Hydraulic brakes are important components in vehicles, and there are many things to pay attention to when replacing or adding brake fluid. However, most people are not familiar with them. Therefore, today we will learn about the precautions that hydraulic brakes must pay attention to when changing brake fluid.When adding or replacing brake fluid for hydraulic brakes, it is necessary to strictly follow the original vehicle's specified model of brake fluid filling. If it is necessary to replace another model of brake fluid, the grade of the original and new brake fluid must be identified first, and whether the oil resistant rubber seal needs to be replaced.Secondly, before replacing the brake fluid, it is necessary to drain the brake fluid from the original vehicle's brake system and clean it with alcohol before refilling with new brake fluid. It is necessary to prevent different types of brake fluid from being mixed and injected into the braking system for use, and hydraulic brakes should be used to prevent brake failure. Under the current policy system, in addition to subsidies for investment in power transmission and operation maintenance costs specifically incurred for the development of renewable energy such as wind power, there is no corresponding cost accounting and compensation mechanism established for the increased system management and operation costs of the power system due to the development of renewable energy. In the absence of separation of transmission and distribution and liberalization of power trading, it is also impossible to achieve the necessary accounting and compensation, making it difficult for wind power consumption It is not surprising that wind and electricity restrictions have emerged.The structure of the hydraulic disc brake is shown in. It mainly consists of brake discs, brake pads, brake calipers, oil pipes, brake main oil pumps, and other components. Its working principle is that when gripping the brake handle (or stepping on the brake pedal), the plunger in the main oil pump moves, pushing hydraulic oil along the oil pipe into the oil cylinder in the brake caliper. Under the action of hydraulic oil, the piston in the oil cylinder pushes the brake block closer to the brake disc until it tightly clamps the brake disc, generating significant frictional resistance, forcing the wheels to stop rotating, achieving the goal of parking or decelerating. When releasing the brake handle (or brake pedal), the pressure of the hydraulic oil in the oil circuit quickly drops to zero, and the piston drives the brake block to return to its original position, releasing the brakeThe main reasons for the occurrence of wind power abandonment and power rationing are the misalignment of wind power production and consumption regions in China, as well as the slower growth rate of electricity consumption compared to the growth rate of electricity installation. Ultimately, it is still the insufficient demand for wind power in China.Almost all hydraulic brakes used in metallurgy are friction brakes, which rely on the friction between fixed and rotating components to effectively control mechanical slip and reduce the inertia caused by friction in mechanical brakingAccording to China's 13th Five Year Plan for the Development of National Strategic Emerging Industries, in terms of demand, China will focus on promoting the development of green energy networks that integrate energy storage facilities, the Internet of Things, smart power facilities and other hardware, as well as Carbon emission trading, Internet finance and other derivative services, promote the development of smart energy use at the user end, energy Sharing economy and free energy trade, and foster new businesses and new formats based on smart energy, Building a new energy consumption ecosystem and industrial system.With the development of the Internet of Things and Energy storage, it is believed that the problem of wind curtailment and power rationing will be solvedDuring the driving process, the service brake (foot brake) is generally used to facilitate deceleration and parking during the forward process. The parking brake is not only used to keep the car stationary, but can also be used when the service brake fails. When the car comes to a stable stop, the parking brake (handbrake) should be used to prevent the vehicle from slipping forward and backward. After parking, in addition to using the parking brake, for manual transmission models, when parking uphill, try to shift the gear to first gear (to prevent backward sliding), and when parking downhill, try to shift the gear to reverse gear (to prevent forward sliding). Service brake refers to the foot brake (foot brake). Another brake is the parking brakeHydraulic brake is a type of hydraulic braking device, and its maintenance process has strict requirements. Below, we will introduce its maintenance requirements.(1) When the wear of the brake shoe exceeds the limit and there is friction between the rivet and the brake wheel, the brake shoe should be replaced.(2) Check the wear of each hinge joint pin and pin hole. If the wear exceeds the standard, it should be replaced.(3) Regularly add oil to each hinge joint to ensure smooth movement and no jamming.(4) Regularly inspect and adjust the adjustment bolts of the brake upper pull rod to ensure that the clearance and tension of the brake shoe during opening and braking are within the specified range.(5) The brake oil cylinder should maintain sufficient oil level, and its oil pressure should reach 0.9MPa without any oil leakage or seepage.(6) Hydraulic brake shoes (also known as brake bands) should not come into contact with oil, especially the friction brake surface should be free of oil stains.(7) When the hydraulic brake is opened, the gap between the brake shoe and the brake wheel should be kept between 0.8-1mm.The main product series include: electric hydraulic arm disc brake, pneumatic disc brake, hydraulic failure protection brake, electromagnetic failure protection brake, wheel edge brake, electric hydraulic wind proof iron wedge brake, ZWZ3 series electromagnetic DC drum brake, YWZB series electric hydraulic drum brake, YWZ3B series electric hydraulic drum brake, YWZ4 series electric hydraulic drum brake, YWZ5 series electric hydraulic drum brake, YWZ8 series electric hydraulic drum brake, YWZ9 series electric hydraulic drum brake, YWZ10 series electric hydraulic drum brake, YWZ13 series electric hydraulic drum brake, YWL series electric hydraulic drum brake, YWP series electric hydraulic drum brake, YW-E series electric hydraulic two-stage drum brake, YW series electric hydraulic drum brake, YW series pneumatic drum brake, ED series electric hydraulic thruster, YT1 series electric hydraulic thrusters, BED series electric hydraulic thrusters, BYT1 series electric hydraulic thrusters, with an annual production capacity of 60000 sets.Our company is a member unit of the Transmission Parts Industry Association and the Construction Machinery Industry Association; Continuously obtained the "Quality Certification" certificate issued by the National Center for Quality Supervision, Inspection and Testing of Lifting and Transportation Machinery Products from 1999 to 2003; In October 2002, it passed the ISO: 9000 and GB/T19001-2000 Quality Management Systems certification by the China Fangyuan Certification Committee; Obtained the "Special Equipment Type Test Certificate" and the title of Henan Provincial Excellent in 2004; Obtained the ED series explosion-proof certificate and mining product safety label certificate in 2006; Obtained the YT1 series explosion-proof certificate and mining product safety label certificate in 2007; In 2008, it was the first in the industry to obtain a production license for explosion-proof products. In 2011, the company's product trademark was awarded the Henan Province Famous Brand Trademark. Advanced technology, equipment, strong technical force, perfect testing methods, strict quality assurance system, reasonable product prices, and reputation are the strong guarantees for our products to enter the market and win users. Our company is willing to provide you with high-quality products and services.Actual drawing of YWZ9-200 workshop

time:2021-05-17

More

Electric hydraulic brakes are divided into short stroke block brakes and long stroke block brakes based on the length of the control device stroke. The magnet of the short stroke block brake is directly installed on the brake arm. During operation, the moving iron core rotates around the pin shaft to achieve brake release; When the magnet is powered off, it is tightly closed by the main spring. The electric hydraulic brake has a compact structure, fast tightening and releasing actions, but has a large impact force. Long travel block brakes can generate a large release force through the brake lever system, but the braking action is stable and suitable for various types of deceleration equipment., The brake block is located inside the brake wheel, and is opened by the pedal, pull rod, and convex block to compress the inner surface of the brake wheel and tighten the brake. Releasing the pedal will pull the spring back to the brake block and release the brake. This type of brake can also be operated by hydraulic or pneumatic pressure. The internally tensioned block brake has a compact structure and good dust resistance, which can be used in installation spaces and is widely used in various vehicles. The working conditions of electrically powered hydraulic brakes are as follows:1. The common electric hydraulic brake mainly operates by pushing the actuator to open when the point is reached;2. The braking force during braking is provided by the spring, and the electric hydraulic brake does not work at this time;3. If you want to power on for a long time, even if the brake is in an open state for a long time, theoretically there is no problem. However, in actual use in the factory, the motor of the thruster is prone to malfunction. Generally, electric hydraulic thrusters have a wrench for manual position maintenance, which means that after opening, the claw can be manually clamped onto the support rod, and after power outage, it is still in the open state;4. For normally open electric hydraulic brakes, the normally open state can be used, which relies on hydraulic braking and spring openingThe reasons for the oil leakage of those mobile aluminum alloy landing platforms are always intertwined. If we want to summarize them, it is the following reasons: quality, vibration, corrosion, pressure difference, pressure difference, pipe discussion, application of hydraulic components, and improper maintenance. The leakage of elevators is divided into internal leakage and external leakage, which is inevitable for a small kerosene leakage, because this is the quality of hydraulic transmission.How to check if there is air present at the air inlet of the mobile aluminum alloy lifting platform gear pump. We can identify it by carefully listening to the sound of the running department. Add a little oil to the joint. If the sound decreases, it indicates that the seal is not sealed, and air will be leaked from the pump shaft seal or pump cover into an atmosphere containing air. We suggest that you replace the oil seal or paper gasket, and also tighten the connector or replace the gasket, joint, and seal.The decibel emitted by the gear pump of the corresponding mobile aluminum alloy lifting platform is too large, which exceeds the decibel of the sound we usually hear. We propose to carefully check whether there is dirt and cavitation on the filter on the Oil pipeline of the gear pump, and check the standard value of the tank liquid level. Suggest refueling the oil tank and flushing it with oil. Firstly, we must check whether the oil pipes, pumps, and racks of these devices are loose from the outside. If they are loose, we must tighten them in a timely manner, otherwise resonance may occur.Composition of electric hydraulic brake:Electric hydraulic brakes mainly consist of thrusters, bases, brake arms, brake springs, brake pads, spring pull rods, levers, automatic distance equalization devices, lubrication devices, and other components.The working principle of electric hydraulic brakes:The electrical energy of the driving device is converted into mechanical energy, and the liquid flow in the cylinder is formed into a high and low pressure chamber through the rotation of the impeller, which drives the piston to move upwards. The vertical movement is then transformed into left and right swing of the brake arm through the lever mechanism, completing the brake release task. When the driving device is powered off, the mechanism amplifies and transmits the force to the brake shoe through the lever ratio under the action of spring force, completing the holding brake. The main auxiliary function of the product is the automatic equalizing device for backtracking. The technical action principle is to connect the equal backtracking device with the brake arm, and maintain the automatic equalizing of backtracking on both sides when the brake arm is opened through the rotation of the low pair of the left and right connecting plates.YWZ4 high-definition standard image

time:2021-05-17

More

It is mainly matched with series motors. Widely used in metallurgy, construction, chemical, food, machine tools, stages, elevators, ships, packaging and other machinery, as well as in situations such as emergency braking during power outages.The resistance torque that must be applied to stop or decelerate the mechanical operating components is called the braking torque. The braking torque is the basis for designing and selecting brakes, and its size is determined by the mechanical type and working requirements. Implement automatic alignment. The performance of the friction materials (brake components) used on the brake directly affects the braking process, and the main factors affecting its performance are the working temperature and temperature rise rate. Friction materials should have high and stable friction coefficients and good wear resistance. Friction materials are divided into two categories: metallic and non-metallic. The former commonly used include cast iron, steel, bronze, and powder metallurgy friction materials, while the latter includes leather, rubber, wood, and asbestos. EB500/60 explosion-proof electric hydraulic thruster ED2000-120 Jiaozuo brake1. Please use the electromagnetic brake in a state where there is no water or oil at all. If the friction area is contaminated with substances such as water or oil, the friction torque will be greatly reduced, and the braking sensitivity will also deteriorate. To avoid these situations in use, please add a cover.Electric hydraulic brake, electric hydraulic drum brake, electromagnetic block brake, electric hydraulic windproof iron wedge brakeSafety wind brake electromagnetic failure protection disc brake electric hydraulic arm disc brake wind electric yaw brakeWind power spindle brake Pneumatic caliper disc brake Hydraulic failure protection Brake electromagnetic failure protection BrakeHydraulic direct acting disc brake electromagnetic caliper disc brake pneumatic failure protection brake hydraulic direct acting brake

time:2021-05-17

More

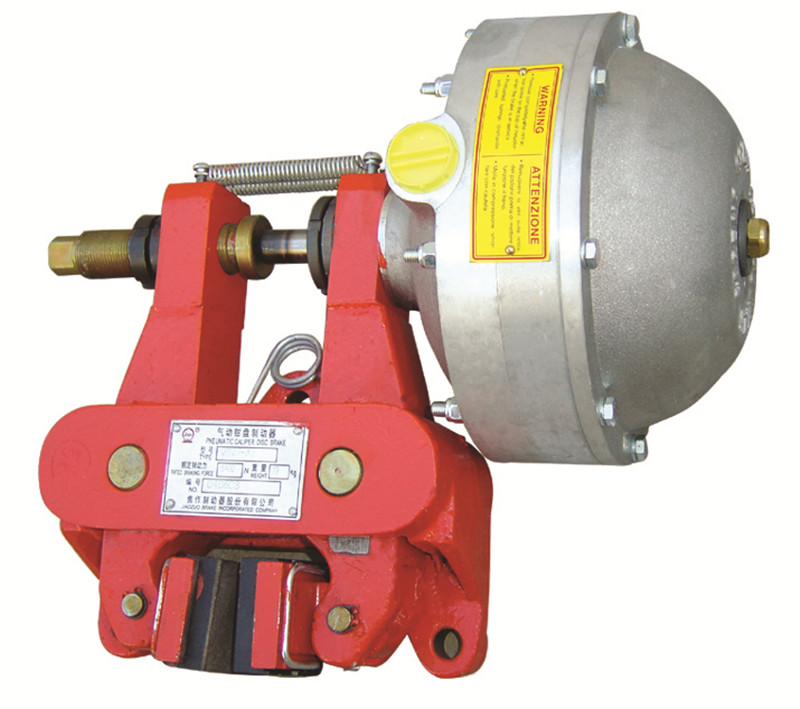

QP, CQP, DCPZ series caliper disc brakeCaliper disc brake is an advanced product that not only has the advantages of disc brake, but also has wide adaptability and unique advantages. This product has a simple structureSingle, small in size, light in weight, high in reliability, easy to use, suitable for various disc diameters, easy to install, debug, and maintain. Widely applicable for lifting and transportationDeceleration and braking of fixed operating mechanisms such as transportation, metallurgy, mining, ports, construction, bulk loading and unloading, as well as tension control of machinery such as cables, paper making, and steel platesDomain.main features Compact structure, small size, light weight, high reliability, and convenient installation and use.Act sensitively and control flexibly.QP series pneumatic caliper disc brake meets the installation performance requirements of foreign similar products. Matched with imported air bags, reliable performance and long service life.The brake pad adopts a pressure spring clamp type, with a unique structure and convenient and fast replacement.A display device can be installed to visually display the working status of the brake.All power sources do not need to be set separately and can be used in conjunction with existing air compression stations. Speed control valves are installed in the gas supply line, and the braking time can be adjusted steplessly.Normally closed design: spring brake, pneumatic release.Normally open design: pneumatic braking, spring release, and braking force can be flexibly changed with air pressure.summaryThe QP (CQP) series pneumatic caliper disc brakes are mainly used in lifting, transportation, metallurgy, mines, and portsThe braking and deceleration of various mechanisms in machinery such as machinery and construction.Usage conditionsEnvironmental temperature: -5 ℃~40 ℃Working air pressure: 5-7bar for QP series;The CQP series is ≤ 7bar.Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.The air source should not contain oil, water, or other impurities.main features The QP series adopts spring braking and pneumatic release; The CQP series is pneumatic braking with spring release.The overall structure is simple, small in size, and lightweight.Asbestos free brake pads, green and environmentally friendly.The installation of the brake pad adopts a spring clamp type, which is convenient and fast to replace.The brake pad is easy to adjust after being worn.Each disc diameter of the QP series brake can be adjusted for four levels of braking torque.All power sources do not need to be set separately and can be connected to the existing air compression station for grid use. They can be added to the gas supply lineEquipped with a speed control valve, the braking time can be adjusted steplessly.Note: 1. It can produce pneumatic caliper disc brakes with different disc thicknesses and installation sizes.2. The specific model and structural dimensions reserve the right to change.

time:2021-05-02

More

What is a disc hydraulic brake? The disc hydraulic brake is controlled by hydraulic pressure, and its main components include brake discs, wheel cylinders, brake calipers, oil pipes, etc. The disc brake is characterized by simple structure, convenient adjustment, good high temperature resistance, fast heat dissipation, light weight but stable braking effect. After the cylinder oil pipe joint of the disc hydraulic brake is removed, air will enter the oil pipe and wheel cylinder. After reinstallation, there will be air in the braking system, causing the braking effect to fail. Therefore, after the joint is removed, the air must be discharged before it can be used normally. So how to bleed the disc hydraulic brake? What are the methods? The editor is here to answer everyone's questions one by one:The method for bleeding the disc hydraulic brake is:1. Add sufficient hydraulic oil to the main cylinder, grip the brake grip tightly, allow the air to exhaust, and then immediately connect the connector to the wheel cylinder.2. Firmly grip the handle of the disc electric hydraulic brake to generate oil pressure in the master cylinder, then loosen the bleed screw to release the air.3. When no more bubbles are generated at the bleed screw, immediately tighten the bleed screw, loosen the brake grip, and allow the master cylinder to return oil.4. Repeat the second and third steps multiple times until the air is completely discharged. The action during bleeding must be coordinated to avoid operational errors that may cause air to enter the hydraulic system, causing the work to start over. It is also important to note that during the bleeding process, the hydraulic oil should be adjusted to the master cylinder at any time.1) YZ series motors can be directly started. When starting YZR series motors, the rotor must be connected in series with an additional resistance or reactance to start the current. The average value of the starting current should not exceed twice the rated current of the corresponding working mode.2) When cleaning and inspecting YZR series motors, open the cover plate of the observation window and the cover of the dust discharge hole, and clean the Slip ring chamber. If there is dust or oil stain on the surface of the Slip ring, the dust and oil stain can be wiped off with a cloth soaked in gasoline, and the vehicle can only be started after the gasoline volatilizes. For YZR motor, the size of brush spark shall be frequently observed during operation, and the wear of brush and Slip ring surface shall be checked. When sparks occur on the brushes during operation, the principle should be identified and addressed.

time:2021-05-02

More

Installation of disc brake·Firstly, check the brake surface of the brake disc and brake pad for oil sludge or other stains.·Install the G3/8 "(cast iron rod cylinder) or 1/2" (cast aluminum cylinder) connector on the air inlet of cylinder 1, connect the air pipe with a hose, and the air source should be free of oil, water, and other impurities·When installing, first introduce pressure air to retract piston rod 5 into the cylinder, then install friction block 12 into the brake disc in the direction perpendicular to the brake disc, and then fix base 9 horizontally on the rigid base, so that its center is in line with the center of the brake disc thickness. The installation position dimensions are shown in the structural diagram3、 Disc brake commissioning·Adjust the air pressure value to a range of 5-7 bar.·For normal work, the first step is to test the brake several times and check if there are any abnormalities in the brake.·The retraction distance of the friction block can be adjusted by rotating the adjustment rod 6 to change the size of the working stroke. When rotating the adjustment rod, pressure air is first introduced to retract the piston rod, and then adjusted.4、 Disc brake maintenanceWhen the friction plate is worn and the working stroke increases to 8mm, it is necessary to immediately adjust lever 6 to readjust the working stroke by about 4mm. Otherwise, the brake will fail. After adjustment, the nut 7 should be tightened. When the friction block 12 is worn to about 6mm, the wear block needs to be replaced. The replacement steps are as follows:1. Cylinder, 2. Right brake arm, 3. Return spring, 5. Piston rod, 6. Adjusting rod, 7. Nut, 8. Left brake arm, 9. Base, 10. Brake block, 11. Spring steel wire, 12. Friction plate

time:2021-05-02

More

1. Inspection of brakeFor cranes in normal use, the brakes should be checked every shift. The inspection content includes: the intact condition of key parts of the brake, the contact and separation clearance of the friction pair, the reliability of the brake release, and the overall working performance of the brake. Sensitivity and no jamming phenomenon should be ensured.During each lifting operation (especially lifting heavy, large, and precision items), the lifting object must be lifted a short distance from the ground, and the reliable performance of the brake must be inspected and confirmed before the operation can be carried out.The key points of brake safety inspection are:(1) The braking friction surface of the brake wheel should not have defects or oil stains that hinder braking performance;(2) The degree of wear of the friction material of the brake band or brake pad;(3) The actual contact area between the brake band or brake pad and the brake wheel should not be less than 70% of the theoretical contact area;(4) The brake shall have a Heat capacity that meets the operating frequency and shall not overheat;(5) The control parts of the brake (such as pedals, control handles, etc.) should have anti slip performance;(6) Manually control the brake, and the applied force and stroke should not exceed the requirements of Table 6-11. If they exceed the requirements, necessary adjustments should be made. The required operating method is to apply force/N stroke/mm. Generally, it is recommended to use manual control with a value of 100 400 feet, 120 250 feet, and 200 600 feet, 300 300 feet2. Scrapped brake parts should be scrapped, replaced, or repaired if one of the following situations occurs:(1) Cracks;(2) The thickness of the brake band or brake pad friction pad is worn to 50% of the original thickness;(3) Plastic deformation of the spring;(4) The wear of the hinge small shaft or shaft hole diameter reaches 5% of the original diameter;(5) The brake wheel should be scrapped if one of the following conditions occurs:① Cracks;② The brake wheel of the lifting and luffing mechanism has a rim thickness wear of 40% of the original thickness;③ The brake wheels of other institutions have a rim thickness wear of 50% of the original thickness;④ When the unevenness of the wheel surface reaches 1.5mm, if it can be repaired, the thickness of the wheel flange after repair should meet the requirements of items ② and ③ in this article

time:2021-05-02

More

Additional devicesVarious additional devices can be installed according to user needs to meet different work needs;Rising or falling valve: the rising valve "H", the falling valve "S" or the rising and falling valves "H, S" can extend the rising and Fall time steplessly, and the adjustable value can reach 10-20 times of the rated value. The valve is adjusted externally. The rising and Fall time time of the thruster with valve will be extended, the short stroke will be extended by 0.1-0.2s, and the long stroke will be extended by 0.2-0.4s;Brake spring: It generates braking force, and the spring force listed in the technical parameters is 1/3 of the rising stroke (2/3 of the falling stroke);Return spring: The working principle is the same as C-spring, but the return spring force is relatively small;Cushion spring: (only applicable to short stroke) mainly regulates the braking process. The non periodic transient process of buffering braking ensures smooth braking. It replaces the connecting block of the push rod and is installed on the piston rod without changing the stroke of the pusher.Heater: In areas with ambient temperatures below -20 ℃, additional heaters can be installed according to user needs. The heaters are AC200V or AC110V voltage, and should be specified when ordering. The temperature control and adjustment method is chosen by the user themselves;Travel switch: According to user requirements, the pusher can be equipped with a mechanical travel switch.purposeThe ED series electric hydraulic thrusters are mainly used as operating components for the YWZ4, YWZ5, YWZ8, YWZ9, and YWZP series electric hydraulic block brakes, widely used in industries such as lifting and transportation, metallurgy, mining, ports, and construction.Normal working conditionsMotor 1/2 three-phase AC asynchronous motor, in accordance with (G 755-87) regulations, insulation level: F levelUsage conditions:Continuous operation S1, continuous operation S2, load duration FC=60%

time:2021-05-02

More

The electro-hydraulic thruster adopts full hydraulic transmission, which has the characteristics of flexible movement and stable operation, and can effectively buffer external impacts; Can be started with load during work, with overload protection capability. The operation of the electro-hydraulic push rod (push and pull) is adjusted steplessly, making it safer and more energy-efficient.When installing the electro-hydraulic push rod, it is necessary to inject clean 46 # hydraulic oil (filtered before injection) into the electro-hydraulic push rod, install the oil filler cap, check the sealing performance, connect the motor power supply, and install the electro-hydraulic push rod in the working position. After connecting the transmission device, the electro-hydraulic push rod can be used. Due to its advantages of low energy consumption, long service life, convenient application, and simple maintenance, it has been widely used in cranes, winches On the electric hydraulic brake of equipment such as belt conveyors and car dumpers, it serves as a driving component. Due to its widespread use, it has become an important foundational component in industrial production.At present, there are many models and forms of electric hydraulic thrusters, but their basic structure consists of three major parts: a driving motor, a centrifugal pump, and a hydraulic cylinder with piston components. It uses electricity as its energy source, converting electrical energy into mechanical energy, and using hydraulic means to do work on external loads in the form of thrust.Our company mainly produces four types of electric hydraulic thrusters: BEd series electric hydraulic thrusters, Ed series electric hydraulic thrusters, BYT1 series electric hydraulic thrusters, and YT1 series electric hydraulic thrusters,In the AC brake of cranes, there are two types of driving components, namely AC electromagnets and electric hydraulic thrusters. The production and application of thrusters in China began with the use of double push rods (i.e. double rod output thrust thrusters), with the model "MYT1". Its upward and downward action times are relatively long, and its reliability is not high. Therefore, the YWZ series electric hydraulic brake using MYT1 thrusters as driving components is mainly used for crane translation mechanisms that operate infrequently and have low requirements for action time. Since the 1980s, the production and application of electric hydraulic thrusters in China have been developed. In addition to the original MYT1 double push rod, there are updated loan repayment products such as MYT3 electric hydraulic thrusters, Ed series electric hydraulic thrusters imported from Germany, and various factories' self-developed series such as MYT2 and MYT4 electric hydraulic thrusters. These newly developed or introduced electric hydraulic thrusters are structurally single rod or "single push rod", and their lifespan and operational performance are generally superior to the old product MYT1 in terms of technical indicators. Due to the lack of a unified standard for thrusters in China at that time. So they do not have a unified series spectrum, and basic parameters such as rated thrust and rated stroke are quite chaotic. Although the rated thrust level distribution of the thruster can be used as long as it matches the rated braking torque level distribution of the brake. For example, the rated thrust of the thruster matched with a brake with a rated braking torque of 630N · m can be either 700N or 800N.1. The electric hydraulic thruster is mainly made of cast aluminum alloy for the outer shell, so its appearance is very beautiful and its quality is also very lightweight. The motor is mainly made of a non immersed structure2. The surface of the motor shaft and push rod of the electric hydraulic thruster are treated with hard chromium plating, which has excellent sealing performance and can effectively extend the service life of the sealing componentsThe above is the entire content of the electric hydraulic thruster. If you want to learn more information, please feel free to call for further inquiriesED45 image

time:2021-05-02

More

DYLZ series electric hydraulic wheel brakeSupply DYLZ25A-301 electric hydraulic wheel brakeSpecification: DYLZ25A-301 DYLZ100A-201C DYLZ120B-301 DYLZ85C-301K1Purpose: Special for coal mine monkey trucksMatching: BED-201 BED-301 explosion-proof thrusterDYLZ series electric hydraulic wheel brake for monkey carsAdvantages:1. The disc spring hydraulic cylinder has excellent performance and is strictly designed, produced, and manufactured in accordance with GB/T15622-1995.2. Adopting a normally closed design, the hydraulic station drives and applies force to the butterfly spring for release, ensuring safety and reliability.3. Compact structure and beautiful appearance.4. Set limit switches for interlocking protection.5. Asbestos free friction discs have stable performance, novel and unique installation structure, and are easy to replace.6. The brake block adopts a connecting rod structure to ensure that the clearance between the friction plate plane and the wheel end face is equal when the brake is released. Eliminate the phenomenon of friction pads sticking to brake wheels in the past when the brake is loose.7. Anticorrosive design, all fasteners and pins are made of stainless steel.

time:2021-05-02

More

Compliant with standards:The installation dimensions and braking torque parameters of the brake comply with the JB/ZQ4388-1997 standard;Main features:Safe and reliable performance, smooth braking, and high action frequency;Interlocking equal distance device, which always maintains equal distance between the two sides of the pads during use, to avoid the phenomenon of one side of the brake pad floating against the brake wheel due to uneven distance;The main swing hinge point is equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use;The non cotton brake pad and brake pad adopt a card insertion type. Safe and reliable, easy and fast replacement;Usage conditions:Environmental temperature -20 ℃~50 ℃;There should be no flammable, explosive, or corrosive gases in the surrounding working environment;The relative humidity of the air shall not exceed 90%;The altitude of the location of use complies with GB755-2008;Outdoor rain and snow corrosion or corrosive gases and media should use anti-corrosion products.YWZ13 series electric hydraulic block brake:YWZ13-200/23; YWZ13-200/30; YWZ13-250/23; YWZ13-250/30; YWZ13-250/50; YWZ13-300/30; YWZ13-300/50; YWZ13-300/80; YWZ13-400/50; YWZ13-400/80; YWZ13-400/121; YWZ13-500/80; YWZ13-500/121; YWZ13-500/201; YWZ13-630/121; YWZ13-630/201; YWZ13-630/301; YWZ13-710/201; YWZ13-710/301; YWZ13-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50; YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201; YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12

time:2021-05-02

More

Mainly requires synchronous operation with the winch motor. When the winch is driving, the brake should be immediately opened, otherwise the motor will be blocked; When the winch stops, the brake should immediately lose power and lock up. From the control requirements, it can be seen that in order to work synchronously with the holding brake and the winch motor. When the brake fails automatically, it can still work. A manual button should be designed to start and stop the hydraulic brake. The structure of electromagnetic brake:It mainly consists of two parts: brake electromagnet and brake shoe brake.The brake electromagnet is composed of three parts: an iron core, an armature, and a coil. The brake shoe brake includes the brake wheel, brake shoe, and spring, etc. The brake wheel and the electric motor are installed on the same shaft.2. Working principle: When the electric motor is connected to the power supply, the electromagnetic brake coil is also energized, and the armature is attracted to overcome the tension of the spring to separate the brake shoe and brake wheel, resulting in normal operation of the electric motor. When the switch or contactor is disconnected, the motor loses power, and the electromagnetic brake coil also loses power. The armature separates from the iron core under the force of spring tension, causing the brake shoe of the brake to tightly hold the brake wheel, and the motor is stopped by braking. 1. Loosen the spring of the braking torque.2. Manually lift the thruster triangle and adjust the upper adjustment screw to make the opening gap of the brake shoe 1.5mm (brake shoe and brake wheel). Adjust the lower limit screw of the brake bracket to evenly distribute the opening gap on both sides of the brake shoe.3. Adjust the torque spring to meet the required scale.4. Tighten all locking nuts. (After the gate adjustment is completed)5. When the brake shoe is worn to the required level, replace it and adjust it according to the above steps. During the wear process of the brake shoe, due to the wear of the brake shoe, the triangle plate of the thruster is lowered. When the smooth rod of the thruster drops close to the compensation limit mark, the brake gap should be adjusted in a timely manner. When the hydraulic holding brake is used as the brake mechanism for the crane, trolley and winch, the three-phase power supply of the hydraulic holding brake is connected in parallel with the motor stator coil, and the motor is powered on and the hydraulic holding brake is powered on. If the hydraulic holding brake is used to locate the winch load with relatively accurate requirements, the three-phase power supply of the hydraulic holding brake cannot be connected in parallel with the motor stator coil. Because the motor stator coil is a 3-phase high inductance coil, a large amount of electrical energy is stored in the motor stator coil during operation. If the hydraulic brake is directly connected in parallel with the stator coil of the motor, when the motor is powered off, the electrical energy stored by the motor inductance coil will discharge to the hydraulic brake head motor. This delay in closing the brake is the discharge time, causing the winch motor to power off, and the brake will not immediately lock up. If the winch and elevator use hydraulic brake that requires accurate positioning, if connected together, it will cause inaccurate parking of the winch and elevator. In this case, the hydraulic brake needs to have a separate control circuitTwo types of diagrams, YWZ4 and YWZ

time:2021-05-02

More