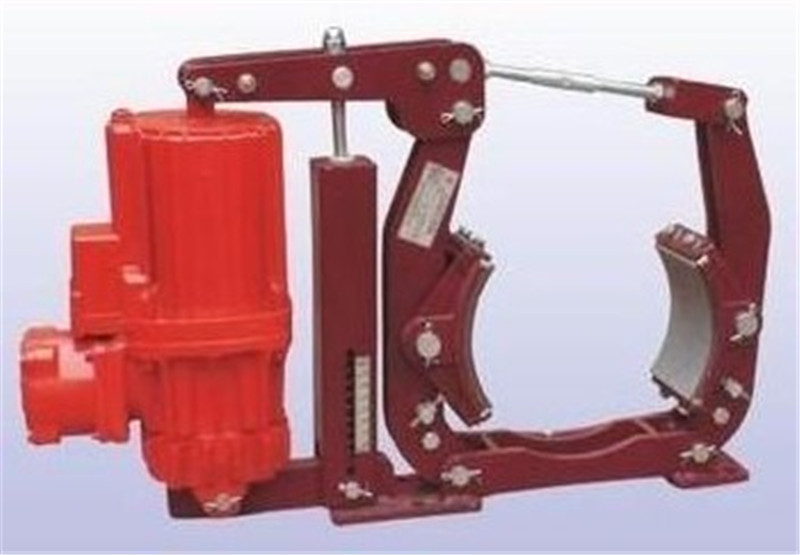

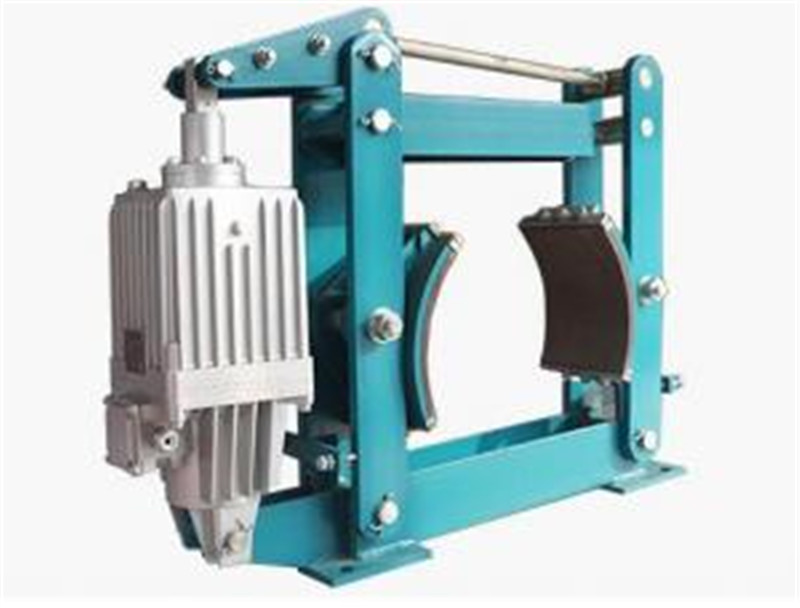

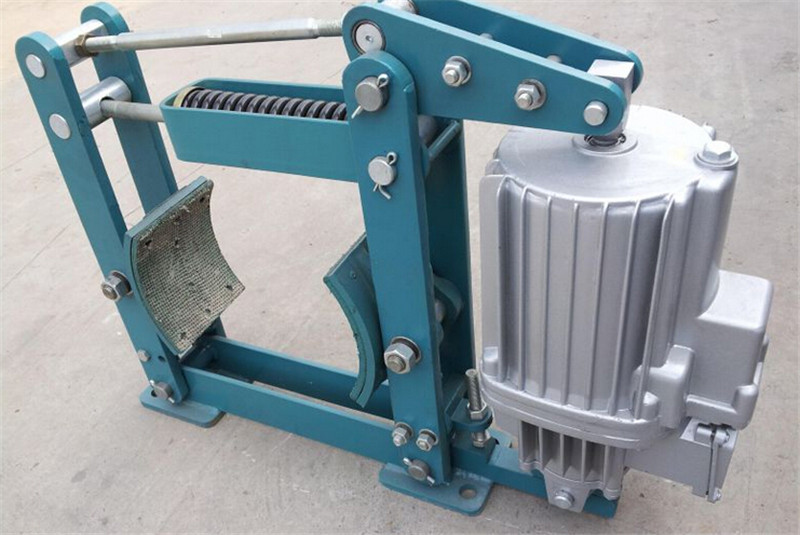

BYWZ5-400/E80 explosion-proof electric hydraulic brakeBYWZ5-400/80 explosion-proof brake | Voltage 660/1140 | Free installation guideElectric hydraulic block brakes: YWL series electric hydraulic block brakes, YWZ3B series electric hydraulic brakes, YWZ4B series electric hydraulic brakes, YWZ5 series electric hydraulic brakes, YWZ8 series electric hydraulic brakes, YWZ9 series electric hydraulic brakes, YWZ12 series electric hydraulic actuators, YWZ13 series electric hydraulic brakes, YWZB series electric hydraulic brakes, and YW series electric hydraulic brakes.Electric hydraulic thrusters: Ed series electric hydraulic thrusters, YT1 series electric hydraulic thrusters.Explosion proof electric hydraulic thruster: BEd series explosion-proof electric hydraulic thruster, BYT1 explosion-proof electric hydraulic thruster.Electromagnetic block brake: MW series electromagnetic block brakeElectric hydraulic arm disc brake: YPZ2 series electric hydraulic arm disc brake, YPZ3 series electric hydraulic arm disc brake.Pneumatic caliper disc brake: QP12.7 series pneumatic caliper disc brakeDC electromagnetic iron block brake: ZWZ series DC electromagnetic iron block brake, ZWZ3 series DC electromagnetic iron block brake, ZWZ3A DC electromagnetic iron block brake.Hydraulic wheel brake: YLBZ hydraulic wheel brakeEnergy saving electromagnetic block brake: JZ energy-saving electromagnetic block brakeAttention 16:14:01BEd series flameproof electric hydraulic thrusters (hereinafter referred to as "thrusters") are mainly used to operate electric hydraulic drum brakes and pumps, ratchets, valves, etc. They can also operate various forms of lever devices to make various movements, such as reciprocating, swinging, Circular motion motion, etc,This product complies with the technical requirements of the enterprise standard Q/JZHF01-2009 explosion-proof electric hydraulic thruster. The explosion-proof sign is "Exd I" and is suitable for electric hydraulic drum type coal mine belt conveyors (non mining working faces) and mine lifting equipmentElectric hydraulic thrusters for brakes.The thruster is an ideal component for achieving semi automation and automation of certain mechanical equipment. The piston rod adopts advanced protection, which can reduce wear and corrosion. The oil chamber of the hydraulic system with double-layer protective seal and double-layer sealing ring greatly improves the service life of the thruster. The thruster has the advantages of stable and noise free operation, low power consumption, long service life, and convenient maintenance.2. Working conditions2.1. The altitude shall not exceed 2000m.2.2. The ambient temperature is -20 ℃ to 40 ℃.2.3. The power supply is a three-phase AC power supply, with a rated frequency of 50Hz and a rated voltage of 380V/660V. The allowable voltage fluctuation is+10% to -25%2.4. The motor working system is S1 continuous working system or S3 intermittent cycle working system, and the load duration during intermittent cycle working system is not more than 60%.2.5. It is allowed to operate in environments with explosive gas mixtures of gas and coal dust. The working conditions should comply with the provisions of the "Coal Mine Safety Regulations" (2006).2.6. The thruster motor is of Class F insulation2.7. The relative humidity of the surrounding air shall not exceed 95%2.8. The pollution level of the surrounding environment is allowed to be level 3.3. Model Naming conventionBEd □/□ ()Voltage level, in volts (V)Rated travel codeThrust codeThe electric motor is a built-in explosion-proof electric hydraulic thruster4. Structure and working principle:The BEd series electric hydraulic thrusters are mainly composed of explosion-proof motors, intermediate flanges, impellers, complete sets of pistons, etc. Connect the power supply to the thruster, and the motor rotates to drive the impeller to generate pressure oil, pushing the piston and connecting rod upward. Maintain its thrust after reaching the predetermined stroke. When the power supply is disconnected, the motor and impeller stop rotating and no longer generate pressure oil. The piston and connecting rod return to their original position under external force. (See Figure 1)6. Installation adjustment and usage requirements6.1. Before installation, the following inspections must be carried out. If they do not meet the requirements, they are not allowed to be used.6.1.1 The thrust on the thruster nameplate should match the required thrust.6.1.2 There are explosion-proof signs and explosion-proof certificate numbers. Products used underground should have a "MA" mark6.1.3 The explosion-proof level and group of the thruster should meet the requirements for explosive mixture locations.6.1.4 All fastening bolts should be tightened, and all components of the explosion-proof enclosure should be properly connected.6.1.5 All explosion-proof parts should be free from cracks and defects that affect explosion-proof performance.6.1.6 The insulation resistance between the stator winding and the casing shall not be less than 0.38M (rated voltage 380V), 0.66M (rated voltage 660V), and 1.4M (rated voltage 1140V)6.2 Installation positionThe thruster is generally installed vertically (the motor should be located below), and can also be tilted or horizontally installed. However, it must be noted that when tilted or horizontally installed, the balance chamber should be facing upwards, and it must be ensured that the thruster can swing as a whole, and the piston rod is not allowed to bear radial force. Connect the upper and lower connecting holes of the thruster with the matching mechanism using a pin shaft, and add washers and split pins. The pusher linkage can rotate When the thruster is in operation, there should be a certain distance between the upper connecting rod and the upper edge of the cylinder block, which should generally not be less than 5mm.6.3 Electrical wiringWhen wiring, use the special wrench to remove the three bolts on the junction box cover, open the junction box cover, enter the cable into the junction box through the flameproof junction nozzle, and connect the three-phase power line (phase sequence is not required) and ground wire as required. Then install the junction box cover and tighten the bolts. The junction box should be kept clean and ensure that the sealing gasket is in the correct position and not damaged. The diameter of the motor cable should match the aperture of the rubber sealing ring. The large cross-section of the cable used is 4X4mm2, ensuring that there is no gap between the rubber ring and the motor outlet, otherwise the explosion-proof performance will be lost. When the sealing ring of the introduction device ages and deteriorates, it should be replaced in a timely manner, with a size of ¥ 16X ¥ 35X26 Before powering on, the three-phase balance of the power supply voltage and the range of voltage fluctuations should be checked to ensure compliance with international regulations.Do not open the cover with electricity!!!6.4. The internal and external grounding bolts should be reliably grounded.6.5. When the thruster leaves the factory, the working oil is already installed and can be used directly. Due to the decrease in oil, the technical value of the thruster may change, and even it cannot be started. Therefore, except for normal maintenance, it is not allowed to open the oil filling plug or overflow plug arbitrarilyAccording to user needs, the following additional functions can be installed:Before adjusting the time control valve, unscrew the blind plugs marked 'S' and' H ', and then rotate the adjusting screw to adjust the rising time and Fall time steplessly.Screw rotation (to the right)=increased travel timeScrew out (turning left)=reduced travel timeIt should be noted that the large adjustment amount is 20 revolutions, and the stroke time of the pusher equipped with a valve has been adjusted to 5 seconds at the factory. After adjustment, the blind plug should be tightened.The travel switch pusher can be equipped with a travel switch to indicate the position of the piston, and can be equipped with single or double travel switches.After the installation of the thruster is completed, it should be powered on and run several times. After checking for any abnormalities, it can be put into use.7. Use and Maintenance7. 1 Regularly check whether the thruster works normally. The inspection period can be set as shift inspection, daily inspection, etc. based on work conditionsCheck if the wiring is firm to prevent short circuits, open circuits, and burning of the motor caused by vibration.Check the oil every six months. When the oil deteriorates or gets mixed with debris, the oil should be changed. If the oil is insufficient, the oil should be replenished. Users can fill the oil from the oil filling plug, which should not exceed the position of the overflow plug. It should be noted that during the oil injection process, pull the push rod up and down several times to exhaust air and fill the oil chamber with oil.7.2 When the thruster is working, pay attention to whether the action is normal, whether there is oil leakage or oil seepage, and whether the oil tank has enough oil. If not, supplement it properly.7.3. When replacing and installing explosion-proof parts, attention should be paid to protecting the explosion-proof surface. All explosion-proof surfaces must not be damaged or rusted, and parts should be coated with 204-1 rust proof oil on the explosion-proof surface during installation.7.4. During the operation of the thruster, the allowable temperature of the bearing should not exceed 95 ℃ (thermometer method). The bearing should be inspected every six months and the lubricating grease should be replaced. Before replacement, it must be washed clean with gasoline, and the lubricating grease should be ZFG-2 composite calcium based grease.7.5. When the thruster is installed on the main engine and needs to be repainted, be careful not to paint the piston rod, otherwise it will damage its sealing.7.6. When the thruster is placed for more than one and a half years, it should be checked for oil leakage before use.8. Storage and transportation1. When storing thrusters, they should be kept dry to prevent moisture and sharp changes in ambient temperature.2. During transportation, it is necessary to prevent rain and not use a rope to cover the push rod for transportation.According to the temperature of the surrounding medium, it is recommended to choose hydraulic oil according to the following table:Surrounding medium temperatureRecommended oil (L-LH hydraulic oil)Executive standards-20 ℃~40 ℃DB-25 Transformer OilGB/T11118. 1-940~-20 ℃YH-10 aviation hydraulic oilGB/T11118. 1-94

time:2021-11-27

More

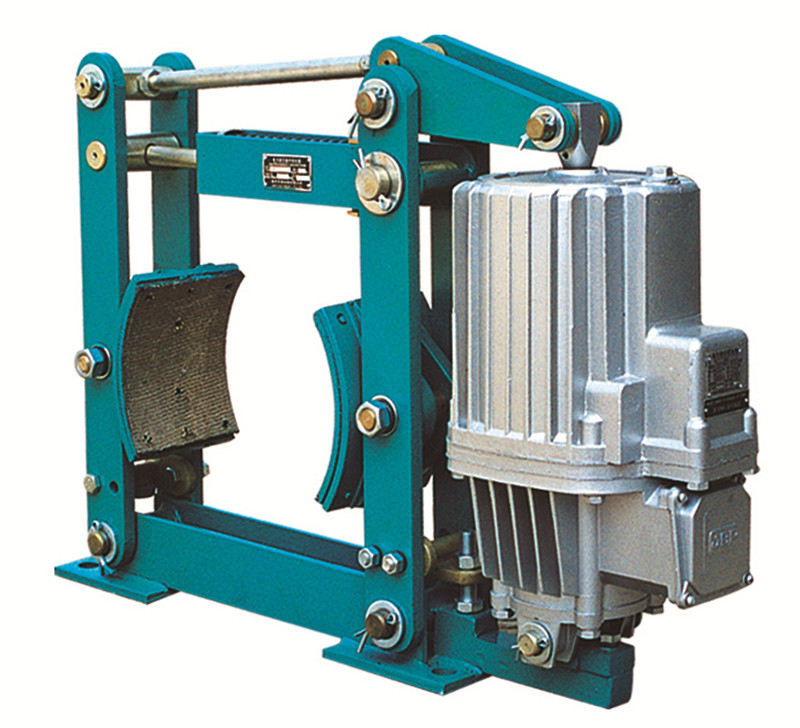

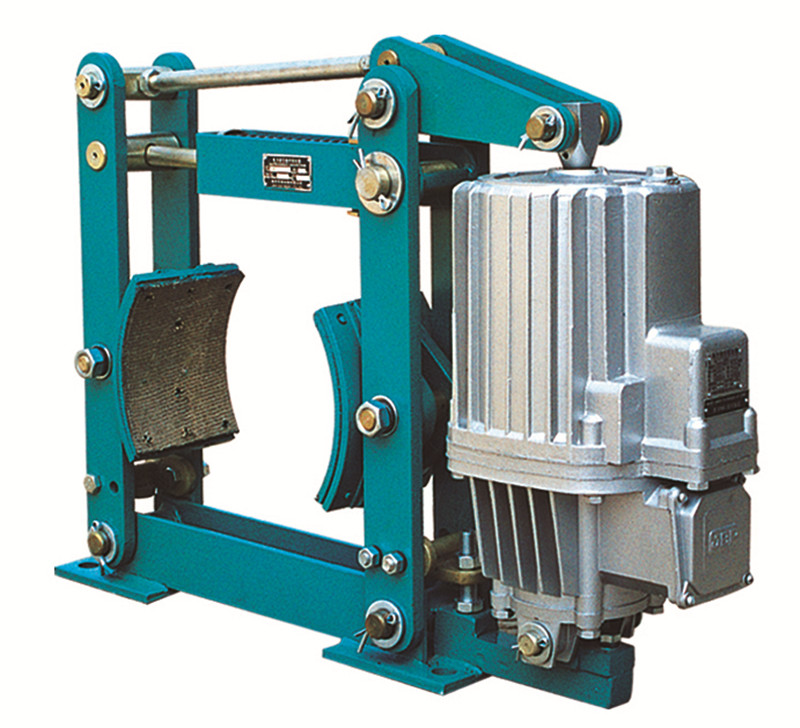

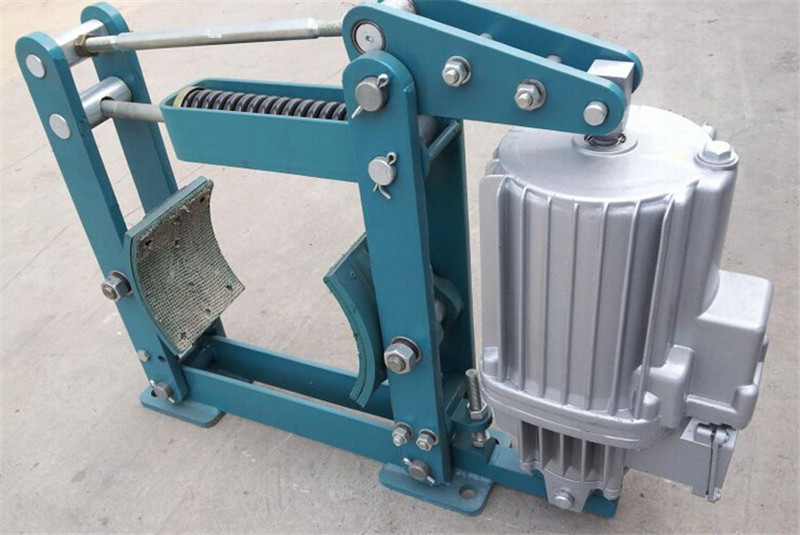

Method and steps for adjusting the service brakes:(1) Fill the brake master cylinder with brake fluid.(2) When pressing the brake pedal, the brake drum can just reach the point where it cannot be turned by hand.(3) Remove the brake shoe support pin nut, turn the mark on the brake shoe support pin towards the center of the brake drum, and then turn it in the opposite direction until the support pin cannot be turned with slight hand force. Repeat this process 2-3 times to tighten the nut.(4) Release the brake pedal and the brake drum should be able to rotate freely by hand. If it cannot be turned, loosen the nut again and gently rotate the shoe support pin in the relaxed direction until the drum can rotate freely, then lock the nut.(5) Adjust according to the process of adjusting the gap between the brake shoes and the brake drum.Brake modelYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesInstallation and adjustment of brakesBrake installation method:Vertical installation: Loosen nuts 4 and 5 to make the main spring in a free state, loosen nuts 6, rotate screw 7 to open the brake arm, and then fit the brake onto the spring seat of brake wheel adjuster 9.Horizontal installation: When the brake wheel is already installed between the motor and other components, loosen nuts 4, 5, 6, 7, and 8, turn the screw to remove screws 3 and 7, and lower the brake arm. Install from the side south onto the brake wheel.Brake adjustmentAdjustment of the working stroke of the thrusterUnder the condition of ensuring a small clearance of the brake shoe, the smaller the working stroke of the thruster, the more ideal it is. Therefore, it is necessary to adjust its installation height H1. The adjustment method is to loosen nuts 6 and 8 (as shown in the figure), and rotate screw 7 to ensure that the installation size of H1 meets the requirements of Table 1. After adjustment, tighten nuts 6 and 8.Adjustment of braking torqueLoosen nut 4, clamp the square head at the tail of the screw, turn nut 5 to make the square spring seat located within the marking line of the spring frame, and tighten nuts 4 and 5 after adjustment.Adjustment of brake shoe setbackWhen the brake shoe is opened, adjust bolt 1 to maintain a consistent distance on both sides.The nut for fixing the brake shoe (see figure) should be appropriately tightened to ensure that the brake shoe and brake wheel can be in place.Use and MaintenanceRegularly check the working condition of the brakes.During the inspection, the following items should be emphasized:Check whether the components of the brake can move normally and whether the adjusting nuts are fastened.Whether the components of the thruster are normal and whether the hydraulic oil is sufficient. Is there any oil leakage or seepage.

time:2021-11-27

More

Crane brake debugging1. InstallationThe brake is installed on the machine after the brake wheel is installed. The brake wheel must be dynamically and statically balanced, with a surface roughness of not less than Ra l. 6 and a hardness of not less than HB=280. When installing and fixing the brake, attention should be paid to whether the brake shoe is parallel to the brake wheel when the brake is released; In the braking state, the brake pads should stick to the brake wheels. The non parallelism and inclination in the released state shall not exceed 0.1mm within the width of the brake wheel of 100mm. The working surface of the brake wheel must not have oil stains.2. Oil injectionBefore the test run of the electric hydraulic thruster, clean and free of any dirt and mechanical impurities hydraulic oil must be injected into the cylinder. Connect the hydraulic power supply and check if the impeller rotates flexibly, if the circular spring is stuck, and if the push rod and piston move up and down without any jamming.3. Adjustment of braking torqueBy adjusting the adjusting nut of the main spring and changing the compression length of the spring, the spring force and braking torque can be adjusted to ensure that the brake operates with as little braking torque as possible.4. Adjustment of the brake pad setback of the brakeDue to the brake's ability to automatically adjust clearance, as the brake pads wear, the clearance between the left brake pad and the brake pad can always remain unchanged, but the clearance between the right brake pad and the brake pad gradually increases with the wear of the brake pads. It is necessary to adjust it in a timely manner according to the situation to ensure that the distance between the two brake pads is basically uniform.5. Stroke adjustment of the thrusterThe smaller the working stroke of the electric hydraulic thruster, the more ideal it is to ensure that the brake shoe has less backlash. Therefore, it is necessary to adjust the height of the electric hydraulic thruster.6. Inspection of brakesThe braking device should be regularly inspected. If used to start the equipment, the brake of the overweight mechanism should be inspected once per shift, and the motion mechanism should be inspected once every three days. Emphasis should be placed on checking whether there is any jamming at the hinge joint; Whether the brake components move normally: whether the electric hydraulic thruster moves normally; Whether there is any oil leakage or seepage phenomenon; Is the installation height of the thruster appropriate; Is the brake shoe correctly pressed against the brake wheel; Is the condition of the friction surface intact and free of oil and dirt.When the thickness of the brake pads is not reduced to half of the original thickness, the brakes can still operate normally. If the brake pads wear unevenly, the wear thickness should not be less than half of the original thickness, and the edge part should not be less than one-third of the original thickness.When the thickness is less than the above, it should be replaced in a timely manner. In addition, it is also necessary to check whether the distance between the brake shoe and the brake wheel is even; The spring pull plate is not allowed to be damaged or cracked.7. The following points should be noted during maintenance and inspection(1) Regularly observe the oil level of the electric hydraulic thruster cylinder, and add oil appropriately when it is insufficient. When changing the oil, unscrew the oil plug to drain the oil. If impurities are found in the oil, the machine should be cleaned and refueled separately.(2) The insulation of the incoming power line should be good.(3) The temperature of the brake wheel should not exceed 200 ℃. If there is a 0.5mm deep crack on the brake wheel, it should be re polished.(4) Before using the brake or after long-term shutdown, lubricating oil should be added to the axle pin, and regular lubrication should be noted. The brake cannot be used without repairing all defects.1、 Electric hydraulic block brake:YWZ4 series electric hydraulic block brake:YWZ4-100/18; YWZ4-150/25; YWZ4-160/25; YWZ4-200/25; YWZ4-200/45; YWZ4-300/25; YWZ4-300/45; YWZ4-300/90; YWZ4-400/45; YWZ4-400/90; YWZ4-400/125; YWZ4-500/90; YWZ4-500/125; YWZ4-500/180; YWZ4-600/180; YWZ4-700/180; YWZ4-800/180; YWZ4-800/320YWZ3B series electric hydraulic block brake:YWZ3B-160/18; YWZ3B-160/25; YWZ3B-200/18; YWZ3B-200/25; YWZ3B-250/25; YWZ3B-250/45; YWZ3B-315/25; YWZ3B-315/45; YWZ3B-315/90; YWZ3B-400/90; YWZ3B-400/125; YWZ3B-500/90; YWZ3B-500/125; YWZ3B-500/180; YWZ3B-630/125; YWZ3B-630/180; YWZ3B-630/320; YWZ3B-710/180; YWZ3B-710/320; YWZ3B-800/320YWZ4B series electric hydraulic block brake:YWZ4B-100/23; YWZ4B-150/23; YWZ4B-200/23; YWZ4B-200/30; YWZ4B-300/30; YWZ4B-300/50; YWZ4B-300/80; YWZ4B-400/50; YWZ4B-400/80; YWZ4B-400/121; YWZ4B-500/121; YWZ4B-600/121; YWZ4B-600/201; YWZ4B-700/201; YWZ4B-700/301; YWZ4B-800/301YWZ5 series electric hydraulic block brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50; YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201; YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12YWZ9 series electric hydraulic block brake:YWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50; YWZ9-300/30; YWZ9-300/50; YWZ9-300/80; YWZ9-315/30; YWZ9-315/50; YWZ9-315/80; YWZ9-400/50; YWZ9-400/80; YWZ9-400/121; YWZ9-500/80; YWZ9-500/121; YWZ9-500/201; YWZ9-600/121; YWZ9-600/201; YWZ9-600/301; YWZ9-630/121; YWZ9-630/201; YWZ9-630/301; YWZ9-700/201; YWZ9-700/301; YWZ9-710/201; YWZ9-710/301; YWZ9-800/301/12

time:2021-11-08

More

Model Selection of Electric Hydraulic Drum BrakesBrake specific model:YWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesYT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various brake wheels and discs, and customized non-standard brakes according to user needs1、 Electric hydraulic block brake:YWZ4 series electric hydraulic block brake:YWZ4-100/18; YWZ4-150/25; YWZ4-160/25; YWZ4-200/25; YWZ4-200/45; YWZ4-300/25; YWZ4-300/45; YWZ4-300/90; YWZ4-400/45; YWZ4-400/90; YWZ4-400/125; YWZ4-500/90; YWZ4-500/125; YWZ4-500/180; YWZ4-600/180; YWZ4-700/180; YWZ4-800/180; YWZ4-800/320YWZ3B series electric hydraulic block brake:YWZ3B-160/18; YWZ3B-160/25; YWZ3B-200/18; YWZ3B-200/25; YWZ3B-250/25; YWZ3B-250/45; YWZ3B-315/25; YWZ3B-315/45; YWZ3B-315/90; YWZ3B-400/90; YWZ3B-400/125; YWZ3B-500/90; YWZ3B-500/125; YWZ3B-500/180; YWZ3B-630/125; YWZ3B-630/180; YWZ3B-630/320; YWZ3B-710/180; YWZ3B-710/320; YWZ3B-800/320YWZ4B series electric hydraulic block brake:YWZ4B-100/23; YWZ4B-150/23; YWZ4B-200/23; YWZ4B-200/30; YWZ4B-300/30; YWZ4B-300/50; YWZ4B-300/80; YWZ4B-400/50; YWZ4B-400/80; YWZ4B-400/121; YWZ4B-500/121; YWZ4B-600/121; YWZ4B-600/201; YWZ4B-700/201; YWZ4B-700/301; YWZ4B-800/301YWZ5 series electric hydraulic block brake:YWZ5-160/23; YWZ5-200/23; YWZ5-200/30; YWZ5-250/23; YWZ5-250/30; YWZ5-250/50; YWZ5-315/23; YWZ5-315/30; YWZ5-315/50; YWZ5-315/80; YWZ5-400/50; YWZ5-400/80; YWZ5-400/121; YWZ5-500/80; YWZ5-500/121; YWZ5-500/201; YWZ5-630/121; YWZ5-630/201; YWZ5-630/301; YWZ5-710/201; YWZ5-710/301; YWZ5-800/301/12YWZ8 series electric hydraulic block brake:YWZ8-200/23; YWZ8-200/30; YWZ8-300/30; YWZ8-300/50; YWZ8-300/80; YWZ8-400/50; YWZ8-400/80; YWZ8-400/121; YWZ8-500/121; YWZ8-500/201; YWZ8-600/121; YWZ8-600/201; YWZ8-600/301; YWZ8-700/201; YWZ8-700/301; YWZ8-800/301/12YWZ9 series electric hydraulic block brake:YWZ9-200/23; YWZ9-200/30; YWZ9-250/23; YWZ9-250/30; YWZ9-250/50; YWZ9-300/30; YWZ9-300/50; YWZ9-300/80; YWZ9-315/30; YWZ9-315/50; YWZ9-315/80; YWZ9-400/50; YWZ9-400/80; YWZ9-400/121; YWZ9-500/80; YWZ9-500/121; YWZ9-500/201; YWZ9-600/121; YWZ9-600/201; YWZ9-600/301; YWZ9-630/121; YWZ9-630/201; YWZ9-630/301; YWZ9-700/201; YWZ9-700/301; YWZ9-710/201; YWZ9-710/301; YWZ9-800/301/12

time:2021-11-08

More

Electric hydraulic block brake: YWZB series electric hydraulic block brake:YWZB-100/18; YWZB-150/25; YWZB-160/25; YWZB-200/25; YWZB-200/45; YWZB-300/25; YWZB-300/45; YWZB-300/90; YWZB-400/45; YWZB-400/90; YWZB-400/125; YWZB-500/90; YWZB-500/125; YWZB-500/180; YWZB-600/180; YWZB-700/180; YWZB-800/180; YWZB-800/320YWZ4B series electric hydraulic block brake:YWZ4B-100/23; YWZ4B-150/23; YWZ4B-200/23; YWZ4B-200/30; YWZ4B-300/30; YWZ4B-300/50; YWZ4B-300/80; YWZ4B-400/50; YWZ4B-400/80; YWZ4B-400/121; YWZ4B-500/121; YWZ4B-600/121; YWZ4B-600/201; YWZ4B-700/201; YWZ4B-700/301; YWZ4B-800/301

time:2021-11-08

More

Jiaozuo explosion-proof brakes mainly produce electric hydraulic explosion-proof brakes BYWZ, BYWZ4, BYWZ5, BYWZ9, BYW, DYW and other series of explosion-proof brakes, as well as explosion-proof thrusters BYT1, BED, BYTD, BMYT1 and other series of explosion-proof thrustersBYT1 explosion-proof electric hydraulic actuator is a manufacturer of BYT1 explosion-proof electric hydraulic actuator in Henan.Price of explosion-proof thrusters, quotation of explosion-proof hydraulic thrusters, manufacturer of explosion-proof thrusters, manufacturer of Jiaozuo explosion-proof thrusters, low-priced supply of explosion-proof thrusters, and nationwide shipment of BYT1 explosion-proof electric hydraulic thrusters of various models.Welcome to inquire and order!Main products of the company:Electric hydraulic block brakes: YWL series electric hydraulic block brakes, YWZ3B series electric hydraulic brakes, YWZ4B series electric hydraulic brakes, YWZ5 series electric hydraulic brakes, YWZ8 series electric hydraulic brakes, YWZ9 series electric hydraulic brakes, YWZ12 series electric hydraulic actuators, YWZ13 series electric hydraulic brakes, YWZB series electric hydraulic brakes, and YW series electric hydraulic brakes.Electric hydraulic thrusters: Ed series electric hydraulic thrusters, YT1 series electric hydraulic thrusters.Explosion proof electric hydraulic thruster: BEd series explosion-proof electric hydraulic thruster, BYT1 explosion-proof electric hydraulic thruster.Electromagnetic block brake: MW series electromagnetic block brakeElectric hydraulic arm disc brake: YPZ2 series electric hydraulic arm disc brake, YPZ3 series electric hydraulic arm disc brake.Pneumatic caliper disc brake: QP12.7 series pneumatic caliper disc brakeDC electromagnetic iron block brake: ZWZ series DC electromagnetic iron block brake, ZWZ3 series DC electromagnetic iron block brake, ZWZ3A DC electromagnetic iron block brake.Hydraulic wheel brake: YLBZ hydraulic wheel brakeEnergy saving electromagnetic block brake: JZ energy-saving electromagnetic block brake

time:2021-11-08

More

Brake for DYW belt conveyorHigh quality DYW160/23, DYW200/30, DYW250/50, DYW315/50, DYW400/80, DYW500/121 and other explosion-proof electric hydraulic brakes have safe and reliable performance, stable braking, high action rate, and long service life.The DYW series belt conveyor uses electric hydraulic drum brakes, with installation dimensions and center height similar to the original BYWZ5, BYWZ9, BYWZ and other specifications of electric hydraulic drum brakes. The technical conditions comply with JB/T6046 and MT912-2002 standards, and the technical standards implemented are different. DYW implements the standards reviewed and determined by the National Mine Product Safety Mark Center of the Safety Standard, and not only does the booster have a coal mine safety certificate for flameproof, The complete explosion-proof brake also has a coal mine safety certificate. The BYWZ5 electric hydraulic drum brake is designed and manufactured based on technical data from German companies such as MAN and EMG. After localization, it is mainly used in lifting and transportation equipment and other institutions. The advantages of this brake are: fast braking, sensitive action, stable operation, high reliability, equipped with shaft sleeves for each joint, and long mechanical life. The disadvantages of this brake are: unequal braking distance, manual adjustment of braking force, and frequent manual maintenance. Telephone 13803910788, DYW is an upgraded or alternative product of BYWZ5 electric hydraulic drum brake. Its versatility and interchangeability are very good, and the safety dimensions and center height are the same as the original BYWZ5, BYWZ9, and BYW, making it unnecessary to make any adjustments on the main equipment during the update. Because it meets the safety requirements of the country for coal mining equipment (AQ1038-2011, MT1117-1995), it is aimed at working brakes for mining equipmentYWZ, YWZ3B, YWZ4B, YWZ5, YWZ8, YWZ9, YW and other series of electric hydraulic brakesED, YT1, YTD, MYT1 and other series of electric hydraulic thrusters

time:2021-11-08

More

China National Heavy Machinery Corporation Jiaozuo BrakeMain products:1. YWZB, YWZ3, YWZ4, YWZ5, YWZ8, YWZ9, YWZ10, YWZ12, YWZ13 series electric hydraulic pad brakes2. YW series electric hydraulic tile brake3. YWL series electric hydraulic tile brake4. EYWZ series two-stage hydraulic block brake5. TWZ (B) series normally open operated pad brake6. JZ, MW, MWZ, ZWZA, ZWZ3, ZWZ3A series electromagnetic pad brakes7. YPZ2 series electric hydraulic arm disc brake8. YFX series electric hydraulic windproof iron wedge brake9. YLBZ series hydraulic wheel edge brake10. ED, YT1 series electric hydraulic thrusters11. BED and BYT1 series explosion-proof electric hydraulic thrusters12. TYWZ series hydraulic tile brake13. DCPZ series electromagnetic caliper disc brake14. QP12.7 series pneumatic caliper disc brake15. TYWZ2 series foot hydraulic block brake16. SE, SH, SP series failure disc protection brakes17. SBD series hydraulic failure protection disc brake18. DYT series electric hydraulic push rod electric push rodOur company adheres to serving society with high-quality products and reasonable prices, promoting the spirit of diligence, dedication, and innovation, adhering to the sales philosophy of customers, grasping high service quality and customer-centric as the long-term development strategy of the enterprise, and striving to provide customers with fast service and more high-quality products.

time:2021-11-08

More

Explosion proof electric hydraulic thruster BEDJiaozuo explosion-proof thruster, Jiaozuo BED explosion-proof thruster manufacturer direct salesThe BED series explosion-proof electric hydraulic thrusters are mainly used as driving devices for electric hydraulic block brakes, and can also achieve rapid movements such as reciprocating, circular, and swinging through lever machinery. They are suitable for industries such as lifting, transportation, metallurgy, mining, ports, and construction. Its explosion-proof performance complies with the provisions of GB3836.2-2000 "Explosion proof Electrical Equipment for Explosive Atmospheres, Explosion proof Electrical Equipment" d ". The explosion-proof symbol is" Exd I ", and" Exd II BT4 "is used for underground coal mines and IIA, IIB temperature groups T1-T4 combustible gases or steam and explosive mixtures formed by airED series electric hydraulic thrusters:ED-23/5; ED-30/5; ED-50/6; ED-80/6; ED-121/6; ED-201/6; ED-301/6; ED-50/12; ED-80/12; ED-121/12; ED-201/12; ED-301/12; ED-630/12BED ED series electric hydraulic thrusters:BED30/5; BED50/6; BED80/6; BED121/6; BED201/6; BED301/6; BED50/12; BED80/12; BED121/12BED201/12; BED301/12; BED630/12BYT1-25/4, BYT1-45/6, BYT1-90/8, BYT1-125/10, BYT1-180/12YT1-25/4, YT1-45/6, YT1-90/8, YT1-125/10, YT1-180/12

time:2021-11-08

More

The adjustment of hydraulic brakes is fundamentally the same as the equipment method of electromagnetic brakes, but the following points should be noted:1) Under the condition of ensuring a small gap in the brake shoe, the smaller the working stroke of the push rod, the better. Therefore, the connecting rod can be used to adjust the push rod to make the equipment height comply with relevant rules.2) In order to ensure that the clearance between the brake pads can still be consistent when the brake pads are worn, the hydraulic electromagnetic brake is equipped with a compensation stroke device, which uses a connecting rod to adjust the distance between the end face of the push rod joint and the cylinder head. This value is called the compensation stroke of the compensation device, and it should comply with the rules.3) When the push rod rises to a high position, while ensuring a small gap in the brake shoe, adjust the limit screws of the pressure rod at both ends to ensure that the gap between the brake shoe and the brake wheel remains flat.4) The force distance of the hydraulic brake tension spring, equipment length, and equipment force should comply with relevant rules.5) The operating oil pressure of the hydraulic brake should meet the requirements of the drawing,. When there is no need for drawings, oil can be recommended according to the operating ambient temperature.Electric hydraulic brakeOur main products include YT1, ED, YTD.ED2, MYT1, MYT2 series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesQP, CQP, QPL series pneumatic caliper disc brake. DCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brake SH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brake SE series electromagnetic failure protection brakeYFX, YDGZ, YLBZ, series windproof brake SP series pneumatic failure protection brake, DP series motor disc brake DYT series electro-hydraulic thrusterCustomized various brake wheels and discs, and customized non-standard brakes according to user needs

time:2021-11-08

More

The YWZB electric hydraulic block brake adopts the Ed series thruster produced with imported German technology as the driving device, which has the advantages of multi-directional installation, high action frequency, stable braking, adjustable braking force distance, convenient and quick replacement of friction pads, long service life, and no noise. It operates 2000 times per hour, has an electrical insulation level of F, a protection level of IP 65, connection dimensions, and braking torque parameters according to GB6333-86 standard, (Equivalent to the German DIN15435-85 standard). The technical conditions comply with JB6406, 2-92 standards. Mainly used for lifting, transportation, metallurgy, mining, ports, construction and other mechanical driving supporting mechanical braking!·Safe and reliable use.·High action frequency, energy-saving.·Green and environmentally friendly, without asbestos pads.·Smooth braking without noise.·Equipped with lifting hook, manual release of brake, convenient maintenance·The main driving point is to install self-lubricating bearings and oil injection holes, which have high rotational efficiency and long service life.YWZ, YWZ2, YWZ3, YWZ4, YWZ5 and other series of hydraulic block brakes are mainly used for mechanical braking of driving devices in lifting, transportation, metallurgy, mining, port, and construction machinery. They have the advantages of smooth braking, safety and reliability, convenient maintenance, low power consumption, long service life, and no noise.① The YWZ series can operate up to 720 times per hour. Comply with JB/ZQ4388-86 standard;② The WYZ2 series can operate up to 1200 times per hour, meeting the JB/ZQ4388-86 standard;③ The YWZ3 series can operate up to 720 times per hour, meeting the GB6333-86 standard;④ The YWZ4 series can operate up to 1200 times per hour, meeting the JB/ZQ4388-86 standard;⑤ The YWZ5 series can operate up to 1200 times per hour, meeting the GB6333-86 standard;Specific model:YT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesYWZ, YWZ3, YWZ4, YWZ5, YWZ8, YWZ10, YWZ9, YWZ13, YW series electric hydraulic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof BrakesDP series motor disc brakeCustomized various brake wheels and discs, and customized non-standard brakes according to user needs.

time:2021-10-14

More

YWZ-100/18Hydraulic brakeYWZ4-100/23Hydraulic brake manufacturerYWZ-150/25Hydraulic brakeYWZ4-150/23Hydraulic brake manufacturerYWZ-200/25Hydraulic brakeYWZ4-150/30Hydraulic brake manufacturerYWZ-300/25Hydraulic brakeYWZ4-200/23Hydraulic brake manufacturerYWZ-300/45Hydraulic brakeYWZ4-200/30Hydraulic brake manufacturerYWZ-400/45Hydraulic brakeYWZ4-300/30Hydraulic brake manufacturerYWZ-400/90Hydraulic brakeYWZ4-300/50Hydraulic brake manufacturerYWZ-400/125Hydraulic brakeYWZ4-300/80Hydraulic brake manufacturerYWZ-500/90Hydraulic brakeYWZ4-400/50Hydraulic brake manufacturerYWZ-500/125Hydraulic brakeYWZ4-400/80Hydraulic brake manufacturerYWZ-600/125Hydraulic brakeYWZ4-400/121Hydraulic brake manufacturerYWZ-600/180Hydraulic brakeYWZ4-500/80Hydraulic brake manufacturerYWZ-700/180Hydraulic brakeYWZ4-500/121Hydraulic brake manufacturerYWZ-700/320Hydraulic brakeYWZ4-600/121Hydraulic brake manufacturerYWZ3-160/18Hydraulic brakeYWZ4-600/201Hydraulic brake manufacturerYWZ3-200/18Hydraulic brakeYWZ4-700/201Hydraulic brake manufacturerYWZ3-200/25Hydraulic brakeYWZ4-700/301Hydraulic brake manufacturerYWZ3-250/25Hydraulic brakeYWZ4-100/D23Hydraulic brake manufacturerYWZ3-250/45Hydraulic brakeYWZ4-150/D23Hydraulic brake manufacturerYWZ3-300/45Hydraulic brakeHydraulic brake manufacturerYWZ, YWZ2, YWZ3, YWZ4, YWZ5 and other series of hydraulic block brakes are mainly used for mechanical braking of driving devices in lifting, transportation, metallurgy, mining, port, and construction machinery. They have the advantages of smooth braking, safety and reliability, convenient maintenance, low power consumption, long service life, and no noise.① The WYZ series can operate up to 720 times per hour. Comply with JB/ZQ4388-86 standard;② The WYZ2 series can operate up to 1200 times per hour, meeting the JB/ZQ4388-86 standard;③ The YWZ3 series can operate up to 720 times per hour, meeting the GB6333-86 standard;④ The YWZ4 series can operate up to 1200 times per hour, meeting the JB/ZQ4388-86 standard;⑤ The YWZ5 series can operate up to 1200 times per hour, meeting the GB6333-86 standard;

time:2021-10-14

More