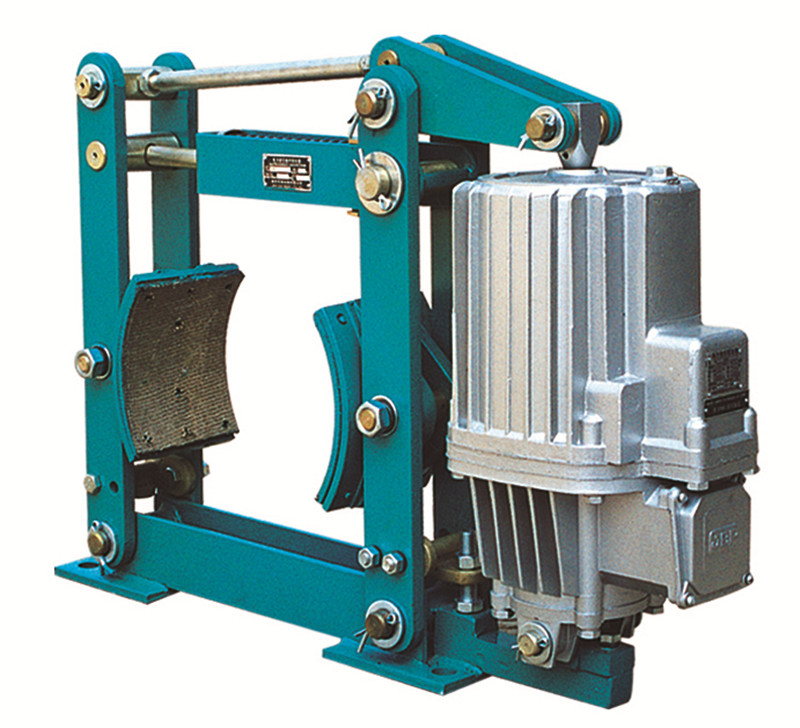

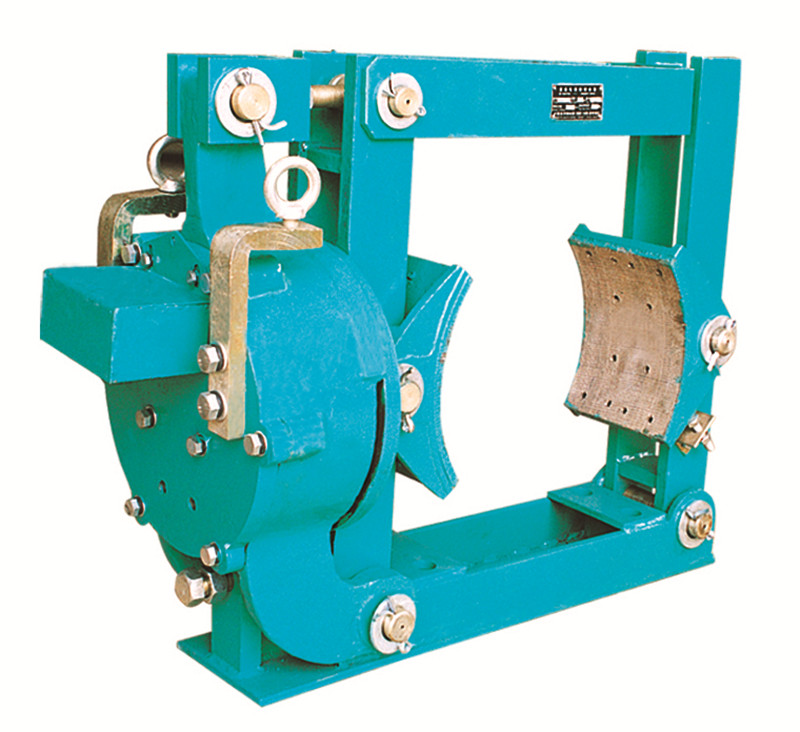

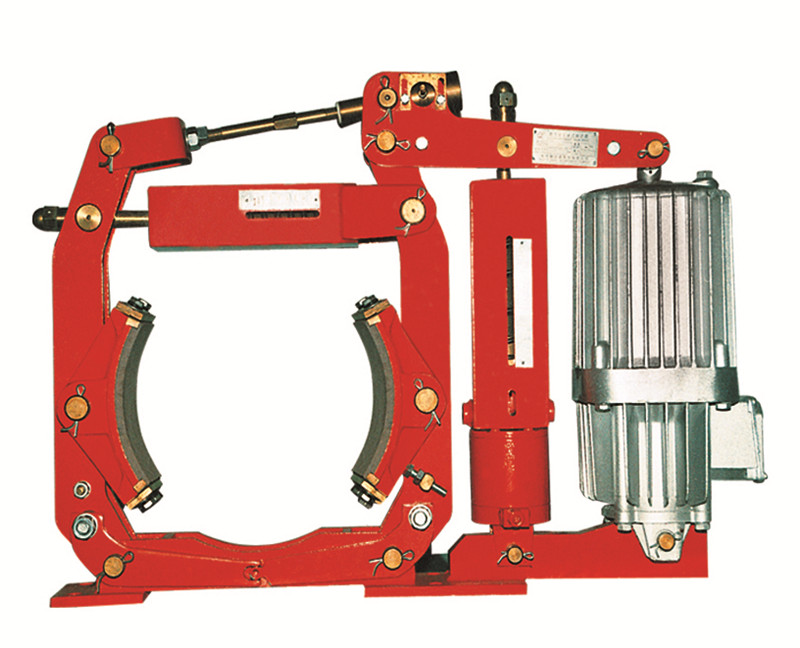

Electric hydraulic brake: Knowledge related to conveyors, belt conveyors, belt conveyors, bulk material conveying equipment, and the role and maintenance methods of brakes in belt conveyors! The installation of brakes in the belt conveyor is mainly to prevent the belt from reversing during emergency stops or shutdowns, and to avoid accidents caused by materials piling up at the tail of the conveyor due to the reversal. So how should we do a good job in correct use and daily maintenance during use? Today, the technical personnel from the manufacturer of Coryson belt conveyor will provide you with a detailed introduction! Maintenance methods for brakes. The brake is easily infected with oil stains at the driving equipment. To avoid affecting the braking effect, the adjacent oil stains should be promptly sorted out. When the driving wheel of the belt mechanism shows cracks and the thickness of the brake wheel flange reaches 40% of the original thickness, it should be discarded. The overall trend in the development of open-pit mining technology both domestically and internationally is towards large-scale mining, continuous production, and modern equipment. With the technological progress of mining technology and equipment in the open-pit mining industry worldwide, mobile belt conveyors, displacement belt conveyors, and semi displacement belt conveyors are the main technical equipment for open-pit mining. Their characteristics are that the belt conveyor uses a displacement machine to pull steel rails or skids to achieve horizontal movement of the entire machine. In addition, this machine also has the characteristics of long transportation distance, large transportation volume, and no fixed foundation, Safety devices to prevent walking and check parking. The brake is responsible for the stopping speed of the conveyor, reducing the stopping time under technically permissible conditions, commonly known as emergency braking. Once an accident or a sign of an accident occurs, the operation can be stopped as soon as possible to prevent the accident from happening or expanding. The type of braking deviceThere are many types of brakes for belt conveyors, and different forms of brakes can be selected based on the technical performance and specific usage conditions of the conveyor (such as power size, installation angle, etc.). Commonly used include belt type backstop, roller backstop, hydraulic electromagnetic brake shoe brake, and disc brake. Belt type backstopHydraulic push rod brakeThe hydraulic push rod brake can be used for both upward and downward conveyor belts, installed on a high-speed shaft, with fast and reliable action. Belt conveyors are generally equipped with this type of brake.The structural principle of the disc brake is shown in the figure. Using fluid to push the brake shoe axially towards the brake disc through the oil cylinder, causing friction and braking. Each set of brakes has four oil cylinders, which are uniformly controlled by a hydraulic system. This type of brake is commonly used for high-power, long-distance and strong belt conveyors and steel rope traction belt conveyors, and can be installed on high-speed shafts. This type of brake is characterized by high braking torque, good heat dissipation performance, adjustable oil pressure, and infinitely adjustable braking torque during operation.The selection of brakes should consider the following points:1. Mechanical operation status, calculate the load torque on the shaft, and have a certain safety reserve.2. The task of the brake shall be paid full attention to. It shall be selected according to different tasks. The brake torque supporting the brake must have sufficient reserves, that is, to ensure a certain Factor of safety. The mechanism with high safety requirements needs to be equipped with dual brakes.3. The brake should ensure good heat dissipation function to prevent harm to personnel, machinery, and the environment. When the conveyor is conveying upwards, it is necessary to prevent the conveyor belt from reversing during parking, and the braking at this time is generally referred to as backstop. When conveying downwards, it is necessary to prevent the conveyor belt from moving forward when parking, which is called braking. The conveyor should be designed with a braking device based on its working conditions. The braking force required for the transmission drum should be determined separately based on the conveyor's horizontal, upward, and downward movements.Electric hydraulic brakes YWZ5-200/23, YWZ5-200/23, YWZ5-250/23, YWZ5-250/23, YWZ5-315/23, YWZ5-315/30, YWZ5-315/50, WZ5-315/80, YWZ5-400/50, YWZ5-400/80, YWZ5-400/121, YWZ5-500/80, YWZ5-500/121, YWZ5-500/201, YWZ5-630/121, YWZ5-630/201, YWZ5-630/301, YWX5-710/201, WZ5-710/301YWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50; YWZ9-300/30; YWZ9-300/50; YWZ9-300/80; YWZ9-315/30; YWZ9-315/50; YWZ9-315/80; YWZ9-400/50; YWZ9-400/80; YWZ9-400/121; YWZ9-500/80; YWZ9-500/121; YWZ9-500/201; YWZ9-600/121; YWZ9-600/201; YWZ9-600/301; YWZ9-630/121; YWZ9-630/201; YWZ9-630/301; YWZ9-700/201; YWZ9-700/301; YWZ9-710/201; YWZ9-710/301; YWZ9-800/301/12YWZ9 explosion-proof 121 workshop diagram

time:2021-04-18

More

Tower crane is also called "tower crane" or "tower crane"; It is also called Tower crane because of its shape like an iron tower.The brake is a device that uses the Friction torque to reduce the speed of the moving parts of the machine or stop them from rotating.The conditions that the brake must meet:(1) Can generate sufficient braking torque.(2) Simple structure and compact appearance.(3) Braking is fast, smooth, and reliable.(4) The brake parts should have sufficient strength and stiffness, and the brake band and drum should have high wear resistance and heat resistance. (5) Convenient adjustment and maintenance.The brake is generally set on the shaft with higher rotational speed (low torque) in the mechanism to reduce the size of the brake.The specific classification is as follows:1) Friction brake can be divided into disc brake, external block brake, internal expansion shoe brake, belt brake, integrated belt brake, double shoe brake, multi shoe brake, simple belt brake, single disc brake, multi disc brake, fixed caliper brake, floating brake, etc. The brake wheel is connected to the shaft with a flat key, and a brake steel strip lined with rubber (or asbestos, leather, canvas) material is wrapped around its outer circumference. When the lever is subjected to external force, the brake band is tightened, and the braking of the shaft is achieved through the friction between the brake band and the brake wheel.3. Features: Simple structure, good braking effect, easy adjustment, uneven single wear, poor heat dissipationComposition of Tower crane: according to the function of each part, Tower crane can be divided into foundation, tower body, jacking, slewing, lifting, balance arm, boom, lifting trolley, tower top, cab, luffing and other parts. Among Overhead crane, the tower body is the body of the tower crane and also the part that is raised; The lifting part allows the tower crane to be raised; Rotation is to maintain the horizontal rotation of the upper body of the tower crane; The lifting mechanism is used to lift heavy objects; The balance arm maintains torque balance; The lifting arm frame is generally the load-bearing part of the lifting object; The trolley is used to install pulley blocks, steel ropes, and hooks, and is also the directly stressed part; The top of the tower is of course used to maintain the balance of force on the boom; The driver's cab is the place for operation; The amplitude change causes the car to move along the trackTower crane brake YWZ3 brake YWZ3B electric hydraulic block brake YWZ3 electric hydraulic push rod brake model parameter price manufacturer accessories brake shoeYWZ3-160/18, YWZ3-200/25, YWZ3-250/25, YWZ3-250/45, YWZ3-315/45, YWZ3-315/90, YWZ3-400/45, YWZ3-400/90, YWZ3-500/121. Environmental temperature -20 ℃~+50% (changed to YH-10 aviation hydraulic oil below the thruster) 2. Relative humidity of the air is not more than 90% 3. Generally used for three-phase AC power supply, 50HZ, 380V; 4. The sea height meets the GB755-87 standard; 5. In the absence of explosion hazards, and in the absence of gases and discharge dust in the medium that are sufficient to corrode metals and damage insulation; 6. YZW and YZW3 use the YTI series thrusters, which are generally suitable for vertical work with a tilt of no more than ± 15 °Technical Data, Outline Dimension Table (mm) V, YWZ3 Technical Data, Outline Dimension Table (mm) Braking Torque Newton · m 8 10 12.5 16-80 100 140-112 140 180-10 125 112 140 180 225 140 180 225 250 315 400 LModel YWZ3-160/18 YWZ3-160/25 YWZ3-200/18 YWZ3-200/25 YWZ3-250/25 YWZ3-250/45 YWZ3-315/45Z-Z9 series brake

time:2021-04-18

More

Special electric hydraulic brake for steel millsInstallation, commissioning and maintenance of electric hydraulic brakes:1. InstallationThe brake is installed on the machine after the brake wheel is installed. The brake wheel must be dynamically and statically balanced, with a surface roughness of not less than Ra l. 6 and a hardness of not less than HB=280. When installing and fixing the brake, attention should be paid to whether the brake shoe is parallel to the brake wheel when the brake is released; In the braking state, the brake pads should stick to the brake wheels. The non parallelism and inclination in the released state shall not exceed 0.1mm within the width of the brake wheel of 100mm. The working surface of the brake wheel must not have oil stains.2. Oil injectionBefore the test run of the electric hydraulic thruster, clean and free of any dirt and mechanical impurities hydraulic oil must be injected into the cylinder. Connect the hydraulic power supply and check if the impeller rotates flexibly, if the circular spring is stuck, and if the push rod and piston move up and down without any jamming.3. Adjustment of braking torqueBy adjusting the adjusting nut of the main spring and changing the compression length of the spring, the spring force and braking torque can be adjusted to ensure that the brake operates with as little braking torque as possible.4. Adjustment of the brake pad setback of the brakeDue to the brake's ability to automatically adjust clearance, as the brake pads wear, the clearance between the left brake pad and the brake pad can always remain unchanged, but the clearance between the right brake pad and the brake pad gradually increases with the wear of the brake pads. It is necessary to adjust it in a timely manner according to the situation to ensure that the distance between the two brake pads is basically uniform.5. Stroke adjustment of the thrusterThe smaller the working stroke of the electric hydraulic thruster, the more ideal it is to ensure that the brake shoe has less backlash. Therefore, it is necessary to adjust the height of the electric hydraulic thruster.Multiple disc drum brakes6. Inspection of brakesThe braking device should be regularly inspected. If used to start the equipment, the brake of the overweight mechanism should be inspected once per shift, and the motion mechanism should be inspected once every three days. Emphasis should be placed on checking whether there is any jamming at the hinge joint; Whether the brake components move normally: whether the electric hydraulic thruster moves normally; Whether there is any oil leakage or seepage phenomenon; Is the installation height of the thruster appropriate; Is the brake shoe correctly pressed against the brake wheel; Is the condition of the friction surface intact and free of oil and dirt.Widely used in steel, lifting, metallurgy, mining, ports, construction, and electricity, Main products in hydraulic machinery include: electric hydraulic block brake series YWZB YWZ3B YWZ4B YWZ5 YWZ8 YWZ9 YWZ12 YWZ13 YW YWL TYWZ2 YWP electromagnetic block brake JZ (TJ2A) MW (Z) ZWZA ZWZ2 ZWZ3A DCW3 electromagnetic failure protection disc brake 5SE 561SE 560SE 56SE DCPZ12.7 4SE 3SE ST1SE ST2SE 450SE hydraulic failure protection disc brake 5SH 4SH 3SH 450SH ST1SH ST2SH SH ST3SH ST4SH SB (YQP) SBDST5SH ST10SH ST16SH ST25SH ST25SH-A ST40SH 904SH SBB electric hydraulic arm disc brake YPZ2 Ⅰ, Ⅱ, Ⅲ YPZ2 Ⅳ, Ⅴ, Ⅵ pneumatic caliper disc brake QP12.7 5SP 4SP 3SP 450SP PD ADP60M-ADP61M-ADP62M hydraulic direct acting disc brake DADH75 ADH60 ADH90 ADH120 DADH80 DADH90 DADH120 DADH103 DADH195 electric hydraulic thruster YT1 Ed

time:2021-04-18

More

How to debug the torque of electric hydraulic brakesThe braking torque decreases and the braking slip increases.The mutual impact between the various parts of the brake intensifies.Delayed braking time, delayed braking action, and even accidents may occur. Some brakes may burn out the electromagnetic coil, while others may burn out the brake pads due to the inability of the brake to release.The brake pads gradually wear and become thinner during the use of the brake, and if the brake pads are too thin, the braking torque will decrease. Therefore, replace the brake pads before they become too thin. After replacement, it should be run repeatedly with no load to match the brake wheel. It is strictly prohibited to suddenly lift heavy objects before completing the running in. The brake pads wear quickly in the early stages of use, and during this period, they should be repaired and adjusted more frequently than usual.The brake refers to lifting the accelerator pedal without depressing the clutch, utilizing the compression resistance generated by the engine's compression stroke, internal friction, and intake and exhaust resistance to form a braking effect on the driving wheel. Jiaozuo brake industry benchmark, with high-quality, long service life, and good performance. Consultation on the price of electric hydraulic actuators. Jiaozuo brake - enterprise, electric hydraulic actuatorsNew YWZ9 Standard Drawing

time:2021-04-18

More

Ed301/12 thruster stroke 120mm voltage 380V power 550WAdditional device for electric hydraulic thruster C W D H S E1 E2 DB Exd l RMultiple thrusters

time:2021-04-18

More

Ed301/12 thruster stroke 120mm voltage 380V power 550WAdditional device for electric hydraulic thruster C W D H S E1 E2 DB Exd l RMultiple thrusters

time:2021-04-18

More

Imported industrial brakes are equally effective as domestic substitutesVarious non-standard customized industrial brakes, brake pads, brake discs, brake wheels, complete models, product quality assurance, lifelong maintenance

time:2021-04-18

More

Benchmark Route for Partner Evaluation in the Brake IndustrySpecial brakes for cranes, belt conveyors, winches, tower cranes, gantry cranes, and mining winches; Large ship mooring winch brake; Various models of crane ship brakes and engineering ship brakes; Windlass series brake; Ship guiding system; There are over 280 varieties of hydraulic rotary crane brakes, telescopic material cranes, and engine room cranes. Especially in the production and manufacturing of various non-standard large-tonnage winches (high-rise winches, suitable for construction of various skyscrapers), reducers, and mining, non-ferrous metal and other mining series winches, we have strong comprehensive strength and can meet the special requirements of various customers, processes, construction winches, product performance stability, lifting winches, reasonable structure, complete product specifications, and advanced design, Improved after-sales service, more reassuring when purchasing a winch, reliable operation, excellent products, and brakes for mining useLong term evaluation helps identify potential obstacles to reaching the baseline. Generally speaking, irregular inspections of the reasons for failure to achieve results can also help identify problems in the service delivery process, changes that must occur based on basic assumptions, and changes in product design. If a new brake manufacturer is in the early stages of providing products or services, then all these considerations are very correct.Only one partner has not reached the baseline, which does not mean that the brake contract cannot be signed again. But this indicates that it is indeed time to carefully examine why the baseline cannot be reached.Such partnerships may be similar to the work of venture capitalists and new entrepreneurial brake companies. Kristin Letz, William Ryan, and Alan Grossman wrote in their article "Charitable Capital: What Foundations Can Learn from Venture Capitalists":When venture capital and startup companies start building their relationships in financial and brake company projects, they act according to a set of performance evaluation standards. These evaluation criteria include cash flow, sales, profit, or market share, and are constantly updated to reflect the progress of the startup company and market conditions. Clear goals give investors and startup managers a clear positioning of their work relationships.Establish a baseline that can be regularly evaluated. In the initial stage, these benchmarks may need to be adjusted. However, having clear goals gives investors and startup managers a clear positioning of their work relationships. This is not to say 'they have no performance', but to say 'the project we are currently working on has not yet achieved results. Let's find the reasons and make corresponding adjustments'. If you remember this, partners have the opportunity to achieve the expected results.Partnership helps improve results and increase revenue. Brakes must consult with those who are greatly affected by the New Partnership and include them in the negotiation process. Their viewpoint is priceless, and their identification is absolutely necessary for the partnership to function.Create an environment that promotes communication and exchange. Keep your partner updated on new developments and establish a feedback mechanism. Partners must be responsible for achieving the expected goals. In today's era, the expectations of the non-profit sector mean effectiveness. Clearly understand the difference between activities and effects. The effect is a change in knowledge, attitude, behavior, or end user satisfaction with brake customers.SBD high-definition image

time:2021-04-18

More

Outline diagram and mechanism diagram of YWB electric hydraulic block brake. The braking principle is as follows: when the driving mechanism loses power or stops working, the electro-hydraulic thruster 2 (see Figure 1) also loses power at the same time or with a delay. At this time, the elastic force of the brake spring 4 is transmitted to the brake pad l3 and brake pad through the two brake arms l2 on both sides, generating friction and forming a braking torque, which plays a braking role. When the driving mechanism motor is energized, the thruster is energized in advance or simultaneously, generating sufficient force to lift the push rod and compress the brake spring in a very short time. The brake arm drives the brake pad to open outward, eliminating the braking torque.1. Base 2, Electro hydraulic thruster 3, Triangle plate 4, Brake spring 5, Torque adjusting nut 6, Tightening nut 7, Compensation tightening bolt, Nut 8, Pullout pin 9, Compensation sleeve 10, Brake rod l1, Anti loosening nut, Spacer sleeve, Spacer 12, Brake arm 13, Brake pad 14, Locking bolt, Nut 15, Return equal lever l6, Interlock pinThe connection dimensions and technical requirements of the YW and YWB series brakes comply with the JB/T6406-2006 standard, and the braking torque parameters comply with the DIN15435 standard; The YW series is equipped with YTD series thrusters that meet the JB/T10603-2006 standard; The YWB series is equipped with Ed series thrusters that meet the DIN15430 standard; This series is suitable for new designs and matching selection of new hosts.The connection dimensions and braking torque parameters of YWZ5 and YWZE series brakes comply with GB6333-86 standard, and the technical requirements comply with JB/T6406-2006 standard; The YWZ5 series is equipped with YTD series thrusters that comply with the JB/T10603-2006 standard; The YWZE series is equipped with Ed series thrusters that comply with the DIN15430 standard.The connection dimensions and braking torque parameters of YWZ6 and YWZF series brakes comply with JB/ZQ4388-86 standards, and the technical requirements comply with JB/T6406-2006 standards; The YWZ6 series is equipped with YTD series thrusters that comply with the JB/T10603-2006 standard; YWZF is equipped with Ed series thrusters that comply with DIN15430 standard; This series is suitable for replacing old products such as YWZ, JCZ, JWZ, and TJ2 series.

time:2021-04-18

More

Authentic Gold Hoop Brand Electric Hydraulic Pusher Ed-301/6Ed23/5 ed-30/5 ed50/6 ed80/6 ed-121/6 ed-201/6 ed-301/12Jiaozuo Jinhoo brand brake Jinhoo brand thruster is a registered trademark of Jiaozuo Brake Co., LtdSince its establishment, the company has been committed to the research and development of industrial brake actuators and the introduction of advanced foreign technologyGold hoop anti-counterfeiting image_ twenty million one hundred and eighty thousand three hundred and nine

time:2021-04-18

More

The function of the brake (1) Support function: to keep the original stationary object in a stationary state. For example, in a lifting mechanism, keep the lifting load stationary in the air; In the luffing mechanism of the boom crane, maintain the boom in a certain position and remain stationary; It plays a role in preventing wind and sliding for outdoor cranes. (2) Resting effect: It consumes the kinetic energy of the motion department, determines the cost of the hydraulic brake, and converts it into frictional heat energy through the friction pair, enabling the mechanism to quickly stop motion within a certain time or stroke. For example, the braking of various mechanisms in motion. (3) Falling weight effect: The balance between braking force and gravity causes the moving body to descend at a steady speedThe advantages of hydraulic braking are: short lag time (0.1-0.3 seconds);The working pressure is high (up to 10-20mpa), so the wheel cylinder size is small and can be installed inside the brake, directly serving as the opening mechanism of the brake shoe (or the pressing mechanism of the brake block), without the need for transmission components such as the brake arm, making it simple in structure and small in weight; Mechanical efficiency is high (hydraulic system has self-lubricating function). The main disadvantage of hydraulic braking is that after excessive heating, some of the brake fluid vaporizes, forming bubbles in the pipeline, seriously affecting hydraulic transmission, reducing the efficiency of the braking system, and even completely failing. Hydraulic braking is widely used in passenger cars and commercial vehicles with a small total mass. The 2.2 parking brake system is used to reliably and without time park the car in a certain position or even on a slope, and also helps the car start on a slope. The parking brake system should use a mechanical drive mechanism instead of hydraulic or pneumatic to avoid malfunctions. By analogy, manual parking brake lever and parking brake lever are applied to the rear wheels. Use both rear wheel brake and parking brake. Rear wheel parking brake: Wheel cylinder or wheel brake, (for the leading shoe brake, only an additional parking brake push rod and a parking lever are required) When using the parking brake, a person moves the parking brake control rod and controls the cable. The balance arm and pull rod (pull rope) pull the parking brake lever to open the two shoes. 2.3 The service braking system is used to force the vehicle to slow down or stop during driving, and to maintain an appropriate stable speed when going downhill on short slopes. Its driving mechanism often adopts a dual circuit or multi circuit structure to ensure its reliable operation. At present, disc brakes have been widely used in cars, but except for some Sports sedan that are used for all wheels, most of them are only used as front wheel brakes, and cooperate with the drum brakes of the rear wheels in order to have a higher directional stability when braking. On freight cars, disc brakes are also used, but they are far from being popularized. During the braking process of a four-wheel sedan, due to inertia, the load on the front wheels usually accounts for 70% -80% of the total load of the car. The braking force on the front wheels is greater than that on the rear wheels, and the rear wheels play an auxiliary braking role. Therefore, in order to save costs, car manufacturers adopt a braking method of front disc and rear drum. Chapter 3: Brake Manual KZP Self Cooling Disc Controllable Control Device? Suitable for controllable braking and parking of large electromechanical equipment, especially suitable for braking and parking of downward conveyor belts. The normally closed structure is suitable for various electromechanical equipment, making it an ideal supporting equipment for downward conveyor belts, Obtained national utility model patent (. Second Prize for Scientific Research Achievements in Shandong Province Universities, Third Prize for Science and Technology Progress of the Ministry of Coal, and Safety Mark Certificate. The main technical performance is to cooperate with the electric control device to maintain the deceleration of the belt conveyor during parking within the range of 0.05 to 0.3m/s2. When the control or drag system suddenly loses power, the traction motor exceeds speed, the conveyor belt slips, or other protective parking commands are issued, the braking device can safely and reliably brake 10 times per hour.) The surface temperature of the brake disc is much lower than 150? c. No sparks generated during braking? Convenient setting of large braking torque; Cooperating with the electric control device of the downward conveyor belt, it has controllable starting, overspeed, slip detection and protection functions when starting under load conditions; The hydraulic system adopts dual circuit explosion-proof electro-hydraulic proportional technology, which is easy to debug and install, and has high working reliability; Suitable for controllable braking of various belt conveyors; Suitable for ground and underground coal mines with coal dust, biogas, and explosive hazards.Explosion-proof hydraulic push rod brake, this product is an essential safety braking device for flammable and explosive mechanical driving equipment. It is widely used in dangerous places such as lifting, transportation, coal mines, metallurgy, mines, railways, ports, buildings, water conservancy and electricity, etc. It has the advantages of smooth braking, low power consumption, long service life, safety and reliability, and convenient maintenance. This product complies with relevant regulations in GB6333-86 Electric Hydraulic Block Brake and GB3836.1/2-2000 Electrical Equipment for Sexual Gas Environment. The explosion-proof signs are EX dIICT4 and EX dIIBT8, suitable for hazardous locations with gas mixtures in factories (coal mines). YWZ, YWZ2, YWZ3, YWZ4, YWZ5, YWZ6, YWZ8, YWZ9, YWZ10, YWZ13, YWL, and YW series electric hydraulic brakes use YT1 and YTD2 (ED) series thrusters as the driving devices for the brakes. The main loader manufacturers have modified their main engine braking system by adopting a fully hydraulic braking system. The principle is to use hydraulic oil as a medium, hydraulic brake price, and transmit braking force. The loader hydraulic system is used as its power oil source, and through hydraulic control components, the pressure oil is directly sent to the brake cylinder for braking, solving the above shortcomings of the pneumatic and hydraulic booster braking system, As the future development direction of wheeled engineering machinery braking systems, hydraulic brakes are currently an ideal substitute for pneumatic and pneumatic braking systems and components. The connection between the motor shaft and the impeller shaft is disconnected, resulting in the motor idling and the push rod not moving. This type of fault occurs frequently and is difficult to determine. The main cause of such failures is the detachment of the square coupling that connects the two shafts. The two ends of this type of coupling are respectively connected to the motor shaft and impeller shaft, but the fastening bolts at the connecting end of the motor shaft are easy to loosen. After it loosens, the square coupling will detach from the motor shaft, and the hydraulic brake model will cause the motor to idle and the push rod to not move. The main reason is that the fastening screws on the coupling are too small and only one screw is tightened unilaterally, with no anti loosening measures at the end of the screw. The brake is mainly used for the walking brake of the gantry crane. When the motor starts, the interaction between the inertia force of the load and the torque of the motor causes the relative rotation between the concave and convex spiral surfaces, generating axial displacement to open the friction pair and release the brake. The distance is opened through a limit device. When the motor is powered off, the force between the concave and convex spiral surfaces disappears, and the spring energy is released, causing the brake pair to fit and produce braking.It is both a brake and a coupling, with two-step braking and dynamic windproof characteristics. Dynamic wind protection refers to the situation where when the gust of wind reaches the driving force of the motor while walking along the wind, the force between the concave and convex spiral surfaces will disappear, and the spring will be released to form instant braking and opening. The driver will have an unstable feeling, prompting the driver to stop. After stopping, the safety will be ensured by the large braking force. The two-step braking inertia brake has the characteristics of low walking braking torque and high braking torque after stopping, which is generated by its structural characteristics.YWZ4 and YWZ images ST, SBD, SH images

time:2021-04-18

More

In port transportation, goods are piled up in large quantities, and to move them, a port crane needs to be used for work. However, the port is affected by the environment and the wind is strong. If the port crane wants to complete its work well, it needs to be fixed with windproof iron wedges to prevent the lifting equipment from collapsing and causing damage to the goods and innocent people during work.The use of windproof iron wedges is a new key mechanical basic component brake product developed according to the requirements of port lifting machinery. This product is a windproof device designed and innovated for the working state of cranes based on the digestion and absorption of foreign technology, and through structural innovation.When the windproof iron wedge is powered on, the electric hydraulic thruster acts, and its push rod quickly rises, and the iron wedge is lifted by a lever and transmission mechanism to ensure normal operation of the crane; When the power is cut off, the push rod of the thruster is under the action of spring force, and the iron wedge is placed on the track through a lever, which blocks the wheels in case of a sudden storm, providing safety protection. This product uses electric hydraulic thrusters and lever and connecting rod mechanisms to achieve action requirements, with a reasonable structure and reliable action. And the use of reasonably shaped iron wedges and high-strength, high hardness friction blocks ensures the overall operation.Brake manufacturer - Jiaozuo power brake

time:2021-04-16

More