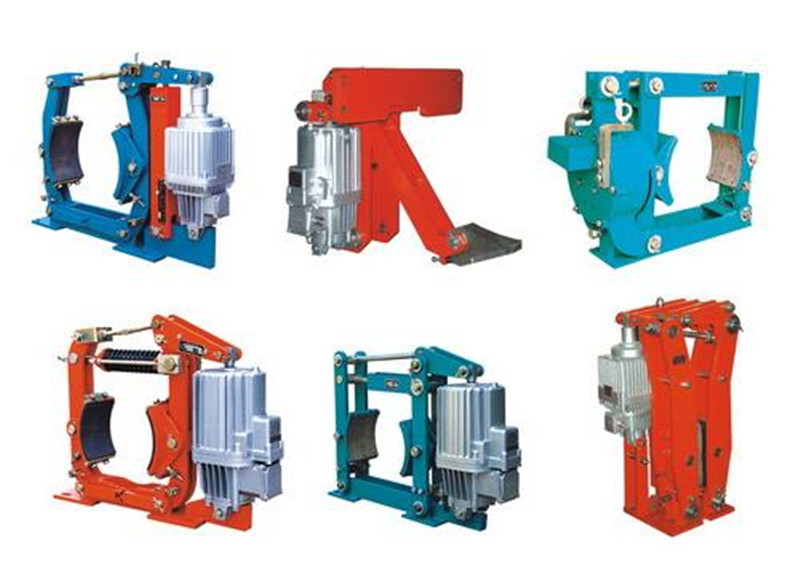

The luffing mechanism is the main working mechanism of a boom type crane, used to change the amplitude of the crane, that is, to change the horizontal distance from the center of the hook (or grab) to the axis of the crane's rotation center, in order to adapt to the loading and unloading of items by the crane under different conditions. It adopts an internal high-precision, hard tooth surface planetary gear reducer, which is characterized by smooth operation, high transmission efficiency, compact structure, convenient installation, high bearing capacity, long service life, and unparalleled advantages compared to cycloidal pinwheel and worm gear worm Xuan deceleration and amplitude changing mechanisms. It is an ideal replacement product for large, medium, and small crane amplitude changing mechanisms. According to its implementation method, the luffing mechanism can be divided into two types: the operating trolley type luffing and the arm type luffing, which can be further divided into the telescopic arm type and the swinging arm type; According to job requirements, it can be divided into non working amplitude and working amplitude; According to performance requirements, it can be divided into unbalanced and balanced amplitudes. The crane brake is installed on the rotating shaft of the electric motor to brake the operation of the motor, so that its operation or lifting mechanism can accurately and reliably stop at the predetermined position. Commonly used are spring type short stroke electromagnetic double brake shoe brakes, abbreviated as short stroke brakes (single-phase brakes); Spring type long stroke electromagnetic double brake shoe brake, abbreviated as long stroke brake (three-phase brake); There are three types of hydraulic push rod dual brake shoe brakes, abbreviated as push rod brakes.The operating trolley type luffing system relies on the operation of a load-bearing trolley along a horizontal arm track to achieve luffing, such as the operating trolley of a shore container crane. The swing arm type luffing system relies on the swing of the arm frame around its hinge axis in the vertical plane to achieve luffing. It is a common luffing method in port cranes, such as the luffing mechanism of portal cranes.Non working amplitude change refers to amplitude change without load, which is characterized by less frequency of amplitude change and lower speed of amplitude change. Working range change refers to load range change, which is characterized by frequent and fast range change as the main component of each working cycle of the crane. This range change method is beneficial for improving the mobility of the crane and expanding its service range. Analyze the reasons for the generation of dynamic load and the factors affecting dynamic load during the braking process of the rack driven variable amplitude mechanism, discuss the motion during the clearance elimination stage of the mechanism's tooth side and the impact vibration response of the mechanism during the collision stage, and propose a calculation method for the large dynamic load during the braking of the variable amplitude mechanismBalanced luffing refers to the process in which the center of gravity of an object can move along a horizontal or approximate horizontal line during the luffing process. The self weight of the arm frame (or arm frame system) is balanced by a movable balance weight, and the combined center of gravity of the two is moved or fixed at a point along the horizontal or approximate horizontal line during the luffing process. The center of gravity of the boom (or boom system) can also be moved along or near the horizontal line during the amplitude change process without relying on the structural characteristics of the boom system itself through the use of movable counterweights. Balanced luffing is often used in working luffing mechanisms. Non balanced luffing refers to the process of raising and lowering the center of gravity of the swinging arm frame and the object during the luffing process. When the amplitude is reduced, it consumes a large amount of driving power, while when the amplitude is increased, potential energy is released, which affects its performance. Non balanced luffing is mainly used for non working luffing mechanisms.The speed of the working luffing mechanism is determined based on its purpose and lifting capacity. When used for loading and unloading operations, the luffing speed is set at 40-90 m/min; When used for installation work, it is taken as 10-35 m/min. When the lifting capacity is large, take the lower valueCalculation principles of variable amplitude drive mechanism1. Selection of electric motorsThe motor of the variable amplitude mechanism is calculated based on the maximum value of the root mean square equivalent resistance moment under various working conditions under normal working conditions, and then the motor is preliminarily selected based on the equivalent power and the continuity of the mechanism's connection. Then verify the overload and heating of the motor.The equivalent luffing resistance torque is the root mean square value calculated based on the luffing resistance torque at different amplitude positions and the luffing time in the corresponding amplitude range during the entire luffing process of the corresponding lifting weight under normal working conditions. The variable amplitude resistance moment is generated by the unbalanced lifting load and the self weight load of the boom system, the wind force acting on the boom system, the horizontal force caused by the swing angle of the lifting rope, the inertia force of the boom system, the slope resistance caused by the crane tilt, and the frictional resistance of the boom system during variable amplitude.2. Selection of brakesLike the lifting mechanism, the brake of the luffing mechanism should be of the normally closed type. For the balanced luffing mechanism, the braking Factor of safety is 1.25 under working condition; Take 1.15 for non working conditions. The main unbalanced luffing mechanism shall be equipped with two support brakes, and the selection principle of its braking Factor of safety is the same as that of the lifting mechanism.3. Force calculation of partsThe comprehensively considered variable amplitude resistance is converted to a calculated part. Due to the variation of amplitude change resistance at different amplitude positions throughout the entire amplitude change process, these resistance should be calculated for several amplitude positions, and the larger one should be compared as the force acting on the component. 6 models of brakesYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brake electromagnetic failure protection disc brake:3SE; 4SE; 5SE; 450SE; 56SE; 560SE; 561SE; ST1SE; ST2SEHydraulic fail safe disc brake:3SH; 4SH; 5SH; 450SH; ST1SH; ST2SH; ST3SH; ST4SH; ST5SH; ST10SH; ST16SH; ST25SH; 904SH;ST40SHPneumatic fail safe disc brake:3SP; 4SP; 5SP; 450SPHydraulic direct acting disc brake:ADH60; ADH90; ADH120; DADH75; DADH80; DADH90; DADH120; DADH195; DADH350Pneumatic direct acting disc brake:ADP60M; ADP61M; ADP62MPneumatic caliper disc brakeCQPL12.7A-A; CQPL12.7A-B; CQPL12.7B; QPL12.7A-A; QPL12.7A-B; QPL12.7-A; QPL12.7-B;QP30-D; QP25.4-D; CQP30-D; CQP25.4-D; PDA5; PDA10; PDB5; PDB10; PDB19; PDC5; PDC10Electromagnetic caliper disc brake:DCPZ12.7-250; DCPZ12.7-300; DCPZ12.7-400Hydraulic caliper disc brake:SB (YQP) 50; SB (YQP) 100; SB (YQP) 160; SB (YQP) 250; SB (YQP) 315; SB (YQP) 400;SBD safety brake:SBD100-A; SBD125-A; SBD160-A; SBD200-A; SBD250-A; SBD-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD80-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD120-D; SBD240-DST, SBD, SH images

time:2021-04-26

More

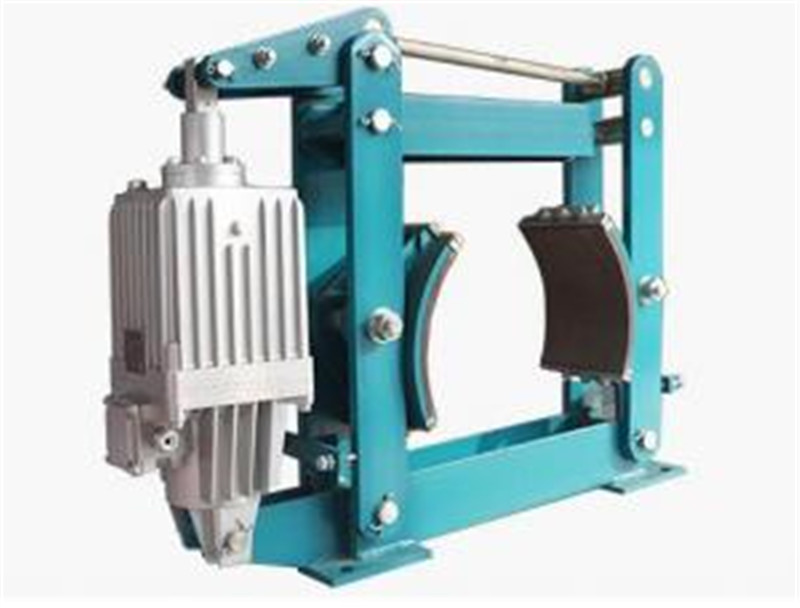

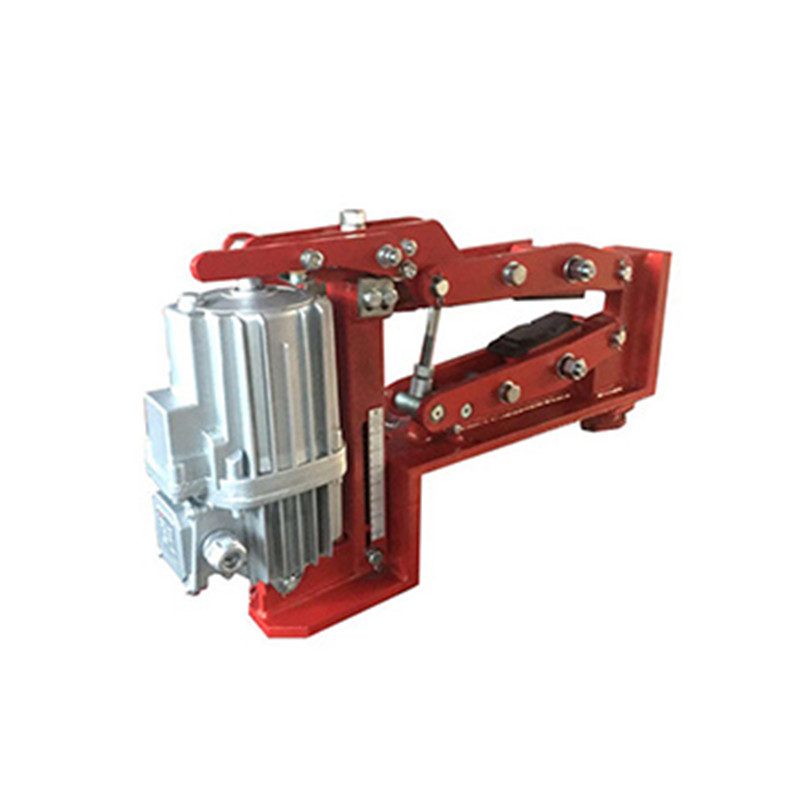

Due to the frequent combination of thrusters and brakes, this article comprehensively introduces their installation, use, and maintenance points: 1) When installing and fixing the brake, attention should be paid to whether the brake shoe is parallel to the brake wheel when the brake is released, and in the braking state, the entire surface of the brake band should be adhered to the brake wheel. The non parallelism and inclination in the released state should not exceed 0.1mm within the width of the brake wheel of 100mm. The working surface of the brake wheel must not have oil stains. 2) The brake is installed on the machine after installing the brake wheel. The brake wheel must be dynamically and statically balanced, and its surface roughness should not be lower than Ra1.6, and its hardness should not be lower than HBThe electric hydraulic brake is composed of electric motors, centrifugal pumps, oil cylinder pistons, and other components. When the mechanism is working, the electric motor 1 is energized, driving the centrifugal pump impeller 5 to rotate under the action of centrifugal force; The high-pressure oil is pumped out and flows into the lower chamber of piston 6, pushing the piston and push rod 2 to rise together. At this time, square shaft 3 rises along the shaft sleeve, and the brake release lever releases the brake.The impeller of a centrifugal pump adopts radial blades, which can pump high-pressure oil to make the piston move regardless of the direction of current, i.e. the direction of motor rotation. When the mechanism is not working, electric motor 1 is powered off, the impeller stops rotating, the oil pressure in the lower chamber of the piston decreases, and the tension of the main spring causes the brake to close and brake. At the same time, the piston quickly resets under the gravity of the piston and push rodElectric hydraulic block brakes are mainly used for mechanical braking of driving devices in lifting, transportation, metallurgy, mines, ports, and construction machinery. They have the advantages of smooth braking, safety and reliability, convenient maintenance, low power consumption, long service life, and no noise.Usage conditionsEnvironmental temperature: -20 ℃~+50% using DB-25 hydraulic oil: below -20 ℃ using YH-10 aviation hydraulic oil, air relative humidity not exceeding 90%, generally used for three-phase AC power supply, 50HZ, 380V, sea level in accordance with GB755-87 standardBrake composition:The brake for cranes consists of brake pads, brake arms, brake wheels, and brake release devices. The brake wheel is often installed as a half body of the coupling on the rotating shaft of the mechanism. The symmetrically arranged brake arm is hinged with the fixed part of the frame, and the two brake pads with friction materials on the inner side are movable and hinged on the two brake arms. Under the action of the brake force on the brake release device, the paired brake pads compress the brake wheel radially and generate braking torque. Brakes can be divided into normally closed and normally open types based on their working status.Normally closed brakes are often in a tight braking state by the action of springs or gravity, and when the mechanism is working, manual labor or brake release can be used to release the brakes.Normally open brakes are often in a loose state and can only be tightened when external force is applied.Brake usage:YWZ, YWZ2, YWZ3, YWZ4, YWZ5, YWZ9 and other series of hydraulic block brakes are mainly used for mechanical braking of driving devices in lifting, transportation, metallurgy, mining, port, and construction machinery. They have the advantages of stable braking, safety and reliability, convenient maintenance, low power consumption, long service life, and no noise.Z-Z9 series brake SBD high-definition diagram

time:2021-04-26

More

Brakes can be divided into normally closed and normally open types based on their working status.Normally closed brakes are often in a tight braking state by the action of springs or gravity, and when the mechanism is working, manual labor or brake release can be used to release the brakes.Normally open brakes are often in a loose state and can only be tightened when external force is applied.Brake usage:YWZ, YWZ2, YWZ3, YWZ4, YWZ5, YWZ9 and other series of hydraulic block brakes are mainly used for mechanical braking of driving devices in lifting, transportation, metallurgy, mining, port, and construction machinery. They have the advantages of stable braking, safety and reliability, convenient maintenance, low power consumption, long service life, and no noise.Due to the frequent combination of thrusters and brakes, this article comprehensively introduces their installation, use, and maintenance points: 1) When installing and fixing the brake, attention should be paid to whether the brake shoe is parallel to the brake wheel when the brake is released, and in the braking state, the entire surface of the brake band should be adhered to the brake wheel. The non parallelism and inclination in the released state should not exceed 0.1mm within the width of the brake wheel of 100mm. The working surface of the brake wheel must not have oil stains. 2) The brake is installed on the machine after installing the brake wheel. The brake wheel must be dynamically and statically balanced, and its surface roughness should not be lower than Ra1.6, and its hardness should not be lower than HBThe electric hydraulic brake is composed of electric motors, centrifugal pumps, oil cylinder pistons, and other components. When the mechanism is working, the electric motor 1 is energized, driving the centrifugal pump impeller 5 to rotate under the action of centrifugal force; The high-pressure oil is pumped out and flows into the lower chamber of piston 6, pushing the piston and push rod 2 to rise together. At this time, square shaft 3 rises along the shaft sleeve, and the brake release lever releases the brake.The impeller of a centrifugal pump adopts radial blades, which can pump high-pressure oil to make the piston move regardless of the direction of current, i.e. the direction of motor rotation. When the mechanism is not working, electric motor 1 is powered off, the impeller stops rotating, the oil pressure in the lower chamber of the piston decreases, and the tension of the main spring causes the brake to close and brake. At the same time, the piston quickly resets under the gravity of the piston and push rodElectric hydraulic block brakes are mainly used for mechanical braking of driving devices in lifting, transportation, metallurgy, mines, ports, and construction machinery. They have the advantages of smooth braking, safety and reliability, convenient maintenance, low power consumption, long service life, and no noise.Usage conditionsEnvironmental temperature: -20 ℃~+50% using DB-25 hydraulic oil: below -20 ℃ using YH-10 aviation hydraulic oil, air relative humidity not exceeding 90%, generally used for three-phase AC power supply, 50HZ, 380V, sea level in accordance with GB755-87 standardBrake composition:The brake for cranes consists of brake pads, brake arms, brake wheels, and brake release devices. The brake wheel is often installed as a half body of the coupling on the rotating shaft of the mechanism. The symmetrically arranged brake arm is hinged with the fixed part of the frame, and the two brake pads with friction materials on the inner side are movable and hinged on the two brake arms. Under the action of the brake force on the brake release device, the paired brake pads compress the brake wheel radially and generate braking torque.YWZE

time:2021-04-26

More

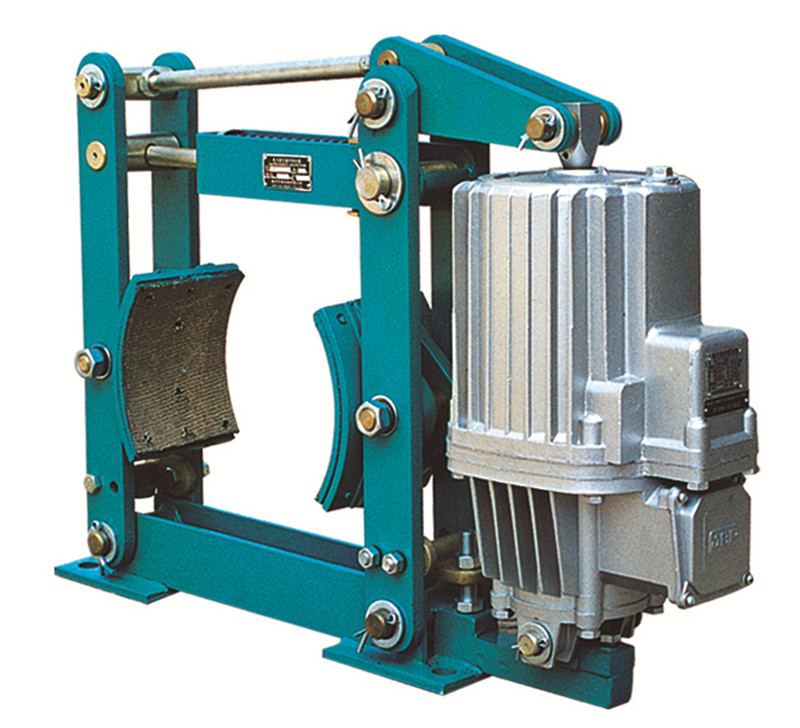

purposeThe YWZ4 series electric hydraulic block brake is driven by the Ed series electric hydraulic thruster. Its installation dimensions comply with JB/ZQ4333-86 standard. This series of brakes is mainly used for mechanical braking of mechanical driving devices in lifting, transportation, metallurgy, mining, ports, construction, and other fields. It has the advantages of smooth braking, high action frequency, safety and reliability, convenient maintenance, cost saving, long service life, and low noise.Normal working conditionsEnvironmental temperature -20 ℃~+50 ℃;The relative humidity of the air shall not exceed 90%;In a place where there is no explosion hazard and there is no gas or discharge dust in the medium that can corrode and damage the insulation;Generally used for three-phase AC power supply 50Hz, 380V;The elevation of the motor installation site meets the GB755-87 standard;When the ambient temperature is below -20 ℃, the working fluid of the thruster is changed to YH-10 aviation fluid or requires a heater. Main technical parametersModel brake torque N. M reverse torque bCDdFG1G2Hh1iKM thruster matching thruster YWZ4-100/23Ed. YWZ4-150/23Ed. YWZ4-200/23Ed. YWZ4-200/30EdYWZ4-300/30Ed. YWZ4-300/50EdYWZ4-300/80Ed80/YWZ4-400/50Ed. YWZ4-400/80EdYWZ4-400/121EdYWZ4-500/121Ed.YWZ4-500/201EdYWWZ4-600/121Ed.8YWZ4-600/201EdYWWWZ4 700/201Ed.5YWZ4-600/301EdYWZ4-800/301Ed.5

time:2021-04-26

More

The WZ4B series electric hydraulic drum brakes are widely used for deceleration or parking braking of mechanical drive devices in lifting, metallurgy, mining, ports, docks, construction machinery, and other fields. Safe and reliable performance, smooth braking, and high action frequency. The main swing hinge point is equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use.TitleCompliant with standardsThe installation dimensions comply with the JB/ZQ4388-1997 standard. There are two types of installation methods for brake pads according to user needs: riveted and plug-in (please specify when ordering)Usage conditionsEnvironmental temperature: -20 ℃~+50 ℃The relative temperature of the air shall not exceed 90%The surrounding environment must not contain flammable, explosive, or corrosive gases. The altitude of the location of use complies with GB755-2000Outdoor rain and snow erosion or corrosive gases and media should use corrosion-resistant productsTitleYWZ4B series electric hydraulic block brake: YWZ4B-100/23; YWZ4B-150/23; YWZ4B-200/23; YWZ4B-200/30; YWZ4B-300/30; YWZ4B-300/50; YWZ4B-300/80; YWZ4B-400/50; YWZ4B-400/80; YWZ4B-400/121; YWZ4B-500/121; YWZ4B-600/121; YWZ4B-600/201; YWZ4B-700/201; YWZ4B-700/301; YWZ4B-800/301YWL-250/E30, YWL-250/E50, YWL-315/E23, hydraulic brake manufacturerYWL-315/E30, YWL-315/E50, YWL-315/E80, hydraulic brake, hydraulic brake manufacturerYWL-400/E30, YWL-400/E50, YWL-400/E80, hydraulic brake manufacturerYWL-500/E121, YWL-500/E201, hydraulic brake 13803910788

time:2021-04-22

More

For heavy machinery like a gantry crane, the function of the brake is not to mention! We are here to explain the main categories and applications of gantry crane brakes!According to different installation and operation situations, brakes are divided into three types: normally closed, normally open, and comprehensive. Generally, normally closed brakes are used. Normally closed brakes are closed during periods when the mechanism is not in operation. If you want the mechanism to work, you only need to release the brake to separate the friction pairs of the brake, and the mechanism can operate. According to the shape, it can be divided into block brake, belt brake, disc brake and cone brake.The braking device is an important component to ensure the safe and normal operation of the crane. During lifting operations, the braking device is used to prevent objects or lifting arms from falling during suspension, and to prevent the turntable or crane from sliding under the action of wind or slope forces; Or reduce the speed of the running mechanism and then stop moving; It can also be operated by clamping heavy objects according to work needs; In special circumstances, the movement speed can be adjusted by controlling the balance between power and gravity.The working mechanism of a crane should generally be equipped with a brake, and only in the following situations can a brake not be installed:1. The mechanism is driven by a linear motion oil cylinder, and the locking oil circuit can stop the mechanism by the ground.2. The manual operating mechanism of Overhead crane is not subject to wind force or ramp force component.Gantry crane is a deformation of Overhead crane, also called gantry crane. Mainly used for loading and unloading operations of outdoor freight yards, stock yards, and bulk cargo. Gantry crane is widely used in port freight yard due to its high site utilization rate, wide operation range, wide adaptability and strong versatility. What are the reasons for the falling of objects from the gantry crane hook?Gantry crane is a mechanical equipment used for loading and unloading operations, where the hook is an important component connecting the lifting mechanism of the gantry crane and the lifted object. Once there is a problem with the hook, it will cause the object to fall and cause serious accidents. Today we will talk about the reasons for the falling of objects suspended by hooks.1、 Design not standardizedFor example, the overload protection fails, the strength of the balance wheel axle is insufficient, there is no anti decoupling device, and the selection of lifting equipment and rigging is unreasonable; There are also issues such as failure to replace scrapped parts in a timely manner, lack of necessary safety protection, poor maintenance and faulty operation, resulting in uncontrolled movement, damage to parts or structures, and irregular safety performance inspections.2、 Environmental factorsFor example, engaging in lifting operations in environments such as high dust, high temperature, high humidity, low temperature, high noise, strong winds, and poor lighting can distract attention and directly affect the reaction ability and technical stability of operators, increasing the chances of misoperation and illegal operations, leading to accidents.3、 Vulnerability in security managementIncluding the level of safety awareness of leaders; Implementation of crane management, inspection, and regular safety performance inspection; Safety education and training for relevant personnel; Special training for lifting operators, formulation of safety operation regulations for cranes, establishment of reward and punishment systems for violations, and emergency response plans for accidents, lack of effective monitoring and management of regular inspections of lifting equipment and lifting aids. Any negligence or inadequate safety management is one of the important reasons for gantry crane casualties.Installation of brakes in the crane workshop

time:2021-04-22

More

Service time of electric hydraulic brake thrusterBrake product features: Disc spring set with an ultra long lifespan of over 2 million times. Single set brake with adjustable braking force. Single sealing ring design, braking force will not be transmitted to the piston, completely solving the problem of oil leakage. The friction plate has a large contact area with the brake disc. The friction plate is made of asbestos free copper based powder metallurgy material, which can adapt to high temperature and high load conditions, ensuring stable friction coefficient during braking. The brake release indicator and wear indicator device signals are accurate, No false alarms will be generated. Application: Ideal choice for large lifting equipment such as container cranes, steel casting cranes, ship unloaders, power station bridge cranes, cable cars, etc. The SIBRE HFC series high elastic coupling is a product developed for high-power transmission. It achieves transmission by squeezing cylindrical elastic components between semicircular claws, making it an ideal choice for high-power transmission. Product features: It has large axial, radial, and angle compensation, good vibration reduction and buffering performance, and can effectively protect the equipment. Elastomers are imported from Germany and have advantages such as oil resistance, wear resistance, high temperature resistance, corrosion resistance, long service life, and maintenance freeThe role of crane brakes in equipment is so important, so it is necessary for us to pay more attention to the maintenance and upkeep of the brakes in our daily life: regularly check whether the brakes are in good working condition, in order to timely identify existing safety hazards and reduce the incidence of crane accidents. Identify any abnormalities in the brake equipment through sound, and regularly inspect the internal wear of the crane brake to see if it exceeds the allowable range, whether the spring is ineffective, and whether there are many impurities and dirt in the internal components. Timely cleaning or replacement of internal components is necessary.The characteristics of few faults and long service lifeThe hydraulic thruster is the main component of the electric hydraulic push rod brake. It contains a small centrifugal oil pump that operates under fully sealed conditions, with clean oil quality and good lubrication conditions. The oil pump blades, rotating shafts, and oil cylinders are not easily worn and damaged, and the service life is of course very long.The brake frame is a metal structure, which is less prone to damage; Brake pads (brake shoes) are vulnerable parts, but their application on belt conveyors has the characteristic of long service life. The frequency of action of the electric hydraulic push rod brake can reach over a few hundred times per minute, while the belt conveyor only needs to operate a few dozen times per day. The brake shoes of the brake appear very durable, and the wear is very small after three years. It is expected that there will be no problems after three to five years of use.2. The maintenance of the electric hydraulic push rod brake is simple and convenientHydraulic thrusters generally do not require maintenance, as long as the clearance between the brake pads and the brake drum is checked. If there is a deviation in the clearance, appropriate adjustments can be made. Some hydraulic thrusters may have some leaks, so it is appropriate to add No. 20 engine oil to the hydraulic thrusters; The brake pads can also be replaced, and replacement is very convenient and quick.Although the types of crane brakes vary according to different job requirements, their functions in mechanical equipment are not the same, mainly by controlling the rotation and inertial motion of the motor, which can control the equipment to stop, accelerate, or decelerate in a certain motion state. Due to the operational function of the crane, brake failure is absolutely not allowed during the lifting of heavy objects. If the brake failure causes inertia control to fail, it can damage the equipment or threaten the health and safety of surrounding personnel. Therefore, the brake plays a very important role in the safe and stable operation of the crane equipment.Two types of diagrams, YWZ4 and YWZ

time:2021-04-22

More

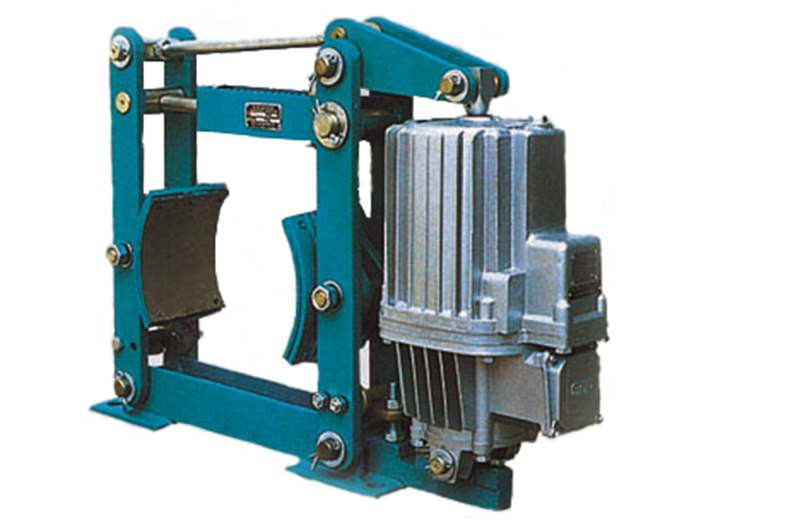

The lifting mechanism and luffing mechanism of a manually driven crane must be equipped with brakes or stoppers. Fifthly, the braking torque of the brakes should meet the following requirements: the braking torque of the brakes, the transmission torque of the M-brake axis, K - Service condition of Factor of safety mechanism Factor of safety: 1.50 for hoisting mechanism, 1.75 for hydraulic transmission with hydraulic braking, 1.25 for hoisting hot metal or 1.25 for hoisting mechanism with two support brakes, 1.25 for each set of brake, 1.25 for each set of brake, there are two sets of driving devices with rigid connection with each other, and each set of device has two sets of support brakes. The fourth pair of each set of brakes is 1.10 unbalanced luffing mechanism 1.75 balanced luffing mechanism in working state 1.25 in non working stateThe connection dimensions and technical requirements of the YW and YWB series brakes comply with the JB/T6406-2006 standard, and the braking torque parameters comply with the DIN15435 standard; The YW series is equipped with YTD series thrusters that meet the JB/T10603-2006 standard; The YWB series is equipped with Ed series thrusters that meet the DIN15430 standard; This series is suitable for new designs and matching selection of new hosts.The connection dimensions and braking torque parameters of YWZ5 and YWZE series brakes comply with GB6333-86 standard, and the technical requirements comply with JB/T6406-2006 standard; The YWZ5 series is equipped with YTD series thrusters that comply with the JB/T10603-2006 standard; The YWZE series is equipped with Ed series thrusters that comply with the DIN15430 standard.The connection dimensions and braking torque parameters of YWZ6 and YWZF series brakes comply with JB/ZQ4388-86 standards, and the technical requirements comply with JB/T6406-2006 standards; The YWZ6 series is equipped with YTD series thrusters that comply with the JB/T10603-2006 standard; YWZF is equipped with Ed series thrusters that comply with DIN15430 standard; This series is suitable for replacing old products such as YWZ, JCZ, JWZ, and TJ2 series. In order to better prevent the vehicle from holding the brake, a series of preventive measures have been taken, especially through the investigation of holding the brake of the through Freight train, which has accumulated some experience. At the same time, in order to find the authenticity of the problem more intuitively, the following measures have been taken: organize special personnel to visit the stations prone to holding the brake one by one, strengthen the contact with the station, and have a detailed understanding of the situation with the relevant personnel of each station who found the holding brake situation, Enable us to have a perceptual understanding and enhance our understanding of the hazards of holding brakes on driving. Timely contact with the train inspection and provide feedback on fault information to reduce or eliminate the occurrence of such faults. In response to the malfunction of other accessories caused by the vehicle's brake application and the serious impact on normal driving order.Brake holding brake failure is the application failure of Goods wagon caused by poor brake release and brake shoe cannot be separated from wheel tread due to brake failure, hand brake non release and other reasons. Its main hazard is to scratch the wheel tread, resulting in slag and rolling on the wheel tread.Two types of diagrams, YWZ4 and YWZ

time:2021-04-22

More

The connection dimensions and braking torque parameters of YWZ5 and YWZE series brakes comply with GB6333-86 standard, and the technical requirements comply with JB/T6406-2006 standard; The YWZ5 series is equipped with YTD series thrusters that comply with the JB/T10603-2006 standard; The YWZE series is equipped with Ed series thrusters that comply with the DIN15430 standard.The spring pressure should be marked, and the greater the torque required, the better the braking performance. It is advisable to shorten the distance between the bolts in the middle of the two brake pads and increase the hydraulic tappet by 0.2-0.5mm. Conversely, the brake fails. The brake pad is pressed tightly on the brake wheel to achieve braking. A single brake block has a large and uneven pressure on the brake wheel axle, so an additional pair of brake blocks is usually used to counteract the pressure exerted by the brake blocks on the brake wheel axle. There are two types of block brakes: externally held and internally tensioned. External block brakeIt is divided into short stroke block brakes and long stroke block brakes according to the length of the control device's stroke. The magnet of the short stroke block brake is directly installed on the brake arm. During operation, the moving iron core rotates around the pin shaft to achieve brake release; When the magnet is powered off, it is tightly closed by the main spring. This type of brake has a compact structure, with fast tightening and releasing actions, but high impact force. Long travel block brakes can generate a large release force through the brake lever system, but the braking action is stable and suitable for various sizes of deceleration equipment.The structure of the YWZE-710/301 hydraulic brake electric hydraulic push rod brake is composed of two major parts: a brake frame and a matching hydraulic thruster (Figure 2). The brake frame is composed of brake pads, main springs, brake arms, adjustment rods, etc. The upper part of the hydraulic thruster is the same small electric motor, and the lower part is the same small centrifugal fuel injector. The piston of the fuel injector is connected to its two upper push rods. Long runningYWZE series electric hydraulic block brakes:YWZE electric hydraulic drum brake shoeYWZE-200/23; YWZE-200/30; YWZE-250/23; YWZE-250/30; YWZE-250/50; YWZE-300/30; YWZE-300/50; YWZE-300/80; YWZE-315/30; YWZE-315/50; YWZE-315/80; YWZ-400/50; YWZE-400/80; YWZE-400/121; YWZE-500/80; YWZE-500/121; YWZE-500/201; YWZE-600/121; YWZE-600/201; YWZE-600/301; YWZE-630/121; YWZE-630/201; YWZ-630/301; YWZ-700/201; YWZE-700/301; YWZE-710/201; YWZE-710/301; YWZE-800/301/12YWZE

time:2021-04-22

More

YWZE-250/30-HL/HR electric hydraulic brakeThe connection dimensions and braking torque parameters of YWZ5 and YWZE series brakes comply with GB6333-86 standard, and the technical requirements comply with JB/T6406-2006 standard; The YWZ5 series is equipped with YTD series thrusters that comply with the JB/T10603-2006 standard; The YWZE series is equipped with Ed series thrusters that comply with the DIN15430 standard.The spring pressure should be marked, and the greater the torque required, the better the braking performance. It is advisable to shorten the distance between the bolts in the middle of the two brake pads and increase the hydraulic tappet by 0.2-0.5mm. Conversely, the brake fails. The brake pad is pressed tightly on the brake wheel to achieve braking. A single brake block has a large and uneven pressure on the brake wheel axle, so an additional pair of brake blocks is usually used to counteract the pressure exerted by the brake blocks on the brake wheel axle. There are two types of block brakes: externally held and internally tensioned. External block brakeIt is divided into short stroke block brakes and long stroke block brakes according to the length of the control device's stroke. The magnet of the short stroke block brake is directly installed on the brake arm. During operation, the moving iron core rotates around the pin shaft to achieve brake release; When the magnet is powered off, it is tightly closed by the main spring. This type of brake has a compact structure, with fast tightening and releasing actions, but high impact force. Long travel block brakes can generate a large release force through the brake lever system, but the braking action is stable and suitable for various sizes of deceleration equipment.The structure of the YWZE-710/301 hydraulic brake electric hydraulic push rod brake is composed of two major parts: a brake frame and a matching hydraulic thruster (Figure 2). The brake frame is composed of brake pads, main springs, brake arms, adjustment rods, etc. The upper part of the hydraulic thruster is the same small electric motor, and the lower part is the same small centrifugal fuel injector. The piston of the fuel injector is connected to its two upper push rods. Long runningYWZE series electric hydraulic block brakes:YWZE electric hydraulic drum brake shoeYWZE-200/23; YWZE-200/30; YWZE-250/23; YWZE-250/30; YWZE-250/50; YWZE-300/30; YWZE-300/50; YWZE-300/80; YWZE-315/30; YWZE-315/50; YWZE-315/80; YWZ-400/50; YWZE-400/80; YWZE-400/121; YWZE-500/80; YWZE-500/121; YWZE-500/201; YWZE-600/121; YWZE-600/201; YWZE-600/301; YWZE-630/121; YWZE-630/201; YWZ-630/301; YWZ-700/201; YWZE-700/301; YWZE-710/201; YWZE-710/301; YWZE-800/301/12YWZEYWZE-315/50 Electric Hydraulic Brake YWZE-315/80

time:2021-04-22

More

The performance and function of the brake YP-W5550/E30 in the process of using the car dumper should not be lower than the performance of the original brake. The key is to ensure that the braking torque and friction material are not lower than the performance of the original brake. 3. When designing customized brakes, brake manufacturers vary according to the usage situation, and there are also differences in specifications and models. When replacing them, it is necessary to ensure that the models match. If the sizes are not the same, it will definitely be difficult to use. 4. The issue of power supply is also quite important. However, if AC power was previously used and the voltage value cannot be changed, it can prevent unnecessary trouble caused by burning.The brake company relies on advanced processing and testing methods, strong technical research and development capabilities, and continuous technological transformation to actively explore the market, so that the product quality and after-sales service of the brake have been widely praised by users, forming a sales network throughout the country. The "Golden Drum" brand brake has become a well-known brand renowned throughout the country, and the company has become a major supplier to major domestic machinery factories. Its products are exported to countries and regions such as Europe, America, Russia, and so on. High production efficiency of YP-W550/E30 brakes: To improve production efficiency, it is necessary to control the production pace. In addition to fixed production and processing rhythms that cannot be improved, automatic loading and unloading have replaced manual operations, and the YP-W5550/E30 brake can effectively control the rhythms, avoiding the impact of human factors on production rhythms and greatly improving production efficiency.Flexible modification of brake process: We can quickly change the production process by modifying the program and gripper fixture, with fast debugging speed and eliminating the need for employee training, allowing for quick production.Brakes improve the quality of workpiece appearance: Robotic automated production line, from loading, clamping, and unloading are completely completed by robots, reducing intermediate links, greatly improving the quality of brake parts, especially the surface of the workpiece is more beautiful. Due to the driver's basic habit of using electric hydraulic brakes to stop the car when passing through traffic lights, refueling and running the brakes when they can pass. To be honest, this operation of the brakes can cause severe friction to the electric hydraulic brakes. So, how should the YP-W550/E30 brake electric hydraulic brake operate when the car is shifting, How should we understand the small formula of "one fast, one slow, and three linked"? This means that before the car starts, the driver needs to first test the working stroke of the electric hydraulic brake, and then test the pedal feel of the brake before starting to lift it quickly. YP-W550/E30 brake cars have relatively high safety performance requirements for brakes. When the brakes are semi linked (at this time, the engine sound changes), the pedal lifting speed is slightly slower; The process from semi linkage to complete connection involves gradually lifting the pedal. As the brake pedal is lifted together, the accelerator pedal is gradually pressed according to the engine resistance to ensure a smooth start of the car. The brake disc is generally made of steel, although it has a certain metal hardness, it will oxidize at high temperatures, not only reducing hardness, but also deforming when cooled too fast, causing rapid wear of the brake disc, reducing the surface roughness of the disc, and generating deep grooves, Even if the brake is replaced with a new friction plate, it will not improve, and severe deformation can cause wheel imbalance and body shaking. Therefore, for the hydraulic braking system of vehicles, in addition to routine inspections, special attention should be paid to the surface roughness of the friction material for the YP-W550/E30 brake. The brake effect is good when installed externally, but the external volume is large and requires the customer to install it themselves. Some require additional brackets, which is quite troublesome. The built-in brake, which uses a brake motor. The YP-W550/E30 brake and motor are integrated, and the installation method is the same as that of a regular motor, making it convenient. Therefore, in general, it is recommended to choose a built-in brake, but for equipment such as elevators and cranes that have strict braking requirements or may cause serious consequences if they fail, it is recommended to use an external brake The brake system not only affects the performance of a vehicle, but also plays an absolute role in driving safety. In the study of the influence of friction material composition on the formation of transfer film and the friction characteristics of friction plate, it is pointed out that the friction vibration decreases with the formation of the interface facial mask. After test and comparison, it was found that the structure and chemical composition of Jieneneneba facial mask were significantly different from those of the original sample,YP-W550/E30 brake YP-W550/E40 brake YP-W550/E30 brake YP-W560/E50 brakeOur factory is a modern enterprise that integrates research, development, design, manufacturing, sales, and service of electric hydraulic block brakes, electromagnetic brakes, thrusters, and lifting appliances. Sincere unity, lofty aspirations, determination to innovate, and striving for progress. We serve several large and small enterprises in China, including mining, machinery, metallurgy, lifting, power, railways, water conservancy, ports, docks, chemical and other industries. Our factory has successfully designed and manufactured specialized brakes with unique characteristics. Products with excellent quality and performance, as well as honest and efficient services, are recognized and praised by users.YP-W500/E30 brake YPZ2 arm disc small

time:2021-04-22

More

The performance and function of the brake YP-W5550/E30 in the process of using the car dumper should not be lower than the performance of the original brake. The key is to ensure that the braking torque and friction material are not lower than the performance of the original brake. 3. When designing customized brakes, brake manufacturers vary according to the usage situation, and there are also differences in specifications and models. When replacing them, it is necessary to ensure that the models match. If the sizes are not the same, it will definitely be difficult to use. 4. The issue of power supply is also quite important. However, if AC power was previously used and the voltage value cannot be changed, it can prevent unnecessary trouble caused by burning.The brake company relies on advanced processing and testing methods, strong technical research and development capabilities, and continuous technological transformation to actively explore the market, so that the product quality and after-sales service of the brake have been widely praised by users, forming a sales network throughout the country. The "Golden Drum" brand brake has become a well-known brand renowned throughout the country, and the company has become a major supplier to major domestic machinery factories. Its products are exported to countries and regions such as Europe, America, Russia, and so on. High production efficiency of YP-W550/E30 brakes: To improve production efficiency, it is necessary to control the production pace. In addition to fixed production and processing rhythms that cannot be improved, automatic loading and unloading have replaced manual operations, and the YP-W5550/E30 brake can effectively control the rhythms, avoiding the impact of human factors on production rhythms and greatly improving production efficiency.Flexible modification of brake process: We can quickly change the production process by modifying the program and gripper fixture, with fast debugging speed and eliminating the need for employee training, allowing for quick production.Brakes improve the quality of workpiece appearance: Robotic automated production line, from loading, clamping, and unloading are completely completed by robots, reducing intermediate links, greatly improving the quality of brake parts, especially the surface of the workpiece is more beautiful. Due to the driver's basic habit of using electric hydraulic brakes to stop the car when passing through traffic lights, refueling and running the brakes when they can pass. To be honest, this operation of the brakes can cause severe friction to the electric hydraulic brakes. So, how should the YP-W550/E30 brake electric hydraulic brake operate when the car is shifting, How should we understand the small formula of "one fast, one slow, and three linked"? This means that before the car starts, the driver needs to first test the working stroke of the electric hydraulic brake, and then test the pedal feel of the brake before starting to lift it quickly. YP-W550/E30 brake cars have relatively high safety performance requirements for brakes. When the brakes are semi linked (at this time, the engine sound changes), the pedal lifting speed is slightly slower; The process from semi linkage to complete connection involves gradually lifting the pedal. As the brake pedal is lifted together, the accelerator pedal is gradually pressed according to the engine resistance to ensure a smooth start of the car. The brake disc is generally made of steel, although it has a certain metal hardness, it will oxidize at high temperatures, not only reducing hardness, but also deforming when cooled too fast, causing rapid wear of the brake disc, reducing the surface roughness of the disc, and generating deep grooves, Even if the brake is replaced with a new friction plate, it will not improve, and severe deformation can cause wheel imbalance and body shaking. Therefore, for the hydraulic braking system of vehicles, in addition to routine inspections, special attention should be paid to the surface roughness of the friction material for the YP-W550/E30 brake. The brake effect is good when installed externally, but the external volume is large and requires the customer to install it themselves. Some require additional brackets, which is quite troublesome. The built-in brake, which uses a brake motor. The YP-W550/E30 brake and motor are integrated, and the installation method is the same as that of a regular motor, making it convenient. Therefore, in general, it is recommended to choose a built-in brake, but for equipment such as elevators and cranes that have strict braking requirements or may cause serious consequences if they fail, it is recommended to use an external brake The brake system not only affects the performance of a vehicle, but also plays an absolute role in driving safety. In the study of the influence of friction material composition on the formation of transfer film and the friction characteristics of friction plate, it is pointed out that the friction vibration decreases with the formation of the interface facial mask. After test and comparison, it was found that the structure and chemical composition of Jieneneneba facial mask were significantly different from those of the original sample,YP-W550/E30 brake YP-W550/E40 brake YP-W550/E30 brake YP-W560/E50 brakeOur factory is a modern enterprise that integrates research, development, design, manufacturing, sales, and service of electric hydraulic block brakes, electromagnetic brakes, thrusters, and lifting appliances. Sincere unity, lofty aspirations, determination to innovate, and striving for progress. We serve several large and small enterprises in China, including mining, machinery, metallurgy, lifting, power, railways, water conservancy, ports, docks, chemical and other industries. Our factory has successfully designed and manufactured specialized brakes with unique characteristics. Products with excellent quality and performance, as well as honest and efficient services, are recognized and praised by users.YP-W500/E30 brake YPZ2 arm disc small

time:2021-04-22

More