Jiaozuo Brake, subordinate to Jiaozuo Hongqi Brake Co., Ltd., is a company integrating brake, actuator, development and manufacturing, sales and service.

time:2022-03-23

More

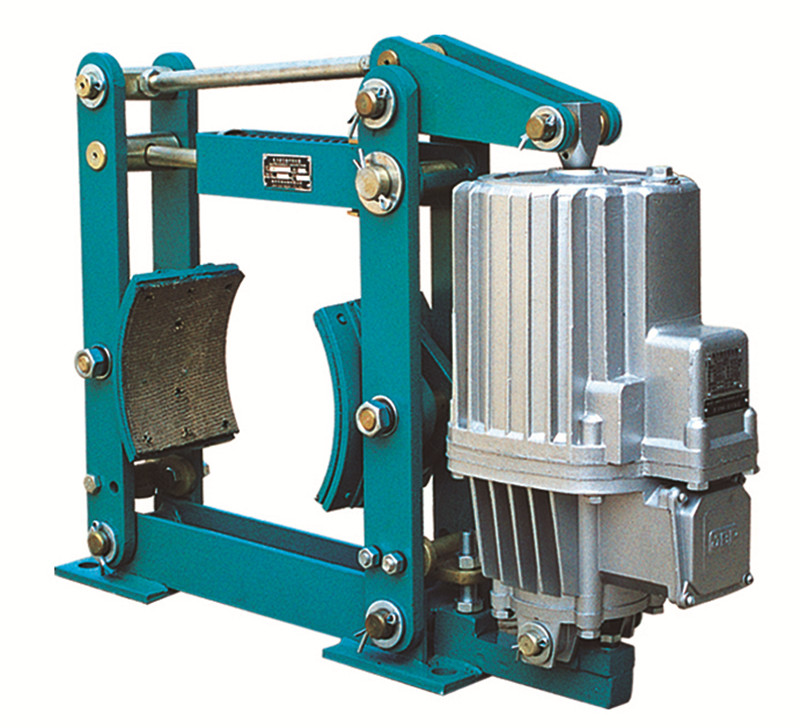

Electric hydraulic brake YWZ3B-250/45 YWZ3B-315/45 YWZ3B-400/90Main products:1. YWZB, YWZ3, YWZ4, YWZ5, YWZ8, YWZ9, YWZ10, YWZ12, YWZ13 series electric hydraulic pad brakes2. YW series electric hydraulic tile brake3. YWL series electric hydraulic tile brake4. EYWZ series two-stage hydraulic block brake5. TWZ (B) series normally open operated pad brake6. JZ, MW, MWZ, ZWZA, ZWZ3, ZWZ3A series electromagnetic pad brakes7. YPZ2 series electric hydraulic arm disc brake8. YFX series electric hydraulic windproof iron wedge brake9. YLBZ series hydraulic wheel edge brake10. ED, YT1 series electric hydraulic thrusters11. BED and BYT1 series explosion-proof electric hydraulic thrusters12. TYWZ series hydraulic tile brake13. DCPZ series electromagnetic caliper disc brake14. QP12.7 series pneumatic caliper disc brake15. TYWZ2 series foot hydraulic block brake16. SE, SH, SP series failure disc protection brakes17. SBD series hydraulic failure protection disc brake18. DYT series electric hydraulic push rod electric push rodOur company adheres to serving society with high-quality products and reasonable prices, promoting the spirit of diligence, dedication, and innovation, adhering to the sales philosophy of customers, grasping high service quality and customer-centric as the long-term development strategy of the enterprise, and striving to provide customers with fast service and more high-quality products.

time:2022-03-23

More

Genuine Jiaozuo Gold Hoop Brake YWZ4YWZ5YWZ9-400/80On October 24, 2014, the company celebrated its 50th anniversary. After research and decision by the party committee of the group company, a celebration event for the company's 50th anniversary was held in the Boai Industrial Park. The party committee of the company held meetings with various subsidiaries, departments, and branches to arrange and deploy specific celebration work. Personnel from each branch and department actively reported all the celebration programs (dance, singing, calligraphy, photography, painting), and worked overtime while not affecting the normal production and operation of the company. They actively responded to the call of the group company and jointly celebrated the 50th anniversary of Jiaozuo Brake (Group).Jiaozuo Gold HoopAt present, many small factories in the market counterfeit "Golden Hoop Brand" products, causing significant losses to our long-term "Golden Hoop Brand" products. This has seriously affected the image of the "Golden Hoop Brand" products in the minds of customers, affected the sales and market share of the "Golden Hoop Brand" products, and also had a significant impact on our factory's sales and after-sales service. The cost of investment in after-sales maintenance services for the products is also constantly increasing. And the phenomenon that it is impossible to remotely confirm whether the product is from our factory before maintenance, and even at the production site, it is necessary to confirm its authenticity based on feelings. These have caused us to invest unnecessary energy, and if we find that it is not our factory's product, it also affects the brand loyalty of our customers. Finished product anti-counterfeiting codes, suppress counterfeit products, increase market share, and establish a good brand image. 1. Scan the QR code through WeChat on your phone, enter the query interface and enter the numerical code to verify whether it is genuine, and display product usage and maintenance instructions; 2. Through the enterprise website, click on the QR code to enter the query interface, enter the numerical code to verify whether it is genuine, and display product usage and maintenance instructions. Continuously establish a good brand image, allowing customers to feel standardized management and meticulous service.

time:2022-03-23

More

YPB disc brake, with a new single push rod electric hydraulic thruster as the driving device, is mainly used in lifting, transportation, metallurgy, mining, port, construction and other mechanical equipment.Product FeaturesThe built-in brake spring can be easily adjusted to achieve different braking torquesEach hinge point adopts self-lubricating bearingsThe spacer sleeve and pin shaft are made of stainless steel, with a beautiful appearance and corrosion resistancePlug-in brake pads for quick replacementAutomatically compensating for wear of brake pads, limit switches form a complete set of safety protection devicesAdopting a new type of asbestos free braking material, it is resistant to high temperatures and has a high and stable friction coefficientThe voltage and frequency of the thruster can be determined according to user requirementsThe brake can be vertically arranged on the left and right sides of the brake disc, or horizontally arranged for use in vertical driving devices, such as rotary mechanismsThis brake has undergone computer simulation tests with the same type of foreign product, and the working coefficient has reached the same level. The parts can be interchangedYPB-1 Technical ParametersH h2 w1 d4 b2 l5 h1 l3 l4 b3 l1 l2 b7 l6 b6 l7 b8 h3 s1670 27 70 18 300 230 80 180 120 111 190 80 100 150 140 20 14 1.25Brake discDiameterBrake disc related dimensions, thruster modelED80/6 ED50/6 ED30/6 ED23/5D1 b1 d2 d3 b1 b4A1 braking force kg f-m (nm) μ = zero point four five315 30 235 120 118 58ninety-nine39 (380) 28 (270)355 30 275 160 138 7899 117 (1150) 68 (670) 45 (440) 33 (320)400 30 320 205 160 10099 138 (1350) 81 (790) 53 (520)450 30 370 205 180 12599 159 (1560) 93 (910)The size unit (mm) is determined by the model of the thrusterB 350 350 385 385L 440 440 455 455B 5 120 117 155 155L 8 160 160 190 190L 5 105 110 120 120YPB-2 Technical ParametersH h 2 w 1 d 4 b 2 l 5 h 1 l 3 l 4 b 3 l 1 l 2 b 7 l 6 b 6 l 7 b 8 h 3 s 1820 330 90 22 370 375 280 130 130 140 145 205 90 150 205 172 20 14 1.6Brake discDiameterBrake disc related dimensions, thruster modelED50/6 ED80/6 ED121/6 ED201/6D 1 b 1 d 2 d 3 b 1 b 4A1 braking force kg f-m (nm) μ = zero point four five400 30 300 160 150 80180 82 (800) 142 (1395) 276 (2700)450 30 350 210 175 105180 94 (920) 166 (1625) 315 (3085)500 30 400 260 200 130206 108 (1060) 189 (1855) 362 (3550)560 30 460 320 230 160two hundred and six218 (2135) 417 (4085) 637 (6250)630 30 530 390 265 195two hundred and six480 (4705) 727 (7125)710 30 610 470 305 235two hundred and sixThe size unit (mm) is determined by the model of the thrusterB 450 450 445 445L 485 485 510 510B 5 155 155 148 148L 8 190 190 240 240L 5 190 190 205 205YPB-3 Technical ParametersH h 2 w 1 d 4 b 2 l 5 h 1 l 3 l 4 b 3 l 1 l 2 b 7 l 6 b 6 l 7 b 8 h 3 s 11100 490 120 27 410 460 370 180 160 170 285 110 230 225 165 30 20 1.6Brake discDiameterBrake disc related dimensions, thruster modelED121/6 ED201/6 ED301/6D 1 b 1 d 2 d 3 b 1 b 4A1 braking force kg f-m (nm) μ = zero point four five560 30 440 250 215 135346 367 (3595) 509 (4985) 743 (7280)630 30 510 320 250 170346 425 (4165) 590 (5780) 861 (8235)710 30 590 400 290 210376 492 (4820) 683 (6690) 996 (9760)800 30 680 490 335 255three hundred and seventy-six1148 (11250)1000 40 880 690 435 355three hundred and seventy-six1486 (14560)The size unit (mm) is determined by the model of the thrusterB 490 490 490L 535 535 535B 5 148 148 148L 8 240 240 240L 5 320 320 320Product diagram

time:2022-03-23

More

Electromagnetic failure protection disc brake:3SE; 4SE; 5SE; 450SE; 56SE; 560SE; 561SE; ST1SE; ST2SEHydraulic fail safe disc brake:3SH; 4SH; 5SH; 450SH; ST1SH; ST2SH; ST3SH; ST4SH; ST5SH; ST10SH; ST16SH; ST25SH; 904SH;ST40SHPneumatic fail safe disc brake:3SP; 4SP; 5SP; 450SPHydraulic direct acting disc brake:ADH60; ADH90; ADH120; DADH75; DADH80; DADH90; DADH120; DADH195; DADH350Pneumatic direct acting disc brake:ADP60M; ADP61M; ADP62MPneumatic caliper disc brakeCQPL12.7A-A; CQPL12.7A-B; CQPL12.7B; QPL12.7A-A; QPL12.7A-B; QPL12.7-A; QPL12.7-B;QP30-D; QP25.4-D; CQP30-D; CQP25.4-D; PDA5; PDA10; PDB5; PDB10; PDB19; PDC5; PDC10Electromagnetic caliper disc brake:DCPZ12.7-250; DCPZ12.7-300; DCPZ12.7-400Hydraulic caliper disc brake:SB (YQP) 50; SB (YQP) 100; SB (YQP) 160; SB (YQP) 250; SB (YQP) 315; SB (YQP) 400;SBD safety brake:SBD100-A; SBD125-A; SBD160-A; SBD200-A; SBD250-A; SBD-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD80-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD120-D; SBD240-DDue to the electromagnetic attraction of the short stroke electromagnetic block brake electromagnet, the braking torque of the short stroke brake is generally not high. Mechanisms that require high braking torque often use long stroke electromagnetic block brakes.The long stroke electromagnetic block brake relies on the main spring to apply and the electromagnet to release.The commonly used long stroke electromagnetic block brake is the JCZ type 200-600 brake. It is mostly used on Overhead crane of 20-30 tons or more.The advantage of electromagnetic block brakes is that they have a simple structure and can be interlocked with the control circuit of the motor. Therefore, when the motor stops working or an accident power outage occurs, the electromagnet can automatically power off and the brake will automatically switch on, ensuring safe and reliable operation. However, there is a major drawback that the electromagnet has a strong impact, causing severe braking on the mechanism and causing mechanical vibration of the transmission mechanism. At the same time, due to frequent starting and braking of the lifting mechanism, the electromagnet produces a huge collision sound, and the service life of the electromagnet is short, requiring frequent repair and replacement.

time:2022-03-20

More

What is the problem with the electric hydraulic brake not holding tightly and not braking properlyThere are three main reasons why the brake cannot stop. Firstly, check if the hydraulic thruster has been reset, secondly, check if the spring screws are loose, thirdly, if the brake pads are severely worn and need to be replaced. Additionally, there may be other reasons that can only be investigated on-site.Electric hydraulic block brakes are widely used for deceleration or parking braking of mechanical drive devices such as lifting, metallurgy, mining, ports, docks, construction machinery, etc. Safe and reliable performance, smooth braking, and high action frequency.The main swing hinge point is equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use. Comply with standard installation dimensions and JB/ZQ4388-1997 standards.Operating conditions Environmental temperature: -20 ℃~+50 ℃ The relative air temperature should not exceed 90%. The surrounding working environment should not contain flammable, explosive, or corrosive gases. The altitude of the location of use should comply with GB755-2000. Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.Note: YWZ4B, YWZB, YWZB, YWZ8, and YWZ13 are interchangeable. YWZB matches the YT type thruster, while YWZ4B, YWZ8, and YWZ13 match the Ed type thruster.Electric hydraulic block brakes are widely used for deceleration or parking braking of mechanical drive devices such as lifting, metallurgy, mining, ports, docks, construction machinery, etc. Safe and reliable performance, smooth braking, and high action frequency.The main swing hinge point is equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use. Comply with standard installation dimensions and JB/ZQ4388-1997 standards.Operating conditions Environmental temperature: -20 ℃~+50 ℃ The relative air temperature should not exceed 90%. The surrounding working environment should not contain flammable, explosive, or corrosive gases. The altitude of the location of use should comply with GB755-2000. Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.Performance description:The product has the advantages of reliable performance, no pollution, no noise, high wear resistance, and long service life. Our company's brake accessories such as friction pads, friction blocks, brake shoes, brake pads, clutch pads, etc. are suitable for use in various types of mechanical brakes such as automobiles, motor vehicles, textile machinery, marine machinery, engineering machinery, etc., mainly for industrial and agricultural machinery such as forklifts, bulldozers, excavators, loaders, tractors, harvesters, etc, There are over 2000 types of products that can provide you with high-quality mechanical accessories. At the same time, the company has developed environmentally friendly friction products that can be applied in various fields. They have low density, good bending strength, high rotational burst strength, stable friction coefficient, low wear rate, and smooth connection during installation and use. Their comprehensive performance meets the requirements of supporting enterprises. The company can design and develop various specifications of friction materials according to customer requirements (samples and drawings)The enterprise has become a domestic producer of heavy-duty vehicles, medium-sized vehicles, sedans, and micro cars by introducing advanced production processes from Japan and German distribution technology through the import of raw materials; Various specifications of (non) asbestos mechanical brake pads, clutch pads, mechanical friction pads, brake pads, brake bands, lining pads, copper based friction pads, paper based friction pads, motor friction rings, brake pads, various types of cork friction plates, asbestos friction plates, (non) asbestos friction plates, and semi metal friction plates, including industrial machinery, engineering machinery, mining machinery, oil drilling rigs, ship machinery, agricultural machinery, and electric bicycles, Electromagnetic friction discs and various non-standard friction materials can be customized. Our company strictly adheres to the corporate tenet of "good management, quality, reasonable price, and excellent service", and always adheres to treating product quality as the life of the enterprise. Since its establishment for over a decade, the company has provided products and services to over 300 customers both domestically and internationally, with customers spread throughout the country. It has established long-term partnerships with multiple large enterprises, and its products are exported to Southeast Asia, the Americas, Japan and other countries and regions, deeply favored by users.2、 Performance indicatorsAfter testing, the main technical indicators of the friction plate are as follows:Hardness: HRL50-90Bending strength ≥ 55 (N/mm2)High strength ≥ 15 (10-3mm/mm)The friction and wear performance meets the requirements in the table:Temperature 100, 150, 200, 250, 300, and then 1001. Suitable and stable friction coefficientThe friction coefficient is an important performance indicator for evaluating any type of friction material, which is related to the performance of the friction plate in executing transmission and braking functions. Our company adds high-temperature friction regulator fillers to friction materials to reduce and overcome "heat decay" and ensure stable friction coefficient of the product.2. Good wear resistanceThe wear resistance of friction materials is a reflection of their service life and an important technical and economic indicator to measure the durability of friction materials. The better the wear resistance, the longer its service life. Our company selects suitable wear reducing fillers and resin and rubber with good heat resistance, which can effectively reduce the working wear of materials, especially thermal wear, and extend their service life.

time:2022-03-20

More

High quality electric hydraulic thruster ED80/6The ED electric hydraulic thruster consists of two parts, driving the electric motor and the body (centrifugal pump). The body part is composed of a cover, cylinder, piston, impeller, and rotor.When energized, the electric motor drives the rotor shaft and the impeller on the rotor shaft to rotate, generating pressure inside the piston. Under the influence of this pressure, the oilSuck from the upper part of the piston to the lower part, forcing the piston and the push rod and crossbeam fixed on it to rise rapidly. By mechanically compressing the load spring through a lever (if the thruster or brake is equipped with a load spring), mechanical motion is generated.When the power is cut off, the impeller stops rotating, and the piston rapidly descends under the force of the load spring and its own gravity, forcing oil to flow back into the upper part of the piston. At this time, it still returns to its original position through the lever mechanism.Electric hydraulic thrusters are often used in conjunction with brake frames and are widely used for braking various transmission devices.??ED series electric hydraulic thrusters1、 OverviewEd series electric hydraulic thruster is a very compact driving control device integrating motor, centrifugal pump and oil cylinder, which is widely used as the driving device of various block brakes and disc brakes, and can also be used for the driving control of various industrial valves, gates, directional swing and rotation (<90 °) devices (mechanisms) and clamping devices.2、 Design FeaturesThe shell is made of cast aluminum alloy, with light weight and beautiful appearance;The motor is of non oil immersed structure, with Class B or F insulation (according to user requirements). Good heat resistance and long service life;The motor junction box cover is equipped with a seal and uses a cable stuffing box for incoming lines, which is firm and reliable. The electrical casing protection level reaches IP55;The surface of the motor shaft and push rod are plated with hard chromium treatment, greatly extending the service life of the sealing element; thirteen billion eight hundred and three million nine hundred and ten thousand seven hundred and eighty-eightThe oil cylinder shell is equipped with a balance chamber on one side, which can allow the thruster to be installed in any direction from 0 to 180 °, thereby expanding its range of use;All seals and bearings of the Ed series are made of world-renowned products, with reliable sealing and long service life;The Ed series fasteners are made of stainless steel material, which is beautiful and durable.3、 Selection of installation methodVertical installation: the piston rod connecting block faces upwards;Horizontal installation and any position in the middle: the main parameter label faces upwards;All push rod connection blocks of thrusters can rotate. The Ed50-Ed301 fixed seat can rotate 90 °, while the Ed23-Ed30 fixed seat can also provide 90 ° rotation, but the installation height dimension A is increased by 8mm;Regardless of the installation position, the piston rod cannot withstand any force to avoid affecting its effectiveness and lifespan.4、 Additional devicesVarious additional devices can be installed according to user needs to meet different work needs;Rising or falling valve: the rising valve "H", the falling valve "S" or the rising and falling valves "H, S" can extend the rising and Fall time steplessly, and the adjustable value can reach 10-20 times of the rated value. The valve is adjusted externally. The rising and Fall time time of the thruster with valve will be extended, the short stroke will be extended by 0.1-0.2s, and the long stroke will be extended by 0.2-0.4s;Brake spring: It generates braking force, and the spring force listed in the technical parameters is 1/3 of the rising stroke (2/3 of the falling stroke);Return spring: The working principle is the same as C-spring, but the return spring force is relatively small;Cushion spring: (only applicable to short stroke) mainly regulates the braking process. The non periodic transient process of buffering braking ensures smooth braking. It replaces the connecting block of the push rod and is installed on the piston rod without changing the stroke of the pusher.Heater: In areas with ambient temperatures below -20 ℃, additional heaters can be installed according to user needs. The heaters are AC200V or AC110V voltage, and should be specified when ordering. The temperature control and adjustment method is chosen by the user themselves;Travel switch: According to user requirements, the pusher can be equipped with a mechanical travel switch.PurposeThe ED series electric hydraulic thrusters are mainly used as operating components for the YWZ4, YWZ5, YWZ8, YWZ9, and YWZP series electric hydraulic block brakes, widely used in industries such as lifting and transportation, metallurgy, mining, ports, and construction.Normal working conditionsMotor 1/2 three-phase AC asynchronous motor, in accordance with (G 755-87) regulations, insulation level: F levelUsage conditions:Continuous operation S1, continuous operation S2, load duration FC=60%Rated voltage is 380V three-phase, frequency 50HzThe altitude level of the location of use complies with the GB755-87 standardThe ambient temperature should be within the range of -20 ℃ to 40 ℃, and the relative humidity of the air should not exceed 90%Vertical installation: piston connection block facing upwards, horizontal installation: marked label facing upwards: (ED630/12 male is suitable for vertical installation)Main technical parametersModel rated thrust(N) Rated stroke(mm) Action stroke brake spring force(N) Rated frequency(Hz) Input power(W) Rated voltage(V) Rated current(A) Working frequency weight (kg)Rising and fallingShort stroke thruster deviation ± 20%Ed23/5 220 50 0.35 0.35 180 50 165 380 0.52 2000 10Ed30/5 300 50 0.35 0.35 270 50 200 380 0.46 2000 14Ed50/6 500 60 0.45 0.39 460 50 210 380 0.48 2000 14Ed80/6 800 60 0.32 0.34 750 50 330 380 1.42 2000 24Ed121/6 1250 60 0.4 0.42 1200 50 330 380 1.44 2000 39Ed201/6 2000 60 0.5 0.32 1900 50 450 380 1.45 2000 39Ed301/6 3000 60 0.58 0.32 2700 50 550 380 1.46 1500 40PurposeContinuously work S1 and continue working S3, and the ambient temperature of chicken feathers reaches+50 ℃.The rated current in the table refers to the line terminal current during rated operation, but if the power supply is at a non rated value, it will inevitably cause a corresponding change in the rated current. Environmental temperature: -20 ℃~+50 ℃, hydraulic oil: DB-25 (SY1351-77) When it is below -20 ℃, YH-10 hydraulic oil can be used without a heater. When using DB-25 hydraulic equipment, a heater must be installed. The travel time is measured at an ambient temperature of 20 ℃.

time:2022-03-20

More

Our company's service tenet: quality first, customer first, enthusiastic service, and commitment to excellence. Our products have been selling well in Shandong, Hebei, Shanxi, Shaanxi, Henan, Anhui, Hubei, and Northeast China since they were launched on the market in 2019More than 20 provinces and cities are well received by users, and the supply of goods is in short supply. We welcome sand mining businesses to come and negotiate business. Our factory provides users with installation, debugging, guidance and training personnel, and provides various spare parts year-round. With comprehensive after-sales serviceEnsure that users are relieved of their worries.The company has passed Elvis Quality Certification and ISO9001-2000 International Quality System Certification, and has a complete quality assurance system, strict management system, strong production capacity, and advanced testing methods to ensure the high quality of productsWhile producing high yields, it also possesses strong market competitiveness. The square sample is a key protected product in Henan Province.The company adheres to the principles of quality and honest service, and the reputation guarantees everything.Normally closed electric hydraulic drum brake:Features: Excellent characteristics, smooth operation, low power impact during closure, and low impact on the double beam crane mechanism. The control is simple, the driving device has non overload and self-protection, high reliability and long service life. It belongs to three-phase AC power supply and generally cannot be used in DC power grid.Application: Widely used for high-speed shaft deceleration and maintenance braking of various lifting and loading and unloading machinery mechanisms, it is currently the mainstream supporting braking product widely used in cranes.Normally open electric hydraulic drum brake:Features: Controllable effects can be achieved through electrical controls such as foot switches and frequency conversion. The operation is light and labor-saving, and the brake system is simple compared to manual operation of steel wire ropes or hydraulic transmission (without steel wire ropes or hydraulic systems). It can achieve foot brake of high-power mechanisms. It belongs to three-phase AC power supply and generally cannot be used in DC power grid.Application: The horizontal normally open type is widely used in the braking of the slewing mechanism of the gantry double girder crane (especially the medium and large Gantry crane with a weight of more than 16 tons), replacing the traditional manual brake. The vertical normally open type is mainly used for the braking of crane cranes that require controllable braking, as well as the braking of the trolley running mechanism.Electromagnetic drum brake with DC excitation:Characteristics: The action impact is large, and the electromagnetic brake with DC excitation, whether it is AC or DC power supply, generally requires an intermediate link of power control, which is relatively complex compared to the control of electric hydraulic brakes. Due to the complexity of the control process and sensitivity to the suction air gap of the armature, operational faults are prone to occur in the event of improper maintenance. Adapt to different power controls and can be used for both DC and AC power sources.Application: Due to the obvious disadvantages of electromagnetic brakes compared to electric hydraulic brakes, they are currently less commonly used in double beam cranes. They are mainly used for high-speed axle braking of certain mechanisms of DC powered cranes or special cranes that require magnetic preservation (such as steel mill special cranes and electromagnetic cranes using DC power grids).

time:2022-03-20

More

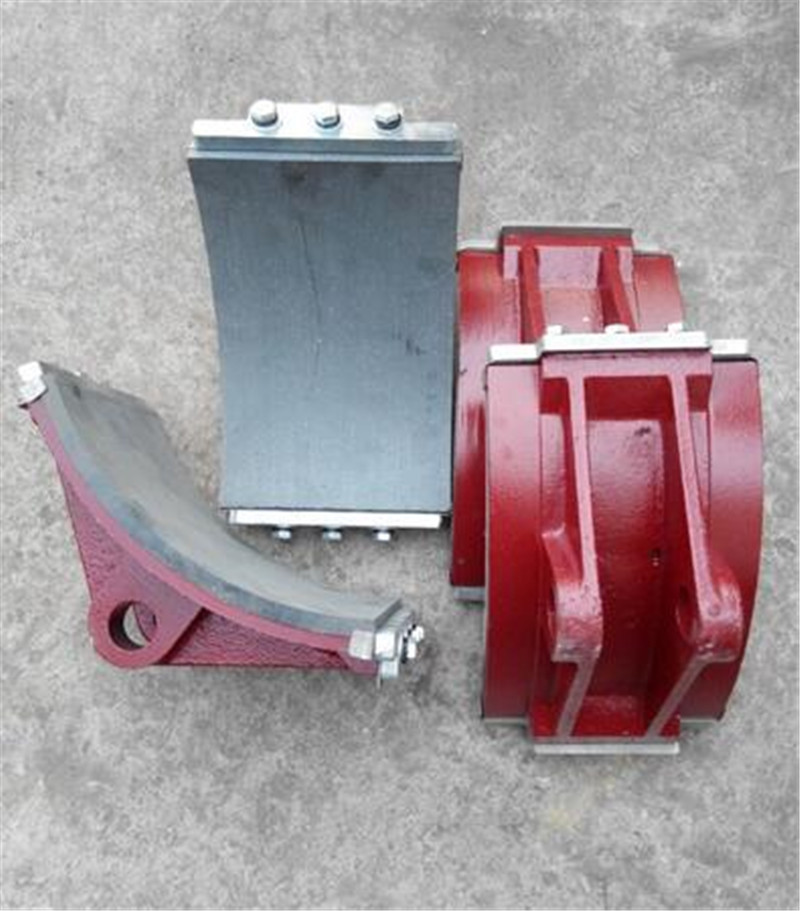

Good disc brake friction plate priceBrake linings, asbestos free brake linings, semi metal brake linings, explosion-proof brake linings, steel backed adhesive linings, Disc brake linings, clutch discs, etc. Suitable for ports, steel cranes, tower cranes, engineering machinery, drilling machinery, hydraulic machinery, and the production of various materials of automotive and power vehicle brake pads. Asbestos-free brake shoes are a new generation of brake friction materials. Traditional asbestos brake materials pose a serious threat to human health and are gradually phased out products. The new asbestos free material not only poses no harm to the human body, but also has superior performance indicators compared to asbestos brake materials. The product is mainly used for brake pads, linings, etc. of various lifting machinery and other brakes.There are two types of brake pads: one is made of asbestos rubber steel wire mesh material for the brake band, and the other is made of asbestos resin. The non asbestos brake pad and brake pad use two types: plug-in and riveted, which are safe and reliable, convenient to replace, and fast.Processing and production of 14010 brake bands | friction pads | brake pads | brake shoesElectromagnetic failure protection disc brake:3SE; 4SE; 5SE; 450SE; 56SE; 560SE; 561SE; ST1SE; ST2SEHydraulic failure protection disc brake:3SH; 4SH; 5SH; 450SH; ST1SH; ST2SH; ST3SH; ST4SH; ST5SH; ST10SH; ST16SH; ST25SH; 904SH;ST40SHPneumatic fail safe disc brake:3SP; 4SP; 5SP; 450SPHydraulic direct acting disc brake:ADH60; ADH90; ADH120; DADH75; DADH80; DADH90; DADH120; DADH195; DADH350Pneumatic direct acting disc brake:ADP60M; ADP61M; ADP62MPneumatic caliper disc brakeCQPL12.7A-A; CQPL12.7A-B; CQPL12.7B; QPL12.7A-A; QPL12.7A-B; QPL12.7-A; QPL12.7-B;QP30-D; QP25.4-D; CQP30-D; CQP25.4-D; PDA5; PDA10; PDB5; PDB10; PDB19; PDC5; PDC10Electromagnetic caliper disc brake:DCPZ12.7-250; DCPZ12.7-300; DCPZ12.7-400Hydraulic caliper disc brake:SB (YQP) 50; SB (YQP) 100; SB (YQP) 160; SB (YQP) 250; SB (YQP) 315; SB (YQP) 400;SBD safety brake:SBD100-A; SBD125-A; SBD160-A; SBD200-A; SBD250-A; SBD-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD80-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD120-D; SBD240-DElectric hydraulic windproof iron wedge brake:YFX series electric hydraulic windproof iron wedge brake:YFX-500/80; YFX-550/80; YFX-600/80; YFX-630/80; YFX-700/80; YFX-710/80; YFX-800/80

time:2022-03-20

More

Price of brake pads from manufacturers of gold hoop brakesBrake linings, asbestos free brake linings, semi metal brake linings, explosion-proof brake linings, steel backed adhesive linings, Disc brake linings, clutch discs, etc. Suitable for ports, steel cranes, tower cranes, engineering machinery, drilling machinery, hydraulic machinery, and the production of various materials of automotive and power vehicle brake pads. Asbestos-free brake shoes are a new generation of brake friction materials. Traditional asbestos brake materials pose a serious threat to human health and are gradually phased out products. The new asbestos free material not only poses no harm to the human body, but also has superior performance indicators compared to asbestos brake materials. The product is mainly used for brake pads, linings, etc. of various lifting machinery and other brakes.There are two types of brake pads: one is made of asbestos rubber steel wire mesh material for the brake band, and the other is made of asbestos resin. The non asbestos brake pad and brake pad use two types: plug-in and riveted, which are safe and reliable, convenient to replace, and fast.Processing and production of 14010 brake bands | friction pads | brake pads | brake shoesBrake drum. The working surface of the inner wall of the brake drum will experience severe wear after long-term braking use. Its roundness has changed, and the coaxiality between its inner working surface and its installation positioning surface has also changed. As a result, various faults may occur when the car is braking, such as poor braking effect, noise, vibration, etc. Therefore, timely repairs must be carried out. As for the repair method to be used, it can be determined based on the wear and tear situation. When the wear of the inner wall working surface is not very severe, and the changes in its roundness and coaxiality of the positioning reference are not too large, the method of honing can be used to solve it. Usually, the roundness of the inner wall working surface reaches 0 5 mm, with a coaxiality of 0 2 mm requires hole lining repair. The common damages of brake drums in operation include wear and grooving of the friction surface, as well as deformation and loss of roundness. These damages will directly affect braking efficiency. Therefore, the working surface of the brake drum must be flat and smooth, and have good contact with the friction plate. Minor scratches, small grooves, and slight mechanical damage on the outer shoulder are allowed without affecting the quality of use. The roundness error can be measured with a dedicated bow inner diameter gauge, and the radius error exceeds 0 13 mm, or severe grooves caused by exposed shoe rivets, should be polished on a lathe or brake drum polishing machine according to the actual wear situation. If the brake drum of a car experiences cracks, severe deformation, or wear, and the inner diameter exceeds the limit, it should be replaced. The repaired brake drum should undergo a static balance check, and its static imbalance should not exceed 200 g • cm. When grooves appear on the working surface of the brake drum, or its roundness and radial total runout (i.e. the deviation from the hub axis) exceed the usage requirements, it will seriously affect the braking efficiency of the car and should be repaired in a timely manner. General requirements for brake drum lining: Position the outer ring of the wheel hub bearing (to ensure coaxiality after lining). After lining, the inner diameter of the brake drum shall not exceed the basic size by 4 mm, and the cylindricity shall not exceed 0 10mm, with a radial runout of no more than 0 10 mm. If the inner diameter of the brake drum is worn beyond the specified limit, it should be replaced with a new one.2. Brake shoe friction lining. When the brake shoe friction lining is severely worn, or the surface of the friction lining is severely contaminated or burned by oil, a new shoe should be replaced. When replacing, both left and right wheels must be carried out simultaneously, and friction linings of the same manufacturer, brand, and material must be selected and installed. When the new shoe after replacement does not fit well with the brake drum, it should be ground until it meets the requirements. The general requirement is to ensure that the bonding area between the shoe and the brake drum is greater than 60% of the total area of the friction lining. The brake shoe return spring should be checked for its free length. If it exceeds 5% of its standard length or if there is a gap between the coils, it should be replaced. If the brake shoe tendon is warped or deformed, it will interfere with the bolt (nut) of the brake clearance adjustment device, and with the groove of the brake cylinder piston and brake support plate. This will affect the free opening and return of the brake shoe friction lining assembly. If this situation occurs, it can be repaired using cold correction methods. If the brake shoe base plate undergoes deformation, it can also be repaired using cold correction methods. For cracks in the brake shoe bottom plate welds caused by deformation or other reasons, the verticality shall not exceed 0 At 25 mm, welding repair and correction can be carried out; If the damage is too severe and cannot be repaired, it should be replaced. The tension spring of the brake shoe must maintain a certain amount of elasticity. If there is a severe decrease in elasticity, it often causes the brake tendon to detach from the groove of the brake support plate and become stuck, causing the brake to not be released. Therefore, it is necessary to replace springs with severely reduced elasticity in a timely manner. During driving, due to the frequent application of braking to the car, the brake drum and brake shoe friction plate will experience varying degrees and types of wear or deformation. To ensure driving safety, it is necessary to repair it. Within the allowable range of repair dimensions, the brake drum is often processed using ordinary lathes or specialized machine tools. At present, there are two ways to process brake friction pads. One is to remove them from the vehicle and fix them on a specialized fixture for grinding or turning. Although this method can improve processing quality, save labor hours, and is suitable for division of labor and flow operations, due to the limitations of current overhaul and maintenance technology in China, the brake shoes processed in this way often cannot meet the assembly requirements of vehicles, thereby affecting braking efficiency in the early stages of driving. Another method is to machine the brake shoe friction plates on the machine. As it is positioned and processed based on actual conditions, it is more suitable for the assembly requirements of the brake. Although this method requires more labor, it is flexible and convenient for general repair shops or workshops to use. The equipment processed using the second method is mostly self-made, which can be divided into integral and separate types from the perspective of the overall structure. The latter is to install the moving tool head and feed mechanism on a small car, while the tool holder and positioning device are fixed on the front or rear axle of the car; The former institutions are installed as a whole on the car. There are two types of integrated brake shoe polishing machines: manual and electric, while the separate types are mostly electricElectromagnetic failure protection disc brake:3SE; 4SE; 5SE; 450SE; 56SE; 560SE; 561SE; ST1SE; ST2SEHydraulic fail safe disc brake:3SH; 4SH; 5SH; 450SH; ST1SH; ST2SH; ST3SH; ST4SH; ST5SH; ST10SH; ST16SH; ST25SH; 904SH;ST40SHPneumatic fail safe disc brake:3SP; 4SP; 5SP; 450SPHydraulic direct acting disc brake:ADH60; ADH90; ADH120; DADH75; DADH80; DADH90; DADH120; DADH195; DADH350Pneumatic direct acting disc brake:ADP60M; ADP61M; ADP62MPneumatic caliper disc brakeCQPL12.7A-A; CQPL12.7A-B; CQPL12.7B; QPL12.7A-A; QPL12.7A-B; QPL12.7-A; QPL12.7-B;QP30-D; QP25.4-D; CQP30-D; CQP25.4-D; PDA5; PDA10; PDB5; PDB10; PDB19; PDC5; PDC10Electromagnetic caliper disc brake:DCPZ12.7-250; DCPZ12.7-300; DCPZ12.7-400Hydraulic caliper disc brake:SB (YQP) 50; SB (YQP) 100; SB (YQP) 160; SB (YQP) 250; SB (YQP) 315; SB (YQP) 400;SBD safety brake:SBD100-A; SBD125-A; SBD160-A; SBD200-A; SBD250-A; SBD-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD80-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD120-D; SBD240-DElectric hydraulic windproof iron wedge brake:YFX series electric hydraulic windproof iron wedge brake:YFX-500/80; YFX-550/80; YFX-600/80; YFX-630/80; YFX-700/80; YFX-710/80; YFX-800/80

time:2022-03-20

More

What is the problem with the electric hydraulic brake slipping and not stoppingThe installation size and operation of each type of brake are different, and the brakes are divided into three types: normally closed, normally open, and comprehensive. Most cranes use normally closed brakes. Normally closed brakes are closed during periods when the mechanism is not in operation. If you want the mechanism to work, you only need to release the brake to separate the friction pairs of the brake, and the mechanism can operate. The brakes used on cranes are divided into block brakes, belt brakes, disc brakes and cone brakes according to their shapes. The purpose of the crane braking device is that the braking device is an important component to ensure the safe and normal operation of the crane. During lifting operations, the braking device is used to prevent objects or lifting arms from falling during suspension, and to prevent the turntable or crane from sliding under the action of wind or slope forces; Or reduce the speed of the running mechanism and then stop moving; It can also be operated by clamping heavy objects according to work needs; In special circumstances, the movement speed can be adjusted by controlling the balance between power and gravity. Brake 15838971872Note: YWZ4B, YWZB, YWZB, YWZ8, and YWZ13 are interchangeable. YWZB matches the YT type thruster, while YWZ4B, YWZ8, and YWZ13 match the Ed type thruster.Electric hydraulic block brakes are widely used for deceleration or parking braking of mechanical drive devices such as lifting, metallurgy, mining, ports, docks, construction machinery, etc. Safe and reliable performance, smooth braking, and high action frequency.The main swing hinge point is equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use. Comply with standard installation dimensions and JB/ZQ4388-1997 standards.Operating conditions Environmental temperature: -20 ℃~+50 ℃ The relative air temperature should not exceed 90%. The surrounding working environment should not contain flammable, explosive, or corrosive gases. The altitude of the location of use should comply with GB755-2000. Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.

time:2022-03-20

More

Explosion proof electric hydraulic thruster BED80/6 can be used in underground mining areasBYT1 series electric hydraulic thrusters:BYT1-18ZB/2; BYT1-25ZB/4; BYT1-25ZC/4; BYT1-45Z/4; BYT1-45Z/5; BYT1-45Z/6; BYT1-90Z/6BYT1-90Z/8; BYT1-125Z/10; BYT1-180Z/8; BYT1-180Z/10; BYT1-180Z/12; BYT1-320Z/12BYT1-320Z/20; BYT1-25/4; BYT1-45/6; BYT1-90/8; BYT1-180/12ED series electric hydraulic thrusters:ED-23/5; ED-30/5; ED-50/6; ED-80/6; ED-121/6; ED-201/6; ED-301/6; ED-50/12; ED-80/12; ED-121/12; ED-201/12; ED-301/12; ED-630/12BED ZED series electric hydraulic thrusters:BED30/5; BED50/6; BED80/6; BED121/6; BED201/6; BED301/6; BED50/12; BED80/12; BED121/12BED201/12; BED301/12; BED630/12The electric hydraulic thruster consists of two parts, driving the electric motor and the body (centrifugal pump). The body part is composed of a cover, cylinder, piston, impeller, and shaft.When energized, the electric motor drives the rotor shaft and the impeller on the rotor shaft to rotate, generating pressure inside the piston. Under the influence of this pressure, the oilSuck from the upper part of the piston to the lower part, forcing the piston and the push rod and crossbeam fixed on it to rise rapidly. By mechanically compressing the load spring through a lever (if the thruster or brake is equipped with a load spring), mechanical motion is generated.When the power is cut off, the impeller stops rotating, and the piston rapidly descends under the force of the load spring and its own gravity, forcing oil to flow back into the upper part of the piston. At this time, it still returns to its original position through the lever mechanism.Electric hydraulic thrusters are often used in conjunction with brake frames and are widely used for braking various transmission devices.The company's products are widely used in domestic lifting and transportation, port machinery, metallurgical machinery, railway machinery, hydraulic machinery, mining machinery and other industries. 1、 OverviewEd series electric hydraulic thruster is a very compact driving control device integrating motor, centrifugal pump and oil cylinder, which is widely used as the driving device of various block brakes and disc brakes, and can also be used for the driving control of various industrial valves, gates, directional swing and rotation (<90 °) devices (mechanisms) and clamping devices.2、 Design FeaturesThe shell is made of cast aluminum alloy, with light weight and beautiful appearance;The motor is of non oil immersed structure, with Class B or F insulation (according to user requirements). Good heat resistance and long service life;The motor junction box cover is equipped with a seal and uses a cable stuffing box for incoming lines, which is firm and reliable. The electrical casing protection level reaches IP55;The surface of the motor shaft and push rod are plated with hard chromium treatment, greatly extending the service life of the sealing element;The oil cylinder shell is equipped with a balance chamber on one side, which can allow the thruster to be installed in any direction from 0 to 180 °, thereby expanding its range of use;All seals and bearings of the Ed series are made of world-renowned products, with reliable sealing and long service life;The Ed series fasteners are made of stainless steel material, which is beautiful and durable.3、 Selection of installation methodVertical installation: the piston rod connecting block faces upwards;Horizontal installation and any position in the middle: the main parameter label faces upwards;All push rod connection blocks of thrusters can rotate. The Ed50-Ed301 fixed seat can rotate 90 °, while the Ed23-Ed30 fixed seat can also provide 90 ° rotation, but the installation height dimension A is increased by 8mm;Regardless of the installation position, the piston rod cannot withstand any force to avoid affecting its effectiveness and lifespan.4、 Additional devicesVarious additional devices can be installed according to user needs to meet different work needs;Rising or falling valve: the rising valve "H", the falling valve "S" or the rising and falling valves "H, S" can extend the rising and Fall time steplessly, and the adjustable value can reach 10-20 times of the rated value. The valve is adjusted externally. The rising and Fall time time of the thruster with valve will be extended, the short stroke will be extended by 0.1-0.2s, and the long stroke will be extended by 0.2-0.4s;Brake spring: It generates braking force, and the spring force listed in the technical parameters is 1/3 of the rising stroke (2/3 of the falling stroke);Return spring: The working principle is the same as C-spring, but the return spring force is relatively small;Cushion spring: (only applicable to short stroke) mainly regulates the braking process. The non periodic transient process of buffering braking ensures smooth braking. It replaces the connecting block of the push rod and is installed on the piston rod without changing the stroke of the pusher.Heater: In areas with ambient temperatures below -20 ℃, additional heaters can be installed according to user needs. The heaters are AC200V or AC110V voltage, and should be specified when ordering. The temperature control and adjustment method is chosen by the user themselves;Travel switch: According to user requirements, the pusher can be equipped with a mechanical travel switch.Usage 15838971872The ED series electric hydraulic thrusters are mainly used as operating components for the YWZ4, YWZ5, YWZ8, YWZ9, and YWZP series electric hydraulic block brakes, widely used in industries such as lifting and transportation, metallurgy, mining, ports, and construction.

time:2022-03-20

More