cylinder forms a high and low pressure chamber to push the piston upward, thereby transforming the vertical movement into left and right swing of the brake arm through the lever mechanism, completing the brake release task. When the driving device is powered off, the mechanism amplifies and transmits the force to the brake shoe through the lever ratio under the action of spring force, completing the holding brake. The main auxiliary function of the product is the automatic equalizing device for backtracking. The technical action principle is to connect the equal backtracking device with the brake arm, and maintain the automatic equalizing of backtracking on both sides when the brake arm is opened through the rotation of the low pair of the left and right connecting plates.2、 Main features:Safe and reliable performance, smooth braking, and high action frequency.Equipped with an interlocking equal distance device, it maintains an equal distance between the two pads during use, avoiding the phenomenon of one brake pad floating against the brake wheel due to uneven distance.The main swing hinge point of the electric hydraulic block brake is equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use.The brake spring is arranged inside the spring tube and is equipped with a brake torque scale on one side, making adjustment convenient and intuitive.The asbestos free brake pad and brake pad adopt a plug-in type, which is safe and reliable, and easy and fast to replace.Additional devices can be added according to customer requirements, as shown in the Additional Function Table.Usage conditions: Environmental temperature: -20 ℃~50 ℃. The relative humidity of the air shall not exceed 90%. The surrounding working environment must not contain flammable, explosive, or corrosive gases. The altitude of the location of use complies with GB755-2000. Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.3、 Prospects for the Promotion and Application of Electric Hydraulic Block BrakesThe successful development of electric hydraulic block brakes has changed the situation where brake products in China do not have auxiliary performance, greatly improving the overall performance of the machine, reducing the labor intensity of manual installation, adjustment, and maintenance. It is an ideal replacement product for the domestic brake industry. In terms of replacing imports and exporting supporting hosts to earn foreign exchange, the demand for them is also increasing day by day, and the market prospects are broad.

time:2021-05-02

More

The electric motor of the electric hydraulic thruster is connected to the middle of the body with a cover. There is a piston with two push rods inside the body, and a blade wheel is connected to the rotating shaft. The rotating shaft is supported by a support plate equipped with rolling bearings, which is fastened to the piston and is sturdy with screws. The upper end of the body is connected to the crossbeam through the push rod, and the crossbeam is equipped with a connecting rod for connecting the pin shaft and the matching hydraulic push rod brake. The pin holes under the body are also used for connection. When energized, the main shaft of the electric motor drives the slide to rotate the shaft and the impeller on the shaft at high speed. Under the action of centrifugal force, the oil in the oil pipeline generates a pressure difference, which causes the oil to be sucked from the upper part of the piston to the lower part, forming high pressure at the lower part of the piston, forcing the piston and the push rod and crossbeam fixed on it to rise rapidly. When the piston rises to the top position, the lower part of the piston maintains a constant pressure. At the same time, mechanical motion is generated by compressing the load spring through a lever mechanism (if the thruster or brake has a load spring). (If matched with the YWZ series hydraulic push rod brake, release the brake) When the power is cut off, the impeller stops rotating, and the piston rapidly drops under the force of the load spring and its own gravity, forcing oil to flow back into the upper part of the piston. At this time, it still returns to its original position through the lever mechanism. (If matched with the YWZ series brake, hold the brake).YT1-18Z/2 YT125ZB/4 YT125ZC/4 YT1-45Z/4 YT1-45Z/5 YT1-45Z/6 YT1-90Z/6 YT1-90Z/8 YT1-125Z/10 YT1-180Z/8 YT1-180Z/10 YT1-180Z/12 YT1-320Z/12 (B) YT1-320Z/20 (A) YT1-320Z/35 YT1-350Z/12 YT1-350Z/20 YT1-350Z/354、 Instructions for use:1. Installation test: First, check whether the thrust on the nameplate of the electric hydraulic thruster product matches the required force: remove oil stains on the motor and body surface, and check whether the push rod lifting is smooth. Unscrew the oil filling plug 5 (Figure 3) and oil level plug 3, and inject suitable and pure hydraulic oil until the screw hole 3 is reached. Then tighten plug 3 and plug 5. According to different ambient medium temperatures, it is recommended to follow Table 6 for hydraulic oil. The temperature of the surrounding medium is+45 ℃~+21 ℃+20 ℃~+0 ℃+0 ℃~-15 ℃~-15 ℃~-30 ℃ - below 30 ℃. 20 # mechanical oil GB443-64, 10 # transformer oil (freezing point -10 ℃) SYB1351-62, 25 # transformer oil (freezing point -25 ℃) SYB1351-62, instrument oil (freezing point -60 ℃), GB487-65, a mixture of alcohol and glycerol. It is recommended to use oil to connect the lower part of the hydraulic thruster with a pin, and connect the connecting rod of the crossbeam with a lever device with a pin. After testing whether the external power supply matches the motor nameplate, correctly connect the motor terminal to the external power supply. Connect the power supply and check whether the impeller operates flexibly and whether the push rod lifts smoothly. 2. Use and maintenance: check whether the electric hydraulic thruster works normally and whether there is oil leakage or oil seepage. A constant amount of oil should be maintained. But note that the oil level cannot be higher than the oil level plug. If it is higher than the oil level plug, there may be oil leakage at the push rod, motor, and cylinder head. Check the oil at least every six months. When the oil deteriorates or mixes with impurities, the oil should be changed when the viscosity increases. If the oil selection is not appropriate, a separate selection should be made. Check if the motor wiring is in good condition and if the protective device is appropriate and reliable.Explosion proof electric hydraulic thruster BED-23/5, thrust 220N, stroke 50mmExplosion proof electric hydraulic thruster BED-30/5, thrust 300N, stroke 50mmExplosion proof electric hydraulic thruster BED-50/6, thrust 500N, stroke 60mmExplosion proof electric hydraulic thruster BED-80/6, thrust 800N, stroke 60mmExplosion proof electric hydraulic thruster BED-121/6, thrust 1250N, stroke 60mmElectric hydraulic thruster BED-201/6, thrust 2000N, stroke 60mmElectric hydraulic thruster BED-301/5, thrust 3000N, stroke 60mmOil for thrustersThe thruster has been equipped with hydraulic oil according to regulations when leaving the factory. If the thruster has been stored for a long time (more than 6 months), screw out the plug before use to check whether the oil level is normal. If the oil level does not reach the specified level, hydraulic oil should be added to the specified level (see Figure 1), otherwise the thruster cannot work properly. The hydraulic oil grade can be found in Table 2 (Mobil, Shell, and other hydraulic oils equivalent to the grade in the table can also be used), and the hydraulic oil filled must not contain impurities or dirt (it should be filtered). When adding hydraulic oil, the push rod should be slowly pulled up and down several times to remove air from the hydraulic cylinder and ensure sufficient oil is added.

time:2021-05-02

More

Hydraulic electromagnetic block brake: Using hydraulic electromagnetic blocks instead of long travel block brake electromagnets, there are two types: YWZ (hydraulic push rod) and YDWZ (hydraulic electromagnet). The YWZ type brake is stable, noiseless, and small in size, making it suitable for operating and rotating mechanisms. Due to its slow braking action, it is not suitable for the use of lifting mechanisms to prevent hook slipping. The YDWZ model has good performance in various aspects and does not require frequent adjustments. It only requires a DC power supply. The working principle of an electrified electromagnetic brake is: when the magnetic coil is used, the electromagnetic force attracts the brake pad, and the brake disc is released using the brake pad. At this time, the transmission shaft runs or starts normally with the brake disc. When the current of the electromagnetic brake is cut off, the brake pad will disengage from the brake disc, Friction torque will be produced between the brake disc, brake pad and flange plate, and the transmission shaft will stop quicklyThe structure of the power outage brake:It mainly consists of two parts: brake electromagnet and brake shoe brake.The brake electromagnet is composed of three parts: an iron core, an armature, and a coil. The brake shoe brake includes the brake wheel, brake shoe, and spring, etc. The brake wheel and the electric motor are installed on the same shaft.Working principle: When the electric motor is connected to the power supply, the electromagnetic brake coil is also energized, and the armature is attracted to overcome the tension of the spring to separate the brake shoe and brake wheel, resulting in normal operation of the electric motor. When the switch or contactor is disconnected, the motor loses power, and the electromagnetic brake coil also loses power. The armature separates from the iron core under the force of spring tension, causing the brake shoe of the brake to tightly hold the brake wheel, and the motor is stopped by braking.Characteristics of electromagnetic holding brake brakingMechanical braking mainly adopts electromagnetic brake and electromagnetic clutch braking, both of which use the electromagnetic coil to generate a magnetic field after being energized, causing the static iron core to generate enough suction to attract the armature or moving iron core (the moving iron core of the electromagnetic clutch is attracted, and the dynamic and static friction plates are separated), overcoming the tension of the spring and meeting the requirements of the work site. Electromagnetic brake relies on the friction plates of the brake shoe to brake the brake wheel. Electromagnetic clutch uses sufficient friction between the dynamic and static friction plates to immediately brake the motor after power failure.In 2004, it was awarded the title of High Quality Product in Henan Province. Obtained the National Industrial Product Production License in April 2008 (For explosion-proof electrical appliances, Jiaozuo Hydraulic Brake Factory, brake manufacturer, crane brake, thruster brake, YT1 thruster, explosion-proof brake, wind brake, electromagnetic brake mainly produces YWZB, YWZ2, YWZ3, YWZ4, YWZ5, YWZ6, YWZ8, YWZ9, YWZ10, YWZ12, YWZ13 series electric hydraulic block brake. All kinds of explosion-proof brakes, TJ2 series new energy-saving electromagnetic brake, JZ electromagnetic brake, ZWZ electric brake Magnetic brake, ZWZ3 electromagnetic brake, ZWZA electromagnetic brake, MW electromagnetic brake, MWZ electromagnetic brake, ZWZ electromagnetic brake coil, ZWZ3 electromagnetic brake coil, ZWZA electromagnetic brake coil, MW electromagnetic brake coil, YPZ2 electric hydraulic arm disk brake, QP pneumatic caliper disk brake, DCPZ electromagnetic caliper disk brake, SB hydraulic caliper disk brake, YQP hydraulic caliper disk brake, SBD hydraulic disk brake, SBD-A safety brake, SBD-B disc brakeDue to the electromagnetic attraction of the short stroke electromagnetic block brake electromagnet, the braking torque of the short stroke brake is generally not high. Mechanisms that require high braking torque often use long stroke electromagnetic block brakes.The long stroke electromagnetic block brake relies on the main spring to apply and the electromagnet to release.The commonly used long stroke electromagnetic block brake is the JCZ type 200-600 brake. It is mostly used on Overhead crane of 20-30 tons or more.The advantage of electromagnetic block brakes is that they have a simple structure and can be interlocked with the control circuit of the motor. Therefore, when the motor stops working or an accident power outage occurs, the electromagnet can automatically power off and the brake will automatically switch on, ensuring safe and reliable operation. However, there is a major drawback that the electromagnet has a strong impact, causing severe braking on the mechanism and causing mechanical vibration of the transmission mechanism. At the same time, due to frequent starting and braking of the lifting mechanism, the electromagnet produces a huge collision sound, and the service life of the electromagnet is short, requiring frequent repair and replacement.Many friends who know about cranes know that cranes are composed of electric motors, brakes, reducers, drums, and pulley blocks, which together form the purpose of cranes.Various electromagnetic diagrams such as JZ

time:2021-05-02

More

Explosion proof electric hydraulic thruster, explosion-proof hydraulic thruster quotation, explosion-proof thruster manufacturer, Henan explosion-proof thruster manufacturer BEd series explosion-proof electric hydraulic thruster (hereinafter referred to as "thruster") is mainly used to operate electric hydraulic drum brake and pump, ratchet, valve, etc., and can also operate various forms of lever devices to make various movements, such as reciprocating, swinging, Circular motion, etc, This product complies with the technical requirements of the enterprise standard Q/JZHF01-2009 explosion-proof electric hydraulic thruster. The explosion-proof sign is "Exd I" and is suitable for electric hydraulic drum brakes used in coal mine belt conveyors (non mining working faces) and mine lifting equipment. The thruster is an ideal component for achieving semi automation and automation of certain mechanical equipment. The piston rod adopts advanced protection, which can reduce wear and corrosion. The oil chamber of the hydraulic system with double-layer protective seal and double-layer sealing ring greatly improves the service life of the thruster. The thruster has the advantages of stable and noise free operation, low power consumption, long service life, and convenient maintenance. 2. Working conditions 2.1, altitude not exceeding 2000m. 2.2. The ambient temperature is -20 ℃ to 40 ℃. 2.3. The power supply is a three-phase AC power supply, with a rated frequency of 50Hz and a rated voltage of 380V/660V. The allowable voltage fluctuation is+10% to -25% 2.4. The motor working system is S1 continuous working system or S3 intermittent cycle working system, and the load duration during intermittent cycle working system is not more than 60%. 2.5. It is allowed to operate in environments with explosive gas mixtures of gas and coal dust. The working conditions should comply with the provisions of the "Coal Mine Safety Regulations" (2006). 2.6. The thruster motor is F grade insulation 2.7, the relative humidity of the surrounding air is not more than 95% 2.8, and the pollution level of the surrounding environment is allowed to be level 3. modelratedthrustNratedstrokeMmpowerWoperationfrequencyC/hrisetime(max)Sdeclinetime(max)SBEd30/5three hundredfiftytwo hundrednine hundredzero point fourzero point fourBYWZ5 explosion-proof brakeBEd50/6five hundredsixtytwo hundred and tennine hundredzero point six zerozero point six zeroBEd80/6eight hundredsixtythree hundrednine hundredzero point six zerozero point five zeroBEd121/6one thousand two hundred and fiftysixtythree hundred and thirtynine hundredzero point six zerozero point six zero301 explosion-proof standard actual drawing newBEd201/6two thousandsixtyfour hundred and fiftynine hundredzero point six zerozero point five zeroBEd301/6three thousandsixtyfive hundrednine hundredzero point eight zerozero point five zeroBED301/12three thousandone hundred and twentyfive hundrednine hundredonezero point six zero6. Installation adjustment and usage requirements6.1. Before installation, the following inspections must be carried out. If they do not meet the requirements, they are not allowed to be used.6.1.1 The thrust on the thruster nameplate should match the required thrust. BED explosion-proof electric hydraulic thruster6.1.2 There are explosion-proof signs and explosion-proof certificate numbers. The BED-30/5 explosion-proof electric hydraulic thruster used underground should have a "MA" markBYT1 explosion-proof electric hydraulic thruster model:BYT1-18ZB/2 BYT1-25ZB/4BYT1-25ZC/4 BYT1-45Z/4BYT1-45Z/5 BYT1-45Z/6BYT1-90Z/6 BYT1-90Z/8BYT1-125Z/10 BYT1-180Z/8BYT1-180Z/10 BYT1-180Z/12BYT1-320Z/12 BYT1-320Z/20BYT1-25/4 BYT1-45/6BYT1-90/8 BYT1-125/10BYT1-180/121. SafetyThe Controllability operation of static silent breaking rod under the static hydraulic environment will not produce some hidden dangers like blasting, other impact demolition and rock drilling equipment; No need to take complex security measures.2. Environmental friendlinessOur static silent crushing rod does not produce vibrations, impacts, noise, dust, flying debris, etc. when working. The surrounding environment will not be affected, and even in densely populated areas or indoors, as well as near precision equipment, it can work without interference.3. EconomyThe static silent crushing rod can complete the splitting process in 2-5 minutes and can work continuously without interruption (even in rainy days and other harsh weather), with high efficiency, low operation and maintenance costs, and no need for isolation or other time-consuming and expensive approval measures like blasting operations.4. AccuracyUnlike most traditional demolition methods and equipment, static silent crushing rods can accurately determine the splitting direction, shape, and precision in advance.5. ApplicabilityThe humanized appearance design and durable structural design of the static silent crushing rod ensure that its use method is simple and easy to learn, requiring only two people to operate, convenient maintenance, and long service life; The handling of static silent crushing rods and hydraulic pump stations is also quite convenient.Our company's main sales channels include Shanghai, Zhejiang, Jiangsu, Anhui, Inner Mongolia, Xinjiang, Chongqing, Yunnan, Shaanxi, Hebei, Henan, Hubei, Hunan, Jiangxi, Sichuan, Guangdong, Guangxi, Hong Kong, Jilin, Heilongjiang, Liaoning, Ningxia, Gansu, Shaanxi, Shandong, Fujian, Hainan, and other cities. Over the years, we have established long-term cooperative relationships with hundreds of customers with our excellent quality and reputation. Pre sales service 1. Provide technical consultation: We will provide you with any technical and price inquiries according to your needs within 10 hours, and mail relevant samples and product information, or promptly respond to any questions you are concerned about. 2、 Provide inspection reception: We welcome you to visit the company's on-site inspection anytime and anywhere, and provide you with any convenient conditions. In sales service 1. Whether you are a foreign or domestic customer, whether you are our old customer or our new friend, whether your contract amount is large or small, we will treat you with integrity, fairness, enthusiasm, and rigor; 2、 We guarantee to strictly implement the terms and conditions stipulated in the contract on time, with high quality and quantity, and provide customers with value-added services. We have established a global after-sales service information processing system to track customers 24 hours a day. 1、 Provide various technical training from the date of purchase. 2、 Logistics: SF Express, Yuantong Express, Tiantian Express, and national highway railway combined transportation. Destination: Major cities or transit or major ports in China. Freight description Logistics: SF Express, Shentong Express, Yuantong Express, Zhongtong Express, Tiantian Express, and national road rail intermodal transportation

time:2021-05-01

More

Electromagnetic brake is an important component of mechanical manufacturing in terms of physics, playing a crucial role in the overall engineering. Electromagnetic brakes are mainly used for mechanical packaging in the mechanical industry, which has brought many conveniences to the construction industry and greatly changed people's lives. But in order for the work to proceed smoothly, we still need to know many questions.The method to accelerate the operation of electromagnetic clutch is to add a lot of lubricant to many parts and adjust its normal value, and also increase its suction force, which can accelerate its operation speed. Ensure the normal progress of work, so that we can gain more benefits.Electromagnetic brakes are used for mechanical packaging or packaging, for example, if a manufacturer only produces products and is not very proficient in packaging, then we can start working with electromagnetic brakes to complete this arduous and glorious task. A new type of electromagnetic brake. Compared with the old brake, it greatly reduces the consumption of coils and enameled wires, thereby reducing costs. It has also made improvements in structure and technology, and is currently used in YJ200 traction machines and gradually promoted in other models.The structure of the new electromagnetic brake is shown in Figure 1, with the fixed iron core and coil in a symmetrical structure. Two top rods are used to open the brake arms on both sides. The power supply voltage for the brake is 110V DC, and when the power is cut off, the traction machine is in the braking state; When powered on, the stationary iron cores on the left and right sides are simultaneously engaged, and the braking mechanism of the traction machine is opened through two top rods. The traction machine is in working condition. The stationary iron core is made of industrial pure iron or low-carbon steel, and the brake housing material is cast aluminum ZL106, effectively solving the problem of residual magnetism caused by the old brake base, ensuring that the brake time lag is within a reasonable range, and reducing the cost by about 30%. It is mainly matched with series motors. The brake for electromagnetic effect braking can be divided into electromagnetic powder brake, electromagnetic eddy current brake, electromagnetic friction brake and other forms① Electromagnetic powder brake: When the excitation coil is energized, a magnetic field is formed, and the magnetic powder is magnetized under the action of the magnetic field, forming a magnetic powder chain, which aggregates between the fixed magnetic conductor and the rotor. Braking is achieved by the binding force and friction force of the magnetic powder. When the excitation current disappears, the magnetic powder is in a free and loose state, and the braking effect is relieved. This type of brake has small volume, light weight, low excitation power, and the braking torque is independent of the rotational speed of the rotating parts. However, magnetic particles can cause component wear. It is convenient for automatic control and suitable for driving systems of various machines. It is widely used in metallurgy, construction, chemical, food, machine tools, stages, elevators, ships, packaging and other machinery, as well as in situations such as braking in case of power outage (risk prevention).The resistance torque that must be applied to stop or decelerate the mechanical operating components is called the braking torque. The braking torque is the basis for designing and selecting brakes, and its size is determined by the mechanical type and working requirements. The performance of the friction materials (brake components) used on the brake directly affects the braking process, and the main factors affecting its performance are the working temperature and temperature rise rate. Friction materials should have high and stable friction coefficients and good wear resistance. Friction materials are divided into two categories: metallic and non-metallic. The former commonly used include cast iron, steel, bronze, and powder metallurgy friction materials, while the latter includes leather, rubber, wood, and asbestosIn order to ensure the uninterrupted operation of the electromagnetic brake, it is necessary to regularly maintain and maintain it:1. Frequently add lubricant to the movable part of the electromagnetic brake.2. Regularly check the length of the armature stroke. Because during the operation of the brake, the travel length of the armature will increase due to wear on the moving surface. When the length of the armature stroke cannot reach the normal value, adjustments must be made to restore the small gap between the brake surface and the rotary table. If the stroke length of the armature increases above the normal value, it may greatly reduce the suction force.3. If the worn brake surface is replaced, the small gap between the brake surface and the rotary table should be adjusted appropriately.4. Regularly check the tightness of the bolts, especially tightening the bolts of the electromagnet, the bolts of the electromagnet and the shell, the bolts of the magnetic yoke, the bolts of the electromagnet coil, and the wiring bolts.5. Regularly inspect the mechanical wear of movable components and remove dust, burrs, and dirt from the surface of electromagnetic components

time:2021-05-01

More

Electromagnetic brake is an important component of mechanical manufacturing in terms of physics, playing a crucial role in the overall engineering. Electromagnetic brakes are mainly used for mechanical packaging in the mechanical industry, which has brought many conveniences to the construction industry and greatly changed people's lives. But in order for the work to proceed smoothly, we still need to know many questions.The method to accelerate the operation of electromagnetic clutch is to add a lot of lubricant to many parts and adjust its normal value, and also increase its suction force, which can accelerate its operation speed. Ensure the normal progress of work, so that we can gain more benefits.Electromagnetic brakes are used for mechanical packaging or packaging, for example, if a manufacturer only produces products and is not very proficient in packaging, then we can start working with electromagnetic brakes to complete this arduous and glorious task. A new type of electromagnetic brake. Compared with the old brake, it greatly reduces the consumption of coils and enameled wires, thereby reducing costs. It has also made improvements in structure and technology, and is currently used in YJ200 traction machines and gradually promoted in other models.The structure of the new electromagnetic brake is shown in Figure 1, with the fixed iron core and coil in a symmetrical structure. Two top rods are used to open the brake arms on both sides. The power supply voltage for the brake is 110V DC, and when the power is cut off, the traction machine is in the braking state; When powered on, the stationary iron cores on the left and right sides are simultaneously engaged, and the braking mechanism of the traction machine is opened through two top rods. The traction machine is in working condition. The stationary iron core is made of industrial pure iron or low-carbon steel, and the brake housing material is cast aluminum ZL106, effectively solving the problem of residual magnetism caused by the old brake base, ensuring that the brake time lag is within a reasonable range, and reducing the cost by about 30%. It is mainly matched with series motors. The brake for electromagnetic effect braking can be divided into electromagnetic powder brake, electromagnetic eddy current brake, electromagnetic friction brake and other forms① Electromagnetic powder brake: When the excitation coil is energized, a magnetic field is formed, and the magnetic powder is magnetized under the action of the magnetic field, forming a magnetic powder chain, which aggregates between the fixed magnetic conductor and the rotor. Braking is achieved by the binding force and friction force of the magnetic powder. When the excitation current disappears, the magnetic powder is in a free and loose state, and the braking effect is relieved. This type of brake has small volume, light weight, low excitation power, and the braking torque is independent of the rotational speed of the rotating parts. However, magnetic particles can cause component wear. It is convenient for automatic control and suitable for driving systems of various machines. It is widely used in metallurgy, construction, chemical, food, machine tools, stages, elevators, ships, packaging and other machinery, as well as in situations such as braking in case of power outage (risk prevention).The resistance torque that must be applied to stop or decelerate the mechanical operating components is called the braking torque. The braking torque is the basis for designing and selecting brakes, and its size is determined by the mechanical type and working requirements. The performance of the friction materials (brake components) used on the brake directly affects the braking process, and the main factors affecting its performance are the working temperature and temperature rise rate. Friction materials should have high and stable friction coefficients and good wear resistance. Friction materials are divided into two categories: metallic and non-metallic. The former commonly used include cast iron, steel, bronze, and powder metallurgy friction materials, while the latter includes leather, rubber, wood, and asbestosIn order to ensure the uninterrupted operation of the electromagnetic brake, it is necessary to regularly maintain and maintain it:1. Frequently add lubricant to the movable part of the electromagnetic brake.2. Regularly check the length of the armature stroke. Because during the operation of the brake, the travel length of the armature will increase due to wear on the moving surface. When the length of the armature stroke cannot reach the normal value, adjustments must be made to restore the small gap between the brake surface and the rotary table. If the stroke length of the armature increases above the normal value, it may greatly reduce the suction force.3. If the worn brake surface is replaced, the small gap between the brake surface and the rotary table should be adjusted appropriately.4. Regularly check the tightness of the bolts, especially tightening the bolts of the electromagnet, the bolts of the electromagnet and the shell, the bolts of the magnetic yoke, the bolts of the electromagnet coil, and the wiring bolts.5. Regularly inspect the mechanical wear of movable components and remove dust, burrs, and dirt from the surface of electromagnetic components

time:2021-05-01

More

Henan Jiaozuo Brake FactoryOur company is a member unit of the Transmission Parts Industry Association and the Construction Machinery Industry Association; Continuously obtained the "Quality Certification" certificate issued by the National Center for Quality Supervision, Inspection and Testing of Lifting and Transportation Machinery Products from 1999 to 2003; In October 2002, it passed the ISO: 9000 and GB/T19001-2000 Quality Management Systems certification by the China Fangyuan Certification Committee; Obtained the "Special Equipment Type Test Certificate" and the title of Henan Provincial Excellent in 2004; Obtained the ED series explosion-proof certificate and mining product safety label certificate in 2006; Obtained the YT1 series explosion-proof certificate and mining product safety label certificate in 2007; In 2008, it was the first in the industry to obtain a production license for explosion-proof products. In 2011, the company's product trademark was awarded the Henan Province Famous Brand Trademark. Advanced technology, equipment, strong technical force, perfect testing methods, strict quality assurance system, reasonable product prices, and reputation are the strong guarantees for our products to enter the market and win users. Our company is willing to provide you with high-quality products and services. Hydraulic disc brake YQP series: YQP50 YQP100 YQP160 YQP250 YQP315 YQP400 YQP3652. SB series: SB50 SB100 SB160 SB250 SB3653. YPZ series: YPZ2-I YPZ2-II YPZ2-III YPZ2-IV YPZ2-V YPZ2-VI P2-III4. QP series: QP12.7 QPL12.7-A QP25.4 QP30 QP405. YP series: YP1 YP2 YP3 YP11 YP21 YP31 YP416. Yaw series: (0.8 MW, 1.5 MW, 2 MW) DADH75 DADH80 DADH90 DADH103 DADH120 DADH1957. ADP series: ADP (H) 60 ADP (H) 90 ADP (H) 1208. SE series: 3SE (P) 4SE (P) 5SE (P) 450SE 56SE9. ST series: ST1SH ST2SH ST3SH ST4SH ST5SH ST10SH ST25SH ST25SH-A ST40SH ST3SH-AWe mainly produce YWZ1, YWZ2, YWZ3, YWZ4, YWZ5, YWZ8, YWZ9, YWZ10, YWZ12, and YWZ13 series electric hydraulic brakes. Various explosion-proof brakes and TJ2 series of new energy-saving electromagnetic brakes, with complete product specifications, reliable performance, and superior quality. It sells well all over the country and is highly praised by users.1. Implement the GB/T19001ISO9000 series standards, improve and improve the quality management system, and ensure timely provision of safe and reliable products according to national and industry standards to users;2. Strictly implement the "Three Guarantees" policy. During the "Three Guarantees" period, any product quality issues are guaranteed to be repaired, replaced, or returned. Beyond the "three guarantees" period, ensure the provision of maintenance accessories and provide good service work;3. Upon receiving notification from the user regarding product quality issues, a response shall be given within 24 hours. If on-site problem-solving is required, technical service personnel shall be dispatched within 48 hours to ensure that the issues are not resolved and service work is not stopped;4. According to user requirements, serve as a good advisor, assist in selection, and proactively provide pre-sales and after-sales service.

time:2021-04-28

More

Brake pad lining is a part of brake friction materials and a key safety component in the automotive industry. The starting, braking, and parking of automobiles rely on friction materials, and the quality and quality of friction materials directly affect the safety of life and property; With the development of the automotive industry and changes in road conditions, the speed of automobiles is also increasing, and the sensitivity requirements for automotive braking are becoming higher. The withdrawal of asbestos based friction materials provides the possibility for the application of more new materials in automotive friction materials. The use of new materials not only requires ensuring the effectiveness and sensitivity of braking, but also puts forward higher requirements for the stability of brakes during service, The stability of new materials and the safety of brakes are the development direction of brake lining and the preparation method of disc brake lining.In order to achieve the above purpose, the technical scheme adopted by the invention is: the provided disc brake lining comprises the following raw materials by weight: steel fiber: 5-10 parts, Barium sulfate: 15-30 parts, copper powder: 10-20 parts, modified cashew nut shell oil: 10-20 parts, aramid fiber: 2-5 parts; Alumina: 2-5 parts; Zircon: 2-5 parts; Graphite: 0-5 parts, mica: 1-3 parts. People have put forward higher requirements for improving the performance of automotive components, extending their service life, and improving their economy. The failure of many components is caused by the inability of the material surface to withstand harsh service conditions, such as wear resistance, corrosion, and surface oxidation.With the rapid development of science and technology, people's requirements for the use of brake components are becoming increasingly high. China's research and development of brake pads is later than that of foreign countries, and there is still a significant gap compared to developed countries in the world. In order to promote the rapid development of domestic brake pads in a timely manner and significantly improve the comprehensive performance of brake pads, brake pads often generate heat, wear, corrosion, and other phenomena during long-term braking, leading to brake failure and serious consequences such as accidents, Therefore, it is an urgent technical problem to improve the performance of the brake pads. Disc brakes. Brake pads. Hydraulic disc brakes. Brake pads. Disc brakes. Hydraulic disc brakes. Brake pads. Arm disc brakes. Caliper disc brakes. Pneumatic disc brakes. Automotive disc brakes. Jiaozuo disc brakes. Disc brake assemblies. Disc brakes. Motorcycle disc brakes. Pneumatic caliper disc brakes Industrial brake brake pad hydraulic arm disc brake hydraulic caliper disc brake electromagnetic caliper disc brake, brake machinery has always adhered to the "integrity," business philosophy, adhere to the user, quality, and served a number of customers. The company provides you with brakes with rich experience in distribution and wholesale; Hydraulic brake; Disc brake; Electromagnetic brake; Explosion proof brake; Motor; Ordinary friction discs; High wear-resistant friction plate; Replace imported high wear-resistant friction discs; Distribution and wholesale of various brake parts.Widely used in lifting, metallurgy, mining, ports Main products in construction and other machinery include: electric hydraulic block brake series YWZB YWZ3B YWZ4B YWZ5 YWZ8 YWZ9 YWZ12 YWZ13 YW YWL TYWZ2 YWP electromagnetic block brake JZ (TJ2A) MW (Z) ZWZA ZWZ2 ZWZ3A DCW3 electromagnetic failure protection disc brake 5SE 561SE 560SE 56SE DCPZ12.7 4SE 3SE ST1SE ST2SE 450SE hydraulic failure protection disc brake 5SH 4SH 3SH 450SH ST1SH ST2SH SH ST3SH ST4SH SB (YQP) SBDST5SH ST10SH ST16SH ST25SH ST25SH-A ST40SH 904SH SBB electric hydraulic arm disk brake YPZ2 Ⅰ, Ⅱ, Ⅲ YPZ2 Ⅳ, Ⅴ, Ⅵ pneumatic caliper disk brake QP12.7 5SP 4SP 3SP 450SP PD ADP60M-ADP61M-ADP62M hydraulic direct acting disk brake DADH75 ADH60 ADH90 ADH120 DADH80 DADH90 DADH120 DADH103 DADH195 electric hydraulic thruster YT1 Ed explosion-proof electric hydraulic thruster BYT1 BED

time:2021-04-28

More

The repair of the SBD safety brake hydraulic cylinder body (cylinder barrel) requires inspection of the size and tolerance of the hydraulic cylinder hole after disassembly (usually H8 or H9, H7 for piston ring sealing, and H6 for gap sealing). The surface roughness of the inner hole (Ra0.8-0.2). The geometric accuracy of the cylinder hole (reference value is that the roundness and cylindricity error should be less than 1/2-1/3 of the diameter size difference). The straightness error of the cylinder hole axis (should not be greater than 0.03mm for a length of 500mm), and the verticality error of the cylinder end facing the axis (should not be greater than 0.04mm for a diameter of 100m).Check the axis of the hole in the SBD safety brake hydraulic cylinder, the position error (reference value is 0.03mm) and verticality error (not greater than 0.1mm on a length of 10mn) of the cylinder axis, and the position error and verticality error (not greater than 0.1mm on a length of 100mm) of the ST3SH safety brake hydraulic cylinder axis. When assembling the ST3SH safety brake hydraulic cylinder, be careful to prevent the sealing lip from being cut. The guide sleeve is inserted into the piston rod to prevent the sealing lip from being cut. After disassembling the hydraulic cylinder, the following key parts and important positions should be inspected to determine which parts can be reused and which need to be repaired before reuse, What should be replaced? If the brake clearance between the two brake pads of the disc brake is too large, loosen the fastening screw of the camshaft bracket, and adjust it using the following method. When rotating the support pin directly, use the brake shoe to jack the camshaft to make it reach the appropriate position. Step on the brake pedal, the cam opens, and use the reaction force of the brake shoe to make the camshaft reach the appropriate position.Adjust when braking for deviation. When the front wheel brake deviates, it can be adjusted by increasing the brake clearance on the other side of the deviation (or reducing the brake clearance on the deviation side). This can relatively increase the stroke of the push rod on the other side of the deviation, increase the effective area of the leather film, and increase the braking force, thereby eliminating the phenomenon of deviation. When increasing the braking clearance, it will cause a decrease in braking force. Therefore, this method can only be used when the effective area of the film increases the braking force, exceeding the decrease in braking force caused by the increase in braking clearance. Therefore, this method is not applicable when the difference between the brake clearances of the left and right disc brakes is too large. Measurement of brake pad thickness and brake clearance Brake clearance and brake shoe brake pad thickness are measured through the inspection hole on the disc brake. When checking the brake clearance, support the axle and suspend the wheels. Use a feeler gauge to measure the clearance between the brake shoes and the brake drum.SBD series safety brakes are produced in Jiaozuo, producing SBD safety brakes with good quality, excellent results, and low prices.We have stock supply, reasonable prices, good quality, specifications: standard colors: bright materials: steel. All products in our factory are guaranteed for one year, delivered to our doorstep, and packaged well to ensure that all products arrive intact and flawless.Main features: Safe and reliable, sensitive to action, and short closing (closing) time. Good effect and long lifespan. Flexible installation position, easy to use, adjust, and maintain.SBD-A: ModelSBD100-ASBD125-ASBD160-ASBD200-ASBD250-ASBD brake hydraulic station group diagram Electromagnetic failure protection disc brake:3SE; 4SE; 5SE; 450SE; 56SE; 560SE; 561SE; ST1SE; ST2SEHydraulic fail safe disc brake:3SH; 4SH; 5SH; 450SH; ST1SH; ST2SH; ST3SH; ST4SH; ST5SH; ST10SH; ST16SH; ST25SH; 904SH;ST40SHPneumatic fail safe disc brake:3SP; 4SP; 5SP; 450SPHydraulic direct acting disc brake:ADH60; ADH90; ADH120; DADH75; DADH80; DADH90; DADH120; DADH195; DADH350Pneumatic direct acting disc brake:ADP60M; ADP61M; ADP62MPneumatic caliper disc brakeCQPL12.7A-A; CQPL12.7A-B; CQPL12.7B; QPL12.7A-A; QPL12.7A-B; QPL12.7-A; QPL12.7-B;QP30-D; QP25.4-D; CQP30-D; CQP25.4-D; PDA5; PDA10; PDB5; PDB10; PDB19; PDC5; PDC10Electromagnetic caliper disc brake:DCPZ12.7-250; DCPZ12.7-300; DCPZ12.7-400Hydraulic caliper disc brake:SB (YQP) 50; SB (YQP) 100; SB (YQP) 160; SB (YQP) 250; SB (YQP) 315; SB (YQP) 400;SBD safety brake:SBD100-A; SBD125-A; SBD160-A; SBD200-A; SBD250-A; SBD-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD80-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD120-D; SBD240-DElectric hydraulic windproof iron wedge brake:YFX series electric hydraulic windproof iron wedge brake:YFX-500/80; YFX-550/80; YFX-600/80; YFX-630/80; YFX-700/80; YFX-710/80; YFX-800/80Electric hydraulic thruster:YT1 series electric hydraulic thruster:YT1-18ZB/2; YT1-25ZB/4; YT1-45Z/5; YT1-90Z/8; YT1-125Z/10; YT1-180Z/10; YT1-320Z/12; YT1-320Z/20; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12; YT1-320Z/12; YT1-350/12;YT1-350/20; YT1-350/35; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12BYT1 series electric hydraulic thrusters:BYT1-18ZB/2; BYT1-25ZB/4; BYT1-25ZC/4; BYT1-45Z/4; BYT1-45Z/5; BYT1-45Z/6; BYT1-90Z/6BYT1-90Z/8; BYT1-125Z/10; BYT1-180Z/8; BYT1-180Z/10; BYT1-180Z/12; BYT1-320Z/12BYT1-320Z/20; BYT1-25/4; BYT1-45/6; BYT1-90/8; BYT1-180/12ED series electric hydraulic thrusters:ED-23/5; ED-30/5; ED-50/6; ED-80/6; ED-121/6; ED-201/6; ED-301/6; ED-50/12; ED-80/12; ED-121/12; ED-201/12; ED-301/12; ED-630/12BED ZED series electric hydraulic thrusters:BED30/5; BED50/6; BED80/6; BED121/6; BED201/6; BED301/6; BED50/12; BED80/12; BED121/12BED201/12; BED301/12; BED630/12

time:2021-04-28

More