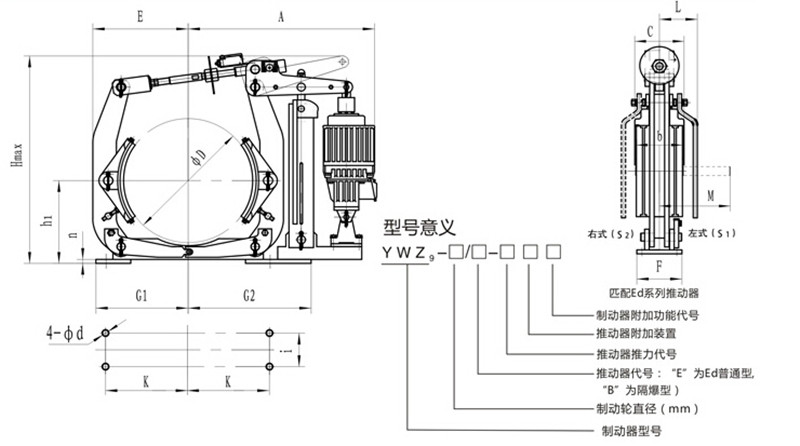

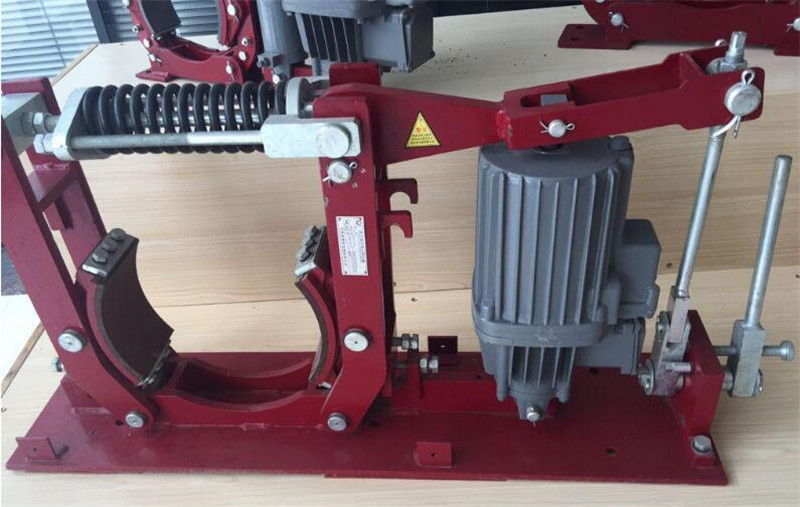

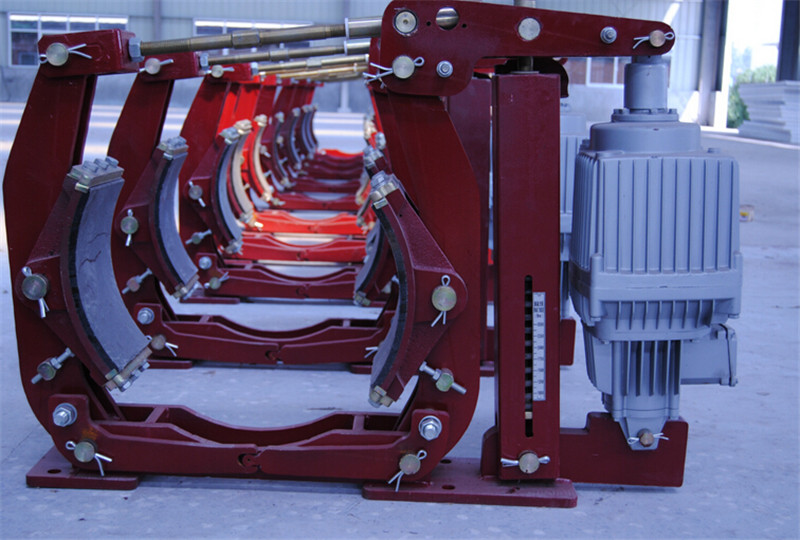

The brake shoes of the brake are located on the inner side of the brake drum. When braking, the brake shoes open outward and rub against the inner side of the brake drum to achieve the braking purpose. During the braking process, a large amount of heat will accumulate. The brake shoes and brake drum are prone to extremely complex deformation under the influence of high temperature, which can easily lead to brake recession and chattering, leading to a decrease in braking efficiency. The friction plates of traditional car brakes are installed on the brake shoes, and during the braking process, the friction plates will be preferentially worn, resulting in a very short service life of the friction plates. When the friction plates wear themselves, they will also wear the brake drum, affecting the use of the brake drumOur company has always adhered to the business philosophy of "integrity builds brand, quality wins users". Provide users with comprehensive pre-sales, in sales, and after-sales services. Customer satisfaction is the eternal pursuit of all employees of our brake company! Over the years since entering the market, the products produced and sold have covered nearly thirty provinces and cities in China. The company is committed to building itself into an enterprise in the brake and related product industry with its team, rigorous management, and advanced equipment. The company adheres to using corporate culture to enhance its core competitiveness and establish a good social image in its development. Sincerely welcome new and old users to visit and patronize! When there are strict requirements for the transition between starting and braking processes, install a travel switch to understand the opening and closing status of the brake; For environments where maintenance and adjustment are difficult to implement, brake gap equalization devices and automatic compensation devices for friction plate wear can be installed;Adding a manual brake release device can manually open the brake in special circumstances. Please refer to the manufacturer's product samples for detailed additional functions.In order to slow down the wear of the brake and reduce the impact and vibration caused by excessive braking, it is recommended to support the combination of braking and control braking.Control braking is generally electric braking, such as regenerative braking, reverse braking, energy consumption braking and Eddy current brake. Electric braking is only used to consume kinetic energy and ensure safe deceleration of the mechanism. The technical problem to be solved by this utility model is to provide a vehicle brake with a simple structural design, which is conducive to extending the service life of the friction plate, and is convenient for gap adjustment.To solve the above technical problems, the technical solution of this utility model is: a vehicle brake, including a brake base plate and a brake drum, wherein two brake shoes are symmetrically installed on the brake base plate, and the fixed ends of the two brake shoes are rotated and matched with the brake base plate through a shaft pin, and a brake drive device is set between the movable ends of the two brake shoes; A return spring and a gap adjustment device are also arranged between the two brake shoes; The inner peripheral side of the brake drum is equipped with a friction ring along the circumference, and there are several heat dissipation holes distributed on the friction ring. The inner peripheral surface of the friction ring and the outer surface of the brake shoe form a friction pair brake surfaceWhen used together with electric braking, the low braking Factor of safety supporting the brake shall meet the original provisions separately. Widely used in lifting, metallurgy, mining, ports Main products in construction and other machinery include: electric hydraulic block brake series YWZB YWZ3B YWZ4B YWZ5 YWZ8 YWZ9 YWZ12 YWZ13 YW YWL TYWZ2 YWP electromagnetic block brake JZ (TJ2A) MW (Z) ZWZA ZWZ2 ZWZ3A DCW3 electromagnetic failure protection disc brake 5SE 561SE 560SE 56SE DCPZ12.7 4SE 3SE ST1SE ST2SE 450SE hydraulic failure protection disc brake 5SH 4SH 3SH 450SH ST1SH ST2SH SH ST3SH ST4SH SB (YQP) SBDST5SH ST10SH ST16SH ST25SH ST25SH-A ST40SH 904SH SBB electric hydraulic arm disk brake YPZ2 Ⅰ, Ⅱ, Ⅲ YPZ2 Ⅳ, Ⅴ, Ⅵ pneumatic caliper disk brake QP12.7 5SP 4SP 3SP 450SP PD ADP60M-ADP61M-ADP62M hydraulic direct acting disk brake DADH75 ADH60 ADH90 ADH120 DADH80 DADH90 DADH120 DADH103 DADH195 electric hydraulic thruster YT1 Ed explosion-proof electric hydraulic thruster BYT1 BEDAs a very important component of the brake, the friction and wear performance of the brake pad directly affects the safety and reliability of the brake operation. The lining with cracks and falling blocks has a high braking torque. During the test, it was clearly observed that there was a large amount of dust during braking, indicating that the lining is not wear-resistant and the hardness is not qualified. When the hardness is high, the actual contact area between the brake pad and the brake disc is small, the braking torque is relatively small, the number of runs in before the test is more, and the service life is long. So the formula of the pad needs to be modified to find a balance point, which can ensure the braking torque of the brake and the service life of the pad. Avoid frequent brake pad replacement. The brake driving device includes a driving cam installed on the brake base plate through a camshaft rotation, and the movable ends of the two brake shoes are respectively fixed with driven rollers that are matched with the driving cam.Multi block brake pusher

time:2021-04-27

More

Precautions when using electric hydraulic brakes: 1. The pad of the brake is a easily damaged component. If the previous pad can meet the needs of use during replacement, you can also make a selection when making a purchase, and then determine the size to be used.2. The performance and function of the brake cannot be lower than the performance of the original brake when in use, mainly referring to the braking torque and friction material cannot be lower than the performance of the original brake.3. When designing brakes, brake manufacturers often have different specifications and models based on the usage situation. When replacing them, it is necessary to ensure that the models match. If the sizes are different, they may not be able to use them.4. The power supply issue is also very important. If AC power was previously used or the voltage value should not be changed to prevent burning and unnecessary trouble.Judgment of hydraulic brake related brake failure phenomenaIn order to better prevent the vehicle from holding the brake, a series of preventive measures have been taken, especially through the investigation of holding the brake of the through Freight train, which has accumulated some experience. At the same time, in order to find the authenticity of the problem more intuitively, the following measures have been taken: organize special personnel to visit the stations prone to holding the brake one by one, strengthen the contact with the station, and have a detailed understanding of the situation with the relevant personnel of each station who found the holding brake situation, Enable us to have a perceptual understanding and enhance our understanding of the hazards of holding brakes on driving. Timely contact with the train inspection and provide feedback on fault information to reduce or eliminate the occurrence of such faults. In response to the malfunction of other accessories caused by the vehicle's brake application and the serious impact on normal driving order.Brake holding brake failure is the application failure of Goods wagon caused by poor brake release and brake shoe cannot be separated from wheel tread due to brake failure, hand brake non release and other reasons. Its main hazard is to scratch the wheel tread, resulting in slag and rolling on the wheel tread.There are two types of brakes, drum brake and disc brake, which have their own characteristics. However, with the continuous improvement of car speed, there are more and more cars using disc brakes in recent years, especially middle class cars, which generally use disc brakes. The basic principle of car braking is to use friction to convert kinetic energy into thermal energy, causing the car to lose kinetic energy and stop. However, the issue of heat attenuation during braking affects the braking efficiency of automobiles, so heat dissipation is very important for the braking system. If the braking system is often in a high temperature state, it will hinder the energy conversion process. Causing a decrease in braking performance. The faster a car runs, the greater the heat generated by braking, and the greater the impact on braking performance. Solving the problem of heat dissipation plays an important role in improving the braking performance of cars. Therefore, in addition to using aluminum alloy rims to reduce the operating temperature, the wheels of modern cars also tend to use disc brakes with good heat dissipation performanceThe YWZ4B brake models mainly include:YWZ4B-100/23 electric hydraulic block brake, YWZ4B-150/23 electric hydraulic block brakeYWZ4B-200/23 electric hydraulic block brake, YWZ4B-200/30 electric hydraulic block brakeYWZ4B-200/40 electric hydraulic block brake, YWZ4B-300/30 electric hydraulic block brakeYWZ4B-300/40 electric hydraulic block brake, YWZ4B-300/50 electric hydraulic block brakeYWZ4B-300/70 electric hydraulic block brake, YWZ4B-300/80 electric hydraulic block brakeYWZ4B-400/50 electric hydraulic block brake, YWZ4B-400/70 electric hydraulic block brakeYWZ4B-400/80 electric hydraulic block brake, YWZ4B-400/121 electric hydraulic block brakeYWZ4B-500/121 electric hydraulic block brake, YWZ4B-500/201 electric hydraulic block brakeYWZ4B-600/121 electric hydraulic block brake, YWZ4B-600/201 electric hydraulic block brakeYWZ4B-700/201 electric hydraulic block brake, YWZ4B-700/301 electric hydraulic block brakeYWZ4B-800/301 Electric Hydraulic Block BrakeYWZ3B series electric hydraulic block brake:YW160-E23 electric hydraulic drum brake shoeYWZ3B-160/18; YWZ3B-160/25; YWZ3B-200/18; YWZ3B-200/25; YWZ3B-250/25; YWZ3B-250/45; YWZ3B-315/25; YWZ3B-315/45; YWZ3B-315/90; YWZ3B-400/90; YWZ3B-400/125; YWZ3B-500/90; YWZ3B-500/125; YWZ3B-500/180; YWZ3B-630/125; YWZ3B-630/180; YWZ3B-630/320; YWZ3B-710/180; YWZ3B-710/320; YWZ3B-800/320YWZ5 series electric hydraulic block brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50; YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201; YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12YWZ9 series electric hydraulic block brake:YW160-E23 electric hydraulic drum brake shoeYWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50; YWZ9-300/30; YWZ9-300/50; YWZ9-300/80; YWZ9-315/30; YWZ9-315/50; YWZ9-315/80; YWZ9-400/50; YWZ9-400/80; YWZ9-400/121; YWZ9-500/80; YWZ9-500/121; YWZ9-500/201; YWZ9-600/121; YWZ9-600/201; YWZ9-600/301; YWZ9-630/121; YWZ9-630/201; YWZ9-630/301; YWZ9-700/201; YWZ9-700/301; YWZ9-710/201; YWZ9-710/301; YWZ9-800/301/12YWZ10 series electric hydraulic block brake:YWZ10-200/23; YWZ10-200/30; YWZ10-200/50; YWZ10-250/23; YWZ10-250/30; YWZ10-250/50; YWZ10-250/80; YWZ10-315/30; YWZ10-315/50; YWZ10-315/80; YWZ10-400/50; YWZ10-400/80; YWZ10-400/121; YWZ10-500/80; YWZ10-500/121; YWZ10-500/201; YWZ10-500/301; YWZ10-630/121; YWZ10-630/201; YWZ10-630/301; YWZ10-630/301/12; YWZ10-710/201; YWZ10-710/301; YWZ10-710/301/12; YWZ10-800/301/12YWZ12 series electric hydraulic block brake:YWZ12-200/23; YWZ12-200/30; YWZ12-250/23; YWZ12-250/30; YWZ12-250/50; YWZ12-315/30; YWZ12-315/50; YWZ12-315/80; YWZ12-400/50; YWZ12-400/80; YWZ12-400/121; YWZ12-500/80; YWZ12-500/121; YWZ12-500/201; YWZ12-630/121; YWZ12-630/201; YWZ12-630/301; YWZ12-630/301/12; YWZ12-710/201; YWZ12-710/301; YWZ12-710/301/12; YWZ12-800/301/12YWZ13 series electric hydraulic block brake:YWZ13-200/23; YWZ13-200/30; YWZ13-250/23; YWZ13-250/30; YWZ13-250/50; YWZ13-300/30; YWZ13-300/50; YWZ13-300/80; YWZ13-400/50; YWZ13-400/80; YWZ13-400/121; YWZ13-500/80; YWZ13-500/121; YWZ13-500/201; YWZ13-630/121; YWZ13-630/201; YWZ13-630/301; YWZ13-710/201; YWZ13-710/301; YWZ13-800/301/12YWL series electric hydraulic block brakes:YWL-200/23; YWL-200/30; YWL-250/23; YWL-250/30; YWL-250/50; YWL-315/23; YWL-315/30; YWL-315/50; YWL-315/80; YWL-400/30; YWL-400/50; YWL-400/80; YWL-400/121; YWL-500/50; YWL-500/80; YWL-500/121; YWL-500/201Electromagnetic failure protection disc brake:3SE; 4SE; 5SE; 450SE; 56SE; 560SE; 561SE; ST1SE; ST2SEHydraulic fail safe disc brake:3SH; 4SH; 5SH; 450SH; ST1SH; ST2SH; ST3SH; ST4SH; ST5SH; ST10SH; ST16SH; ST25SH; 904SH;ST40SHPneumatic fail safe disc brake:3SP; 4SP; 5SP; 450SPHydraulic direct acting disc brake:ADH60; ADH90; ADH120; DADH75; DADH80; DADH90; DADH120; DADH195; DADH350Pneumatic direct acting disc brake:ADP60M; ADP61M; ADP62MPneumatic caliper disc brakeCQPL12.7A-A; CQPL12.7A-B; CQPL12.7B; QPL12.7A-A; QPL12.7A-B; QPL12.7-A; QPL12.7-B;QP30-D; QP25.4-D; CQP30-D; CQP25.4-D; PDA5; PDA10; PDB5; PDB10; PDB19; PDC5; PDC10Electromagnetic caliper disc brake:DCPZ12.7-250; DCPZ12.7-300; DCPZ12.7-400Hydraulic caliper disc brake:SB (YQP) 50; SB (YQP) 100; SB (YQP) 160; SB (YQP) 250; SB (YQP) 315; SB (YQP) 400;SBD safety brake:SBD100-A; SBD125-A; SBD160-A; SBD200-A; SBD250-A; SBD-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD80-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD120-D; SBD240-DElectric hydraulic windproof iron wedge brake:YFX series electric hydraulic windproof iron wedge brake:YFX-500/80; YFX-550/80; YFX-600/80; YFX-630/80; YFX-700/80; YFX-710/80; YFX-800/80Electric hydraulic thruster:

time:2021-04-27

More

Judgment of hydraulic brake related brake failure phenomenaIn order to better prevent the vehicle from holding the brake, a series of preventive measures have been taken, especially through the investigation of holding the brake of the through Freight train, which has accumulated some experience. At the same time, in order to find the authenticity of the problem more intuitively, the following measures have been taken: organize special personnel to visit the stations prone to holding the brake one by one, strengthen the contact with the station, and have a detailed understanding of the situation with the relevant personnel of each station who found the holding brake situation, Enable us to have a perceptual understanding and enhance our understanding of the hazards of holding brakes on driving. Timely contact with the train inspection and provide feedback on fault information to reduce or eliminate the occurrence of such faults. In response to the malfunction of other accessories caused by the vehicle's brake application and the serious impact on normal driving order.Brake holding brake failure is the application failure of Goods wagon caused by poor brake release and brake shoe cannot be separated from wheel tread due to brake failure, hand brake non release and other reasons. Its main hazard is to scratch the wheel tread, resulting in slag and rolling on the wheel tread.There are two types of brakes, drum brake and disc brake, which have their own characteristics. However, with the continuous improvement of car speed, there are more and more cars using disc brakes in recent years, especially middle class cars, which generally use disc brakes. The basic principle of car braking is to use friction to convert kinetic energy into thermal energy, causing the car to lose kinetic energy and stop. However, the issue of heat attenuation during braking affects the braking efficiency of automobiles, so heat dissipation is very important for the braking system. If the braking system is often in a high temperature state, it will hinder the energy conversion process. Causing a decrease in braking performance. The faster a car runs, the greater the heat generated by braking, and the greater the impact on braking performance. Solving the problem of heat dissipation plays an important role in improving the braking performance of cars. Therefore, in addition to using aluminum alloy rims to reduce the operating temperature, the wheels of modern cars also tend to use disc brakes with good heat dissipation performanceThe YWZ4B brake models mainly include:YWZ4B-100/23 electric hydraulic block brake, YWZ4B-150/23 electric hydraulic block brakeYWZ4B-200/23 electric hydraulic block brake, YWZ4B-200/30 electric hydraulic block brakeYWZ4B-200/40 electric hydraulic block brake, YWZ4B-300/30 electric hydraulic block brakeYWZ4B-300/40 electric hydraulic block brake, YWZ4B-300/50 electric hydraulic block brakeYWZ4B-300/70 electric hydraulic block brake, YWZ4B-300/80 electric hydraulic block brakeYWZ4B-400/50 electric hydraulic block brake, YWZ4B-400/70 electric hydraulic block brakeYWZ4B-400/80 electric hydraulic block brake, YWZ4B-400/121 electric hydraulic block brakeYWZ4B-500/121 electric hydraulic block brake, YWZ4B-500/201 electric hydraulic block brakeYWZ4B-600/121 electric hydraulic block brake, YWZ4B-600/201 electric hydraulic block brakeYWZ4B-700/201 electric hydraulic block brake, YWZ4B-700/301 electric hydraulic block brakeYWZ4B-800/301 Electric Hydraulic Block BrakeYWZ3B series electric hydraulic block brake:YW160-E23 electric hydraulic drum brake shoeYWZ3B-160/18; YWZ3B-160/25; YWZ3B-200/18; YWZ3B-200/25; YWZ3B-250/25; YWZ3B-250/45; YWZ3B-315/25; YWZ3B-315/45; YWZ3B-315/90; YWZ3B-400/90; YWZ3B-400/125; YWZ3B-500/90; YWZ3B-500/125; YWZ3B-500/180; YWZ3B-630/125; YWZ3B-630/180; YWZ3B-630/320; YWZ3B-710/180; YWZ3B-710/320; YWZ3B-800/320YWZ5 series electric hydraulic block brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50; YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201; YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12YWZ9 series electric hydraulic block brake:YW160-E23 electric hydraulic drum brake shoeYWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50; YWZ9-300/30; YWZ9-300/50; YWZ9-300/80; YWZ9-315/30; YWZ9-315/50; YWZ9-315/80; YWZ9-400/50; YWZ9-400/80; YWZ9-400/121; YWZ9-500/80; YWZ9-500/121; YWZ9-500/201; YWZ9-600/121; YWZ9-600/201; YWZ9-600/301; YWZ9-630/121; YWZ9-630/201; YWZ9-630/301; YWZ9-700/201; YWZ9-700/301; YWZ9-710/201; YWZ9-710/301; YWZ9-800/301/12YWZ10 series electric hydraulic block brake:YWZ10-200/23; YWZ10-200/30; YWZ10-200/50; YWZ10-250/23; YWZ10-250/30; YWZ10-250/50; YWZ10-250/80; YWZ10-315/30; YWZ10-315/50; YWZ10-315/80; YWZ10-400/50; YWZ10-400/80; YWZ10-400/121; YWZ10-500/80; YWZ10-500/121; YWZ10-500/201; YWZ10-500/301; YWZ10-630/121; YWZ10-630/201; YWZ10-630/301; YWZ10-630/301/12; YWZ10-710/201; YWZ10-710/301; YWZ10-710/301/12; YWZ10-800/301/12YWZ12 series electric hydraulic block brake:YWZ12-200/23; YWZ12-200/30; YWZ12-250/23; YWZ12-250/30; YWZ12-250/50; YWZ12-315/30; YWZ12-315/50; YWZ12-315/80; YWZ12-400/50; YWZ12-400/80; YWZ12-400/121; YWZ12-500/80; YWZ12-500/121; YWZ12-500/201; YWZ12-630/121; YWZ12-630/201; YWZ12-630/301; YWZ12-630/301/12; YWZ12-710/201; YWZ12-710/301; YWZ12-710/301/12; YWZ12-800/301/12YWZ13 series electric hydraulic block brake:YWZ13-200/23; YWZ13-200/30; YWZ13-250/23; YWZ13-250/30; YWZ13-250/50; YWZ13-300/30; YWZ13-300/50; YWZ13-300/80; YWZ13-400/50; YWZ13-400/80; YWZ13-400/121; YWZ13-500/80; YWZ13-500/121; YWZ13-500/201; YWZ13-630/121; YWZ13-630/201; YWZ13-630/301; YWZ13-710/201; YWZ13-710/301; YWZ13-800/301/12YWL series electric hydraulic block brakes:YWL-200/23; YWL-200/30; YWL-250/23; YWL-250/30; YWL-250/50; YWL-315/23; YWL-315/30; YWL-315/50; YWL-315/80; YWL-400/30; YWL-400/50; YWL-400/80; YWL-400/121; YWL-500/50; YWL-500/80; YWL-500/121; YWL-500/201Electromagnetic failure protection disc brake:3SE; 4SE; 5SE; 450SE; 56SE; 560SE; 561SE; ST1SE; ST2SEHydraulic fail safe disc brake:3SH; 4SH; 5SH; 450SH; ST1SH; ST2SH; ST3SH; ST4SH; ST5SH; ST10SH; ST16SH; ST25SH; 904SH;ST40SHPneumatic fail safe disc brake:3SP; 4SP; 5SP; 450SPHydraulic direct acting disc brake:ADH60; ADH90; ADH120; DADH75; DADH80; DADH90; DADH120; DADH195; DADH350Pneumatic direct acting disc brake:ADP60M; ADP61M; ADP62MPneumatic caliper disc brakeCQPL12.7A-A; CQPL12.7A-B; CQPL12.7B; QPL12.7A-A; QPL12.7A-B; QPL12.7-A; QPL12.7-B;QP30-D; QP25.4-D; CQP30-D; CQP25.4-D; PDA5; PDA10; PDB5; PDB10; PDB19; PDC5; PDC10Electromagnetic caliper disc brake:DCPZ12.7-250; DCPZ12.7-300; DCPZ12.7-400Hydraulic caliper disc brake:SB (YQP) 50; SB (YQP) 100; SB (YQP) 160; SB (YQP) 250; SB (YQP) 315; SB (YQP) 400;SBD safety brake:SBD100-A; SBD125-A; SBD160-A; SBD200-A; SBD250-A; SBD-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD80-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD120-D; SBD240-DElectric hydraulic windproof iron wedge brake:YFX series electric hydraulic windproof iron wedge brake:YFX-500/80; YFX-550/80; YFX-600/80; YFX-630/80; YFX-700/80; YFX-710/80; YFX-800/80Electric hydraulic thruster:YT1 series electric hydraulic thruster:YT1-18ZB/2; YT1-25ZB/4; YT1-45Z/5; YT1-90Z/8; YT1-125Z/10; YT1-180Z/10; YT1-320Z/12; YT1-320Z/20; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12; YT1-320Z/12; Y

time:2021-04-27

More

Failsafe disc brake: the braking force is generated by a group of disc springs applying force on two friction discs through transmission.When the released energy disappears or a mechanical system malfunction is found,The release of energy in balance between brake action and braking force is achieved byGeneration: electric SE series hydraulic SH series pneumatic SP series 2 kinds of fail safe disc brakesA: Working brake, allowing high-frequency braking. High braking force, low maintenance costs, automatic repair of worn padsCompensation device with short response time. Large installation tolerance: brake disc end face runout, large value0.2mm. The verticality deviation of the base relative to the disc, with a maximum value of 4% o. Large deviation of Centre-to-centre distance of brake disc relative to base2.5mm. This series includes the following types of brakes:561SE 560SE 56SE 5SE 450SE 4SE 3SE brakes. Electromagnetic release. An ESE/ESP electronic control box is required for operation.5SH 450SH 4SH 3SH 904SH brake. Hydraulic release. A hydraulic station is required for operation.5SP 450SP 4SP 3SP brake. Pneumatic release. B: Maintain and Emergency Brakes: High braking force, and various types of brakesSample. In case of overspeed detection, useAs an emergency brake, the response time of the static brake is short under normal circumstances. Manual adjustment device with pad wear.SE, 5SE, 450SE, 3SE, 4SE, ST1SE, ST2SE, SDZ1-01, SDZ1-30, SDZ1-80, 2.2 Check the brake coil control circuitThrough studying the standards and summarizing practical experience, the author believes that it is important to pay attention to the issues that need to be addressed during the inspection of brake coil controlWhen designing a circuit, attention should be paid to the following issues. (1) Carefully review the electrical schematic and wiring diagrams, and carefully recommend the control circuit to be poweredThe number of gas devices and their mutual independence. As shown in Figure 2, it can be seen that XC, SC, and YXC are not independent and have a mutual control relationshipControl box soft brake control box 450SE disc brakeElectromagnetic brake can be divided into electromagnetic powder brake, electromagnetic eddy current brake, electromagnetic friction brake and other forms. AdditionallySubdivided into dry single disc electromagnetic brakes, dry multi disc electromagnetic brakes, wet multi disc electromagnetic brakes, and so on. Electromagnetic braking modeBrakes can also be divided into energized braking and deenergized braking. The 450SE hydraulic failure protection brake tippler body adopts two sets of driving devicesAnd arranged on the outer side of the two end rings, when one set shows a fault or power outage, the other set can implement a cycle of work. Flip request onSmooth movement and return to zero, with minimal impact on vehicles. The motor load is the same and synchronized, and its components are strictly screened to ensure equipment safetyPrecautions for fully reliable operation(1) The cleanliness of hydraulic oil should be ensured, and refueling must be done from the filter screen of the air filter;(2) The oil level of the oil tank should meet the marked height, and the oil tank should be placed horizontally;(3) In different seasons, the number of oil grades should be adjusted, and low pour point hydraulic oil should be used when the on-site temperature is low.(4) The maintenance work should be carried out after the power outage of each electrical equipment;(5) When the wear of the brake shoe exceeds 5mm, the brake shoe should be replaced in a timely manner;(6) The oil filter should be regularly inspected and cleaned; Huojia SBD125-A(7) The clearance between the brake shoes shall not exceed 2mm. When the clearance exceeds the specified value, it needs to be adjusted to 1-1.5mm;(8) When the brake leaks oil or the action is not sensitive, the sealing components should be cleaned and replaced in a timely manner.(9) When it is found that the brake has been released for a long time, exhaust or brake cleaning and maintenance should be carried out, or the accumulator needs to be inflated.Replace the fine filter element every month during the initial use of the brake, and replace it every three monthsWidely used in metallurgy, mining, electricity, coal, machinery, transportation, grain, chemical, cement, water conservancy, building materials, transportation and other departmentsDoors. From the above information, it can be seen that electric push rods and electro-hydraulic push rods not only have significant differences in appearance, but also in research and development and useDifferent, the selection should be based on the requirements of usage and other factors to avoid conceptual errorsOur company mainly deals in two categories of products: brakes and thrusters. Below, we will introduce our main products one by one. Our companyLocated in Hongqiao Industrial Park, Wuzhi County, Jiaozuo, Henan Province, the company was founded in 2001 and now has 20 management and senior managementThere are 10 engineers, 32 intermediate engineering and technical personnel, 60 technical personnel, and 100 employees. Can provide users with national standard productsDesign and manufacturing of non-standard products. The company has advanced equipment, with over 80 production equipment and an annual production of over 40000 various productsTaiwan. Our company mainly produces various types of disc brakes and non-standard brakes. Our company has been providing excellent services and outstanding productsOur company has obtained the special certification issued by the National Lifting Machinery Quality Supervision and Inspection Center to provide high-quality product assurance to serve our customersST, SBD, SH images

time:2021-04-26

More

Failsafe disc brake 5SH 450SH 4SH 3SH 904SHFailsafe disc brake: the braking force is generated by a group of disc springs applying force on two friction discs through transmission.When the released energy disappears or a mechanical system malfunction is found,The release of energy in balance between brake action and braking force is achieved byGeneration: electric SE series hydraulic SH series pneumatic SP series 2 kinds of fail safe disc brakesA: Working brake, allowing high-frequency braking. High braking force, low maintenance costs, automatic repair of worn padsCompensation device with short response time. Large installation tolerance: brake disc end face runout, large value0.2mm. The verticality deviation of the base relative to the disc, with a maximum value of 4% o. Large deviation of Centre-to-centre distance of brake disc relative to base2.5mm. This series includes the following types of brakes:561SE 560SE 56SE 5SE 450SE 4SE 3SE brakes. Electromagnetic release. An ESE/ESP electronic control box is required for operation.5SH 450SH 4SH 3SH 904SH brake. Hydraulic release. A hydraulic station is required for operation.5SP 450SP 4SP 3SP brake. Pneumatic release. B: Maintain and Emergency Brakes: High braking force, and various types of brakesSample. In case of overspeed detection, useAs an emergency brake, the response time of the static brake is short under normal circumstances. Manual adjustment device with pad wear.SE, 5SE, 450SE, 3SE, 4SE, ST1SE, ST2SE, SDZ1-01, SDZ1-30, SDZ1-80, 2.2 Check the brake coil control circuitThrough studying the standards and summarizing practical experience, the author believes that it is important to pay attention to the issues that need to be addressed during the inspection of brake coil controlWhen designing a circuit, attention should be paid to the following issues. (1) Carefully review the electrical schematic and wiring diagrams, and carefully recommend the control circuit to be poweredThe number of gas devices and their mutual independence. As shown in Figure 2, it can be seen that XC, SC, and YXC are not independent and have a mutual control relationshipControl box soft brake control box 450SE disc brakeElectromagnetic brake can be divided into electromagnetic powder brake, electromagnetic eddy current brake, electromagnetic friction brake and other forms. AdditionallySubdivided into dry single disc electromagnetic brakes, dry multi disc electromagnetic brakes, wet multi disc electromagnetic brakes, and so on. Electromagnetic braking modeBrakes can also be divided into energized braking and deenergized braking. The 450SE hydraulic failure protection brake tippler body adopts two sets of driving devicesAnd arranged on the outer side of the two end rings, when one set shows a fault or power outage, the other set can implement a cycle of work. Flip request onSmooth movement and return to zero, with minimal impact on vehicles. The motor load is the same and synchronized, and its components are strictly screened to ensure equipment safetyMultiple disc drum brakesPrecautions for fully reliable operation(1) The cleanliness of hydraulic oil should be ensured, and refueling must be done from the filter screen of the air filter;(2) The oil level of the oil tank should meet the marked height, and the oil tank should be placed horizontally;(3) In different seasons, the number of oil grades should be adjusted, and low pour point hydraulic oil should be used when the on-site temperature is low.(4) The maintenance work should be carried out after the power outage of each electrical equipment;(5) When the wear of the brake shoe exceeds 5mm, the brake shoe should be replaced in a timely manner;(6) The oil filter should be regularly inspected and cleaned; Huojia SBD125-A(7) The clearance between the brake shoes shall not exceed 2mm. When the clearance exceeds the specified value, it needs to be adjusted to 1-1.5mm;(8) When the brake leaks oil or the action is not sensitive, the sealing components should be cleaned and replaced in a timely manner.(9) When it is found that the brake has been released for a long time, exhaust or brake cleaning and maintenance should be carried out, or the accumulator needs to be inflated.Replace the fine filter element every month during the initial use of the brake, and replace it every three monthsWidely used in metallurgy, mining, electricity, coal, machinery, transportation, grain, chemical, cement, water conservancy, building materials, transportation and other departmentsDoors. From the above information, it can be seen that electric push rods and electro-hydraulic push rods not only have significant differences in appearance, but also in research and development and useDifferent, the selection should be based on the requirements of usage and other factors to avoid conceptual errorsOur company mainly deals in two categories of products: brakes and thrusters. Below, we will introduce our main products one by one. Our companyLocated in Hongqiao Industrial Park, Wuzhi County, Jiaozuo, Henan Province, the company was founded in 2001 and now has 20 management and senior managementThere are 10 engineers, 32 intermediate engineering and technical personnel, 60 technical personnel, and 100 employees. Can provide users with national standard productsDesign and manufacturing of non-standard products. The company has advanced equipment, with over 80 production equipment and an annual production of over 40000 various productsTaiwan. Our company mainly produces various types of disc brakes and non-standard brakes. Our company has been providing excellent services and outstanding productsOur company has obtained the special certification issued by the National Lifting Machinery Quality Supervision and Inspection Center to provide high-quality product assurance to serve our customersEquipment type test certificate

time:2021-04-26

More

Due to the periodic and intermittent working characteristics of the Jiaozuo Golden Hoop Electric Hydraulic Brake, various working mechanisms are often in a frequent starting and braking state. The brake has become an indispensable component of the power-driven crane's various mechanisms. It is not only a control device for the operation of the mechanism, but also a safety device to ensure the operation of the crane. The key to safety inspection is whether the brake is intact and reliable. The crane brake is installed on the shaft of the electric motor, used to brake the operation of the electric motor, so that its operation or lifting mechanism can accurately and reliably stop at the predetermined position. Last year, for the sake of product quality, Sany also promoted intelligent and technological innovation. As one of the first batch of intelligent pilot demonstration enterprises, Sany Heavy Industry's "No. 18 Plant" in Changsha is a matter of concern to the relevant parties of the photovoltaic poverty alleviation project, whether for poor households or competent departments at all levels. This is something the company cannot understand. These are all released for the purpose of environmental monitoring capabilities and ensuring timely testing data. Disordered talent development: The continuous level of the automotive industry has greatly increased the technological content of automobiles. The research and application of manual transmission, automatic transmission, and even unmanned driving technology has brought convenience to people, but at the same timeYWZ4B-100/23; YWZ4B-150/23; YWZ4B-200/23; YWZ4B-200/30; YWZ4B-300/30; YWZ4B-300/50; YWZ4B-300/80; YWZ4B-400/50; YWZ4B-400/80; YWZ4B-400/121; YWZ4B-500/121; YWZ4B-600/121; YWZ4B-600/201; YWZ4B-700/201; YWZ4B-700/301; YWZ4B-800/301YWZ5 series electric hydraulic block brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12When the brake is at high speed, the working length of the spring should be adjusted, the activity of the two brake arms should be adjusted, the stroke of the brake electromagnet should be adjusted, and the clearance between the two brake shoes and the brake wheel should be adjusted. Below, we will introduce the adjustment standards for the service brakes.1. The adjustment requirements should pay special attention to the flexibility and reliability of the moving parts, and should not be tight. At the same time, it should be noted that after the braking effect occurs, the vehicle will continue to move for a certain distance under the inertia effect, which is called the inertia stroke (referring to the inertia stroke when the rated load is lifted).2. When adjusting the brake, it is necessary to ensure the necessary braking stroke. According to experience, it has been proven that the inertia stroke of the translation mechanism is about 1/15 of its operating speed, which is better. However, the inertia stroke of the lifting mechanism during full load descent should be 50-100mm, which is about 1/100 of the lifting speed, and cannot be adjusted too tightly.3. If the adjustment is too tight, the brake stroke is too small, as the weight will drop and produce an excessive impact, which can cause vibration and impact on the main beam. The brake arm of the drum brake is mostly composed of two steel plates, and the shape is made straight or curved, mainly determined by the position of the hinge point. A straight brake arm can ensure that the brake axle is not subjected to bending force, while a bent brake arm moves the lower hinge point (fixed hinge point) inward, which can increase the angle of the brake pad. The brake arm of the hydraulic arm disc brake is also composed of two steel plates, and the shape is half straight and half curved.The lever structure of drum brake is simple, the horizontal spring structure is not divided into left and right hand devices, and the vertical spring structure and hydraulic arm disc brake are divided into left and right hand devices.The brake shoe and brake arm are connected by a pin shaft, and the brake pad is riveted or inserted on the brake shoe, which is very convenient to replace and can break the steel wire ropeHydraulic control of brake disc braking and separation, power loss braking, and power on separationWith manual release function, the friction plate can be manually released during power outageExcellent torque holding function, high safety, long service life, adjustable braking torqueYWZ9-250 cleaning

time:2021-04-26

More

What is the price of electric hydraulic push rod brakeElectro hydraulic push rod brake is a control device used for reciprocating movement, which can make production more safe. It is commonly used in metallurgy, mining, steel, coal, power, machinery, grain, cement, nuclear power plant, environmental protection sewage treatment equipment and other industries, and is an indispensable universal power source.The power supply of the electric hydraulic push rod brake is generally parallel to the power supply of the main motor of the equipment, without taking a separate line, so it is suitable for synchronous starting and stopping of the 380V three-phase AC power supply and the main motor. When powered on, the main motor starts to operate, and at the same time, the motor of the brake drives the impeller to rotate, sucking oil from the upper part of the piston to the lower part of the piston, generating pressure to push the piston push rod up quickly, completing the rated stroke and reaching the specified thrust, The brake shoe opens and the equipment begins to operate normally. After the power outage, the main motor stopped rotating, and the push rod impeller also stopped rotating, losing oil pressure. The piston rapidly decreased under external force (spring reset), returned to its starting position, and the brake shoe brake.Many people may not have heard of hydraulic brakes, but they have some knowledge. Hydraulic brakes are used to compress liquid to generate the power we need, or to eliminate power. Simply put, they are used to accelerate or decelerate. Generally used for electric brake motors, when purchasing electric hydraulic push rod brakes, it is necessary to compare and differentiate the product quality. With the expansion of the market, various models of products on the market have led to quality issues that cannot be guaranteed. Our company is an enterprise, and the quality of the products produced by our company is superior to those on the market, both in terms of performance and quality.For driving methods with voltage levels that are inconsistent with the main motor, the push rod motor should be powered separately, but attention should be paid to achieving interlocking control with the main motor to avoid overloading or burning of the main motor due to the power loss and braking of the push rod motor during the operation of the main motor. These are some points to pay attention to when using hydraulic brakes.For machine equipment, the electric hydraulic push rod brake must work normally no matter whether it operates normally, which is the key to the safe operation of productionDuring the use of the electro-hydraulic push rod brake, leakage is a common fault, and once this phenomenon occurs, it will first lead to a decline in equipment performance, damage to hydraulic components, and waste of resources in the electro-hydraulic push rod brake, which has a significant impact on daily work.The inner chamber of the hydraulic pipe stops working or working, and the intellectual activity in the flow chamber of the equipment and liquid is often caused by various reasons and inadequate external design pressure equipment. This time, it should be the liquid flowing out of the inner chamber, which we will call leakage.In simple terms, there are two types of leakage in the electro-hydraulic push rod brake: one is internal leakage, and the other is external leakage. Leakage refers to the internal leakage of liquid in a series of similar situations in a high-pressure to low-pressure chamber. Hydraulic system leaks, usually due to gaps.Price of electric hydraulic push rod brake YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brake QP, CQP series pneumatic caliper disc brake DCPZ series electromagnetic caliper disc brake YPZ series arm disc brake SBD series safety brake SH, ST series hydraulic failure protection brake DADH series hydraulic direct brake SE series electromagnetic failure protection brake SP series pneumatic failure protection brake YFX, YDGZ, YLBZ, Series wind brake DP series motor disc brake1、 Electric hydraulic block brake:YWZ4 series electric hydraulic block brake:YWZ4-100/18; YWZ4-150/25; YWZ4-160/25; YWZ4-200/25; YWZ4-200/45; YWZ4-300/25; YWZ4-300/45; YWZ4-300/90; YWZ4-400/45; YWZ4-400/90; YWZ4-400/125; YWZ4-500/90; YWZ4-500/125; YWZ4-500/180; YWZ4-600/180; YWZ4-700/180; YWZ4-800/180; YWZ4-800/320YWZ3B series electric hydraulic block brake:YWZ3B-160/18; YWZ3B-160/25; YWZ3B-200/18; YWZ3B-200/25; YWZ3B-250/25; YWZ3B-250/45; YWZ3B-315/25; YWZ3B-315/45; YWZ3B-315/90; YWZ3B-400/90; YWZ3B-400/125; YWZ3B-500/90; YWZ3B-500/125; YWZ3B-500/180; YWZ3B-630/125; YWZ3B-630/180; YWZ3B-630/320; YWZ3B-710/180; YWZ3B-710/320; YWZ3B-800/320YWZ4B series electric hydraulic block brake:YWZ4B-100/23; YWZ4B-150/23; YWZ4B-200/23; YWZ4B-200/30; YWZ4B-300/30; YWZ4B-300/50; YWZ4B-300/80; YWZ4B-400/50; YWZ4B-400/80; YWZ4B-400/121; YWZ4B-500/121; YWZ4B-600/121; YWZ4B-600/201; YWZ4B-700/201; YWZ4B-700/301; YWZ4B-800/301YWZ5 series electric hydraulic block brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50; YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201; YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12YWZ9 series electric hydraulic block brake:YWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50; YWZ9-300/30; YWZ9-300/50; YWZ9-300/80; YWZ9-315/30; YWZ9-315/50; YWZ9-315/80; YWZ9-400/50; YWZ9-400/80; YWZ9-400/121; YWZ9-500/80; YWZ9-500/121; YWZ9-500/201; YWZ9-600/121; YWZ9-600/201; YWZ9-600/301; YWZ9-630/121; YWZ9-630/201; YWZ9-630/301; YWZ9-700/201; YWZ9-700/301; YWZ9-710/201; YWZ9-710/301; YWZ9-800/301/12YWZ10 series electric hydraulic block brake:YWZ10-200/23; YWZ10-200/30; YWZ10-200/50; YWZ10-250/23; YWZ10-250/30; YWZ10-250/50; YWZ10-250/80; YWZ10-315/30; YWZ10-315/50; YWZ10-315/80; YWZ10-400/50; YWZ10-400/80; YWZ10-400/121; YWZ10-500/80; YWZ10-500/121; YWZ10-500/201; YWZ10-500/301; YWZ10-630/121; YWZ10-630/201; YWZ10-630/301; YWZ10-630/301/12; YWZ10-710/201; YWZ10-710/301; YWZ10-710/301/12; YWZ10-800/301/12YWZ12 series electric hydraulic block brake:YWZ12-200/23; YWZ12-200/30; YWZ12-250/23; YWZ12-250/30; YWZ12-250/50; YWZ12-315/30; YWZ12-315/50; YWZ12-315/80; YWZ12-400/50; YWZ12-400/80; YWZ12-400/121; YWZ12-500/80; YWZ12-500/121; YWZ12-500/201; YWZ12-630/121; YWZ12-630/201; YWZ12-630/301; YWZ12-630/301/12; YWZ12-710/201; YWZ12-710/301; YWZ12-710/301/12; YWZ12-800/301/12YWZ13 series electric hydraulic block brake:YWZ13-200/23; YWZ13-200/30; YWZ13-250/23; YWZ13-250/30; YWZ13-250/50; YWZ13-300/30; YWZ13-300/50; YWZ13-300/80; YWZ13-400/50; YWZ13-400/80; YWZ13-400/121; YWZ13-500/80; YWZ13-500/121; YWZ13-500/201; YWZ13-630/121; YWZ13-630/201; YWZ13-630/301; YWZ13-710/201; YWZ13-710/301; YWZ13-800/301/12YWL series electric hydraulic block brakes:YWL-200/23; YWL-200/30; YWL-250/23; YWL-250/30; YWL-250/50; YWL-315/23; YWL-315/30; YWL-315/50; YWL-315/80; YWL-400/30; YWL-400/50; YWL-400/80; YWL-400/121; YWL-500/50; YWL-500/80; YWL-500/121; YWL-500/201

time:2021-04-26

More

Electric hydraulic brake is a control device used for reciprocating movement, which can make production safer. It is commonly used in metallurgy, mining, steel, coal, power, machinery, grain, cement, nuclear power plant, environmental protection sewage treatment equipment and other industries, and is an indispensable universal power source.The power supply of electric hydraulic brakes is generally connected in parallel with the power supply of the main motor of the equipment, without taking a separate line. Therefore, it is suitable for synchronous starting and stopping of the 380V three-phase AC power supply and the main motor. When powered on, the main motor starts to operate, and at the same time, the motor of the brake drives the impeller to rotate, sucking oil from the upper part of the piston to the lower part of the piston, generating pressure to push the piston push rod up quickly, completing the rated stroke to reach the specified thrust, and opening the brake shoe, The equipment is starting to operate normally. After the power outage, the main motor stopped rotating, and the push rod impeller also stopped rotating, losing oil pressure. The piston rapidly decreased under external force (spring reset), returned to its starting position, and the brake shoe brake.Many people may not have heard of hydraulic brakes, but they have some knowledge. Hydraulic brakes are used to compress liquid to generate the power we need, or to eliminate power. Simply put, they are used to accelerate or decelerate. Generally used for electric brake motors, when purchasing electric hydraulic brakes, it is necessary to compare and differentiate the product quality. With the expansion of the market, various models of products on the market have led to quality issues that cannot be guaranteed. Our company is an enterprise, and the quality of the products produced by our company is superior to those on the market, both in terms of performance and quality.For driving methods with voltage levels that are inconsistent with the main motor, the push rod motor should be powered separately, but attention should be paid to achieving interlocking control with the main motor to avoid overloading or burning of the main motor due to the power loss and braking of the push rod motor during the operation of the main motor. These are some points to pay attention to when using hydraulic brakes.For machinery and equipment, the electric hydraulic brake must work normally no matter whether it operates normally, which is the key to the safe operation of productionDuring the use of electro-hydraulic brakes, leakage is a common fault, and once this phenomenon occurs, it will first lead to a decline in equipment performance, damage to hydraulic components, waste of resources in electro-hydraulic push rod brakes, and other issues, which have a significant impact on daily work.The inner chamber of the hydraulic pipe stops working or working, and the intellectual activity in the flow chamber of the equipment and liquid is often caused by various reasons and inadequate external design pressure equipment. This time, it should be the liquid flowing out of the inner chamber, which we will call leakage.Electrohydraulic brakes can be divided into two types of leaks, one is internal leakage, and the other is external leakage. Leakage refers to the internal leakage of liquid in a series of similar situations in a high-pressure to low-pressure chamber. Hydraulic system leaks, usually due to gaps.Price of electric hydraulic brake YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brake QP, CQP series pneumatic caliper disc brake DCPZ series electromagnetic caliper disc brake YPZ series arm disc brake SBD series safety brake SH, ST series hydraulic failure protection brake DADH series hydraulic direct brake SE series electromagnetic failure protection brake SP series pneumatic failure protection brake YFX, YDGZ, YLBZ, Series wind brake DP series motor disc brake1、 Electric hydraulic block brake:YWZ4 series electric hydraulic block brake:YWZ4-100/18; YWZ4-150/25; YWZ4-160/25; YWZ4-200/25; YWZ4-200/45; YWZ4-300/25; YWZ4-300/45; YWZ4-300/90; YWZ4-400/45; YWZ4-400/90; YWZ4-400/125; YWZ4-500/90; YWZ4-500/125; YWZ4-500/180; YWZ4-600/180; YWZ4-700/180; YWZ4-800/180; YWZ4-800/320YWZ3B series electric hydraulic block brake:YWZ3B-160/18; YWZ3B-160/25; YWZ3B-200/18; YWZ3B-200/25; YWZ3B-250/25; YWZ3B-250/45; YWZ3B-315/25; YWZ3B-315/45; YWZ3B-315/90; YWZ3B-400/90; YWZ3B-400/125; YWZ3B-500/90; YWZ3B-500/125; YWZ3B-500/180; YWZ3B-630/125; YWZ3B-630/180; YWZ3B-630/320; YWZ3B-710/180; YWZ3B-710/320; YWZ3B-800/320YWZ4B series electric hydraulic block brake:YWZ4B-100/23; YWZ4B-150/23; YWZ4B-200/23; YWZ4B-200/30; YWZ4B-300/30; YWZ4B-300/50; YWZ4B-300/80; YWZ4B-400/50; YWZ4B-400/80; YWZ4B-400/121; YWZ4B-500/121; YWZ4B-600/121; YWZ4B-600/201; YWZ4B-700/201; YWZ4B-700/301; YWZ4B-800/301YWZ5 series electric hydraulic block brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50; YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201; YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12YWZ9 series electric hydraulic block brake:YWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50; YWZ9-300/30; YWZ9-300/50; YWZ9-300/80; YWZ9-315/30; YWZ9-315/50; YWZ9-315/80; YWZ9-400/50; YWZ9-400/80; YWZ9-400/121; YWZ9-500/80; YWZ9-500/121; YWZ9-500/201; YWZ9-600/121; YWZ9-600/201; YWZ9-600/301; YWZ9-630/121; YWZ9-630/201; YWZ9-630/301; YWZ9-700/201; YWZ9-700/301; YWZ9-710/201; YWZ9-710/301; YWZ9-800/301/12YWZ10 series electric hydraulic block brake:YWZ10-200/23; YWZ10-200/30; YWZ10-200/50; YWZ10-250/23; YWZ10-250/30; YWZ10-250/50; YWZ10-250/80; YWZ10-315/30; YWZ10-315/50; YWZ10-315/80; YWZ10-400/50; YWZ10-400/80; YWZ10-400/121; YWZ10-500/80; YWZ10-500/121; YWZ10-500/201; YWZ10-500/301; YWZ10-630/121; YWZ10-630/201; YWZ10-630/301; YWZ10-630/301/12; YWZ10-710/201; YWZ10-710/301; YWZ10-710/301/12; YWZ10-800/301/12YWZ12 series electric hydraulic block brake:YWZ12-200/23; YWZ12-200/30; YWZ12-250/23; YWZ12-250/30; YWZ12-250/50; YWZ12-315/30; YWZ12-315/50; YWZ12-315/80; YWZ12-400/50; YWZ12-400/80; YWZ12-400/121; YWZ12-500/80; YWZ12-500/121; YWZ12-500/201; YWZ12-630/121; YWZ12-630/201; YWZ12-630/301; YWZ12-630/301/12; YWZ12-710/201; YWZ12-710/301; YWZ12-710/301/12; YWZ12-800/301/12YWZ13 series electric hydraulic block brake:YWZ13-200/23; YWZ13-200/30; YWZ13-250/23; YWZ13-250/30; YWZ13-250/50; YWZ13-300/30; YWZ13-300/50; YWZ13-300/80; YWZ13-400/50; YWZ13-400/80; YWZ13-400/121; YWZ13-500/80; YWZ13-500/121; YWZ13-500/201; YWZ13-630/121; YWZ13-630/201; YWZ13-630/301; YWZ13-710/201; YWZ13-710/301; YWZ13-800/301/12YWL series electric hydraulic block brakes:YWL-200/23; YWL-200/30; YWL-250/23; YWL-250/30; YWL-250/50; YWL-315/23; YWL-315/30; YWL-315/50; YWL-315/80; YWL-400/30; YWL-400/50; YWL-400/80; YWL-400/121; YWL-500/50; YWL-500/80; YWL-500/121; YWL-500/201Multi block brake pusher

time:2021-04-26

More

Henan Jiaozuo Brake Group Co., Ltd. is a mechanical and industry equipment enterprise approved and registered by relevant national departments. Our factory is a modern enterprise that integrates research, development, design, manufacturing, sales, and service of electric hydraulic block brakes, electromagnetic brakes, thrusters, and lifting appliances. Sincere unity, lofty aspirations, determination to innovate, and striving for progress. We serve several large and small enterprises in China, including mining, machinery, metallurgy, lifting, power, railways, water conservancy, ports, docks, chemical and other industries. Our factory has successfully designed. The manufacturer has passed ISO9001 certification and the company's main products include YWZ, YWZ2, YWZ3, YWZ4, YWZ5, YWZ6, YWZ7, YWZ8, YWZ9, YWZ10, YWZ12, YWZ13, YW, YWP series block brakes; Electric hydraulic thrusters of SBD series, ST, SH, SB, YPZ, YT1, YTD, ED, MYT1 series of various disc brakes; ZWZ, ZWZ3A, TJ2, TJ5, TJ2A and other series of electromagnetic brakes, as well as BYWZ series of electric hydraulic explosion-proof brakes. Various models of brakes, thrusters, and explosion-proof brakes are complete, with reasonable prices, quality, and fast delivery. Welcome to inquire and order by phoneWithin one year from the delivery of the product to the purchaser, the design, manufacturing, materials, and workmanship of the product shall be free from defects that may affect its functionality and use. During the warranty period, our company is responsible for replacing or repairing any product that has been proven to be defective after our testing. The user is responsible for returning this product to our company or authorized service station and maintaining its integrity. In addition, our company does not make any other express or implied warranties, including (but not limited to) the design, condition, or workmanship of the product, as well as the implied warranties of conformity with specific usage purposes.To the extent permitted by relevant laws, the Company will not be liable for any special, indirect, accidental or accidental damage (including but not limited to: transportation costs, loss of profits, Vandalism, product loss, loss of life or personal injury). In any case, the total amount of responsibility borne by our company is limited to the sales price of the products obtained

time:2021-04-26

More

Brake disc thicknessThe thickness of the brake disc has an impact on the quality of the brake disc and the temperature rise during operation. To reduce the mass, the thickness of the brake disc should not be too large; In order to reduce temperature, the thickness of the brake disc should not be too small. The brake disc can be made solid, or a ventilation hole can be cast in the middle of the brake disc for heat dissipation and ventilation. Generally, the thickness of solid brake discs can be taken as 10-20mm, while that of ventilated brake discs can be taken as 20-50mm. The commonly used thickness is 20-30mm. During emergency braking at high speeds, the brake disc will form thermal deformation and tremble. To improve the heat dissipation performance of the brake disc friction surface, most brake discs are made into ventilated brake discs with hollow holes in the middle, which can reduce the temperature of the brake disc by 20% to 30%.Friction padFriction pad refers to the friction material pushed and squeezed onto the brake disc by the clamp piston. The friction pad is divided into friction material and base plate, which are directly pressed together.The ratio of the outer radius of the friction pad to the inner radius and the recommended outer radius to the inner radius of the friction pad should not exceed 1.5. If this ratio is too high, there will be a significant difference in circumferential velocity between the outer edge and inner side of the pad during operation, resulting in uneven wear and reduced contact area, ultimately leading to a significant change in braking torque.For the working area A of the disc brake pad, it is recommended to select the brake pad from 1.6 to 3.5 (kg/cm2) according to the vehicle mass per unit area of the brake pad.The brake disc is made of alloy steel and fixed to the wheels, rotating with the wheels. The wheel cylinder is fixed on the bottom plate of the brake and remains stationary. The two friction plates on the brake caliper are installed on both sides of the brake disc. The piston of the wheel cylinder is subjected to hydraulic pressure from the oil pipe, pushing the friction plates towards the brake disc for frictional braking. The action is like using pliers to grip the rotating plate and force it to stop. Since the brake is a working device, it is also a safety device. With the development of technology and the increasing requirements for energy conservation and environmental protection, more and more permanent magnet synchronous gearless traction machines will replace traditional worm gear and worm type traction machines. It is uncertain whether there will be no need to install a separate upstream overspeed protection device. The brake of this type of permanent magnet synchronous gearless traction machine (which should undergo type testing) has an upstream overspeed protection function. According to the requirements of Article 9.10 of GB, the upward overspeed protection device of the car generally consists of two parts: a speed monitoring component and a deceleration execution component. For elevators, the brakes of permanent magnet synchronous gearless traction machines (all brake components involved in applying force to the brake wheels or discs are assembled in two as redundancy within these components) are precisely used as deceleration actuators to slow down or stop the elevator. Therefore, during the inspection, it is necessary to check whether the brake still has the type test certificate and report with uplink overspeed protection function, whether the brake is directly and rigidly connected to the traction wheel, and whether there should be an electrical device to verify whether the brake works normally, but it is not necessary to connect the brake to the safety circuit in series.As a very important safety control device, it is widely used in lifting, metallurgy, mining, ports Main products in construction and other machinery include: electric hydraulic block brake series YWZB YWZ3B YWZ4B YWZ5 YWZ8 YWZ9 YWZ12 YWZ13 YW YWL TYWZ2 YWP electromagnetic block brake JZ (TJ2A) MW (Z) ZWZA ZWZ2 ZWZ3A DCW3 electromagnetic failure protection disc brake 5SE 561SE 560SE 56SE DCPZ12.7 4SE 3SE ST1SE ST2SE 450SE hydraulic failure protection disc brake 5SH 4SH 3SH 450SH ST1SH ST2SH SH ST3SH ST4SH SB (YQP) SBDST5SH ST10SH ST16SH ST25SH ST25SH-A ST40SH 904SH SBB electric hydraulic arm disk brake YPZ2 Ⅰ, Ⅱ, Ⅲ YPZ2 Ⅳ, Ⅴ, Ⅵ pneumatic caliper disk brake QP12.7 5SP 4SP 3SP 450SP PD ADP60M-ADP61M-ADP62M hydraulic direct acting disk brake DADH75 ADH60 ADH90 ADH120 DADH80 DADH90 DADH120 DADH103 DADH195 electric hydraulic thruster YT1 Ed explosion-proof electric hydraulic thruster BYT1 BEDBrake FactoryBraking performance is directly related to driving safety and is an important guarantee for car driving. With the rapid development of highways and the increasing density of traffic flow, frequent traffic accidents have occurred. Therefore, improving the braking performance of Automotive design is always the main task of automobile design, manufacturing and use departments. The function of the braking system is to slow down the car at an appropriate deceleration until it stops; When driving downhill, keep the car at an appropriate stable speed; Make the car reliably stop in place or on a slope. The braking system should have at least two independent braking devices, namely the service braking device and the parking braking device. The former is used to ensure that

time:2021-04-26

More

Adjustment of the clearance between the brake friction plate and the brake wheelThe safety of a crane is very important, so how to ensure its safety? Its safety performance refers to active safety (the ability to avoid accidents) and passive safety, also known as active safety. In terms of behavior, when a heavy object wants to stop in the air, it needs to be braked, which belongs to active safety, but accidents usually occur at this time. Nowadays, most factories use double pad brakes for crane brakes. When it is necessary to open or brake, the electromagnetic attraction, release, or oil pump start and stop are used to compress or release the elastic force of the brake spring, causing the brake pads to leave the brake wheel or fit onto the brake wheel, achieving the requirements of opening or braking. When a derailment or hook slipping accident occurs (usually when lifting a large heavy object), several staff members who are responsible for monitoring the crane will use tools such as crowbars to increase the pressure on the brake shoes on the brake wheels, in order to achieve emergency braking and prevent the occurrence of the accident or reduce the degree of damage caused by the accident. In some accidents, the staff responsible for monitoring on the bridge crane also took such measures, but did not achieve the corresponding effect. Instead, it was a major accident where the brake cracked and the brake fragments flew out, causing casualties to the monitoring personnel. The function of brakes is not only reflected in cars, elevators, cranes, etc., but also has excellent performance in the operation of various equipment. Its function is manifested in:1. The brake can act on its own when the elevator power supply is cut off, and the brake shoe holds the brake wheel to stop the elevator from running. The deceleration of the elevator during braking shall not exceed the deceleration generated by the safety clamp stopping the car or the car stopping on the buffer.2. When the elevator stops running at the station, the brake should be able to ensure that the elevator remains stationary at a rated load of 125-150% and should not be opened before restarting.3. When the elevator exceeds the speed limit and reaches the operating speed of the speed limiter during operation, the brake first acts and applies braking to the brake wheels, causing the elevator to stop running. The brake of the elevator traction machine must be released when powered on to enable the elevator to operate; When the power or control power supply of the elevator is cut off, or when the elevator runs beyond the limit, exceeds the speed limit, or malfunctions, immediate braking is applied to stop or prevent the elevator from starting, ensuring that the brake can achieve reliable braking in the event of a power outage or various unexpected accidents; When the elevator is running normally, the brakes must be fully released and the brake shoes must not come into any contact with the brake wheels. The brake is one of the most frequently used devices in elevators and has a significant impact on safe operation. The brake is an important component in a vehicle. Whenever there is a problem with the brake, it needs to be addressed immediately. After replacing the brake friction plate, reprocessing the brake drum, or disassembling the brake base plate, the gap between the friction plate and the brake drum must be readjusted. The steps are as follows:1) Remove the inspection hole cover on the brake drum, loosen the fixing nut of the brake shoe support pin and the nut of the camshaft bracket fastening bolt.2) Rotate the shoe support pin with the markings on the two pin ends facing inward.3) By repeatedly twisting the screw shaft of the brake shoe support pin and adjusting arm, the brake friction plate and brake drum are fully fitted. At the adjusted position, slowly tighten the fastening nut of the bracket and the locking nut of the automatic shoe support pin to maintain the position of the brake shoe support pin unchanged (it is possible to press and hold the brake pedal to tighten all the bolts and nuts that have been adjusted on it, provided that the air pressure meets the regulations).4) Loosen the worm shaft by 1/2-2/3 turns, and the brake drum should be able to rotate freely without colliding with the brake friction plate or other parts. The clearance position between the brake friction plate and the automatic drum: at the brake shoe support pin end, it is 0.25-0.40mm, and at the cam end, it is 0.40-0.55mm. The difference in clearance between the two shoes at the same end should not exceed 0.1mm.5) After the adjustment is completed, compressed air is introduced into the brake chamber, and the stroke of the push rod should be 25-40mm. The rear wheel automatically adjusts the small worm shaft of the arm, and the stroke of the push rod changes by 5mm with each movement, while the front wheel is 4mm.6) When the stroke of the push rod exceeds 40mm due to wear of the friction plate, local adjustment can be made (at this time, do not twist the support pin to avoid damaging the original good contact state). The method is to face the worm head of the adjustment arm, tighten the screw clockwise at two places on the front wheel (clearance decreases), loosen counterclockwise (clearance increases), tighten counterclockwise at two places on the rear wheel, and loosen clockwise. Attention, do not use the method of twisting the brake chamber push rod to change the ratio of the push rod for "adjustment".Two types of diagrams, YWZ4 and YWZ

time:2021-04-26

More

In the use of hydraulic brakes, the power supply of the electro-hydraulic push rod is generally connected in parallel with the power supply of the main motor of the equipment, and no separate circuit is taken. Therefore, it is suitable for the synchronous start and stop of the 380V three-phase AC power supply and the main motor. When powered on, the main motor starts to run, and at the same time, the motor of the brake drives the impeller to rotate, sucking oil from the upper part of the piston to the lower part of the piston, generating pressure to push the piston push rod up quickly, completing the rated stroke and reaching the specified thrust, The brake shoe opens and the equipment begins to operate normally. After the power outage, the main motor stopped rotating, and the push rod impeller also stopped rotating, losing oil pressure. The piston rapidly decreased under external force (spring reset), returned to its starting position, and the brake shoe brake.For driving methods with voltage levels that are inconsistent with the main motor, the push rod motor should be powered separately, but attention should be paid to achieving interlocking control with the main motor to avoid overloading or burning of the main motor due to the power loss and braking of the push rod motor during the operation of the main motor. These are some points to pay attention to when using hydraulic brakes. The YTD2 (ED) series electric hydraulic thrusters are mainly used as operating components for the YWZ4, YWZ5, YWZ8, YWZ9, and YWZP series electric hydraulic block brakes. They are widely used in industries such as lifting and transportation, metallurgy, mining, ports, and construction.Product FeaturesThe shell is made of cast aluminum alloy, with light weight and beautiful appearance;The motor is of non oil immersed structure, with Class B or F insulation (according to user requirements). Good heat resistance and long service life;The motor junction box cover is equipped with a seal and uses a cable stuffing box for incoming lines, which is firm and reliable. The electrical casing protection level reaches IP55;The surface of the motor shaft and push rod are plated with hard chromium treatment, greatly extending the service life of the sealing element;The oil cylinder shell is equipped with a balance chamber on one side, which can allow the thruster to be installed in any direction from 0 to 180 °, thereby expanding its range of use;All seals and bearings of the YTD2 series adopt world-renowned products, with reliable sealing and long service life;The YTD2 series fasteners are made of stainless steel material, which is beautiful and durable.Electric hydraulic thruster is a very compact drive control device integrating motor, centrifugal pump and oil cylinder. It is widely used as the drive device of various block brakes and disc brakes, and can also be used for the drive control of various industrial valves, gates, directional swing and rotation (<90 °) devices (mechanisms) and clamping devices. The main feature of the shell is cast aluminum alloy, with light weight and beautiful appearance. The motor is of a non immersed structure, with Class B or F insulation (according to user requirements), good heat resistance, and long service life. The motor junction box cover is equipped with a seal and uses a cable stuffing box for incoming lines, which is firm and reliable. The electrical casing protection level reaches IP55. The surface of the motor shaft and push rod are specially treated, greatly extending the service life of the sealing element. The oil cylinder shell is equipped with a balance chamber on one side, which allows the thruster to be installed in any direction from 0 to 180 °, thereby expanding its range of use. All seals and bearings are made of world-renowned products, with reliable sealing and long service life. The fasteners are made of stainless steel material, which is beautiful and durable. Additional device upper limit switch: can indicate whether the brake is on, whether the push rod is pushed to the specified position, and other information. Lower limit switch: It can indicate whether the brake is correctly closed, whether the push rod returns to the specified position, and other information. It can also set upper and lower limit switches. Add a built-in spring (only available for short stroke thrusters), which is determined by the user but must not exceed the built-in spring force (see parameter table). Adding a heater: When the ambient temperature at the place of use is below -25 ℃, if needed by the user, a heater can be added. The heater parameters are shown in Appendix 1. The rising and falling delay valves or the rising and falling delay valves can extend the rising or Fall time steplessly. The delay range is from the rated action time to 30 seconds. The specific delay value can be adjusted according to the user's requirements. The thruster is suitable for intermittent (S3-60%) and continuous (S1) working systems. Environmental temperature: generally -25~+50 ℃. When the specified environmental temperature is exceeded, please contact our technical personnel. Relative humidity: Generally, it should be ≤ 90%. When used in humid and hot areas or environments with corrosive atmospheres (gases), anti-corrosion products should be selected.The hydraulic brake is the safety Wheel slide protection of the shearer, which is supplied by the auxiliary oil circuit of the pump box to release the brake. When the auxiliary oil supply is cut off, the spring presses the brake pad installed on the housing and the axially sliding brake disc installed on the motor gear with the help of the piston to produce Friction torque, and the machine is braked. The casing, cylinder body, and cover are fixed together with screws, and the hydraulic brake is fixed to the traction part casing with screws. Hydraulic oil enters the cylinder body through holes.ED80/6, ED50/12, ED80/12, ED-23/5, electric hydraulic thrusterMYT1-180Z/12 MYT1-320Z/12 electric hydraulic thrusterMYT1-45Z/6 MYT1-90Z/8 electric hydraulic thrusterMYT1-180/12 MYT1-18Z/2 electric hydraulic thrusterMYT1-25/4 MYT1-45/6 electric hydraulic thrusterBED201/12 BED301/12 BED630/12 explosion-proof electric hydraulic thrusterBED201/6 BED301/6 BED121/12 explosion-proof electric hydraulic thrusterBED50/12 BED80/12 BED121/6 explosion-proof electric hydraulic thrusterBED30/5 BED50/6 BED80/6 explosion-proof electric hydraulic thrusterYTD2-2000/120 YTD2-3000/120 electric hydraulic thrusterED-2000/120 YTD2-1250/120 electric hydraulic thrusterED-1250/120 ED-2000/120 electric hydraulic thrusterED-1250/60 ED-2000/60 electric hydraulic thrusterED-800/60 ED-500/120 electric hydraulic thrusterED-220/50 ED-300/50 ED-500/60 electric hydraulic thrusterYTD2-1250/60 YTD2-2000/60 electric hydraulic thrusterYTD2-800/60 YTD2-500/120 electric hydraulic thrusterYTD2-220/50 YTD2-300/50 electric hydraulic thrusterMYT3-200-8 MYT3-315/8 electric hydraulic thrusterMYT3-125/5 MYT3-125E/5 electric hydraulic thrusterMYT3-22/4 MYT3-40/4 MYT3-70/5 electric hydraulic thrusterED301/12 ED630/12 electric hydraulic thrusterED121/12 ED201/12 electric hydraulic thrusterED301/6 ED50/12 ED80/12 electric hydraulic thrusterED80/6 ED121/6 ED201/6 electric hydraulic thrusterED23/5 ED30/5 ED50/6 electric hydraulic thrusterYT1-45/6 YT1-90/8 electric hydraulic thrusterYT1-320Z/12 YT1-320Z/20 electric hydraulic thrusterYT1-180Z/8 YT1-180Z/10 electric hydraulic thrusterYT1-90Z/6 YT1-90Z/8 electric hydraulic thrusterYT1-45Z/4 YT1-45Z/5 YT1-45Z/6 electric hydraulic thrusterYT1-18ZB/2 YT1-25ZB/4 electric hydraulic thrusterYDWZ-600/200J YDWZ-600/200Z Hydraulic Electromagnetic Brake

time:2021-04-26

More