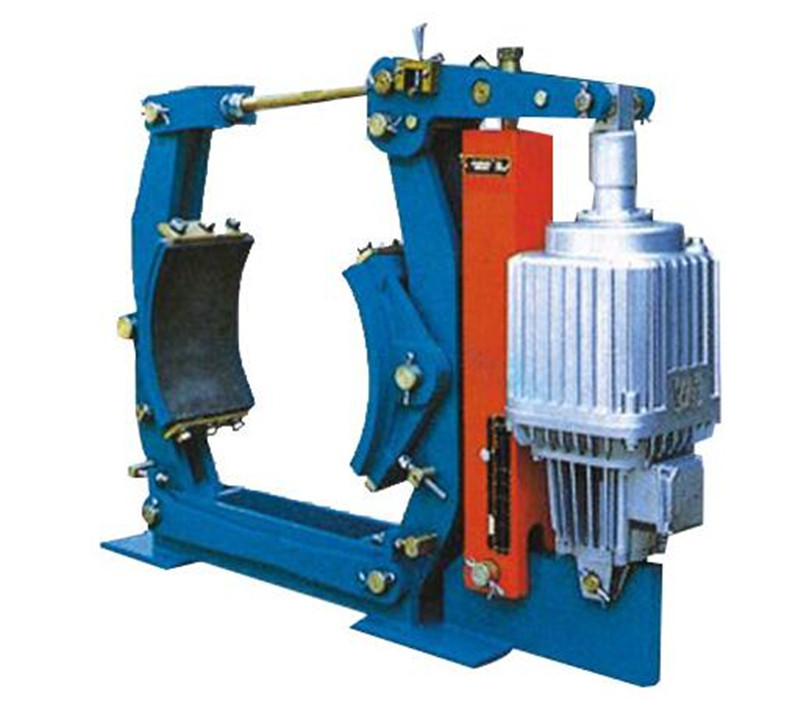

How to repair and maintain electromagnetic brakes? Remind you to pay attention to the following aspects: frequently add lubricant to the movable part of the electromagnetic brake, and regularly check the length of the armature stroke, as during the operation of the brake, the stroke length of the armature will increase due to wear on the cutting surface. When the length of the armature stroke cannot reach the normal value, adjustments must be made to restore the small gap between the brake surface and the rotary table. If the stroke length of the armature increases above the normal value, it may greatly reduce the suction force. If the worn brake surface is replaced, the small gap between the brake surface and the rotary table should be adjusted appropriately. Regularly check the tightness of the bolts, especially tightening the bolts of the electromagnet, the bolts of the electromagnet and the shell, the bolts of the magnetic yoke, the bolts of the electromagnet coil, and the wiring bolts. Regularly inspect the mechanical wear of movable components and remove dust, burrs, and dirt from the surface of electromagnetic componentsThe brake is very important and an essential component for ensuring the safe operation of the crane, which is used to ensure accurate, reliable, and safe operation of the crane. The braking device of the lifting mechanism ensures the stop position of the lifting object, and can keep the lifting object in that position after the lifting mechanism stops running, playing a role in preventing the heavy object from falling. The braking devices of the operating mechanism and other mechanisms are not only used to achieve parking and maintain the stationary position, but also can reduce or adjust the operating speed of the mechanism according to work needs in special circumstances.The braking device of a crane usually consists of a crane brake, a braking wheel, and a braking drive device. This includes adjustment work in three aspects: adjusting the working stroke, adjusting the braking force, and adjusting the brake clearance. It achieves mechanism braking through the principle of friction. When the friction component of the brake set on the stationary base presses against the friction component on a certain operating shaft in the mechanism with a certain force, when the coil is energized, the armature presses against the friction plate on the rotor or brake yoke through electromagnetic force, achieving the combination of the active side and the driven side, and transmitting power. After the coil is powered off, the electromagnetic force disappears, and the armature returns to its original position with the help of the restoring force of the spring. The armature detaches from the rotor or brake yoke, and the power transmission effect disappears. Friction power loss electromagnetic brake. If there is oil or water on the friction surface, it will cause torque to decrease. Therefore, it needs to be used in a dry environment. To prevent oil, water, or dust from getting stuck, please use a protective coverThe ambient temperature for the use of micro electromagnetic brakes is -10 ℃~+100 ℃. If it exceeds this range, please consult our company.Excessive voltage fluctuations will affect the performance of the brake, so the voltage used by the brake should be controlled within ± 10% of the rated voltage and should be smooth and interference free.The micro brake of the electromagnetic brake model has been adjusted for working clearance before leaving the factory, and there is no need to adjust it during use. Users are advised not to open the brake without permission, as improper clearance may cause it to malfunction.The company produces and sells YWZ-YWZ13, YW, YWL series drum brake electric hydraulic brake, ZWZ, TJ2A series electromagnet brake, YPZ series disc brake Ed thruster, YT1 series electric hydraulic thruster, BYT1 series explosion-proof electric hydraulic thruster, pneumatic thruster and hydraulic pressure device. At present, the product has more than 30 series and over 500 specifications, with an annual production capacity of 60000 sets. Our company is a member unit of the Crane Association and the Construction Machinery Industry Association, and has obtained the brake "Product Quality Approval Certificate", "Type Test Approval Certificate", and "Special Equipment Type Test Qualification Certificate" issued by the National Center for Quality Supervision, Inspection and Testing of Lifting and Transportation Machinery Products. And passed the ISO: 9000 and GB/T19001-2000 Quality Management System Certification of the China Fangyuan Certification Committee. In 2004, it was awarded the title of High Quality Product in Henan Province. Obtained the National Industrial Product Production License in April 2008 (For explosion-proof electrical appliances, Jiaozuo Hydraulic Brake Factory, brake manufacturer, crane brake, thruster brake, YT1 thruster, explosion-proof brake, wind brake, electromagnetic brake mainly produces YWZB, YWZ2, YWZ3, YWZ4, YWZ5, YWZ6, YWZ8, YWZ9, YWZ10, YWZ12, YWZ13 series electric hydraulic block brake. All kinds of explosion-proof brakes, TJ2 series new energy-saving electromagnetic brake, MWZ electromagnetic brake, Electric hydraulic arm disc brake, mine explosion-proof electromagnetic starter and mine vacuum feed switch, with complete specifications, reliable performance and high quality

time:2021-04-28

More

There are two types of disc brake structures: normally open and normally closed. The structure of a normally open point disc brake for loaders. The brake consists of a caliper (1), a piston (2), a brake disc (3), a brake disc (4), and a sealing ring (5). When pressure oil enters the cylinder and pushes the piston towards the brake disc, braking is achieved. There are two types of automatic adjustment for brake release (or piston return) and clearance after wear: sealing ring type and spring type. Because the brake clearance of the point disc brake is very small (about 0.1mm on each side), when the brake pushes out the piston, the friction forces the seal ring to deform. When the brake is released, the oil in the cylinder is depressurized, and the piston automatically resets due to the elastic force caused by the deformation of the sealing ring. If the brake clearance increases due to the wear of the friction lining, the piston movement will be greater than the deformation of the sealing ring, thus overcoming the friction force. The piston will move outward relative to the sealing ring until the brake disc is compressed. When releasing the brake, the elastic force of the sealing ring causes the piston to return to its original position. The return distance is not the original piston extension distance, but only the size of the deformation of the sealing ring, in order to achieve the goal of automatically adjusting the brake clearanceThe QP (CQP) series pneumatic caliper disc brakes are mainly used in lifting, transportation, metallurgy, mines, and portsBraking and deceleration of various mechanisms in machinery such as Kou and construction.Usage conditionsEnvironmental temperature: -5 ℃~40 ℃Working air pressure: 5-7bar for QP series;The CQP series is ≤ 7bar.Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.The air source should not contain oil, water, or other impurities.main features The QP series adopts spring braking and pneumatic release; CQP12.7 pneumatic caliper disc brake is pneumatic brake with spring released.The overall structure is simple, small in size, and lightweight.Asbestos free brake pads, green and environmentally friendly.The installation of the brake pad adopts a spring clamp type, which is convenient and fast to replace.The brake pad is easy to adjust after being worn.Each disc diameter of the QP series brake can be adjusted for four levels of braking torque.All power sources do not need to be set separately and can be connected to the existing air compression station for grid use. They can be added to the gas supply lineEquipped with a speed control valve, the braking time can be adjusted steplessly.Note: 1. It can produce pneumatic caliper disc brakes with different disc thicknesses and installation sizes.2. The specific model and structural dimensions reserve the right to change. The characteristic of brakes is high efficiency. The brake chamber has a small size and fast charging and discharging response. Energy saving and automatic adjustment mechanism with clearance ensures good braking force matching, directional stability, and braking stability during use. The floating brake structure is adopted, which ensures stable braking torque output, good braking follow-up, and can reduce noise and alarm. Due to the small diameter of the brake drum, wide friction plate, and good heat dissipation conditions, the thermal stability is improved, and high-speed braking performance is improved. It also creates conditions for using small tires with fewer types of parts, The number of parts is also small, with good interchangeability and versatility, facilitating serialization and low quality.For example, transmission equipment in steel and metallurgical workshops, we know that both indoor and outdoor work have unique characteristics and problems. If the problem cannot be solved, it will affect its normal use. What we want to say here is the port crane. We know that the port is relatively open, and the wind is usually strong due to the influence of the sea, and the crane will be blown over in case of severe wind. At this time, to ensure the normal operation of the crane, it is necessary to install wind brake, thruster, electric hydraulic brake, hydraulic brake, hydraulic thruster, ED electric hydraulic thruster, ED thruster, explosion-proof thruster, disk brake, Electromagnetic brake, brake shoe, brake accessories, brake manufacturer, brake price, Jiaozuo brake, Jiaozuo brake, Jiaozuo brake factory, Jiaozuo hydraulic brake factory, brake manufacturer, crane brake, thruster brake, YT1 actuator, explosion-proof brake, wind brake, electromagnetic brake mainly produces YWZB, YWZ2, YWZ3, YWZ4, YWZ5, YWZ6, YWZ8, YWZ9, YWZ10, YWZ12 YWZ13 series electric hydraulic block brake. All kinds of explosion-proof brakes, TJ2 series new energy-saving electromagnet brakes, electro-hydraulic arm disc brakes, mine explosion-proof electromagnetic starters and mine vacuum feed switches have complete specifications, reliable performance and high quality

time:2021-04-28

More

Henan Jiaozuo Brake Factory produces electric hydraulic brakes, electric hydraulic thrusters, disc brakes, pneumatic brakes, wind brakes, electromagnet brakes and other industrial brakes. The performance of the products is smooth, and the brake brakes and holding brake brakes are mainly applicable to port terminals, steel, mining, metallurgy, water conservancy, power, wind power, transmission machinery and other equipment. Users have consistently responded well, And it is exported to Europe, America and the Asia Pacific region with the main engine, with a long service life. DC brakes, wind power brakes, and safety brakes have low energy consumption, and are highly favored. Power outage brakingLow energy consumption, smooth braking, and long service lifeAdvantages of drum brakesThe drum brake is cheap and in line with traditional design. During the braking process of a four-wheel sedan, due to inertia, the load on the front wheels usually accounts for 70% -80% of the total load of the car. The braking force on the front wheels is greater than that on the rear wheels, and the rear wheels play an auxiliary braking role. Therefore, in order to save costs, car manufacturers adopt a braking method of front disc and rear drum. However, for heavy vehicles, the speed is generally not very high, and the durability of brake shoes is higher than that of disc brakes, so many heavy vehicles still use the four-wheel drum design.Disadvantages of hydraulic drum brakesThe braking efficiency and heat dissipation of drum brakes are much worse. The braking force stability of drum brakes is poor, and the braking force varies greatly on different road surfaces, making it difficult to control. Due to poor heat dissipation performance, a large amount of heat will accumulate during the braking process. The brake pads and wheel drums are prone to extremely complex deformation under the influence of high temperatures, which can lead to brake decay and vibration, leading to a decrease in braking efficiency. In addition, after using the drum brake for a period of time, it is necessary to regularly adjust the gap between the brake shoes, and even remove the entire brake drum to clean the accumulated brake powder. Mechanical transmission mechanisms can change the mode, direction, or speed of motion provided by power and be purposefully utilized by people. There were many types of transmission mechanisms in ancient China, which were widely used. In addition to the ones mentioned above, such as seismographs, blowers, and so on, they were all products of mechanical transmission mechanisms. In ancient China, transmission mechanisms mainly included gear transmission, rope transmission, and chain transmission.Gear transmission. It appeared no later than the Western Han Dynasty. The South-pointing chariot and Jili Drum Car in the Western Han Dynasty and the hydraulic astronomical instrument invented by Zhang Heng in the Eastern Han Dynasty all used quite complex gear transmission systems. These gears are only used to transmit motion and do not require high strength. As for the gears used in production, they need to transmit a large amount of power and generally have a high stress and strength requirement. In ancient times, such gears were used for water extraction, grain processing, and other work using animal power, water power, and wind power. For example, on a rollover, a primary gear transmission mechanism must be applied to change the direction and transmission of motion to meet the working requirements of the rollover. Hydraulic oil brakes can be widely used for deceleration or parking braking of mechanical drive devices such as lifting, metallurgy, mining, ports, docks, construction machinery, etc. The products comply with national standards.The hydraulic oil brake uses an electric hydraulic thruster as the driving device. The thruster is equipped with a DC electromagnet holding device. During the operation of the brake, the thruster motor only completes the brake opening and release process and turns off the thruster motor. The DC electromagnet holding force maintains the brake open state. The DC electromagnet has a low current and a low temperature rise in the thruster, extending its service life; When braking, the electromagnet loses power. As the motor has already been cut off, the hydraulic oil has completely released pressure, and the push rod and piston are no longer damped by the hydraulic oil when lowering and resetting. The hydraulic brake quickly brakes, improving the hook sliding phenomenon. When the ambient temperature is 0-20 ℃, use No. 10 transformer oil; Use No. 20 transformer oil at 20-45 ℃- 25 # transformer oil for 15-0 ℃The common faults of hydraulic brakes are as follows:1. The relaxation distance of the brake pedal is incorrect;2. There is a lack of brake fluid in the brake master cylinder or air enters the brake system (there is elasticity when pressing the brake pedal or uneven feeling when pressing it);3. The piston cup of the brake master cylinder is swollen, the compensation oil hole of the master cylinder is stained, or the oil level inside the master cylinder is too high, causing the brake to bite;4. The oil tank inside the brake fine pump is stuck;5. The piston inside the wheel cylinder is stuck and the leather cup is damaged.

time:2021-04-27

More

Various models of crane accessories are complete and the quality is guaranteed. Please rest assured to purchase them. However, as the accessories on the crane are generally heavy, the shipping cost will be more expensive if using express delivery. Therefore, we generally recommend using logistics or bus transportation. The shipping cost of our products can only be used as a reference and cannot be used as the actual shipping cost. We support freight on delivery. We apologize for any inconvenience this may cause. Please feel free to contact our hotline at 9. Kind reminder: After each transaction is completed, you have an opportunity to evaluate our store's products and services. We attach great importance to your evaluation and strive to achieve service excellence. If you have any questions or dissatisfaction, please feel free to contact us in a timely manner. After solving your problems, please give us a review. Buyers must read: 1. Our default express delivery is Shentong Express. If you need any other express delivery, please contact customer service and make up for the price difference. Thank you for your cooperation. 2. All products in our store support Alipay payment, or direct bank transfer. If you need bank transfer, please contact customer service in advance. 3. All payments will be received and shipped, and we will promptly ship the goods upon receiving your payment. 4. Before confirming the purchase of this treasure, please contact customer service to see if there is any stock available. Generally, there is no shortage. Please be clear to avoid any inconvenience to youWhen using the hydraulic brake, there may be some problems. At this time, the engine is idling and the brake pedal is pressed. If the force remains constant, the pedal slowly drops, indicating that the hydraulic brake is leaking. To ensure that the brake is truly leaking, it can be observed from several aspects: check the level of the main cylinder liquid level, If it is normal friction lining wear, it will cause a slight decrease in the liquid level in the reservoir. If there is a significant decrease, it means that the system has leaked; Check if there is any leakage at the connection of the brake pipeline and hose. If there is leakage or damage, it needs to be replaced in a timely manner; Check if there is a problem with the components connecting the brake. If there is a problem with the brake components, they need to be replaced.Usage conditionsThis machine is used in 380V, 50Hz three-phase AC power supply; The altitude of the plateau does not exceed 1000 meters; The temperature of the cooling medium used shall not exceed+40.2. Precautions before use;(1) Check whether the components are complete and whether the fastening parts are loose.(2) Pull the rotor by hand and listen carefully for any internal noise such as friction, and check if the bearing rotates freely(3) Use a 500 megohmmeter to measure the insulation resistance between phases and ground of the motor, and the value should not be less than 0.5 megohm. Otherwise, it must be dried until the requirements are met before use. Block brakes require frequent inspection, as the simultaneous braking stroke of block brakes is very small.The same action card will cause vibration of the bridge under the action of inertia.Short stroke brakes can be used for the running mechanism of small carts and the running mechanism of large vehicles.Because short stroke electromagnetic block brakes can receive the suction of electromagnets, and short stroke brakes generally have low braking torque

time:2021-04-27

More

Product Overview 1. PurposeYPZ2 series electric hydraulic arm disc brakes (hereinafter referred to as brakes) are widely used for the deceleration, braking and safety protection of modern large-scale special handling machinery, lifting and transportation machinery, ports and docks, metallurgy and other industries. The installation dimensions of this series of brakes comply with the German DIN5435 standard. 2. Features: This series of brakes features self-lubricating bearings at the main swing hinge points, high transmission efficiency, long service life, and no need for lubrication during use; The asbestos free brake pad is plug-in, making it easy and fast to replace; The automatic compensation device for brake pad wear (imported for one-way bearings) can maintain a constant distance between pads and brake torque during use; Other characteristics. Its structural components have been optimized and designed to be safe and reliable. Various additional devices can be installed according to user needs (please specify when ordering): (1) Manual release device (2) Various limit switches: (Release limit switch, Close limit switch, Friction plate damage limit switch, Manual release limit switch) Through PLC control, fault alarm (interlocking) is achieved to ensure the safety of the entire machine in use. (3) According to user needs, anti-corrosion products can be provided, which can adapt to salt mist environments in coastal areas and acid mist environments in the metallurgical industry. 3. The applicable conditions are generally: (1) Environmental temperature -40 ℃ -+45 ℃2) There should be no flammable, explosive, or corrosive gases in the surrounding working environment, and the relative humidity of the air should not exceed 90%. (3) The power supply voltage is usually three-phase 380V, 50HZ AC (suitable for 60HZ or other power supply voltages according to user needs, please specify in advance when ordering). (4) The altitude of the location of use should comply with GB755-2000 and German VDE0530 standards When the temperature is below -20 ℃, the working fluid of the thruster should be changed to YH-10 aviation hydraulic oil or a heater is required. Please refer to the Ed thruster user manual for details. 4. Model Meaning YPZ2- □ □/□ □ - □ Brake Additional Function Code Pusher Additional Function Code Pusher Thrust Code (10N) Pusher Code (E) Brake Center Height (I, II, III) Brake Disc Diameter (mm) Design Number Brake ModelBrake Additional Function Code Table: Brake Additional Function Code Table:Function code M K1 K2 K3 SoneMeaning: Automatic compensation device for friction plate wear Release (up) limit travel switch Close (down) limit travel switch Friction plate wear limit limit switch Left manual Right manual upper manualS2 S3Pusher Additional Function Code Table: Pusher Additional Function Code Table:Function code C d H S R W represents the meaning of brake spring, buffering spring, rising delay valve, lowering delay valve, heater, return springJudgment of hydraulic brake related brake failure phenomenaIn order to better prevent the vehicle from holding the brake, a series of preventive measures have been taken, especially through the investigation of holding the brake of the through Freight train, which has accumulated some experience. At the same time, in order to find the authenticity of the problem more intuitively, the following measures have been taken: organize special personnel to visit the stations prone to holding the brake one by one, strengthen the contact with the station, and have a detailed understanding of the situation with the relevant personnel of each station who found the holding brake situation, Enable us to have a perceptual understanding and enhance our understanding of the hazards of holding brakes on driving. Timely contact with the train inspection and provide feedback on fault information to reduce or eliminate the occurrence of such faults. In response to the malfunction of other accessories caused by the vehicle's brake application and the serious impact on normal driving order.Brake holding brake failure is the application failure of Goods wagon caused by poor brake release and brake shoe cannot be separated from wheel tread due to brake failure, hand brake non release and other reasons. Its main hazard is to scratch the wheel tread, resulting in slag and rolling on the wheel tread.Of course, disc brakes have their own shortcomings. For example, there are high requirements for the manufacturing of brakes and brake pipelines, resulting in high consumption and cost of friction pads. Moreover, due to the small area of the friction pads and the relatively small working surface of the friction, high braking hydraulic pressure is required, and vehicles with power assistance devices must be equipped to use them. The cost of drum brakes is relatively low and relatively economical.YPZ2 series electric hydraulic arm disc brake: YPZ2-315I/23; YPZ2-315I/30; YPZ2-315I/50; YPZ2-315I/80; YPZ2-355I/23; YPZ2-355I/30; YPZ2-355I/50; YPZ2-355I/80; YPZ2-400I/30; YPZ2-400I/50; YPZ2-400I/80; YPZ2-450I/50; YPZ2-450I/80; YPZ2-450/50; YPZ2-450/121; YPZ2-450/201; YPZ2-500/50; YPZ2-500/80; YPZ2-500/121; YPZ2-500/201; YPZ2-560/50; YPZ2-560/80; YPZ2-560/121; YPZ2-560/201; YPZ2-630/80; YPZ2-630/121; YPZ2-630/201; YPZ2-710/121; YPZ2-710/201; YPZ2-630/201; YPZ2-630/301; YPZ2-710/201; YPZ2-710/301; YPZ2-800/201; YPZ2-800/301; YPZ2-900/201; YPZ2-900/301; YPZ2-1000/201; YPZ2-1000/301; YPZ2-1250/201; YPZ2-1250/301

time:2021-04-27

More

Short stroke thruster ED23/5 Short stroke thruster deviation ± 20%ED23/5 220 50 0.35 0.35 180 50 165 380 0.52 2000 10ED30/5 300 50 0.35 0.35 270 50 200 380 0.46 2000 14ED50/6 500 60 0.45 0.39 460 50 210 380 0.48 2000 14ED80/6 800 60 0.32 0.34 750 50 330 380 1.42 2000 24ED121/6 1250 60 0.4 0.42 1200 50 330 380 1.44 2000 39ED201/6 2000 60 0.5 0.32 1900 50 450 380 1.45 2000 39ED301/6 3000 60 0.58 0.32 2700 50 550 380 1.46 1500 40purposeContinuously work S1 and continue working S3, and the ambient temperature of chicken feathers reaches+50 ℃.The rated current in the table refers to the line terminal current during rated operation, but if the power supply is at a non rated value, it will inevitably cause a corresponding change in the rated current. Environmental temperature: -20 ℃~+50 ℃, hydraulic oil: DB-25 (SY1351-77) When it is below -20 ℃, YH-10 hydraulic oil can be used without a heater. When using DB-25 hydraulic equipment, a heater must be installed. The travel time is measured at an ambient temperature of 20 ℃.Main technical parametersModel A B C D E F G H K L M N O P Q R S T UEN23/5 286 50 26 12 20 16 20 160 80 40 200 16 85 55 75 100 20EN30/5 370 50 34 15 16 25 16 18 160 80 80 40 197 16 85 55 75 100 20EN50/6 435 60 36 18 20 30 20 23 195 97 120 60 254 22 85 55 75 100 20EN80/6 450 60 36 18 20 30 23 195 97 120 60 254 22 85 55 75 100 20EN50/12 515 120 36 18 20 30 20 23 195 97 120 60 254 22EN80/12 530 120 36 18 20 30 20 23 195 97 120 60 254 22EN121/6 645 60 38 25 25 40 25 35 240 112 90 40 260 25 130 80 120 147 35EN201/6 645 60 38 25 40 25 35 240 112 90 40 260 25 130 80 120 147 35EN301/6 645 60 38 25 25 40 25 35 240 112 90 40 260 25 130 80 120 147 35

time:2021-04-27

More

Specific model:YT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various brake wheels and discs, and customized non-standard brakes according to user needs. Our sales channelsOur company mainly sells to cities such as Shanghai, Zhejiang, Jiangsu, Anhui, Inner Mongolia, Xinjiang, Chongqing, Yunnan, Shaanxi, Hebei, Henan, Hubei, Hunan, Jiangxi, Sichuan, Guangdong, Guangxi, Hong Kong, Jilin, Heilongjiang, Liaoning, Ningxia, Gansu, Shaanxi, Shandong, Fujian, Hainan, etc. Over the years, we have established long-term cooperative relationships with hundreds of customers with our excellent quality and reputation.

time:2021-04-27

More

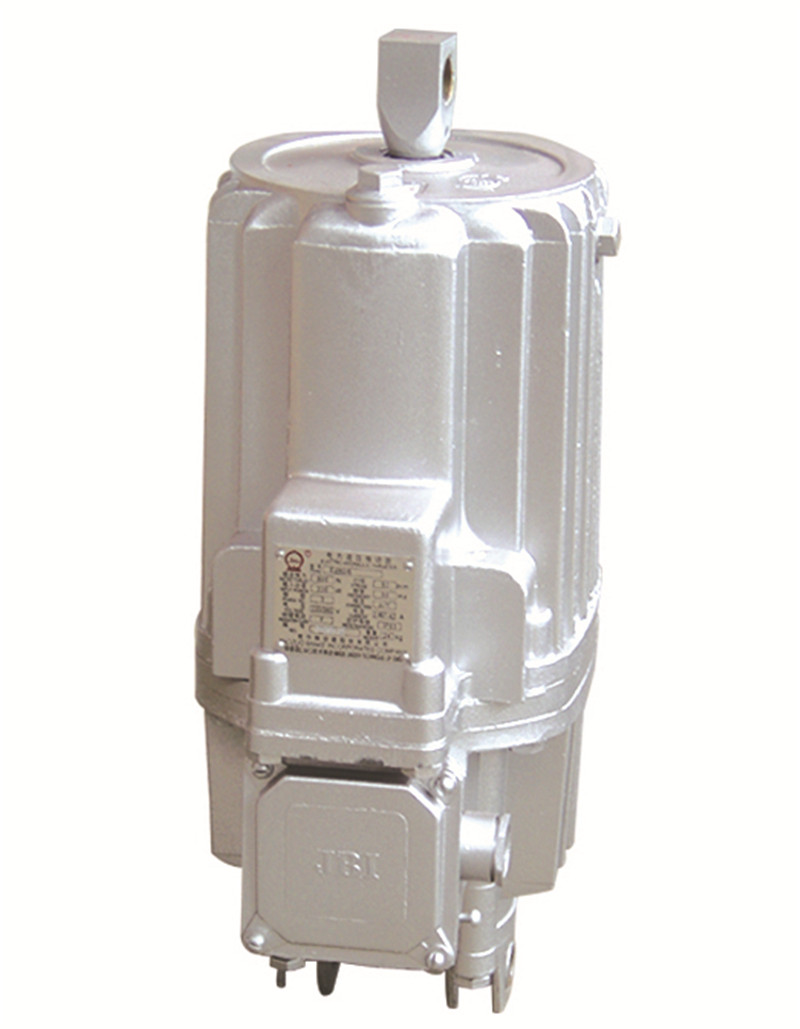

Compliant with standardsThe ED series complies with DIN15430, JB/T6406 3-92 standard.main features 1. The shell is made of cast aluminum alloy, with light weight and beautiful appearance;2. The motor is a non oil immersed structure, with Class B or F insulation (according to user requirements), good heat resistance, and long service life;3. The motor junction box is equipped with a seal and uses a cable stuffing box for incoming lines, which is firm and reliable. The electrical casing protection level reaches IP55;4. The surface of the motor shaft and push rod are specially treated, greatly extending the service life of the sealing element;5. The oil cylinder shell is equipped with a balance chamber on one side, allowing the thruster to be installed in any direction from 0 to 180 °, thereby expanding its range of use;6. All seals and bearings are made of world-renowned products, with reliable sealing and long service life;7. The fasteners are made of stainless steel material, which is beautiful and durable.Additional devices1. Upper limit switch: can indicate whether the brake is on, whether the push rod is pushed to the specified position, and other information;2. Lower limit switch: can indicate whether the brake is correctly closed, whether the push rod returns to the specified position, and can also set the upper and lower limit switches;3. Add a built-in spring (only available for short stroke thrusters), with the spring force determined by the user but not exceeding the built-in spring force (see parameter table);4. Adding a heater: When the ambient temperature at the place of use is below -25 ℃, users can add a heater as needed. The heater parameter table is shown in Appendix 1;5. The rising time delay valve and the falling time delay valve can extend the rising or Fall time steplessly. The delay range is from the rated action time to 30 seconds. The specific delay value can be adjusted according to the user's requirements.ED-23/5, ED-30/5, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-50/6, ED-80/6, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-121/6, ED-201/6, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters,ED-301/6, ED-50/12, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-80/12, ED-121/12, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters,ED-201/12, ED-301/12, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters

time:2021-04-27

More

Electric hydraulic thrusters: Ed series electric hydraulic thrusters, YT1 series electric hydraulic thrusters.Explosion proof electric hydraulic thruster: BEd series explosion-proof electric hydraulic thruster, BYT1 explosion-proof electric hydraulic thruster.Product details: YT1 series hydraulic thruster:YT1-18ZB/2 Hydraulic Pusher YT1-25ZB/4 Hydraulic Pusher YT1-25ZC/4 Hydraulic Pusher YT1-45Z/4 Hydraulic Pusher YT1-45Z/5 Hydraulic Pusher YT1-45Z/6 Hydraulic Pusher YT1-90Z/6 Hydraulic Pusher YT1-90Z/8 Hydraulic Pusher YT1-125Z/10 Hydraulic Pusher YT1-180Z/8 Hydraulic Pusher YT1-180Z/10 Hydraulic Pusher YT1-180Z/12 Hydraulic Pusher YT1-320Z/12 Hydraulic Pusher YT1-320Z/20 Hydraulic Pusher YT1-25/4 Hydraulic Pusher YT1-45/6 fluids Pressure thruster YT1-90/8 Hydraulic thruster YT1-125/10 Hydraulic thruster YT1-180/12 Hydraulic thruster

time:2021-04-27

More

1、 Electric hydraulic block brake:YWZ4 series electric hydraulic block brake:YWZ4-100/18; YWZ4-150/25; YWZ4-160/25; YWZ4-200/25; YWZ4-200/45; YWZ4-300/25; YWZ4-300/45; YWZ4-300/90; YWZ4-400/45; YWZ4-400/90; YWZ4-400/125; YWZ4-500/90; YWZ4-500/125; YWZ4-500/180; YWZ4-600/180; YWZ4-700/180; YWZ4-800/180; YWZ4-800/320YWZ3B series electric hydraulic block brake:YWZ3B-160/18; YWZ3B-160/25; YWZ3B-200/18; YWZ3B-200/25; YWZ3B-250/25; YWZ3B-250/45; YWZ3B-315/25; YWZ3B-315/45; YWZ3B-315/90; YWZ3B-400/90; YWZ3B-400/125; YWZ3B-500/90; YWZ3B-500/125; YWZ3B-500/180; YWZ3B-630/125; YWZ3B-630/180; YWZ3B-630/320; YWZ3B-710/180; YWZ3B-710/320; YWZ3B-800/320YWZ4B series electric hydraulic block brake:YWZ4B-100/23; YWZ4B-150/23; YWZ4B-200/23; YWZ4B-200/30; YWZ4B-300/30; YWZ4B-300/50; YWZ4B-300/80; YWZ4B-400/50; YWZ4B-400/80; YWZ4B-400/121; YWZ4B-500/121; YWZ4B-600/121; YWZ4B-600/201; YWZ4B-700/201; YWZ4B-700/301; YWZ4B-800/301YWZ5 series electric hydraulic block brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50; YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201; YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12YWZ9 series electric hydraulic block brake:YWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50; YWZ9-300/30; YWZ9-300/50; YWZ9-300/80; YWZ9-315/30; YWZ9-315/50; YWZ9-315/80; YWZ9-400/50; YWZ9-400/80; YWZ9-400/121; YWZ9-500/80; YWZ9-500/121; YWZ9-500/201; YWZ9-600/121; YWZ9-600/201; YWZ9-600/301; YWZ9-630/121; YWZ9-630/201; YWZ9-630/301; YWZ9-700/201; YWZ9-700/301; YWZ9-710/201; YWZ9-710/301; YWZ9-800/301/12YWZ10 series electric hydraulic block brake:YWZ10-200/23; YWZ10-200/30; YWZ10-200/50; YWZ10-250/23; YWZ10-250/30; YWZ10-250/50; YWZ10-250/80; YWZ10-315/30; YWZ10-315/50; YWZ10-315/80; YWZ10-400/50; YWZ10-400/80; YWZ10-400/121; YWZ10-500/80; YWZ10-500/121; YWZ10-500/201; YWZ10-500/301; YWZ10-630/121; YWZ10-630/201; YWZ10-630/301; YWZ10-630/301/12; YWZ10-710/201; YWZ10-710/301; YWZ10-710/301/12; YWZ10-800/301/12YWZ12 series electric hydraulic block brake:YWZ12-200/23; YWZ12-200/30; YWZ12-250/23; YWZ12-250/30; YWZ12-250/50; YWZ12-315/30; YWZ12-315/50; YWZ12-315/80; YWZ12-400/50; YWZ12-400/80; YWZ12-400/121; YWZ12-500/80; YWZ12-500/121; YWZ12-500/201; YWZ12-630/121; YWZ12-630/201; YWZ12-630/301; YWZ12-630/301/12; YWZ12-710/201; YWZ12-710/301; YWZ12-710/301/12; YWZ12-800/301/12YWZ13 series electric hydraulic block brake:YWZ13-200/23; YWZ13-200/30; YWZ13-250/23; YWZ13-250/30; YWZ13-250/50; YWZ13-300/30; YWZ13-300/50; YWZ13-300/80; YWZ13-400/50; YWZ13-400/80; YWZ13-400/121; YWZ13-500/80; YWZ13-500/121; YWZ13-500/201; YWZ13-630/121; YWZ13-630/201; YWZ13-630/301; YWZ13-710/201; YWZ13-710/301; YWZ13-800/301/12YWL series electric hydraulic block brakes:YWL-200/23; YWL-200/30; YWL-250/23; YWL-250/30; YWL-250/50; YWL-315/23; YWL-315/30; YWL-315/50; YWL-315/80; YWL-400/30; YWL-400/50; YWL-400/80; YWL-400/121; YWL-500/50; YWL-500/80; YWL-500/121; YWL-500/201

time:2021-04-27

More

Brake parts Brake thruster Friction plate Electric hydraulic drum brake Electric hydraulic disc brake Electric hydraulic explosion-proof brake Electromagnetic brake Non standard brake and industrial brake of various well-known manufacturers.Our products include electric hydraulic wheel brakes: YWZ3B, YWZ4, YWZ8, YWZ9, YWZ10, YWZ13, YW, YWL, TJ2, JZ and other series;Electric hydraulic disc brakes: YPZ2, YPZ3, QP12.7 and other series;Various models of thrusters: YT1, MYT1, BYT1, BED and other series. In addition, we also produce various hydraulic cylinders, non-standard brakes, conventional friction discs for brakes, and substitute imported high wear resistant rigid back friction discs. The products are widely used in industries such as material handling, wind power generation, port machinery, mining, metallurgy, coal, petrochemical, and engineering machinery.In recent years, our company has been committed to improving the localization and development of drum brake friction pads, non-standard friction pads, and imported brake friction pads, as well as new formula development projects; In the past three years, in order to adapt to the domestic economic situation and reduce operating costs for industrial brake users, our company has hired multiple experienced engineers and domestic chemical experts in the brake industry to develop a series of friction plate products, such as TE series, SB series, USB2 series, USB3 series, 7080080-Z series, DB-0435-K series, BSF series, etc., which have good on-site use effects and low prices, All received unanimous recognition and praise from users

time:2021-04-27

More

Electric hydraulic tile brake, abbreviated as tile brake, has a simple structure, convenient manufacturing and installation, dual tile without axial force, convenient maintenance, and low price. There is a certain amount of impact and vibration. Widely used in various lifting and transportation machinery, petroleum machinery, mining machinery, excavation machinery, metallurgical machinery and equipment, construction machinery, ship machinery, etc. Brakes can be divided into two types according to their purpose: stop type and speed control type. The former only has the function of braking and supporting moving objects; the latter can also adjust the speed of object movement in addition to the above functions.According to the control method, it can be divided into manual, automatic, and hybrid.It can be divided into normally open and normally closed according to its working state. The normally open type is often in a released state and requires external force to achieve braking. The normally closed type is often in a closed or braking state, and only by applying external force can the braking state be released. The lifting mechanism in lifting machinery often uses a normally closed brake system, while the main brakes of various vehicles use a normally open brake system.Common brakes often use friction brakes, which can be divided into block type, belt type, and disc type according to their structural characteristics. They all utilize the frictional resistance moment generated between friction components to consume the kinetic energy of mechanical moving parts, in order to achieve the purpose of braking. It mainly consists of three parts: brake frame, friction components, and driving device. The brake frame is the foundation for the installation and support of other parts of the brake. The friction elements are in contact with the brake wheel to generate the brake Friction torque. The driving device amplifies and transmits the driving force acting on the brake to the friction element to achieve braking (tight braking) or to release the friction element from contact with the brake wheel.The working conditions of using electrically powered hydraulic brakes are as follows:1. The common electric hydraulic brake mainly operates by pushing the actuator to open when the point is reached;2. The braking force during braking is provided by the spring, and the electric hydraulic brake does not work at this time;3. If you want to power on for a long time, even if the brake is in an open state for a long time, theoretically there is no problem. However, in actual use in the factory, the motor of the thruster is prone to malfunction. Generally, electric hydraulic thrusters have a wrench for manual position maintenance, which means that after opening, the claw can be manually clamped onto the support rod, and after power outage, it is still in the open state;4. For electric hydraulic brakes in the normally open state, the normally open state can be used, which relies on hydraulic braking and spring opening.When the excitation coil of the block brake is energized, it will attract the armature. Through the action of the push rod, the two brake arms overcome the pulling force of the spring and rotate outward. This way, the pads connected to the two brakes release the brake wheels, allowing the machinery to operate freely. To brake, simply cut off the electric probe, release the armature from the excitation coil, and clamp the two brake arms inward under the tension of the spring. At this point, the tile will hold the brake wheel tightly. For safety reasons, this type of brake adopts a normally closed structure with power off braking.What is the adjustment method for electric hydraulic brakes?1. Loosen the spring of the braking torque.2. Manually lift the thruster triangle and adjust the upper adjustment screw to make the opening gap of the brake shoe 1.5mm (brake shoe and brake wheel). Adjust the lower limit screw of the brake bracket to evenly distribute the opening gap on both sides of the brake shoe.3. Adjust the torque spring to meet the required scale.4. Tighten all locking nuts. (After the gate adjustment is completed)5. When the brake shoe is worn to the required level, replace it and adjust it according to the above steps. During the wear process of the brake shoe, due to the wear of the brake shoe, the triangle plate of the thruster is lowered. When the smooth rod of the thruster drops close to the compensation limit mark, the brake gap should be adjusted in a timely manner.Electric hydraulic block brake series YWZB YWZ3B YWZ4B YWZ5 YWZ8 YWZ9 YWZ12 YWZ13 YW YWL TYWZ2 YWP electromagnetic block brake JZ (TJ2A) MW (Z) ZWZA ZWZ2 ZWZ3A DCW3 electromagnetic failure protection disc brake 5SE 561SE 560SE 56SE DCPZ12.7 4SE 3SE ST1SE ST2SE 450SE hydraulic failure protection disc brake 5SH 4SH 3SH 450SH ST1SH ST1SH ST2SH ST3SH 4SH SB (YQP) SBDST5SH ST10SH ST16SH ST25SH ST25SH-A ST40SH 904SH SBB electric hydraulic arm disk brake YPZ2 Ⅰ, Ⅱ, Ⅲ YPZ2 Ⅳ, Ⅴ, Ⅵ pneumatic caliper disk brake QP12.7 5SP 4SP 3SP 450SP PD ADP60M-ADP61M-ADP62M hydraulic direct acting disk brake DADH75 ADH60 ADH90 ADH120 DADH80 DADH90 DADH120 DADH103 DADH195 electric hydraulic thruster YT1 Ed explosion-proof electric hydraulic thruster BYT1 BEDProduct details: YT1 ED YTD series hydraulic thrusters:YT1-18ZB/2 Hydraulic Pusher YT1-25ZB/4 Hydraulic Pusher YT1-25ZC/4 Hydraulic Pusher YT1-45Z/4 Hydraulic Pusher YT1-45Z/5 Hydraulic Pusher YT1-45Z/6 Hydraulic Pusher YT1-90Z/6 Hydraulic Pusher YT1-90Z/8 Hydraulic Pusher YT1-125Z/10 Hydraulic Pusher YT1-180Z/8 Hydraulic Pusher YT1-180Z/10 Hydraulic Pusher YT1-180Z/12 Hydraulic Pusher YT1-320Z/12 Hydraulic Pusher YT1-320Z/20 Hydraulic Pusher YT1-25/4 Hydraulic Pusher YT1-45/6 fluids Pressure thruster YT1-90/8 Hydraulic thruster YT1-125/10 Hydraulic thruster YT1-180/12 Hydraulic thruster

time:2021-04-27

More