Safe use method of BED explosion-proof brake thrusterSafe use method of BED explosion-proof brake thrusterED series electric hydraulic thrusters:ED-23/5; ED-30/5; ED-50/6; ED-80/6; ED-121/6; ED-201/6; ED-301/6; ED-50/12; ED-80/12; ED-121/12; ED-201/12; ED-301/12; ED-630/12BED ZED series electric hydraulic thrusters:BED30/5; BED50/6; BED80/6; BED121/6; BED201/6; BED301/6; BED50/12; BED80/12; BED121/12BED201/12; BED301/12; BED630/12The electric hydraulic thruster consists of two parts, driving the electric motor and the body (centrifugal pump). The body part is composed of a cover, cylinder, piston, impeller, and shaft.When energized, the electric motor drives the rotor shaft and the impeller on the rotor shaft to rotate, generating pressure inside the piston. Under the influence of this pressure, the oilSuck from the upper part of the piston to the lower part, forcing the piston and the push rod and crossbeam fixed on it to rise rapidly. By mechanically compressing the load spring through a lever (if the thruster or brake is equipped with a load spring), mechanical motion is generated.When the power is cut off, the impeller stops rotating, and the piston rapidly descends under the force of the load spring and its own gravity, forcing oil to flow back into the upper part of the piston. At this time, it still returns to its original position through the lever mechanism.Electric hydraulic thrusters are often used in conjunction with brake frames and are widely used for braking various transmission devices.The company's products are widely used in domestic lifting and transportation, port machinery, metallurgical machinery, railway machinery, hydraulic machinery, mining machinery and other industries. 1、 OverviewEd series electric hydraulic thruster is a very compact driving control device integrating motor, centrifugal pump and oil cylinder, which is widely used as the driving device of various block brakes and disc brakes, and can also be used for the driving control of various industrial valves, gates, directional swing and rotation (<90 °) devices (mechanisms) and clamping devices.2、 Design FeaturesThe shell is made of cast aluminum alloy, with light weight and beautiful appearance;The motor is of non oil immersed structure, with Class B or F insulation (according to user requirements). Good heat resistance and long service life;The motor junction box cover is equipped with a seal and uses a cable stuffing box for incoming lines, which is firm and reliable. The electrical casing protection level reaches IP55;The surface of the motor shaft and push rod are plated with hard chromium treatment, greatly extending the service life of the sealing element;The oil cylinder shell is equipped with a balance chamber on one side, which can allow the thruster to be installed in any direction from 0 to 180 °, thereby expanding its range of use;All seals and bearings of the Ed series are made of world-renowned products, with reliable sealing and long service life;The Ed series fasteners are made of stainless steel material, which is beautiful and durable.3、 Selection of installation methodVertical installation: the piston rod connecting block faces upwards;Horizontal installation and any position in the middle: the main parameter label faces upwards;All push rod connection blocks of thrusters can rotate. The Ed50-Ed301 fixed seat can rotate 90 °, while the Ed23-Ed30 fixed seat can also provide 90 ° rotation, but the installation height dimension A is increased by 8mm;Regardless of the installation position, the piston rod cannot withstand any force to avoid affecting its effectiveness and lifespan.4、 Additional devicesVarious additional devices can be installed according to user needs to meet different work needs;Rising or falling valve: the rising valve "H", the falling valve "S" or the rising and falling valves "H, S" can extend the rising and Fall time steplessly, and the adjustable value can reach 10-20 times of the rated value. The valve is adjusted externally. The rising and Fall time time of the thruster with valve will be extended, the short stroke will be extended by 0.1-0.2s, and the long stroke will be extended by 0.2-0.4s;Brake spring: It generates braking force, and the spring force listed in the technical parameters is 1/3 of the rising stroke (2/3 of the falling stroke);Return spring: The working principle is the same as C-spring, but the return spring force is relatively small;Cushion spring: (only applicable to short stroke) mainly regulates the braking process. The non periodic transient process of buffering braking ensures smooth braking. It replaces the connecting block of the push rod and is installed on the piston rod without changing the stroke of the pusher.Heater: In areas with ambient temperatures below -20 ℃, additional heaters can be installed according to user needs. The heaters are AC200V or AC110V voltage, and should be specified when ordering. The temperature control and adjustment method is chosen by the user themselves;Travel switch: According to user requirements, the pusher can be equipped with a mechanical travel switch.purposeThe ED series electric hydraulic thrusters are mainly used as operating components for the YWZ4, YWZ5, YWZ8, YWZ9, and YWZP series electric hydraulic block brakes, widely used in industries such as lifting and transportation, metallurgy, mining, ports, and construction.

time:2022-03-20

More

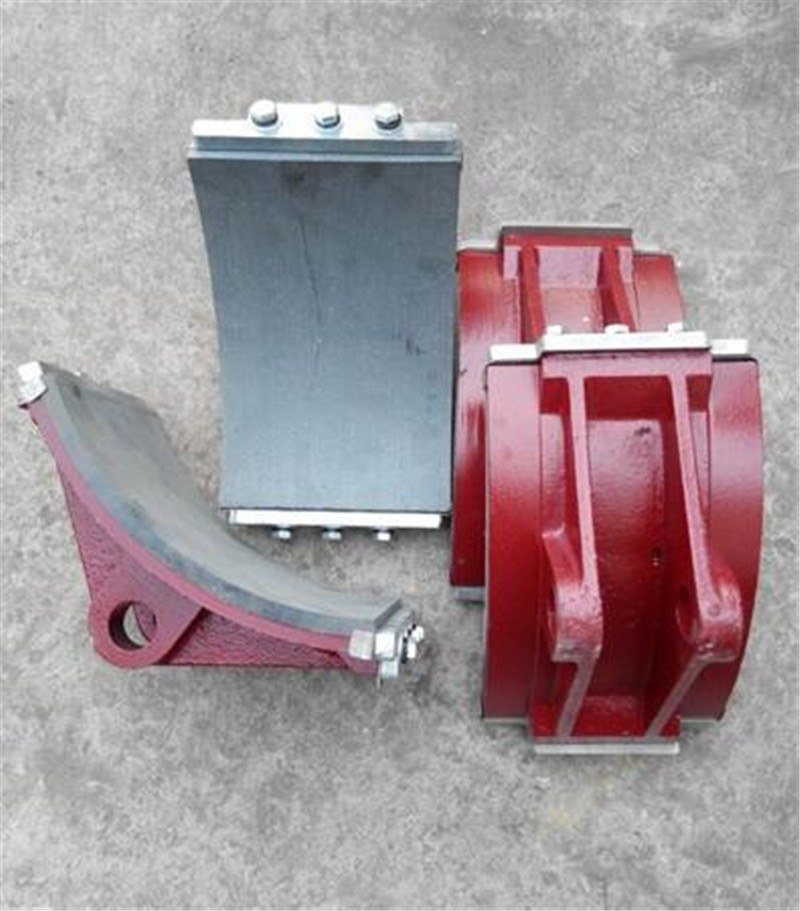

Friction coefficient of wear-resistant electric hydraulic disc brake padBrake linings, asbestos free brake linings, semi metal brake linings, explosion-proof brake linings, steel backed adhesive linings, Disc brake linings, clutch discs, etc. Suitable for ports, steel cranes, tower cranes, engineering machinery, drilling machinery, hydraulic machinery, and the production of various materials of automotive and power vehicle brake pads. Asbestos-free brake shoes are a new generation of brake friction materials. Traditional asbestos brake materials pose a serious threat to human health and are gradually phased out products. The new asbestos free material not only poses no harm to the human body, but also has superior performance indicators compared to asbestos brake materials. The product is mainly used for brake pads, linings, etc. of various lifting machinery and other brakes.There are two types of brake pads: one is made of asbestos rubber steel wire mesh material for the brake band, and the other is made of asbestos resin. The non asbestos brake pad and brake pad use two types: plug-in and riveted, which are safe and reliable, convenient to replace, and fast.Powder metallurgy brake pads and friction padsFRK980 copper based powder metallurgy wind power brake pads are a friction material independently developed by our company. Its performance is similar to the MD550 friction material of foreign Miba company. FRK980 is a friction material made with copper powder as the matrix and special wear-resistant alloy particles as the friction components through a special sintering process. At high temperatures (700 ℃), it has stable friction coefficient, small wear, minimal damage to the brake disc, easy installation, and safe use, It can meet the requirements of heavy-duty and high-speed braking for engineering machinery such as wind turbines and high-speed trains. Currently, it has been widely used both domestically and internationally. The following are the products and performance indicators produced by our company, which can also be processed according to the specifications and dimensions required by customers.Supply high-performance brake materials, supply wind turbine brake pads, supply wind turbine brake pads, supply wind turbine brake pad manufacturersSupply of water pump thrust discs, supply of wind turbine brake pads, supply of wind turbine brake pads, supply of high-performance wind turbine brake padsSupply high-performance wind turbine brake pads, supply MD550 wind turbine brake pads, supply wind turbine brake pads, supply high-performance brake materialsSupply of brake pads for wind turbines Supply of brake pads for high-speed axis wind turbines Supply of economical and applicable wind turbine accessoriesSupply high-performance wind turbine brake pads, supply SYFS-05E high-speed train brake pads, supply SYFS-05D high-performance copper based powder wind turbine brake padsSupply of wear-resistant metallurgical powder brake pads Supply of SYFS-W20D high-performance brake pads - wind turbines, construction machinery, high-speed trainsSupply of wind turbine brake pads Supply of wind turbine brake pads Supply of wind turbine brake pads Supply of high-performance wind turbine brake padsSupply MD550 wind turbine brake pads Supply high-speed shaft wind turbine brake pads Supply wind turbine brake pads High speed shaft wind turbine brake padsSupply high-performance wind turbine brake pads Supply low wear wind turbine friction lining Baoding wind turbine brake pads Manufacturer supply wind turbine brake padsElectromagnetic failure protection disc brake:3SE; 4SE; 5SE; 450SE; 56SE; 560SE; 561SE; ST1SE; ST2SEHydraulic fail safe disc brake:3SH; 4SH; 5SH; 450SH; ST1SH; ST2SH; ST3SH; ST4SH; ST5SH; ST10SH; ST16SH; ST25SH; 904SH;ST40SHPneumatic fail safe disc brake:3SP; 4SP; 5SP; 450SPHydraulic direct acting disc brake:ADH60; ADH90; ADH120; DADH75; DADH80; DADH90; DADH120; DADH195; DADH350Pneumatic direct acting disc brake:ADP60M; ADP61M; ADP62MPneumatic caliper disc brakeCQPL12.7A-A; CQPL12.7A-B; CQPL12.7B; QPL12.7A-A; QPL12.7A-B; QPL12.7-A; QPL12.7-B;QP30-D; QP25.4-D; CQP30-D; CQP25.4-D; PDA5; PDA10; PDB5; PDB10; PDB19; PDC5; PDC10Electromagnetic caliper disc brake:DCPZ12.7-250; DCPZ12.7-300; DCPZ12.7-400Hydraulic caliper disc brake:SB (YQP) 50; SB (YQP) 100; SB (YQP) 160; SB (YQP) 250; SB (YQP) 315; SB (YQP) 400;SBD safety brake:SBD100-A; SBD125-A; SBD160-A; SBD200-A; SBD250-A; SBD-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD80-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD120-D; SBD240-DElectric hydraulic windproof iron wedge brake:YFX series electric hydraulic windproof iron wedge brake:YFX-500/80; YFX-550/80; YFX-600/80; YFX-630/80; YFX-700/80; YFX-710/80; YFX-800/80Electric hydraulic thruster:YT1 series electric hydraulic thruster:YT1-18ZB/2; YT1-25ZB/4; YT1-45Z/5; YT1-90Z/8; YT1-125Z/10; YT1-180Z/10; YT1-320Z/12; YT1-320Z/20; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12; YT1-320Z/12; YT1-350/12;YT1-350/20; YT1-350/35; YT1-25/4; YT1-45/6; YT1-90/8; YT1-180/12BYT1 series electric hydraulic thrusters:BYT1-18ZB/2; BYT1-25ZB/4; BYT1-25ZC/4; BYT1-45Z/4; BYT1-45Z/5; BYT1-45Z/6; BYT1-90Z/6BYT1-90Z/8; BYT1-125Z/10; BYT1-180Z/8; BYT1-180Z/10; BYT1-180Z/12; BYT1-320Z/12BYT1-320Z/20; BYT1-25/4; BYT1-45/6; BYT1-90/8; BYT1-180/12ED series electric hydraulic thrusters:ED-23/5; ED-30/5; ED-50/6; ED-80/6; ED-121/6; ED-201/6; ED-301/6; ED-50/12; ED-80/12; ED-121/12; ED-201/12; ED-301/12; ED-630/12BED ZED series electric hydraulic thrusters:BED30/5; BED50/6; BED80/6; BED121/6; BED201/6; BED301/6; BED50/12; BED80/12; BED121/12BED201/12; BED301/12; BED630/12Band brake:DZ band brake:DZ400-I; DZ400-II; DZ480-I; DZ480-II; DZ600-I; DZ800-I; DZ800-II; DZ900-I; DZ900-II

time:2022-03-20

More

Electric hydraulic brake padBrake parts Brake thruster Brake shoe friction plate Electric hydraulic drum brake Electric hydraulic disc brake Electric hydraulic explosion-proof brake Electromagnetic brake Pneumatic brake Non standard brake and industrial brake of various well-known manufacturers.Our products include electric hydraulic wheel brakes: YWZB YWZ2 YWZ3B, YWZ4, YWZ8, YWZ9, YWZ10, YWZ13, YW, YWL, TJ2, JZ, and other series;Electric hydraulic disc brake: YPZ2, YPZ3, QP12.7 and other series;Various models of thrusters: YT1, MYT1, BYT1, BED and other series. In addition, we also produce various hydraulic cylinders, non-standard brakes, conventional friction discs for brakes, and substitute imported high wear resistant rigid back friction discs. The products are widely used in industries such as material handling, wind power generation, port machinery, mining, metallurgy, coal, petrochemical, and engineering machinery.In recent years, our company has been committed to improving the localization and development of drum brake friction pads, non-standard friction pads, and imported brake friction pads, as well as new formula development projects; In the past three years, in order to adapt to the domestic economic situation and reduce operating costs for industrial brake users, our company has hired multiple experienced engineers and domestic chemical experts in the brake industry to develop a series of friction plate products, such as TE series, SB series, USB2 series, USB3 series, 7080080-Z series, DB-0435-K series, BSF series, etc., which have good on-site use effects and low prices, All received unanimous recognition and praise from users

time:2022-03-18

More

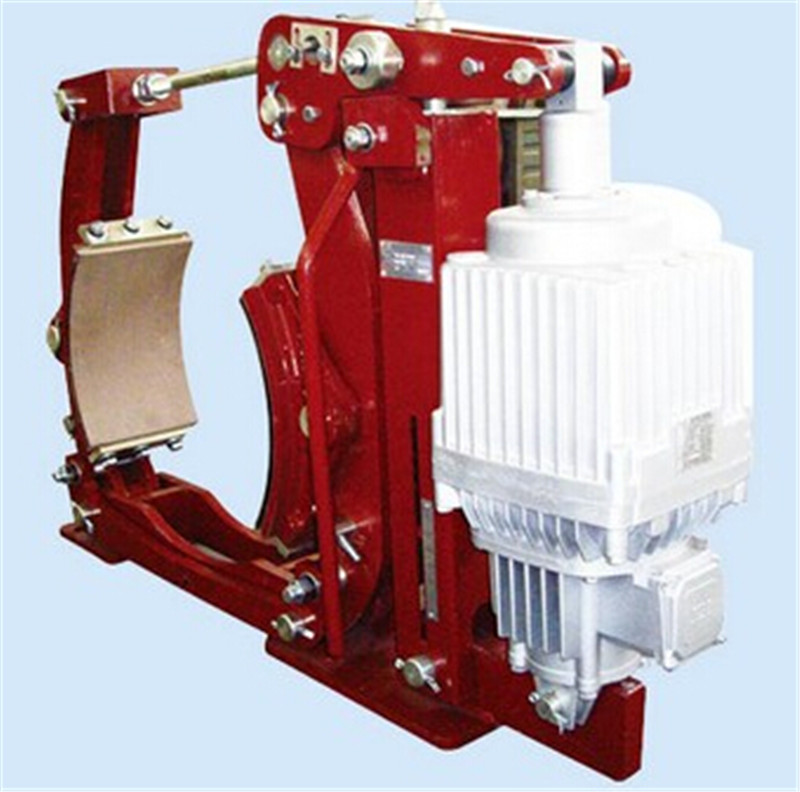

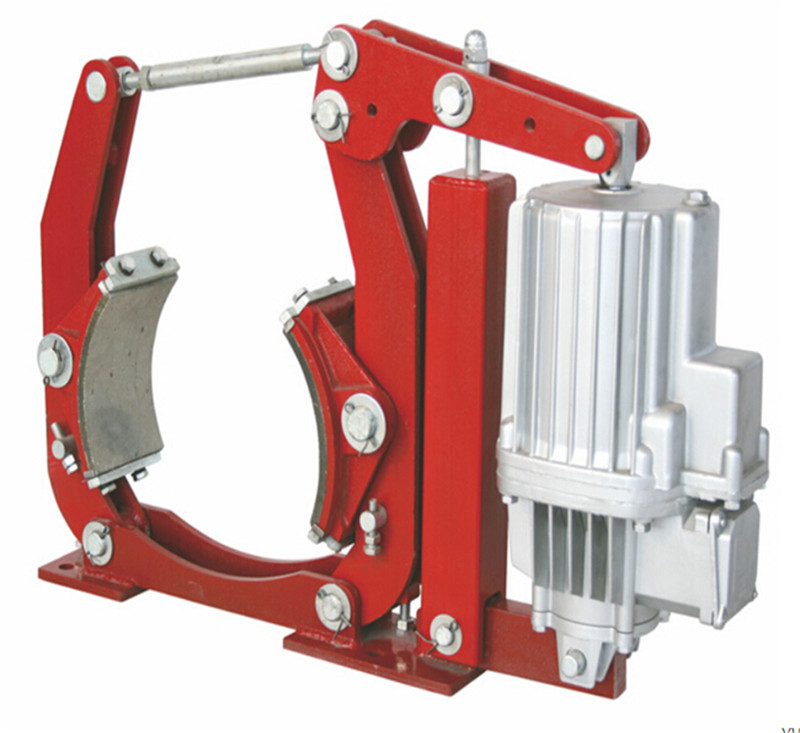

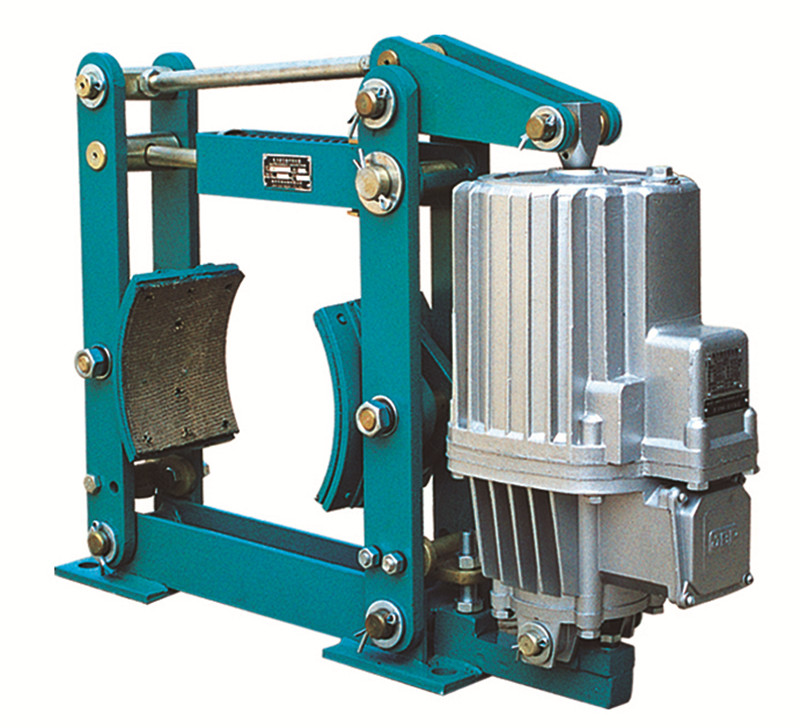

YWZ5-250/30 electric hydraulic thrusterThe YWZ5 series electric hydraulic block brake is driven by the Ed series electric hydraulic thruster. Its installation dimensions comply with JB/ZQ4333-86 standard. Mainly used for mechanical braking of mechanical driving devices in lifting, transportation, metallurgy, mining, ports, construction, and other fields.Product Introduction:Electric hydraulic block brakes are widely used for deceleration or parking braking of mechanical drive devices such as lifting, metallurgy, mining, ports, docks, construction machinery, etc.Compliant with standards:The installation dimensions of the YWZ5 series electric hydraulic block brake comply with the GB6333-86 standard, and the technical requirements comply with the JB6406-2006 standard.Main features:The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and do not require lubrication during use;The main performance is safe and reliable, with smooth braking and high action frequency.The brake spring is arranged inside the spring tube and is equipped with a brake torque scale on one side, making adjustment convenient and intuitive;The asbestos free brake pad and brake pad adopt a plug-in type, which is safe and reliable, and easy and fast to replace.Usage conditions:Environmental temperature -20 ℃~+50 ℃;Power supply: 380V, 50HZ;Relative humidity: should not exceed 90%;There should be no flammable, explosive, or corrosive gases in the surrounding working environment;The altitude of the location of use complies with GB755-2000;Outdoor rain and snow erosion or corrosive gases and media should use anti-corrosion productsYWZ5 series electric hydraulic drum brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12

time:2022-03-18

More

Product IntroductionDetailed information on YWZ3B-250/25 and YWZ3B-250/45 hydraulic block brakesBrand/Model: YWZ3-250/45YWZ3B-250/25, YWZ3B-250/45 hydraulic block brakeYWZ3B series electric hydraulic block brake:YWZ3B-160/18 Electric Hydraulic Block BrakeYWZ3B-160/25 Electric Hydraulic Block BrakeYWZ3B-200/18 Electric Hydraulic Block BrakeYWZ3B-200/25 Electric Hydraulic Block BrakeYWZ3B-250/25 Electric Hydraulic Block BrakeYWZ3B-250/45 electric hydraulic block brakeYWZ3B-315/25 Electric Hydraulic Block BrakeYWZ3B-315/45 Electric Hydraulic Block BrakeYWZ3-315/90 Electric Hydraulic Block BrakeYWZ3-400/45 electric hydraulic block brakeYWZ3-400/90 electric hydraulic block brakeYWZ3-400/125 electric hydraulic block brakeYWZ3-500/90 Electric Hydraulic Block BrakeYWZ3-500/125 electric hydraulic block brakeYWZ3-500/180 Electric Hydraulic Block BrakeYWZ3-630/125 Electric Hydraulic Block BrakeYWZ3-630/180 electric hydraulic block brakeYWZ3-710/180 Electric Hydraulic Block BrakeYWZ3-160/18 YWZ3-160/25 YWZ3-200/18 YWZ3-200/25 YWZ3-250/25YWZ3-250/45 YWZ3-315/25 YWZ3-315/45 YWZ3-315/90 YWZ3-400/45YWZ3-400/90 YWZ3-400/125 YWZ3-500/90 YWZ3-500/125 YWZ3-500/180YWZ3-630/125 YWZ3-630/180 YWZ3-710/180

time:2022-03-18

More

EDM1250 electromagnet maintains electric hydraulic thrusterThe electric hydraulic thruster maintained by the distribution magnet is a very compact electric hydraulic drive control device that integrates electric motors, centrifugal pumps, oil cylinders, and DC electromagnets. It can be used as a driving device for brakes that need to be kept open for a long time, and can be widely used in various port loading and unloading, metallurgical lifting, mining and other mechanical equipment. It can also be used as a driving device for driving and controlling various industrial valves, gates, and clamping devices.Main features:The shell is made of cast aluminum alloy, with light weight and beautiful appearance.The motor is of a non oil immersed structure, with Class F insulation (according to user requirements), good heat resistance, and long service life.The wiring of the thruster motor and electromagnet is led out from the junction box, and the junction box cover is sealed. When used, it is equipped with corresponding specifications of cable stuffing boxes, and the electrical enclosure protection level reaches IP65.The surface of the motor shaft and push rod are treated with special processes, greatly extending their service life.The oil cylinder shell is equipped with a balance chamber on one side, which can allow the thruster to be installed in any direction from 0 to 180 °, thereby expanding its range of use.All seals and bearings are made of world-renowned products, with reliable sealing and long service life.The fasteners are made of stainless steel material, which is beautiful and durable.The electric hydraulic thruster can work for a long time under the maintenance of an electromagnet, with low temperature rise and operating power consumption, and high energy-saving rate.The return time (i.e. reset response time) of the push rod is short, and the action is fast.■ Anti corrosive design.Basic parameters:Product models: EDM220, EDM500, EDM800, EDM1250, EDM2000, EDM3000, EDM4500Controller models: DKXDC03-1, DKXDC03-2

time:2022-03-18

More

How to adjust the use of windproof iron wedge brakesApplication scope: 1. Used for outdoor large and medium-sized cranes and port loading and unloading machinery.Usage conditions: 1. Environmental temperature: -20 ℃~50 ℃; Relative humidity: ≤ 95%.Product Description: 1. Equipped with a release limit switch for interlocking protection. 2. The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency, sensitive and reliable action, and long service life. 3. Equipped with manual release function, easy to maintain. 4. Matched with Ed descent delay thruster, it has excellent action performance, good sealing performance, high protection level of the shell, and has a lower delay function to avoid large impact on the wedge block by the crane after power outage. 5. The wedge block has been specially processed with high friction coefficient and good anti-corrosion performanceBrakes:Electric hydraulic brake, electric hydraulic drum brake, electromagnetic block brake, electric hydraulic windproof iron wedge brakeSafety wind brake electromagnetic failure protection disc brake electric hydraulic arm disc brake wind electric yaw brakeWind power spindle brake Pneumatic caliper disc brake Hydraulic failure protection Brake electromagnetic failure protection BrakeHydraulic direct acting disc brake electromagnetic caliper disc brake pneumatic failure protection brake hydraulic direct acting brake

time:2022-03-18

More

Electromagnetic brake is an ideal automatic execution component in modern industry, which mainly plays a role in transmitting power and controlling motion in mechanical transmission systems. It has the advantages of compact structure, simple operation, sensitive response, long service life, reliable use, and easy to achieve remote control.It is mainly matched with series motors. Widely used in metallurgy, construction, chemical, food, machine tools, stages, elevators, ships, packaging and other machinery, as well as in situations such as emergency braking during power outages.The resistance torque that must be applied to stop or decelerate the mechanical operating components is called the braking torque. The braking torque is the basis for designing and selecting brakes, and its size is determined by the mechanical type and working requirements. The performance of the friction materials (brake components) used on the brake directly affects the braking process, and the main factors affecting its performance are the working temperature and temperature rise rate. Friction materials should have high and stable friction coefficients and good wear resistance. Friction materials are divided into two categories: metallic and non-metallic. The former commonly used include cast iron, steel, bronze, and powder metallurgy friction materials, while the latter includes leather, rubber, wood, and asbestos.

time:2022-03-18

More

In order to ensure the uninterrupted operation of the electromagnetic brake, it is necessary to regularly maintain and maintain it:1. Frequently add lubricant to the movable part of the electromagnetic brake.2. Regularly check the length of the armature stroke. Because during the operation of the brake, the travel length of the armature will increase due to wear on the moving surface. When the length of the armature stroke cannot reach the normal value, adjustments must be made to restore the minimum clearance between the braking surface and the rotary table. If the stroke length of the armature increases above the normal value, it may greatly reduce the suction force.3. If a worn brake surface is replaced, the minimum clearance between the brake surface and the rotary table should be adjusted appropriately.4. Regularly check the tightness of the bolts, especially tightening the bolts of the electromagnet, the bolts of the electromagnet and the shell, the bolts of the magnetic yoke, the bolts of the electromagnet coil, and the wiring bolts.5. Regularly inspect the mechanical wear of movable components and remove dust, burrs, and dirt from the surface of electromagnetic components.

time:2022-03-18

More

Hydraulic push rod brakes are commonly used on port gantry cranes. The reliability of the brake is directly related to the safety of personnel and equipment, so the requirements for its reliability are particularly high. However, there are currently many hydraulic push rod brakes that have been put into use, with the main symptoms being: (1) the square coupling between the motor shaft and the impeller shaft loosens and falls off, causing the motor shaft to spin while the hydraulic cylinder does not operate. (2) The push rod of the hydraulic push rod brake release device is bent and deformed, and the brake release device is not working properly. (3) The hydraulic push rod brake spring is broken and the brake cannot be closed. (4) The movable hinge point of the brake frame is stuck, and the opening and closing actions of the brake are slow or not moving. (5) The movable hinge pin of the brake frame is loose, and the brake does not work properly; (6) Brake bands and wheels are severely worn, resulting in reduced or lost braking torque. (7) The drive motor of the hydraulic push rod brake release device is out of phase, and the motor and brake release device do not operate. The above faults directly lead to a decrease in the reliability of the lifting mechanism and luffing mechanism of the gantry crane, especially the brake failure during the lowering and increasing processes, seriously endangering production safety. Therefore, improving the reliability of the lifting mechanism and luffing mechanism brake has always been the focus of our equipment management and technical research.

time:2022-03-18

More

YWK series hydraulic brakeYWK series electric hydraulic drum brakes are mainly used for the deceleration braking of the crane running mechanism of all kinds of general bridges and Gantry crane, and also for the deceleration braking of the non lifting winch drive device.Compliant with standards:The connection dimensions and braking torque parameters of YWK series normally open brakes comply with JB/T6406-2006 and DIN15435 standards, and are matched with YTD series thrusters that comply with JB/T10603-2006 standards.Main features:Interlocking type equal back distance device (patented technology) and automatic tile following device can always maintain equal back distance of both sides of the tiles without adjustment, completely avoiding the phenomenon of one brake pad floating against the brake wheel due to uneven back distance.The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use.The brake pad is a card mounted integral molding structure, which is very convenient and fast to replace. There are different materials of brake pads available for users to choose from, including semi metal (asbestos free) hard and semi hard, soft (asbestos free) brake pads.Basic parameters:Product models: YWK160, YWK200, YWK250, YWK300, YWK315, YWK400, YWK500Applicable wheel diameter: 160-500mmBraking torque: 100-3550NmThe YWH series electric hydraulic drum brake is widely used for deceleration and parking (maintenance) braking of various mechanisms in various lifting and transportation, port loading and unloading, metallurgical equipment, mining machinery, and engineering machinery.Compliant with standards:The connection dimensions and braking torque parameters of the YWH series brake comply with the JB/T6406-2006 standard and DIN15435 standard; Equipped with Ed series thrusters that comply with DIN15430 standard. This series is mainly suitable for places with small installation space, where YW, YWZ2, YWZ4 and other forms cannot be arranged.Main features:Interlocking type equal back distance device (patented technology) and automatic tile following device can always maintain equal back distance of both sides of the tiles without adjustment, completely avoiding the phenomenon of one brake pad floating against the brake wheel due to uneven back distance.The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use.The brake spring is arranged inside the square tube and equipped with a ruler, making it very convenient for users to read the braking torque value, eliminating the trouble of measurement and calculation.The brake pad is a card mounted integral molding structure, which is very convenient and fast to replace. There are different materials of brake pads available for users to choose from, including semi metal (asbestos free) hard and semi hard, soft (asbestos free) brake pads.The matching series of thruster products are sensitive in action and have a long service life.Basic parameters:Product models: YWH160, YWH200, YWH250, YWH300, YWH315, YWH400, YWH500Applicable wheel diameter: 160-500mmBraking torque: 80-4000Nm

time:2022-02-10

More

Special brake for winch holding brakeBrake parts Brake thruster Friction plate Electric hydraulic drum brake Electric hydraulic disc brake Electric hydraulic explosion-proof brake Electromagnetic brake Non standard brake and industrial brake of various well-known manufacturers.Our products include electric hydraulic brakes: YWZ3B, YWZ4, YWZ8, YWZ9, YWZ10, YWZ13, YW, YWL, TJ2, JZ and other series;SB, SBD, ST, SH, SE and other series disc brakesElectric hydraulic disc brake: YPZ2, YPZ3, QP12.7 and other series;Various models of thrusters: YT1, MYT1, BYT1, BED and other series. In addition, we also produce various hydraulic cylinders, non-standard brakes, conventional friction discs for brakes, and substitute imported high wear resistant rigid back friction discs. The products are widely used in industries such as material handling, wind power generation, port machinery, mining, metallurgy, coal, petrochemical, engineering machinery, etc

time:2022-02-10

More