Advantages of German SIBRE SIBRE USb3 hydraulic push rod disc brake:1. Patented design, with a 70% increase in braking force compared to regular designs.2. Due to the action of the spring on the center, the brake arm is no longer subjected to bending force, thereby extending the service life of the shaft sleeve and improving the transmissionEfficiency.3. The standard design is equipped with a new generation of equal backlash mechanism from the Sieber, which does not require manual adjustment to meet the equal clearance of the gasket,Implement automatic alignment.4. Designed without distinction between left and right hands, with a central layout.5. It has a sturdy and strong structure, high performance, and simple maintenance.6. The braking torque is adjustable and easy to adjust accurately.7. Using large brake pads, made of JURID755 friction material (previously used in motorcycle racing and high-speed trains, resistant toHigh temperature, up to 900 degrees Celsius, wear-resistant, stable friction coefficient under high loads and high temperatures.8. All hinge points and shaft pins are tightly combined and self lubricating shaft sleeves are used.9. Adopting EMG thruster, high quality, reliable, with a lifespan of over 10 years and no oil leakage.10. The standard design is equipped with a new generation of automatic friction plate wear compensation device.1、 Product Introduction: The DZS1 series electromagnetic power loss brake is a friction type brake (hereinafter referred to as the brake) that is powered on to release (release) and powered off to spring brake. It is mainly matched with the Y series motor to form the YEJ series electromagnetic braking three-phase asynchronous motor. Widely used in metallurgical, construction, chemical, food, machine tools, packaging and other machinery, as well as in safe (anti risk) braking situations during power outages, achieving fast parking and accurate positioning. This type of brake has the advantages of compact structure, convenient installation, wide adaptability, low noise, high working frequency, sensitive action, and reliable braking. It can be attached with a manual release device and is an ideal automatic control execution component. It is divided into two types: torque adjustable (conventional type) and non adjustable (N-type). DZS-05, DZS-08, DZS-15, electromagnetic power loss brake, brake manufacturer, price DZS-30, DZS-40, DZS-80, electromagnetic power loss brake, brake manufacturer, Price Jiaozuo 15838971872 brake SIBRE brake pad TE200-ED30/6 supporting brake pad (Semi metal DZS-150, DZS-200, DZS-300, electromagnetic power loss brake, brake manufacturer, price DZS-450, DZS-600, DZS-850, DZS-2000 electromagnetic power loss brake, brake manufacturer, price electromagnetic power loss brake 15838971872 Jiaozuo brake SIBRE thruster ED23/5 thruster SDZ1-02, SDZ1-04, electromagnetic power loss brake, brake manufacturer, price efficiency. SDZ1-08, SDZ1-15, electromagnetic power loss brake, brake manufacturer, price SDZ1-30) SDZ1-40, electromagnetic power loss brake, brake manufacturer, price SDZ1-80, SDZ1-150, electromagnetic power loss brake, brake manufacturer, price SDZ1-200, SDZ1-300, electromagnetic power loss brake, brake manufacturer, price SDZ1-450, SDZ1-600, electromagnetic power loss brake, brake manufacturer, price SDZ1-850, SDZ1-2000, electromagnetic power loss brake, brake manufacturer, price? SDZ1-4000, electromagnetic power loss brake, brake manufacturer, price? 15838971872 Jiaozuo brake SIBRE wheel brake ED201/6 230/400VAC, 50HZDZS3-05, DZS3-08, electromagnetic power loss brake, brake manufacturer, price DZS3-15, DZS3-30, electromagnetic power loss brake, brake manufacturer, price DZS3-4, DZS3-80, electromagnetic power loss brake, brake manufacturer, price DZS3-150, DZS3-200, electromagnetic power loss brake, brake manufacturer, price DZS3-300, DZS3-4, electromagnetic power loss brake, Brake manufacturer, prices DZS3-600, DZS3-850, electromagnetic power loss brake, brake manufacturer, prices DZS3-2000, DZS3-2500, electromagnetic power loss brake, brake manufacturer, prices DLTZ3-04, DLTZ3-05, electromagnetic power loss brake, brake manufacturer, prices DLTZ3-08, DLTZ3-15, electromagnetic power loss brake, brake manufacturer, prices DLTZ3-30, DLTZ3-40, electromagnetic power loss brake, brake manufacturer, Price Jiaozuo brake SIBRE accessory USB 3/I 40030DLTZ3-80, DLTZ3-150, electromagnetic power loss brake, brake manufacturer, price DLTZ3-200, DLTZ3-300, electromagnetic power loss brake, brake manufacturer, price DLTZ3-450, DLTZ3-600, electromagnetic power loss brake, brake manufacturer, price DLTZ3-850, DLTZ3-2000, electromagnetic power loss brake, brake manufacturer, price? Jiaozuo brake SIBRE pushing cylinder GH160.28/5218870104 (Installation method of 230VAC electromagnetic deenergized brake Disk brake Hydraulic disk brake Electromagnetic disk brake Pneumatic disk brake Pneumatic block brake Explosion proof hydraulic thruster Explosion proof electric hydraulic block brake Product introduction: Brake: YT1 series electric hydraulic thruster Electric hydraulic brake Electric hydraulic drum brake Electromagnetic block brake Electric hydraulic wind proof iron wedge brake Safety windproof brake electromagnetic failure protection disc brake electric hydraulic arm disc brake wind power yaw brake wind power spindle brake pneumatic caliper disc brake hydraulic failure protection brake electromagnetic failure protection brake hydraulic direct acting disc brake electromagnetic caliper disc brake pneumatic failure protection brake hydraulic direct acting brake motor disc brake thruster: Jiaozuo Brake SIBRE Brake YMZ-400/121E Electric Hydraulic Pusher Explosion-proof Electric Hydraulic Pusher Phone: 15838971872 Brake Pad: 1. Ordinary Material (High Temperature Resistance 400 ° C) 2. High Wear Resistant Material (4-8 Times Service Life of Ordinary Material) 3. Special Wear Resistant Material (8-12 Times Service Life of Ordinary Material) 4. Explosion proof Material 5. Copper Base Material (High Temperature Resistance 800 ° C) 6. Non standard anti-corrosion material: Jiaozuo Linrui brake SIBRE brake pad TE250-ED50/6 matched brake pad (Semi metal 1. YQP series: YQP50 YQP100 YQP160 YQP250 YQP315 YQP365 2. SB series: SB50 SB100 SB160 SB250 SB3653. YPZ series: YPZ2-I YPZ2-II YPZ2-III YPZ2-IV YPZ2-V YPZ2-VI P2-III4.QP series: QP12.7-A QP25.4 QP30 QP405.YP series: YP1 YP2 YP3 YP11 YP21 YP31 YP41 telephone 15838971872 disc brake 6. Yaw series: (0.8 MW, 1.5 MW 2 MW) DADH75 DADH80 DADH90 DADH103 DADH120 DADH1957. ADP series: ADP (H) 60 ADP (H) 90 ADP (H) 1208. SE series: 3SE (P) 4SE (P) 5SE (P) 450SE 56SE9. ST series: ST1SH ST2SH ST3SH ST4SH ST5SH ST10SH ST25SH ST25SH-A ST40SH ST3SH-A10. Wheel edge: YLVZ25-160 YLVZ40-16011. Copper base: FSH30 BSFA70 HB3012. Drilling rig: BSC90 ZWPS65-1 brake SIBRE brake TE200/EB 2513. Wind power high-speed shaft: (0.8 MW, 1.5 MW, 2 MW) According to your needs, choose temperature resistance, wear resistance, select materials, provide drawings, or provide technical requirements to design friction coefficients according to production requirements.Jiaozuo brake SIBRE friction plate SHI 106 brake matching friction plateJiaozuo brake SIBRE accessory GH160.28 D205V ED25/100%Jiaozuo brake SIBRE brake pad TE500-ED201/6S3 matched brake padJiaozuo brake SIBRE brake TPI 315/40/80 Nr: 134025Jiaozuo brake SIBRE manual pump V3-PUMJiaozuo brake SIBRE mechanical brake STE250/50/6Jiaozuo brake SIBRE brake TE630/3000-6Jiaozuo brake SIBRE hydraulic push rod EMG-ELTMA EB 1250-60IIJiaozuo brake SIBRE electrical components TE250-EB300/50Jiaozuo brake SIBRE brake TE315/ED80/6Jiaozuo brake SIBRE pushing cylinder GH160.28/5218870104 (230VACBrake SIBRE brake holder TE-S200-23-5 MBR 85-400 ED23/5Jiaozuo brake SIBRE brake YWZ5-400/E121 push model Ed121/6Jiaozuo brake SIBRE disc brake shoe matched with SIBRE-0060 brake shoeJiaozuo brake SIBRE brake pads USB2-11-121-6 phone 13803910788Jiaozuo brake SIBRE electromagnetic brake TMB400-GH180, AC220-240Jiaozuo brake SIBRE coupling AFN-SB90-40030Jiaozuo brake SIBRE brake TE315-EB800/60Jiaozuo brake SIBRE brake USB3-III-ED/121/6-630/30Jiaozuo brake SIBRE brake TE500-EB2000/60 380VAC 50HZJiaozuo brake SIBRE brake USB4-II-EB 1250/6063030Jiaozuo brake SIBRE electrical components brake shoe TE200/23/5 componentsJiaozuo brake SIBRE brake TE630/3000-6Jiaozuo brake SIBRE brake TMB 315/GH160.28Jiaozuo brake SIBRE accessory USB3- Ⅲ -2000/60Jiaozuo brake SIBRE brake pad USB3-111-1250/6Jiaozuo brake SIBRE brake TE250/30/5 380VAC, 50HZ brakeJiaozuo brake SIBRE rotary brake shoe 58-400NmJiaozuo brake SIBRE brake USB-3-I-ED50/6-40030Jiaozuo brake SIBRE brake USB2-05-EB300/50 415VJiaozuo brake SIBRE brake USB3-I-EB800/60SJiaozuo brake SIBRE hydraulic push rod EB3000-60 hydraulic push rodJiaozuo brake SIBRE electric hydraulic thruster ZB2500-60S Ⅱ T2MJiaozuo brake SIBRE brake TE400-3/30 D=400Jiaozuo brake SIBRE brake USB-III-ED201/6-63030Jiaozuo brake SIBRE shoe USB3/I 40030Jiaozuo brake SIBRE electrical components ED-201/6 thrusterJiaozuo brake SIBRE brake USB-I-Ed30/5-40030Jiaozuo brake SIBRE spring assembly spring assembly (acting on TE500-ED201/6)Jiaozuo brake SIBRE brake USB3-I-ED50/6 brakeJiaozuo brake SIBRE brake shoe TE 200/23/5 componentsJiaozuo brake SIBRE overflow valve V3-PVAL overflow valveJiaozuo brake SIBRE brake USB3- III/EB2000/60Jiaozuo brake SIBRE thruster EB800-60Jiaozuo brake SIBRE pneumatic chuck brake E4N-0311080340340305SIBRE brake GSd 135.6010 126408

time:2022-03-27

More

Jiaozuo Golden Hoop Electric Hydraulic Brake PriceSpecific model:YT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesQP, CQP, CQP, QPL, CQPL series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various brake wheel couplings, brake friction pads, brake discs, and non-standard brakes according to user needs.

time:2022-03-27

More

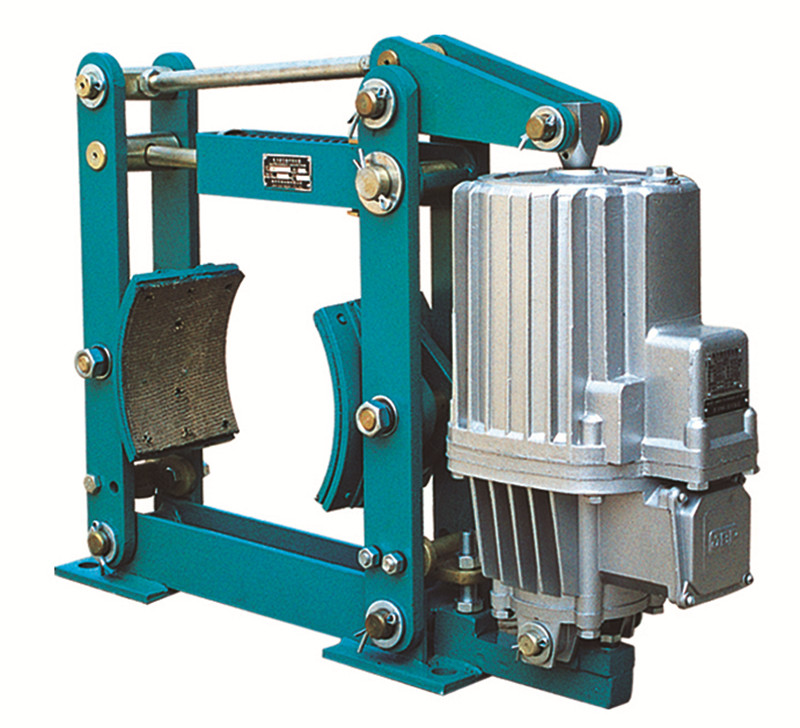

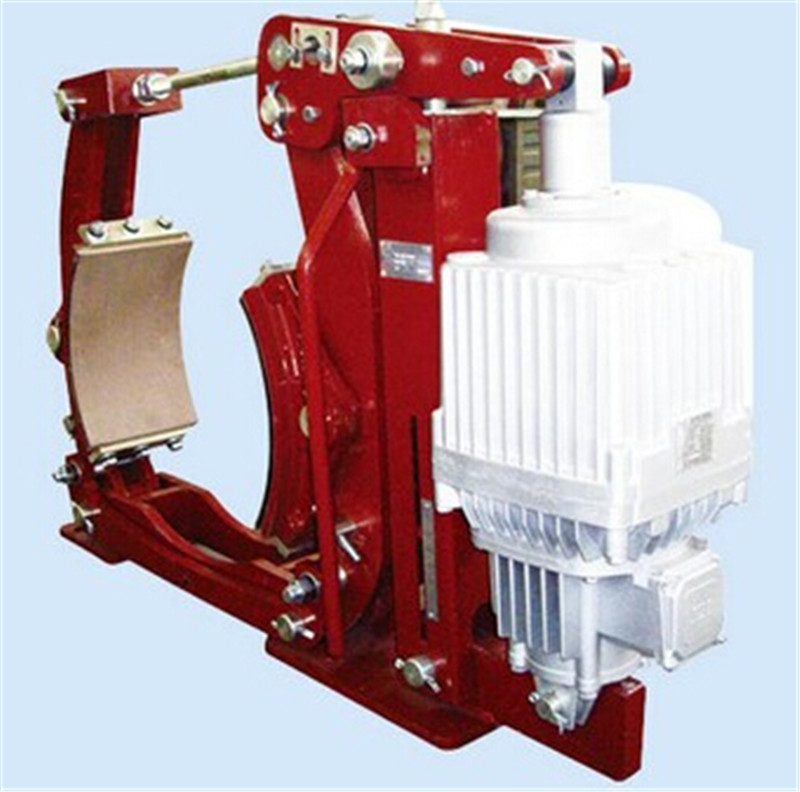

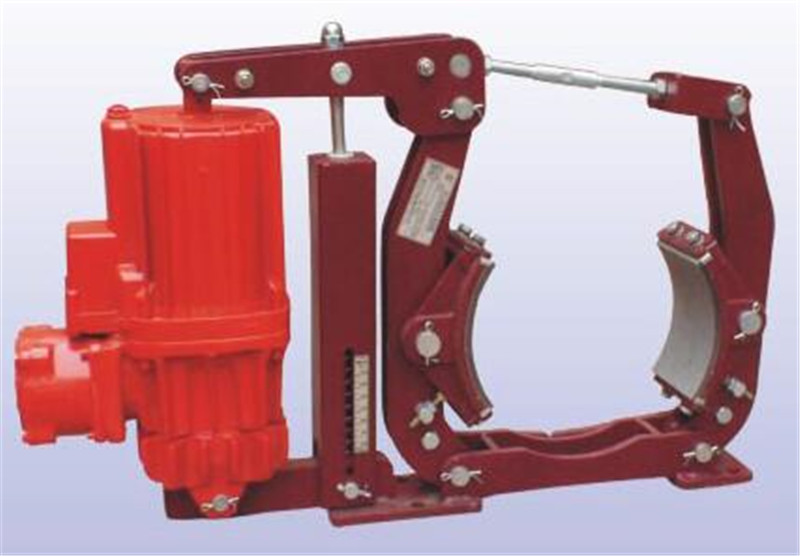

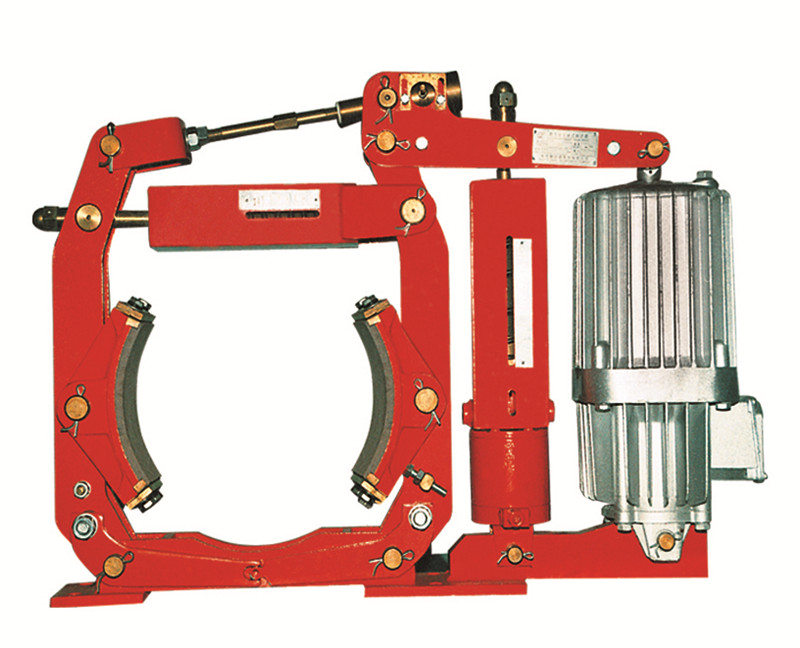

Good manufacturer of electric hydraulic thrusters in JiaozuoOur company produces various series of electric hydraulic brake actuators, mainly used for mechanical braking of mechanical driving devices in lifting, transportation, metallurgy, mining, ports, construction, etc. It has the advantages of stable braking, safety and reliability, convenient maintenance, low power consumption, long service life, no noise, and high frequency. Our company is the first to pass the ISO 9001.2000 quality management system standard certification. Advanced process equipment, strong technical strength, comprehensive testing methods, strict quality management system, reasonable product prices, and reputation are the strong guarantees for the company's products to enter the market and win users.Tel: 15838971872Brake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeED-23/5, ED-30/5, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-50/6, ED-80/6, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-121/6, ED-201/6, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters,ED-301/6, ED-50/12, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-80/12, ED-121/12, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters,ED-201/12, ED-301/12, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters

time:2022-03-27

More

Order BYWZ5 explosion-proof electric hydraulic brakeConsulting and ordering model: BYWZ5-160/23 BYWZ5-200/23BYWZ5-250/23 BYWZ5-250/50BYWZ5-315/23 BYWZ5-315/50 BYWZ5-315/50 BYWZ5-315/80BYWZ5-400/50 BYWZ5-400/80 BYWZ5-400/121BYWZ5-500/80 BYWZ5-500/121 BYWZ5-500/201BYWZ5-630/121 BYWZ5-630/201 BYWZ5-630/301BYWZ5-710/201 BYWZ5-710/301 BYWZ5-800/301/201Dedicated to coal mines, cranes, and mining machineryBYWZ5 explosion-proof electric hydraulic brake has complete models, low prices, excellent quality, complete certificates, fast delivery, Cash on delivery and door-to-door delivery.The order is packaged in wooden boxes and straw ropes, with a one-year shelf life.The main sales regions for explosion-proof brakes are Henan, Hebei, Shandong, Shanxi, Zhejiang, Chongqing, Gansu, Xinjiang, and Urumqi.ED-23/5, ED-30/5, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-50/6, ED-80/6, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-121/6, ED-201/6, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters,ED-301/6, ED-50/12, electric hydraulic thruster, price of electric hydraulic thruster, manufacturer of electric hydraulic thruster,ED-80/12, ED-121/12, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrusters,ED-201/12, ED-301/12, electric hydraulic thrusters, prices of electric hydraulic thrusters, manufacturers of electric hydraulic thrustersYWZ3B series electric hydraulic block brake: YWZ9-200/E23 electric hydraulic drum brake priceYWZ3B-160/18; YWZ3B-160/25; YWZ3B-200/18; YWZ3B-200/25; YWZ3B-250/25; YWZ3B-250/45; YWZ3B-315/25; YWZ3B-315/45; YWZ3B-315/90; YWZ3B-400/90; YWZ3B-400/125; YWZ3B-500/90; YWZ3B-500/125; YWZ3B-500/180; YWZ3B-630/125; YWZ3B-630/180; YWZ3B-630/320; YWZ3B-710/180; YWZ3B-710/320; YWZ3B-800/320Low price of YWZ9-200/E23 electric hydraulic drum brakeYWZ4B series electric hydraulic block brake: YWZ9-200/E23 electric hydraulic drum brake with low priceYWZ4B-100/23; YWZ4B-150/23; YWZ4B-200/23; YWZ4B-200/30; YWZ4B-300/30; YWZ4B-300/50; YWZ4B-300/80; YWZ4B-400/50; YWZ4B-400/80; YWZ4B-400/121; YWZ4B-500/121; YWZ4B-600/121; YWZ4B-600/201; YWZ4B-700/201; YWZ4B-700/301; YWZ4B-800/301YWZ5 series electric hydraulic drum brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50; YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201; YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12YWZ9 series electric hydraulic block brake:YWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50

time:2022-03-27

More

YWZ9 series electric hydraulic block brakeProduct Introduction:Electric hydraulic block brakes are widely used for deceleration or parking braking of mechanical drive devices such as lifting, metallurgy, mining, ports, docks, construction machinery, etc.Compliant with standards:The installation dimensions of the YWZ9 series electric hydraulic block brake comply with the GB6333-86 standard, and the technical requirements comply with the JB6406-2006 standard.Main features:The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and do not require lubrication during use;The main performance is safe and reliable, with smooth braking and high action frequency.Equipped with a chain type equal distance device, it always maintains equal distance between the two side tiles during use, avoiding the phenomenon of one side brake pad floating against the brake wheel due to uneven distance;The brake spring is arranged inside the spring tube and is equipped with a brake torque scale on one side, making adjustment convenient and intuitive;The asbestos free brake pad and brake pad adopt a plug-in type, which is safe and reliable, and easy and fast to replace.Usage conditions:Environmental temperature -20 ℃~+50 ℃;Power supply: 380V, 50HZ;Relative humidity: should not exceed 90%;There should be no flammable, explosive, or corrosive gases in the surrounding working environment;The altitude of the location of use complies with GB755-2000;Outdoor rain and snow erosion or corrosive gases and media should use anti-corrosion products.

time:2022-03-27

More

BYWZ5-400/80 explosion-proof brake | Voltage 660/1140 | Free installation guideMain production: explosion-proof brakes, explosion-proof thrusters.BYWZ series explosion-proof electric hydraulic brake produced by Henan manufacturer. Welcome to consult the company for various models of brakes, thrusters, explosion-proof brakes, and explosion-proof thrusters.Common models of coal mines and cranes:BYWZ-200/25 BYWZ-300/45 BYWZ-400/90BYWZ3-250/45 BYWZ3-315/45BYWZ5-315/50 BYWZ5-400/80 BYWZ5-400/121BYWZ5-500/121 BYWZ5-630/301National standard explosion-proof models, commonly used models are available in stock, and upon signing the contract, they will be shipped immediately and delivered to your doorstep.The BYWz series explosion-proof electric hydraulic brakes produced by Henan explosion-proof brake manufacturers are suitable for supporting use in coal mines, cranes, winches, and mining machinery. The company has complete explosion-proof and coal safety certificates.

time:2022-03-27

More

BEd series flameproof electric hydraulic thrusters (hereinafter referred to as "thrusters") are mainly used to operate electric hydraulic drum brakes and pumps, ratchets, valves, etc. They can also operate various forms of lever devices to make various movements, such as reciprocating, swinging, Circular motion motion, etc,This product complies with the technical requirements of the enterprise standard Q/JZHF01-2009 explosion-proof electric hydraulic thruster. The explosion-proof sign is "Exd I" and is suitable for electric hydraulic drum type coal mine belt conveyors (non mining working faces) and mine lifting equipmentElectric hydraulic thrusters for brakes.The thruster is an ideal component for achieving semi automation and automation of certain mechanical equipment. The piston rod adopts advanced protection, which can reduce wear and corrosion. The oil chamber of the hydraulic system with double-layer protective seal and double-layer sealing ring greatly improves the service life of the thruster. The thruster has the advantages of stable and noise free operation, low power consumption, long service life, and convenient maintenance.2. Working conditions2.1. The altitude shall not exceed 2000m.2.2. The ambient temperature is -20 ℃ to 40 ℃.2.3. The power supply is a three-phase AC power supply, with a rated frequency of 50Hz and a rated voltage of 380V/660V. The allowable voltage fluctuation is+10% to -25%2.4. The motor working system is S1 continuous working system or S3 intermittent cycle working system, and the load duration during intermittent cycle working system is not more than 60%.2.5. It is allowed to operate in environments with explosive gas mixtures of gas and coal dust. The working conditions should comply with the provisions of the "Coal Mine Safety Regulations" (2006).2.6. The thruster motor is of Class F insulation2.7. The relative humidity of the surrounding air shall not exceed 95%2.8. The pollution level of the surrounding environment is allowed to be level 3.3. Model Naming conventionBEd □/□ ()Voltage level, in volts (V)Rated travel codeThrust codeThe electric motor is a built-in explosion-proof electric hydraulic thruster4. Structure and working principle:The BEd series electric hydraulic thrusters are mainly composed of explosion-proof motors, intermediate flanges, impellers, complete sets of pistons, etc. Connect the power supply to the thruster, and the motor rotates to drive the impeller to generate pressure oil, pushing the piston and connecting rod upward. Maintain its thrust after reaching the predetermined stroke. When the power supply is disconnected, the motor and impeller stop rotating and no longer generate pressure oil. The piston and connecting rod return to their original position under external force. (See Figure 1)6. Installation adjustment and usage requirements6.1. Before installation, the following inspections must be carried out. If they do not meet the requirements, they are not allowed to be used.6.1.1 The thrust on the thruster nameplate should match the required thrust.6.1.2 There are explosion-proof signs and explosion-proof certificate numbers. Products used underground should have a "MA" mark6.1.3 The explosion-proof level and group of the thruster should meet the requirements for explosive mixture locations.6.1.4 All fastening bolts should be tightened, and all components of the explosion-proof enclosure should be properly connected.6.1.5 All explosion-proof parts should be free from cracks and defects that affect explosion-proof performance.6.1.6 The insulation resistance between the stator winding and the casing shall not be less than 0.38M (rated voltage 380V), 0.66M (rated voltage 660V), and 1.4M (rated voltage 1140V)6.2 Installation positionThe thruster is generally installed vertically (the motor should be located below), and can also be tilted or horizontally installed. However, it must be noted that when tilted or horizontally installed, the balance chamber should be facing upwards, and it must be ensured that the thruster can swing as a whole, and the piston rod is not allowed to bear radial force. Connect the upper and lower connecting holes of the thruster with the matching mechanism using a pin shaft, and add washers and split pins. The pusher linkage can rotate When the thruster is in operation, there should be a certain distance between the upper connecting rod and the upper edge of the cylinder block, which should generally not be less than 5mm.6.3 Electrical wiringWhen wiring, use the special wrench to remove the three bolts on the junction box cover, open the junction box cover, enter the cable into the junction box through the flameproof junction nozzle, and connect the three-phase power line (phase sequence is not required) and ground wire as required. Then install the junction box cover and tighten the bolts. The junction box should be kept clean and ensure that the sealing gasket is in the correct position and not damaged. The diameter of the motor cable should match the aperture of the rubber sealing ring. The large cross-section of the cable used is 4X4mm2, ensuring that there is no gap between the rubber ring and the motor outlet, otherwise the explosion-proof performance will be lost. When the sealing ring of the introduction device ages and deteriorates, it should be replaced in a timely manner, with a size of ¥ 16X ¥ 35X26 Before powering on, the three-phase balance of the power supply voltage and the range of voltage fluctuations should be checked to ensure compliance with international regulations.Do not open the cover with electricity!!!6.4. The internal and external grounding bolts should be reliably grounded.6.5. When the thruster leaves the factory, the working oil is already installed and can be used directly. Due to the decrease in oil, the technical value of the thruster may change, and even it cannot be started. Therefore, except for normal maintenance, it is not allowed to open the oil filling plug or overflow plug arbitrarilyAccording to user needs, the following additional functions can be installed:Before adjusting the time control valve, unscrew the blind plugs marked 'S' and' H ', and then rotate the adjusting screw to adjust the rising time and Fall time steplessly.Screw rotation (to the right)=increased travel timeScrew out (turning left)=reduced travel timeIt should be noted that the large adjustment amount is 20 revolutions, and the stroke time of the pusher equipped with a valve has been adjusted to 5 seconds at the factory. After adjustment, the blind plug should be tightened.The travel switch pusher can be equipped with a travel switch to indicate the position of the piston, and can be equipped with single or double travel switches.After the installation of the thruster is completed, it should be powered on and run several times. After checking for any abnormalities, it can be put into use.7. Use and Maintenance7. 1 Regularly check whether the thruster works normally. The inspection period can be set as shift inspection, daily inspection, etc. based on work conditionsCheck if the wiring is firm to prevent short circuits, open circuits, and burning of the motor caused by vibration.Check the oil every six months. When the oil deteriorates or gets mixed with debris, the oil should be changed. If the oil is insufficient, the oil should be replenished. Users can fill the oil from the oil filling plug, which should not exceed the position of the overflow plug. It should be noted that during the oil injection process, pull the push rod up and down several times to exhaust air and fill the oil chamber with oil.7.2 When the thruster is working, pay attention to whether the action is normal, whether there is oil leakage or oil seepage, and whether the oil tank has enough oil. If not, supplement it properly.7.3. When replacing and installing explosion-proof parts, attention should be paid to protecting the explosion-proof surface. All explosion-proof surfaces must not be damaged or rusted, and parts should be coated with 204-1 rust proof oil on the explosion-proof surface during installation.7.4. During the operation of the thruster, the allowable temperature of the bearing should not exceed 95 ℃ (thermometer method). The bearing should be inspected every six months and the lubricating grease should be replaced. Before replacement, it must be washed clean with gasoline, and the lubricating grease should be ZFG-2 composite calcium based grease.7.5. When the thruster is installed on the main engine and needs to be repainted, be careful not to paint the piston rod, otherwise it will damage its sealing.7.6. When the thruster is placed for more than one and a half years, it should be checked for oil leakage before use.8. Storage and transportation1. When storing thrusters, they should be kept dry to prevent moisture and sharp changes in ambient temperature.2. During transportation, it is necessary to prevent rain and not use a rope to cover the push rod for transportation.According to the temperature of the surrounding medium, it is recommended to choose hydraulic oil according to the following table:Surrounding medium temperatureRecommended oil (L-LH hydraulic oil)Executive standards-20 ℃~40 ℃DB-25 Transformer OilGB/T11118. 1-940~-20 ℃YH-10 aviation hydraulic oilGB/T11118. 1-94

time:2022-03-27

More

Where can there be a brake product that can replace the French SIM 645 brakeJiaozuo Brake Co., Ltd. produces electric hydraulic brakes, thrusters, disc brakes, pneumatic brakes, arm disc brakes, windproof iron wedge brakes and other industrial brakes. The products have safe and reliable performance, stable braking, high smoothness of action and long service life.Specific model:YT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesCustomization of various imported brakesCustomized various brake wheels and discs, and customized non-standard brakes according to user needs.

time:2022-03-27

More

Replacement and maintenance of the hydraulic brake pusher of the winchSpecific model:YT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD SB Series Safety BrakesSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various brake wheels and discs, and customized non-standard brakes according to user needsPneumatic disc brake CQPL12.7-B electric hydraulic brake electric hydraulic drum brake electromagnetic block brake electric hydraulic windproof iron wedge brakeSafety wind brake electromagnetic failure protection disc brake electric hydraulic arm disc brake wind electric yaw brakeWind power spindle brake Pneumatic caliper disc brake Hydraulic failure protection Brake electromagnetic failure protection BrakeHydraulic direct acting disc brake electromagnetic caliper disc brake pneumatic failure protection brake hydraulic direct acting brakeMotor disc brake

time:2022-03-23

More

YWZ5-300/E50 YWZ5-300/E80 electric hydraulic brakeYWZ5 series electric hydraulic block brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50; YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201; YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12YWZ9 series electric hydraulic block brake:YWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50; YWZ9-300/30; YWZ9-300/50; YWZ9-300/80; YWZ9-315/30; YWZ9-315/50; YWZ9-315/80; YWZ9-400/50; YWZ9-400/80; YWZ9-400/121; YWZ9-500/80; YWZ9-500/121; YWZ9-500/201; YWZ9-600/121; YWZ9-600/201; YWZ9-600/301; YWZ9-630/121; YWZ9-630/201; YWZ9-630/301; YWZ9-700/201; YWZ9-700/301; YWZ9-710/201; YWZ9-710/301; YWZ9-800/301/12

time:2022-03-23

More

YWZE-250/30 electric hydraulic brakeYWZE type electric hydraulic block brakeYWZE-160/22twenty-fiveYWZE-200/22thirty-nineYWZE-200/30forty-twoYWZE-250/30forty-nineYWZE-250/50sixty-oneYWZE-315/30eightyYWZE-315/50eighty-sixYWZE-315/80eighty-eightYWZE-400/50one hundred and eightYWZE-400/80one hundred and tenYWZE-400/125one hundred and thirty-threeYWZE-500/80two hundred and twoYWZE-500/125two hundred and sixYWZE-500/200two hundred and eightYWZE-630/125three hundred and nineYWZE-630/200three hundred and tenYWZE-630/300three hundred and fifteenYWZE-710/200four hundred and sixty-eightYWZE-710/300four hundred and seventyYWZE-800/300six hundred and fifty-fiveScoring coefficient

time:2022-03-23

More

Smelting special pneumatic caliper disc brake QP12.7-ACQP12.7■ QP, CQP, DCPZ series caliper disc brakeCaliper disc brake is an advanced product that not only has the advantages of disc brake, but also has wide adaptability and unique advantages. This product has a simple structureSingle, small in size, light in weight, high in reliability, easy to use, suitable for various disc diameters, easy to install, debug, and maintain. Widely applicable for lifting and transportationDeceleration and braking of fixed operating mechanisms such as transportation, metallurgy, mining, ports, construction, bulk loading and unloading, as well as tension control of machinery such as cables, paper making, and steel platesDomain.main features Compact structure, small size, light weight, high reliability, and convenient installation and use.Sensitive action and flexible control.● QP series pneumatic caliper disc brake meets the installation performance requirements of foreign similar products. Matched with imported air bags, reliable performance and long service life.The brake pad adopts a pressure spring clamp type, with a unique structure and convenient and fast replacement.A display device can be installed to visually display the working status of the brake.All power sources do not need to be set separately and can be used in conjunction with existing air compression stations. Speed control valves are installed in the gas supply line, and the braking time can be adjusted steplessly.● Normally closed design: spring braking, pneumatic release.Normally open design: pneumatic braking, spring release, and braking force can be flexibly changed with air pressure.OverviewThe QP (CQP) series pneumatic caliper disc brakes are mainly used in lifting, transportation, metallurgy, mines, and portsThe braking and deceleration of various mechanisms in machinery such as machinery and construction.Usage conditionsEnvironmental temperature: -5 ℃~40 ℃● Working air pressure: 5-7bar for QP series;The CQP series is ≤ 7bar.Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.The air source should be free of oil, water, and other impurities.Main featuresThe QP series adopts spring braking and pneumatic release; The CQP series is pneumatic braking with spring release.The overall structure is simple, small in size, and lightweight.Asbestos free brake pads, green and environmentally friendly.The installation of the brake pad adopts a spring clamp type, which is convenient and fast to replace.● The brake pad is easy to adjust after being worn.Each disc diameter of the QP series brake can be adjusted for four levels of braking torque.All power sources do not need to be set separately and can be connected to the existing air compression station for grid use. They can be added to the gas supply lineEquipped with a speed control valve, the braking time can be adjusted steplessly.Note: 1. It can produce pneumatic caliper disc brakes with different disc thicknesses and installation sizes.2. The specific model and structural dimensions reserve the right to change.QP series pneumatic caliper disc brakes are mainly used for braking and deceleration of various mechanisms in hoisting, transportation, metallurgy, mining, port, construction and other machinery, as well as tension control of cables, paper making, steel plate and other machinery.Pneumatic caliper disc brakeQP12.7-A, QP15, QP20, QP25.4, QP30CQPL12.7A-A; CQPL12.7A-B; CQPL12.7B; QPL12.7A-A; QPL12.7A-B; QPL12.7-A; QPL12.7-B;QP30-D; QP25.4-D; CQP30-D; CQP25.4-D; PDA5; PDA10; PDB5; PDB10; PDB19; PDC5; PDC10Electric hydraulic block brakes are widely used for deceleration or parking braking of mechanical drive devices such as lifting, metallurgy, mining, ports, docks, construction machinery, etc. Safe and reliable performance, smooth braking, and high action frequency.The main swing hinge point is equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use. Comply with standard installation dimensions and JB/ZQ4388-1997 standards.Operating conditions Environmental temperature: -20 ℃~+50 ℃ The relative air temperature should not exceed 90%. The surrounding working environment should not contain flammable, explosive, or corrosive gases. The altitude of the location of use should comply with GB755-2000. Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.Note: YWZ4B, YWZB, YWZB, YWZ8, and YWZ13 are interchangeable. YWZB matches the YT type thruster, while YWZ4B, YWZ8, and YWZ13 match the Ed type thruster.Electric hydraulic block brakes are widely used for deceleration or parking braking of mechanical drive devices such as lifting, metallurgy, mining, ports, docks, construction machinery, etc. Safe and reliable performance, smooth braking, and high action frequency.The main swing hinge point is equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use. Comply with standard installation dimensions and JB/ZQ4388-1997 standards.Operating conditions Environmental temperature: -20 ℃~+50 ℃ The relative air temperature should not exceed 90%. The surrounding working environment should not contain flammable, explosive, or corrosive gases. The altitude of the location of use should comply with GB755-2000. Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.

time:2022-03-23

More