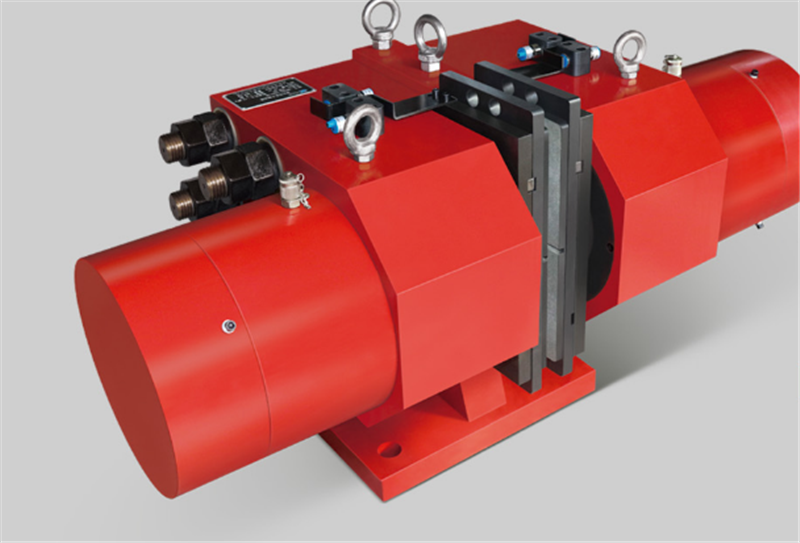

The YLZ40-180I/IIRLD hydraulic wheel edge brake YLBZ brake is mainly used for windproof braking and auxiliary windproof braking in the state of no state for large and medium-sized cranes and port loading and unloading machinery used in the open air in ports, docks, and other areas.main features Compact structure and beautiful appearance.The disc spring hydraulic cylinder has excellent performance and is strictly designed, produced, and manufactured in accordance with GB/T15622-1995.Adopting a normally closed design, the hydraulic station drives and applies force to the disc spring for release, ensuring safety.Set limit switches for interlocking protection.Asbestos free friction discs have stable performance, novel installation structure, and convenient replacement.The brake block adopts a connecting rod structure to ensure that the clearance between the friction plate plane and the wheel end face is equal when the brake is released. Eliminate the phenomenon of friction pads sticking to brake wheels in the past when the brake is loose.Anticorrosive design, all fasteners and pins are made of stainless steel, and the DLZ series electric wheel edge brakeDLZ series electric wheel brakeBasic parameters:Product models: DLZ25- □, DLZ40- □, DLZ63- □, DLZ100- □Applicable wheel diameter: 500-1000mmSuitable rated Stiction: 36~150KNWheel pressure: ≤ 100TMain features: Normally closed design, safe and reliable; The disc spring applies force to brake, opens electrically, maintains the electromagnet, and automatically switches on when powered off;The drive part has a fully sealed structure, high protection level, long service life, small size, compact structure, and easy installation;Corrosion resistant design, all fasteners and pins are made of stainless steel (or QPQ surface treatment), with good corrosion resistance;High transmission efficiency, accurate and fast operation;The electric opening method achieves oil-free operation, avoiding brake failure caused by aging of oil pipes, seals, wear of hydraulic components, and avoiding environmental pollution caused by hydraulic oil leakage;The electromagnet maintains an open state, reducing the energy consumption of the brake when it is in an open state for a long time;High performance asbestos free friction lining with high and stable friction coefficient, insensitive to water and salt spray (seawater);Equipped with a manual release device, it can achieve separate release of the brake for easy maintenance;Condition:Environmental temperature: -20 ° C+ 50 ° C;Relative humidity: ≤ 90%;Working voltage: AC380V~AC690V 50Hz/60Hz;Protection level: IP65;Adaptive working system: Continuous working system S1-100%; Intermittent work S3-60%; The working frequency shall not exceed 400 times/hour.

time:2023-06-04

More

If the initial operation time of the winch is not long and repairs are found due to damage to certain seals, then it is not necessary to remove all the winches.The main purpose of explosion-proof winch! Firstly, as lifting equipment, it is used for mine lifting, sinking lifting, and suspension (lifting) sinking equipment, that is, lifting ore along the wellbore, lifting winches, and independently using each other to lift waste (gangue), lift personnel, lower materials, tools, and equipment; Secondly, as a transportation equipment, it is used for underground scheduling and transporting ore (ore trucks), raking ore (slag) in the mining area, filling, and removing pillars.When the excitation coil of the brake is connected to the rated voltage (DC), the electromagnetic force pulls on the armature to separate (release) the armature from the brake disc. At this time, the transmission shaft runs or starts normally with the brake disc. When the transmission system is separated or powered off, the brake is also powered off at the same time. At this time, the spring is applied to the armature, forcing the brake disc to produce Friction torque between the armature and the flange disc, so that the transmission shaft stops quickly. When the heat dissipation environment of the brake is poor and the transmission shaft is continuous for a long time, if conditions permit, the voltage can be converted to 70% -80% of the rated voltage after the brake to reduce heating. The BED series explosion-proof electric hydraulic thruster mainly uses the driving device of the electric hydraulic drum brake, and can also achieve rapid movements such as reciprocating, circular, and swinging through levers. It is suitable for lifting, transportation, metallurgy, mining, ports, etc Construction and other industries; Its explosion-proof performance complies with the provisions of GB3836.2-2000 "Explosion proof Electrical Equipment and Explosion proof Electrical Equipment for Explosive Atmospheres" d ". The explosion-proof signs are" dI "and" DIICT4 ", which are respectively used in coal mines and IIA, IIB, IIC (Class I, Class A, Class II, Class B, Class II, Class C, Class II) temperature groups T1-T4 combustible gas or steam and explosive mixtures formed by airBYWZ9 explosion-proof electric hydraulic brakeConsulting and ordering model: BYWZ9-160/23 BYWZ9-200/23BYWZ9-250/23 BYWZ9-250/50BYWZ9-315/23 BYWZ9-315/50 BYWZ9-315/50 BYWZ5-315/80BYWZ9-400/50 BYWZ9-400/80 BYWZ9-400/121BYWZ9-500/80 BYWZ9-500/121 BYWZ9-500/201

time:2023-06-04

More

The winch winch is equipped with an electric hydraulic thruster brake ED.YT1 series parallel electric hydraulic push rod, which uses an electric motor as the power source. The electric motor rotates in the forward (reverse) direction, causing hydraulic oil to output pressure oil through a bidirectional gear pump. Through the oil circuit integrated block, it is sent to the working oil cylinder to achieve reciprocating movement of the piston rod. Advantages:1. Equipped with overload automatic protection function: When the electro-hydraulic push rod is working, if the external force on the piston rod exceeds the rated output force or the piston has reached the end point, and the motor is still rotating, the oil pressure in the oil circuit increases to the set pressure, and the overflow valve quickly and accurately overflows to achieve overload automatic protection. Although the motor is rotating, it will burn out. 2. Self locking function: A pressure self locking mechanism is designed in the oil circuit integrated block of the electro-hydraulic push rod. When the motor stops rotating, the piston rod immediately stays in the same position, and the pressure oil is in a pressure maintaining state. 3. Stepless adjustment: It can be adjusted steplessly within the rated speed, output force, and stroke range according to user requirements. New Drawing of Workshop 30045_ copyStyling Description: The electro-hydraulic push rod is mainly composed of six basic elements: the type of push rod, the protection level of the motor, rated output force, stroke, rated speed, and usage angle. It can also be equipped with three adjustment functions according to support requirements, namely: speed adjustment push, tension adjustment, and stroke adjustment (positioning of travel switch). Except for the three adjustment functions mentioned above, please refer to the model preparation method and carefully fill in the six key elements when ordering. Technical parameters of DYTZ parallel electro-hydraulic push rod (selection table)Model Rated Output Force (10N) Rated Speed (mm/s) Motor Model Travel Manufacturing Range (mm) Travel Manufacturing Range (mm)Thrust, pulling force, pushing speed, pulling speedDYTZ450-/110 450 310 110 140 Y802-4-0.75KW 50-800 10-110DYTZ700-/110 700 510 110 140 Y90S-4-1.1KW 50-1500 10-110DYTZ1000-/110 1000 750 110 140 Y90L-4-1.5KW 50-1500 10-110DYTZ1750-/90 1750 1300 90 115 Y100L1-4-2.2KW 50-2000 10-90DYTZ2500-/90 2500 2050 90 115 Y100L2-4-3KW 50-2000 10-90DYTZ3000-/90 3000 2500 90 115 Y100L2-4-3KW 50-2000 10-90DYTZ4000-/80 4000 2950 80 100 Y112M-4-4KW 50-2000 10-80DYTZ5000-/60 5000 3300 60 90 Y112M-4-4KW 50-2000 10-60DYTZ6000-/60 6000 3800 60 90 Y132S-4-5.5KW 50-2500 5-60DYTZ7000-/50 7000 4500 50 75 Y132S-4-5.5KW 50-2500 5-50DYTZ8000-/50 8000 5000 50 80 Y132M-4-7.5KW 50-2500 5-50DYTZ1000-/40 10000 6500 40 60 Y132M-4-7.5KW 50-2500 5-40DYTZ15000-/35 15000 11000 35 45 Y132M-4-7.5KW 50-2500 5-35DYTZ20000-/25 20000 15000 25 35 Y132M-4-7.5KW 50-2500 5-25

time:2023-06-04

More

Features and advantages of hydraulic safety failure protection disc brake:1. The sturdy steel brake arm and base minimize the brake's deflection and idle loss during operation.2. The optimized geometric design of the lever allows for greater braking torque within a limited lever ratio, without being affected by rotation.3. The square coil spring component is equipped with a torque scale for simpler, safer, and more reliable torque adjustment.4. A special braking pressure spring with a constant as small as possible can fully utilize aerodynamics to improve performance during normal release.5. Lightweight metal brake shoes are sturdy and durable, with stable friction coefficient of friction pads and no asbestos or metal components, making them durable.6. The special clamping spring fixes the brake shoe in the appropriate position and adopts a special barrier free design, making the replacement of the brake shoe more convenient and fast.7. Standard components are galvanized to improve corrosion resistance; Equipped with an accurate automatic compensation device, it can provide certain compensation for the wear of the friction plate.8. Adopting an equal retraction mechanism to ensure synchronous secondary braking on both sides and balanced braking force; Ideal brake and emergency brake for container cranes, ship unloaders, steel casting cranes, water and electricity bridge cranes, elevators, cable cranes, and other equipment.Technical advantages of safety disc brake:1. All hinge points and shaft pins are tightly matched and use self-lubricating shaft sleeves.2. The pins are all acid resistant, up to 850 ° C.7. Automatic compensation for friction and wear can reduce maintenance times.8. The boom adopts an equal torque mechanism, with equal clearance on both sides when releasing the brake.To sum up, the above is about the safety disc brake. For more details, please visit our website. The hydraulic station of the hydraulic disc brake can be configured to tow one or tow two or tow multiple disc brakes. Please consult our company for details. The disc brake hydraulic pump station can be customized. This model is a one driven two type hydraulic pump station. One hydraulic station can understand two disc brakes, and one driven two hydraulic pump station can be used for two disc brakes. It is easy to install, use, and maintain. It is equipped with special wear-resistant hydraulic oil. The hydraulic station, stainless steel, high temperature resistance, and other conditions need to be customized in specific circumstances, can be equipped for use

time:2023-06-04

More

Unit brake TZD-1-840-T-X track brake DZD-1 locomotive unit brake JZD-1Unit brake definitionA combined braking component in which a brake cylinder acts on only one brake shoe (or a pair of brake pads, or a brake beam component) through some transmission components. The tread brake unit consists of a brake cylinder, a lever installed in the box, a set of automatic brake shoe clearance adjusters, as well as brake shoes, brake shoe holders, brake shoe holders, etc. In this way, the basic braking device of a car will become composed of many sets of braking unitsDue to the short-term operation of the braking unit, which means that the power on time is very short, the temperature rise of the braking unit cannot reach a stable temperature rise during the power on time; The intermittent time after each power on is longer, during which the temperature is enough to drop to the same level as the ambient temperature. Therefore, the rated power of the braking resistor will be greatly reduced, and the price will also decrease accordingly; In addition, due to the fact that I only has one, with a braking time of ms level, there is a low requirement for the transient performance indicators of power tube opening and closing, and even a requirement for the shutdown time to be as short as possible to reduce the shutdown pulse voltage and protect the power tube; The control mechanism is also relatively simple and easy to implement. Due to the above advantages, it is widely used in potential loads such as cranes and in situations where quick braking is required but short-term working conditions are required. Track unit brake parameters

time:2023-06-04

More

The working principle of the pneumatic brake QP12.7-A pneumatic caliper disc brake is to input pressurized gas into the air bag of the pneumatic brake, so as to push the piston to move in a straight line, so that the friction block of the brake can press the brake wheel to produce friction and brake. The pneumatic brake is connected by air pressure, released by a reset spring, and the disc slides along the axis with air pressure to contact the friction plate. Discs, friction plates, etc. are assembled onto the wheel hub to form an integrated structure. The friction plate can be disassembled by unscrewing the adjusting nut, and the exchange is simple. Pneumatic brakes are constructed by installing a tapered shaft sleeve with a wedge onto the shaft, with friction plates that can be exchanged while maintaining the mechanical equipment in its original state. The heat generated by friction is dissipated by a cooling plate installed on a disc with a hub. The friction plate is a double cut split type, which can be exchanged by using a screwdriver to remove the countersunk screw through the hole of the hub disc. Pneumatic brakes have good heat dissipation and can be applied in industries such as packaging machinery, wire and cable equipment, thin paper, and corrugated paperPneumatic brakes are also known as ventilated brakes, which means that there is a fully inflated air that applies pressure to tightly close the socket to achieve braking effect. This type of industrial use is more effective. When it comes to pneumatic brakes, they are also divided into normally closed brakes and normally open brakes. Normally closed brakes keep their sockets open when they are not working, and when they are ventilated during operation, they brake and form a brake. QP installed pneumatic direct acting disc brake:ADP60M; ADP61M; ADP62MPneumatic caliper disc brakeCQPL12.7A-A; CQPL12.7A-B; CQPL12.7B; QPL12.7A-A; QPL12.7A-B; QPL12.7-A; QPL12.7-B;QP30-D; QP25.4-D; CQP30-D; CQP25.4-D; PDA5; PDA10; PDB5; PDB10; PDB19; PDC5; PDC10QP12.7 Blue Image

time:2023-06-04

More

The hydraulic station of the hydraulic disc brake can be configured to tow one or tow two or tow multiple disc brakes. Please consult our factory for details. The disc brake hydraulic pump station can be customized. This model is a one driven two type hydraulic pump station. One hydraulic station can understand two disc brakes, and one driven two hydraulic pump station can be used for two disc brakes. It is easy to install, use, and maintain. It is equipped with special wear-resistant hydraulic oil. The hydraulic station, stainless steel, high temperature resistance, and other conditions need to be customized in specific circumstances, can be equipped for useLow speed disc brake. The caliper disc brake is directly used on the flange wheel of the rope reel. Protect and prevent falling loads (even if the gear shaft breaks).Direct use/no leverageContact force per clamp system up to 400 kNPossible combinations on a brake disc (e.g. 4 x SCFH-4=contact pressure up to 1600 kN)High braking torque independent of rotation directionTwo identical half pliersBrake pad wear can be manually adjustedAdjustable air gap from 1 mm to 3 mmFully enclosed hydraulic systemStandard low wear sintered brake padsA110b7bebf3f05f7b4fa3ccc9dfbcb9c

time:2023-06-04

More

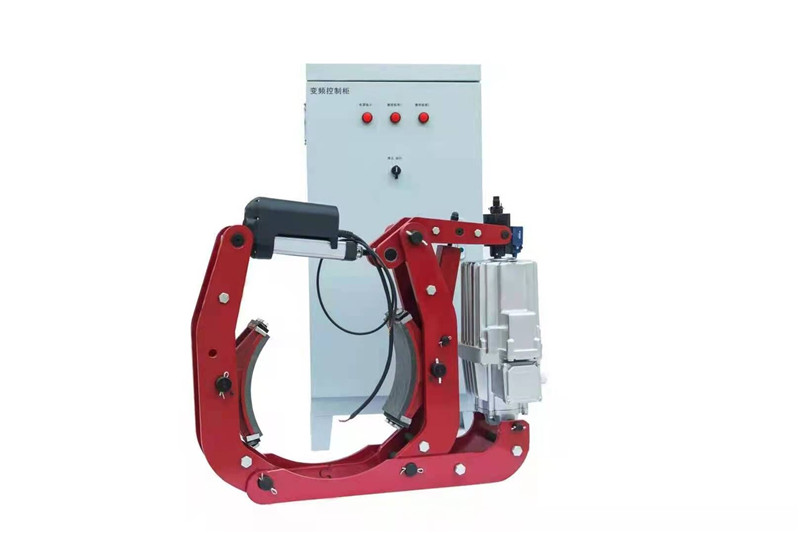

Rotary high-speed brake model RKWD400-500- I/II - RL pedal variable frequency brake electronic control box DKXBPO41 sets of braking torque: 800NmInstallation method: Type I and Type II, 1 set each, with bracketPusher model Ed500-60, rated thrust 500N, rated stroke 60mm, rated power 25OW, rated current 0.78A, protection level IP65, pusher motor inlet hole G3/4 ", motor voltage level 380V/5OHZ. QQ screenshot 20220922083319

time:2023-06-04

More

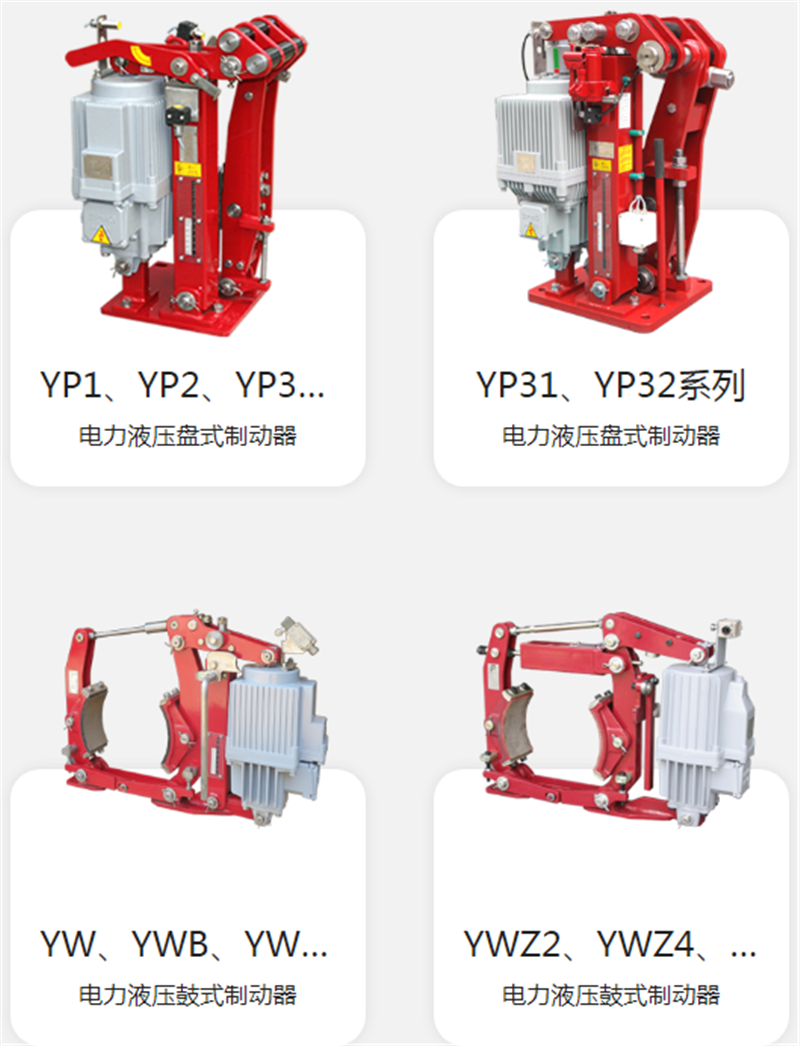

It replaces Jiangxi Huawei YP11.YP21.YP31 series electric hydraulic disc brake YP11.YP21.YP31.YP32 series electric hydraulic disc brake, which is an advanced product with high performance and multi-function. Due to its advanced functions such as automatic equalization of tile setback and automatic compensation for pad wear, it is easy to maintain during use. By adding various limit switches, the required interlocking protection signals can be provided to the host PLC. Suitable for deceleration and maintenance (parking) braking of various modern large-scale specialized loading and unloading machinery, lifting and transportation machinery, metallurgical equipment, mining equipment, and engineering machinery.Main features:The interlocking equal distance device and automatic tile following device can always maintain equal distance between the two tile blocks during use without adjustment, completely avoiding the phenomenon of brake pads floating against the brake disc.The main swing hinge points are equipped with self-lubricating bearings, which do not require lubrication during use; High transmission efficiency, sensitive operation, and brake closing (up) time of 0.25~0.4 seconds.The stepless lining friction automatic compensation device can maintain a constant distance between the pads and the braking torque during use, avoiding the trouble of frequent adjustment.Adjustable torque built-in spring with torque scale.The brake pad is plug-in and easy to replace. Provide various materials such as semi metal and powder metallurgy liners to adapt to different working conditions. Equipped with our company's new thruster, it is sensitive in operation and has a long service life.Basic parameters:Product models: YP11, YP21, YP31, YP32Applicable disc diameter: 355-1100mmBraking torque: 935-21200Nm0.25~0.4S.one thousand six hundred and seventy-four trillion and nine hundred and ninety-eight billion two hundred and eighty million nine hundred and eighty-eight thousand nine hundred and forty-five

time:2023-06-04

More

What are the things to pay attention to when using the brake? We have provided a brief summary regarding the electric hydraulic brake as an example, hoping that this content can be helpful to everyone.During the operation of the brake, it will affect the cutting surface, and the length of the armature must be controlled within a reasonable range. If the length of the armature is not within a reasonable range, it needs to be adjusted in a timely manner.2. Checking the tightness of the bolts is very helpful for the effectiveness of the brake.3. Lubricating oil can be used appropriately to reduce damage caused by friction.If the braking surface of the brake is replaced, it needs to be readjusted.In summary, there are some maintenance and upkeep tasks that we need to do when using electric hydraulic brakes. At the same time, our company reminds everyone that during use, the equipment needs to be regularly cleaned of the appearance of electromagnetic components, as well as nearby dirt.01The interlocking equal distance device and automatic tile following device can always maintain equal distance between the two tile blocks during use without adjustment, completely avoiding the phenomenon of brake pads floating against the brake disc.02The main swing hinge points are equipped with self-lubricating bearings, which do not require lubrication during use; High transmission efficiency, sensitive operation, and brake closing (up) time of 0.25~0.4 seconds.03The stepless pad wear automatic compensation device can maintain a constant distance between the pads and the braking torque during use, avoiding the trouble of frequent adjustment.

time:2023-06-04

More

Under the guidance of the concept of "professionalism, focus, concentration, and innovation", the company has gathered a team of professional brake engineers, technicians, and managers. With its first-class management and always adhering to the corporate philosophy of "producing professional products and providing first-class services.", we ensure that Sanrui Brake is definitely your best partner. The company adheres to meeting customer needs as its own responsibility, strives for practicality and innovation, keeps up with the times, and achieves advanced quality indicators in foreign countries. We look forward to cooperating or business dealings with more customers. The braking torque that must be applied to stop or slow down mechanical operating components is called the braking torque. The caliper disc brake has a wide range of products, including manual brake, pneumatic brake and hydraulic brake; It can also be used as a fail safe product (spring brake) for safety and emergency braking. The braking force ranges from 150 to 40000 Newton. All models are equipped with an automatic compensation system for friction plate wear, brake tilt installation correction, and brake pad self calibration system. Optional accessories: friction plate wear indicator, switch indicator. The warehouse also provides ductile iron brake discs.The hydraulic brake friction plate standard component brake system is combined with a pneumatic braking device (braking force from 50 to 3600 Newton) to obtain an efficient, reliable, and recombined braking system; It can also be used as a shutdown failure protection product (using spring braking) for safety and emergency braking. The installation methods are diverse and simple, making it easy for users to install and maintain. The braking torque is the basis for designing and selecting the brake, and the size of the hydraulic brake friction plate is determined by the mechanical type and working requirements. The performance of the friction materials (brake components) used on the brake directly affects the braking process, and the main factors affecting its performance are the working temperature and temperature rise rate. Friction materials should have high and stable friction coefficients and good wear resistance. Friction materials are divided into two categories: metallic and non-metallic. The former commonly used hydraulic brake friction plates include cast iron, steel, bronze, and powder metallurgy friction materials, while the latter includes leather, rubber, wood, and asbestos

time:2022-09-13

More

What is the reason for the slow response of hydraulic brakes in crane operation? Large lifting equipment requires the use of brakes. Brakes are a type of braking device, whose main function is to ensure good control of work and avoid danger. But we know that, taking bicycles as an example, as they are used for a long time, the braking device on the brakes will wear out, causing delayed braking or slow response, which can become very dangerous. So what should be done when encountering slow response from the brakes?There are generally several reasons for slow brake response:(1) Excessive free travel of the brake wheel and brake.2) Lack of brake fluid in the brake master cylinder, or blockage of the compensation hole, aging, swelling, deformation, or overturning of the master cylinder cup and ring.(3) The piston and cylinder body of the brake master cylinder are excessively worn and loose, resulting in oil leakage. The sealing of the return valve is poor, and the tension spring of the outlet valve is broken.4) The brake wheel cylinder cup is aged, swollen, and the piston is stuck, resulting in excessive wear and loose oil leakage between the wheel cylinder piston and the cylinder body.(5) Severe wear of brake shoes, excessive or reversed brake clearance.6) The brake drum is out of round, grooved or worn too thin, the brake shoe surface has oil, burns and hardens, and rivets are exposedThe brake of the crane must be well maintained. Now, Xinxiang Zhongrui Lifting Machinery Co., Ltd. will introduce it to us.Before the operation of the crane, the brake should be checked for the sensitivity of the connecting rods and pins at each movable contact point, whether there is any sign of loosening or falling of the bolts, whether the wear of the brake pads has reached the invalid standard, whether the spacing between the two pads and the outer surface of the brake wheel is equal when the brake pads are open, whether there is any sign of loosening between the brake wheel and the transmission, whether the interference between the shaft and the hole is met, and whether there is any sign of loosening when tightening the bolts, Is there any oil stains on the surface of the brake wheel, and is there any significant scratches or signs of falling on the surface of the brake wheel. Is there any jamming or wear at the hinge, and is the hydraulic system normal.Large cranes are used in the metallurgical industry to transport molten steel for smelting furnaces. There are generally five main mechanisms: main lifting, auxiliary lifting, crane, main trolley, and auxiliary trolley mechanisms. The motor is installed on the high-speed shaft, and the drum is installed on the low-speed shaft. The high-speed shaft and low-speed shaft are connected together through a reducer. The traditional lifting mechanism brake is set on the high-speed shaft brake. In this case, if the high-speed shaft and brake wheel

time:2022-09-13

More