Generally, there are some signs of brake failure before it occurs, such as shaking of the steering wheel during braking or a fine scream during braking. This all reflects a problem with the brake system, and it is time to replace or repair the brake discs or pads. Because the brake disc is damaged, it will cause uneven force on the brake disc during braking, causing the steering wheel to shake. A very thin and sharp metal friction sound is emitted, indicating that the brake pads have been worn very thin and need to be replaced in a timely mannerSafety principle. When selecting a crane brake, the key consideration is whether the brake is safe enough in practical application, analyzing the actual application performance of the crane brake, and ensuring that the brake is safe and reliable enough in practical application. Due to the large workload of cranes and their ability to carry large loads, there are requirements for the construction materials of crane brakes. It is necessary to focus on the stiffness and safety of the brake materials. If conditions permit, performance testing is required, especially for some core components in the brakes. It is necessary to ensure that all components comply with national regulations and standards, such as brake rods, brake arms, springs, etc. For more details, please follow "KTPM Lean Management Xinyi Consulting" on WeChatAdaptability principle. For the crane brake, as the core component of the crane, the brake has a direct or indirect connection with other components. Therefore, it is necessary to focus on analyzing the compatibility between the crane brake and other components. In the process of selecting brakes, it is necessary to fully consider the matching issues between various systems in the crane, whether the brakes meet the adaptation standards, including the performance of each system and the application environmentHydraulic caliper disc brake:SB (YQP) 50; SB (YQP) 100; SB (YQP) 160; SB (YQP) 250; SB (YQP) 315; SB (YQP) 400;SBD safety brake:SBD100-A; SBD125-A; SBD160-A; SBD200-A; SBD250-A; SBD-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD80-B; SBD160-B; SBD250-C; SBD365-C; SBD425-C; SBD120-D; SBD240-DSBD high-definition image

time:2021-05-26

More

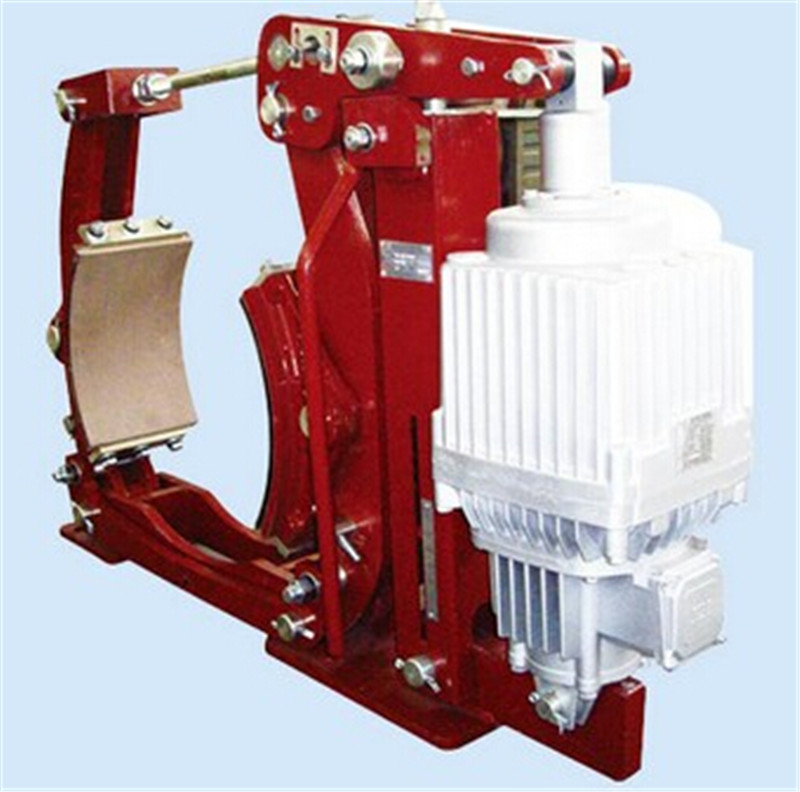

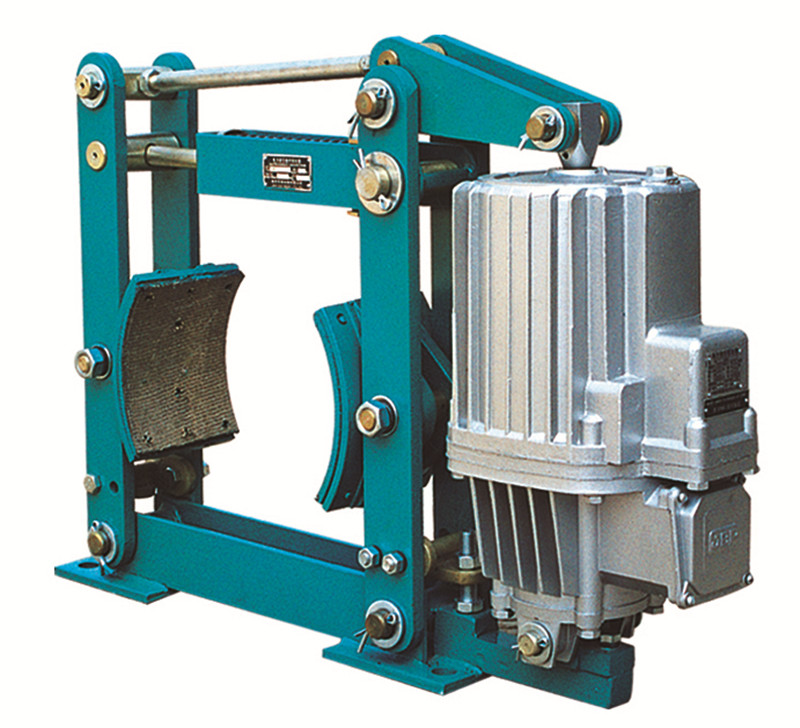

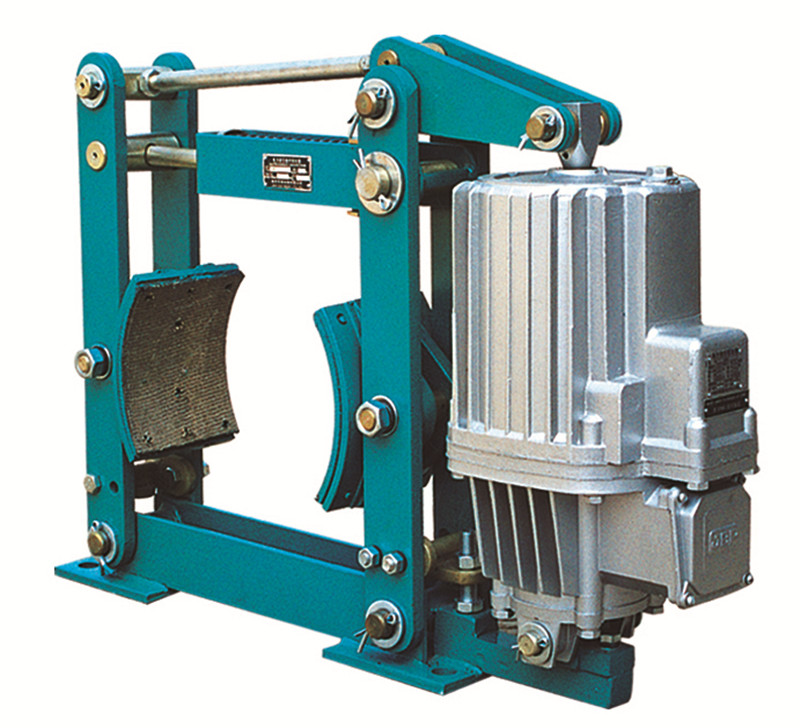

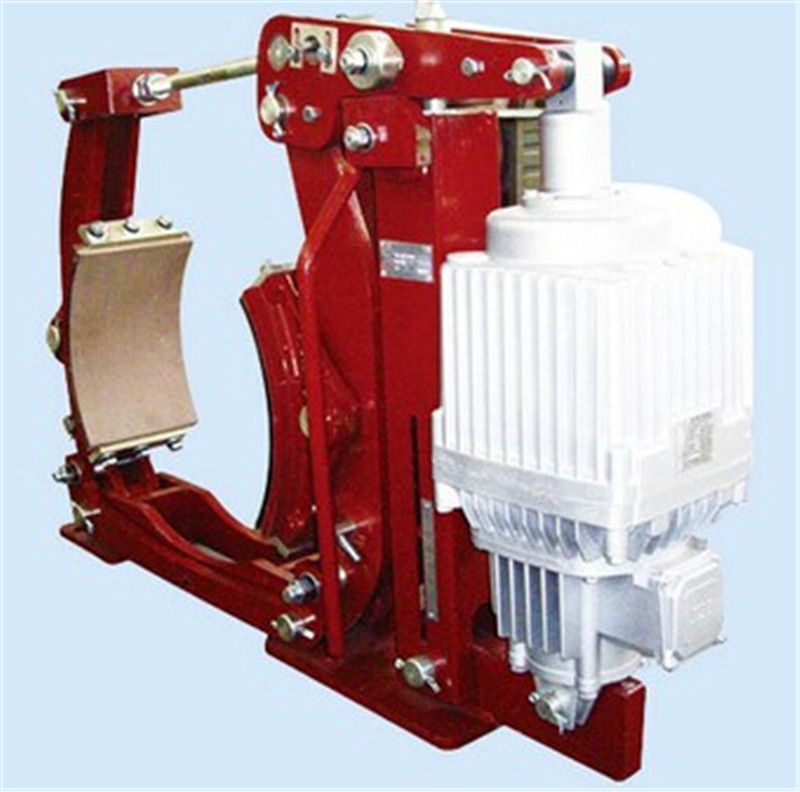

YPZ2 series electric hydraulic arm disc brake padsElectric hydraulic arm disc brake consists of electric hydraulic thruster and block brake frame. It involves mechanical, Fluid mechanics, hydraulic, electromagnetic and other disciplines. Its working principle is to convert the electrical energy of the driving device into mechanical energy, and through the rotation of the impeller, the liquid flow in the cylinder forms a high and low pressure chamber to push the piston upward, thereby transforming the vertical movement into left and right swing of the brake arm through the lever mechanism, and completing the brake release. The main auxiliary function of the product is the automatic equalizing device for backtracking. The technical working principle is to rigidly connect the equidistant device to the brake arm, and maintain the automatic equalizing of backtracking on both sides when the brake arm is opened through the transmission pairs of the left and right connecting plates. The technical research results of this project carried out by our company are at the domestic advanced level, especially in the key technical indicators of temperature rise and rise and fall time. The product has the advantages of light weight, low noise, good heat dissipation performance, stable work quality, and reasonable price. As a very important safety control device, it is widely used in lifting, metallurgy, mining, ports, construction and other machineryYPZ2 series electric hydraulic arm disc brake: YPZ2-315I/23; YPZ2-315I/30; YPZ2-315I/50; YPZ2-315I/80; YPZ2-355I/23; YPZ2-355I/30; YPZ2-355I/50; YPZ2-355I/80; YPZ2-400I/30; YPZ2-400I/50; YPZ2-400I/80; YPZ2-450I/50; YPZ2-450I/80; YPZ2-450/50; YPZ2-450/121; YPZ2-450/201; YPZ2-500/50; YPZ2-500/80; YPZ2-500/121; YPZ2-500/201; YPZ2-560/50; YPZ2-560/80; YPZ2-560/121; YPZ2-560/201; YPZ2-630/80; YPZ2-630/121; YPZ2-630/201; YPZ2-710/121; YPZ2-710/201; YPZ2-630/201; YPZ2-630/301; YPZ2-710/201; YPZ2-710/301; YPZ2-800/201; YPZ2-800/301; YPZ2-900/201; YPZ2-900/301; YPZ2-1000/201; YPZ2-1000/301; YPZ2-1250/201; YPZ2-1250/301YPZ2I II III electric hydraulic arm disc brake: service conditions: QP25.4-D pneumatic caliper disc brake; ambient temperature: -20 ° C~~50 ° C; The relative humidity of the air shall not be less than 90%; Frequently used for three-phase AC power supply 50HZ, 380V; The altitude meets the GB755-2000 standard, and when it is below -20 °, the working oil of the thruster is changed to YH-10 aviation hydraulic oil. Outdoor rain and snow erosion or corrosive gases and media should use anti-corrosion products. Friction pad refers to the friction material pushed and squeezed onto the brake disc by the clamp piston. The friction pad is divided into friction material and base plate, both of which are directly pressed together. The outer radius of the friction pad is only equal to the inner radius, indicating that the ratio of the outer radius to the inner radius of the friction pad is not higher than 1.5. If this ratio is too high, there will be a significant difference in circumferential velocity between the outer edge and inner side of the pad during operation, resulting in uneven friction damage and a ring to ring ratio of contact area, ultimately leading to a significant change in braking torque. The second initial pioneer applied his experience and knowledge of airships to create a twin engine with steel shafts and aluminum blades as his 14 propellers. Some of his research and development used curved aluminum plates for blades, resulting in airfoil shapesWhen replacing the friction plate, it is necessary to remove the entire brake. After replacing the friction plate, reinstalling it is very inconvenient. Especially for fans above 1.5MW, large sized yaw brakes are installed, usually weighing over 200 kilograms, with a total of 12 installation bolts, each with a tightening torque of over 2000 Nm. In addition, the space inside the fan compartment is very small, making it difficult to replace (if the time to remove or tighten a bolt is calculated as 5-6 minutes, the time to remove and tighten a dozen bolts alone would take two to three hours). The maintenance workload and cost of the owner have greatly increased.2. The gap between the friction plate and the brake body cannot be adjusted. As the friction plate wears, the gap between the friction plate and the brake body gradually increases over time. At this point, the piston sealing ring will be subjected to tangential force, which will affect the service life of the sealing ring and increase the possibility of oil leakageImplement the GB/T19001ISO9000 series standards, improve and improve the quality management system, and ensure timely provision of safe and reliable products according to national and industry standards to users;2. Strictly implement the "Three Guarantees" policy. During the "Three Guarantees" period, any product quality issues are guaranteed to be repaired, replaced, or returned. Beyond the "three guarantees" period, we guarantee to provide maintenance accessories and provide good service work

time:2021-05-26

More

Hydraulic brakes are important components in vehicles, and there are many things to pay attention to when replacing or adding brake fluid. However, most people are not familiar with them. Therefore, today we will learn about the precautions that hydraulic brakes must pay attention to when changing brake fluid.When adding or replacing brake fluid for hydraulic brakes, it is necessary to strictly follow the original vehicle's specified model of brake fluid filling. If it is necessary to replace another model of brake fluid, the grade of the original and new brake fluid must be identified first, and whether the oil resistant rubber seal needs to be replaced.Secondly, before replacing the brake fluid, it is necessary to drain the brake fluid from the original vehicle's brake system and clean it with alcohol before refilling with new brake fluid. It is necessary to prevent different types of brake fluid from being mixed and injected into the braking system for use, and hydraulic brakes should be used to prevent brake failure. Under the current policy system, in addition to subsidies for investment in power transmission and operation maintenance costs specifically incurred for the development of renewable energy such as wind power, there is no corresponding cost accounting and compensation mechanism established for the increased system management and operation costs of the power system due to the development of renewable energy. In the absence of separation of transmission and distribution and liberalization of power trading, it is also impossible to achieve the necessary accounting and compensation, making it difficult for wind power consumption It is not surprising that wind and electricity restrictions have emerged.The structure of the hydraulic disc brake is shown in. It mainly consists of brake discs, brake pads, brake calipers, oil pipes, brake main oil pumps, and other components. Its working principle is that when gripping the brake handle (or stepping on the brake pedal), the plunger in the main oil pump moves, pushing hydraulic oil along the oil pipe into the oil cylinder in the brake caliper. Under the action of hydraulic oil, the piston in the oil cylinder pushes the brake block closer to the brake disc until it tightly clamps the brake disc, generating significant frictional resistance, forcing the wheels to stop rotating, achieving the goal of parking or decelerating. When releasing the brake handle (or brake pedal), the pressure of the hydraulic oil in the oil circuit quickly drops to zero, and the piston drives the brake block to return to its original position, releasing the brakeThe main reasons for the occurrence of wind power abandonment and power rationing are the misalignment of wind power production and consumption regions in China, as well as the slower growth rate of electricity consumption compared to the growth rate of electricity installation. Ultimately, it is still the insufficient demand for wind power in China.Almost all hydraulic brakes used in metallurgy are friction brakes, which rely on the friction between fixed and rotating components to effectively control mechanical slip and reduce the inertia caused by friction in mechanical brakingAccording to China's 13th Five Year Plan for the Development of National Strategic Emerging Industries, in terms of demand, China will focus on promoting the development of green energy networks that integrate energy storage facilities, the Internet of Things, smart power facilities and other hardware, as well as Carbon emission trading, Internet finance and other derivative services, promote the development of smart energy use at the user end, energy Sharing economy and free energy trade, and foster new businesses and new formats based on smart energy, Building a new energy consumption ecosystem and industrial system.With the development of the Internet of Things and Energy storage, it is believed that the problem of wind curtailment and power rationing will be solvedDuring the driving process, the service brake (foot brake) is generally used to facilitate deceleration and parking during the forward process. The parking brake is not only used to keep the car stationary, but can also be used when the service brake fails. When the car comes to a stable stop, the parking brake (handbrake) should be used to prevent the vehicle from slipping forward and backward. After parking, in addition to using the parking brake, for manual transmission models, when parking uphill, try to shift the gear to first gear (to prevent backward sliding), and when parking downhill, try to shift the gear to reverse gear (to prevent forward sliding). Service brake refers to the foot brake (foot brake). Another brake is the parking brakeHydraulic brake is a type of hydraulic braking device, and its maintenance process has strict requirements. Below, we will introduce its maintenance requirements.(1) When the wear of the brake shoe exceeds the limit and there is friction between the rivet and the brake wheel, the brake shoe should be replaced.(2) Check the wear of each hinge joint pin and pin hole. If the wear exceeds the standard, it should be replaced.(3) Regularly add oil to each hinge joint to ensure smooth movement and no jamming.(4) Regularly inspect and adjust the adjustment bolts of the brake upper pull rod to ensure that the clearance and tension of the brake shoe during opening and braking are within the specified range.(5) The brake oil cylinder should maintain sufficient oil level, and its oil pressure should reach 0.9MPa without any oil leakage or seepage.(6) Hydraulic brake shoes (also known as brake bands) should not come into contact with oil, especially the friction brake surface should be free of oil stains.(7) When the hydraulic brake is opened, the gap between the brake shoe and the brake wheel should be kept between 0.8-1mm.The main product series include: electric hydraulic arm disc brake, pneumatic disc brake, hydraulic failure protection brake, electromagnetic failure protection brake, wheel edge brake, electric hydraulic wind proof iron wedge brake, ZWZ3 series electromagnetic DC drum brake, YWZB series electric hydraulic drum brake, YWZ3B series electric hydraulic drum brake, YWZ4 series electric hydraulic drum brake, YWZ5 series electric hydraulic drum brake, YWZ8 series electric hydraulic drum brake, YWZ9 series electric hydraulic drum brake, YWZ10 series electric hydraulic drum brake, YWZ13 series electric hydraulic drum brake, YWL series electric hydraulic drum brake, YWP series electric hydraulic drum brake, YW-E series electric hydraulic two-stage drum brake, YW series electric hydraulic drum brake, YW series pneumatic drum brake, ED series electric hydraulic thruster, YT1 series electric hydraulic thrusters, BED series electric hydraulic thrusters, BYT1 series electric hydraulic thrusters, with an annual production capacity of 60000 sets.Our company is a member unit of the Transmission Parts Industry Association and the Construction Machinery Industry Association; Continuously obtained the "Quality Certification" certificate issued by the National Center for Quality Supervision, Inspection and Testing of Lifting and Transportation Machinery Products from 1999 to 2003; In October 2002, it passed the ISO: 9000 and GB/T19001-2000 Quality Management Systems certification by the China Fangyuan Certification Committee; Obtained the "Special Equipment Type Test Certificate" and the title of Henan Provincial Excellent in 2004; Obtained the ED series explosion-proof certificate and mining product safety label certificate in 2006; Obtained the YT1 series explosion-proof certificate and mining product safety label certificate in 2007; In 2008, it was the first in the industry to obtain a production license for explosion-proof products. In 2011, the company's product trademark was awarded the Henan Province Famous Brand Trademark. Advanced technology, equipment, strong technical force, perfect testing methods, strict quality assurance system, reasonable product prices, and reputation are the strong guarantees for our products to enter the market and win users. Our company is willing to provide you with high-quality products and services.Actual drawing of YWZ9-200 workshop

time:2021-05-26

More

The company mainly produces:Electric hydraulic block brake, electric hydraulic thruster, explosion-proof electric hydraulic thruster, explosion-proof electric hydraulic brake, electromagnetic power loss brake, electromagnetic power on brake, motor brake, electromagnetic brake, wind power yaw brake, hydraulic direct disc brake, yaw brake pad, PZ series disc brake, QP12.7 series disc brake, wind iron wedge series brake, wind power generator brake Wind power brake friction lining, disc brake lining, hydraulic failure protection disc brake, pneumatic failure protection disc brake, electric failure protection disc brake, explosion-proof brake, YT series thruster, ED series thruster, explosion-proof thruster and other series of products are developed, manufactured, sold and served as a chemical industrial brake manufacturer. Electric hydraulic double caliper disc brake pads YP11, YP21, YP31, YP41 Electric hydraulic double caliper disc brake padsThe disc brake system of the brake factory mainly consists of mechanical disc brakes and hydraulic control stations. Its working principle is to generate braking torque by applying frictional braking force to the brake disc through the brake. The hydraulic station can adjust the size of the oil pressure in the brake and the positive pressure of the brake, thereby adjusting the size of the braking torque. The hydraulic station adopts electro-hydraulic proportional control technology, which has advantages such as high braking torque, sensitive action, good heat dissipation performance, and convenient use and maintenance. When the ambient temperature of the disc brake reaches 40 ℃, brake for 10 times/h, and the high temperature of the disc surface is far less than 150 ℃, so no spark will be generated. It meets the requirements for safe use in mines.The company produces dozens of series, more than 800 varieties and specifications, and various non-standard products, such as electric hydraulic block brake, electromagnetic block brake, hydraulic, electromagnetic, pneumatic caliper disc brake, hydraulic wind proof iron wedge brake, electro-hydraulic push rod, electric hydraulic thruster, etc., with the advantages of smooth braking, safety and reliability, easy maintenance, low power consumption, long life, no noise, high frequency, etcThere are many types of disc brake. According to the brake type, the service brake is usually used as the foot brake of the car, while the parking brake is used as the hand brake of the car. Our common service brakes are bicycles and motorcycles. These two wheeled vehicles, whether they are handbrake or foot brake, are all service brakes. The reasons for brake failure without a parking brake are as follows:(1) The disc brake control mechanism is improperly adjusted. After applying braking force, the brake cam of the drum brake does not rotate properly, and the angle of the brake shoe opening is not large enough to tightly press the friction plate onto the inner surface of the brake drum, resulting in brake failure; Or the plunger valve stroke of the disc brake is not enough, and the brake pad cannot clamp the brake disc, which makes the brake system lose its function.(2) Wear of friction plates (or brake pads). Due to prolonged use of the brake, especially during continuous downhill operations, the surface temperature of the friction plate can rise, leading to phenomena such as erosion, aging, or severe wear, resulting in a significant decrease in the friction coefficient and an impact on braking performance.(3) There is oil and water in the brake. If the wheel bearing is filled with too much lubricating grease, it will leak into the brake drum when the seal is worn or damaged after melting at high temperature. Make the friction surface slip. When the motorcycle is wading or washed with water, if there is water in the brake, it will also slip, leading to brake failure.(4) The friction plate of disc brake falls off. The friction plate and brake shoe are generally bonded together with adhesive (also fixed with rivets) and cured at a certain constant temperature. If the adhesion is not firm or due to wear, the friction plate may partially or completely detach from the brake shoe, causing brake failure.

time:2021-05-23

MoreWhat is a disc hydraulic brake? The disc hydraulic brake is controlled by hydraulic pressure, and its main components include brake discs, wheel cylinders, brake calipers, oil pipes, etc. The disc brake is characterized by simple structure, convenient adjustment, good high temperature resistance, fast heat dissipation, light weight but stable braking effect. After the cylinder oil pipe joint of the disc hydraulic brake is removed, air will enter the oil pipe and wheel cylinder. After reinstallation, there will be air in the braking system, causing the braking effect to fail. Therefore, after the joint is removed, the air must be discharged before it can be used normally. So how to bleed the disc hydraulic brake? What are the methods? The editor is here to answer everyone's questions one by one:The method for bleeding the disc hydraulic brake is:1. Add sufficient hydraulic oil to the main cylinder, grip the brake grip tightly, allow the air to exhaust, and then immediately connect the connector to the wheel cylinder.2. Firmly grip the handle of the disc electric hydraulic brake to generate oil pressure in the master cylinder, then loosen the bleed screw to release the air.3. When no more bubbles are generated at the bleed screw, immediately tighten the bleed screw, loosen the brake grip, and allow the master cylinder to return oil.4. Repeat the second and third steps multiple times until the air is completely discharged. The action during bleeding must be coordinated to avoid operational errors that may cause air to enter the hydraulic system, causing the work to start over. It is also important to note that during the bleeding process, the hydraulic oil should be adjusted to the master cylinder at any time. The brake caliper is fixed together with the front fork guide column and is a fixed part of the braking device. The hydraulic brake disc is fixed to the wheel and rotates with the wheel. When holding the handlebar tightly, push the piston to move. Because of the non Compressibility of the brake fluid, the piston pushes the oil in the master cylinder to flow into the cylinder of the slave cylinder along the hose, and pushes the piston and friction plate to clamp the brake disc from both sides, producing great friction resistance, forcing the wheels to stop rotating, so as to achieve the purpose of deceleration or parking. Release the brake handle, and the return spring inside the master cylinder pushes the plunger back to its original position. The pressure in the oil circuit rapidly decreases, and the oil cylinder drives the friction plate to return to its original position, thereby releasing the brake.

time:2021-05-23

More

TJ2-200/200 Electromagnetic BrakeYWZ10-630/201 Hydraulic BrakeMYT3-70 Hydraulic PusherMWZ315-630 Electromagnetic Block BrakeYWZ9-250/50 hydraulic brakeBED301/6 explosion-proof hydraulic thruster YW500-E121YW hydraulic brakeYWZ12-500/121S hydraulic brakeYWZ9-250/E50 hydraulic brakeYWZ5-500/121 hydraulic brakeYWZ4B-400/90YWZ4 hydraulic brakeYWZ3B-250/25YWZ3 series hydraulic brakeYWZ2-300/30YWZ series hydraulic brakeMYT3-80 Hydraulic PusherMYTD2-1250/50 hydraulic thrusterED-70/5 hydraulic thruster YW-500/201 hydraulic brakeYWK250-300YWK electric hydraulic brakeTJ2A-300 energy-saving electromagnetic block brakeHydraulic push rod brakeED-301/12 hydraulic thrusterYWZ-150/25YWZ series hydraulic brakeYWZ4-200/30YWZ4 hydraulic brakeYWZ5-630/E201 Hydraulic BrakeYWZ10-630/121 hydraulic brakeYWB-710/301 Hydraulic Brake ED-1250/120 Hydraulic Pusher_ ZWZ3-500/500ZWZ3-400/400YW630-E1250YW Hydraulic BrakeYWZ10-630/E121 Hydraulic BrakeYWZ5-250/E23 Hydraulic BrakeYWZ3B-160/25YWZ3 series hydraulic brakeMYTD2-2000/120 Hydraulic PusherYT1CJ-45Z/6 hydraulic thrusterJCZ-300/25H electromagnetic brakeYWP-400/121 Hydraulic Brake

time:2021-05-23

More

Jiaozuo Brake is a company that integrates research, development, manufacturing, sales, and service of brakes, thrusters, and lifting appliances. The company has a strong technical force and a large number of intermediate engineering and technical personnel. The research center specializes in the research and development of brakes, and can provide users with the design, consultation, and manufacturing of non-standard products. We have developed over 20 series and over 380 specifications of products. 6 products have won the Provincial Science and Technology Progress Award. The company has over 80 large-scale production equipment and 2 brake production lines, with an annual production capacity of over 50000 sets of various types of brake and actuator products. The company has advanced brake and actuator testing equipment, established a comprehensive quality control and assurance system, and applied a scientific and strict modern system to ensure that 100% of the factory products are qualified through comprehensive testing equipment and methods, thereby ensuring timely provision of safe and reliable products that meet relevant requirements to users. The pursuit of quality and endless service is the consistent tenet of the company. The company has established strict service measures: pre-sales and during sales are completed by a nationwide sales network, and after-sales is implemented by the company's after-sales service department. Thus enabling users to receive comprehensive pre-sales, in sales, and after-sales services

time:2021-05-23

More

ED hydraulic thruster ED-121/6, ED121/6 usageThe ED series electric hydraulic thrusters are mainly used as operating components for the YWZ4, YWZ5, YWZ8, YWZ9, and YWZP series electric hydraulic block brakes, widely used in industries such as lifting and transportation, metallurgy, mining, ports, and construction.Normal working conditionsMotor 1/2 three-phase AC asynchronous motor, in accordance with (G 755-87) regulations, insulation level: F levelUsage conditions:Continuous operation S1, continuous operation S2, load duration FC=60%Rated voltage is 380V three-phase, frequency 50HzThe altitude level of the location of use complies with the GB755-87 standardThe ambient temperature should be within the range of -20 ℃ to 40 ℃, and the relative humidity of the air should not exceed 90%Vertical installation: piston connection block facing upwards, horizontal installation: marked label facing upwards: (ED630/12 male is suitable for vertical installation)Main technical parametersModel rated thrust(N) Rated stroke(mm) Action stroke brake spring force(N) Rated frequency(Hz) Input power(W) Rated voltage(V) Rated current(A) High operating frequency weight (kg)Rising and fallingShort stroke thruster deviation ± 20%ED23/5 220 50 0.35 0.35 180 50 165 380 0.52 2000 10ED30/5 300 50 0.35 0.35 270 50 200 380 0.46 2000 14ED50/6 500 60 0.45 0.39 460 50 210 380 0.48 2000 14ED80/6 800 60 0.32 0.34 750 50 330 380 1.42 2000 24ED121/6 1250 60 0.4 0.42 1200 50 330 380 1.44 2000 39ED201/6 2000 60 0.5 0.32 1900 50 450 380 1.45 2000 39ED301/6 3000 60 0.58 0.32 2700 50 550 380 1.46 1500 40purposeContinuously work S1 and continue working S3, and the ambient temperature of chicken feathers reaches+50 ℃.The rated current in the table refers to the line terminal current during rated operation, but if the power supply is at a non rated value, it will inevitably cause a corresponding change in the rated current. Environmental temperature: -20 ℃~+50 ℃, hydraulic oil: DB-25 (SY1351-77) When it is below -20 ℃, YH-10 hydraulic oil can be used without a heater. When using DB-25 hydraulic equipment, a heater must be installed. The travel time is measured at an ambient temperature of 20 ℃.Main technical parametersModel A B C D E F G H K L M N O P Q R S T UEN23/5 286 50 26 12 20 16 20 160 80 40 200 16 85 55 75 100 20EN30/5 370 50 34 15 16 25 16 18 160 80 80 40 197 16 85 55 75 100 20EN50/6 435 60 36 18 20 30 20 23 195 97 120 60 254 22 85 55 75 100 20EN80/6 450 60 36 18 20 30 23 195 97 120 60 254 22 85 55 75 100 20EN50/12 515 120 36 18 20 30 20 23 195 97 120 60 254 22EN80/12 530 120 36 18 20 30 20 23 195 97 120 60 254 22EN121/6 645 60 38 25 25 40 25 35 240 112 90 40 260 25 130 80 120 147 35EN201/6 645 60 38 25 40 25 35 240 112 90 40 260 25 130 80 120 147 35

time:2021-05-17

More

Jiaozuo Brake is a company that integrates research, development, manufacturing, sales, and service of brakes, thrusters, and lifting appliances. The company has a strong technical force and a large number of intermediate engineering and technical personnel. The research center specializes in the research and development of brakes, and can provide users with the design, consultation, and manufacturing of non-standard products. We have developed over 20 series and over 380 specifications of products. 6 products have won the Provincial Science and Technology Progress Award. The company has over 80 large-scale production equipment and 2 brake production lines, with an annual production capacity of over 50000 sets of various types of brake and actuator products. The company has advanced brake and actuator testing equipment, established a comprehensive quality control and assurance system, and applied a scientific and strict modern system to ensure that 100% of the factory products are qualified through comprehensive testing equipment and methods, thereby ensuring timely provision of safe and reliable products that meet relevant requirements to users. The pursuit of quality and endless service is the consistent tenet of the company. The company has established strict service measures: pre-sales and during sales are completed by a nationwide sales network, and after-sales is implemented by the company's after-sales service department. Thus enabling users to receive comprehensive pre-sales, in sales, and after-sales services

time:2021-05-17

More

Crane holding brake electric hydraulic drum brake YWZ4YWZ4B electric hydraulic brake, Jiaozuo electric hydraulic brake YWZ9-400 E121 port crane crane brake holding brake, industrial hydraulic brake YWZ4B-500/121 crane block holding brake hydraulic tank brake deviceThe installation dimensions of YWZ9 electric hydraulic block brake comply with GB6333-86 standard, and the technical requirements comply with JB/T6406-2006 standard.1、 Main structure and working principleThe YWZ9 electric hydraulic block brake mainly consists of a thruster, base, brake arm, brake spring, brake pad, spring pull rod, lever, automatic distance equalization device, lubrication device, and other parts.Its working principle: YWZ9 electric hydraulic block brake project involves machinery, Fluid mechanics, hydraulics and other disciplines. The working principle of the YWZ9 electric hydraulic block brake is mainly to convert the electrical energy of the driving device into mechanical energy, and through the rotation of the impeller, the liquid flow in the cylinder forms a high and low pressure chamber to push the piston upward, thereby transforming the vertical movement into left and right swing of the brake arm through the lever mechanism, completing the brake release task. When the driving device is powered off, the mechanism amplifies and transmits the force to the brake shoe through the lever ratio under the action of spring force, completing the holding brake. The main auxiliary function of the product is the automatic equalizing device for backtracking. The technical action principle is to connect the equal backtracking device with the brake arm, and maintain the automatic equalizing of backtracking on both sides when the brake arm is opened through the rotation of the low pair of the left and right connecting plates.2、 Main features:Safe and reliable performance, smooth braking, and high action frequency.Equipped with an interlocking equal distance device, it maintains an equal distance between the two pads during use, avoiding the phenomenon of one brake pad floating against the brake wheel due to uneven distance.The main swing hinge point of the YWZ9 electric hydraulic block brake is equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use.The brake spring is arranged inside the spring tube and is equipped with a brake torque scale on one side, making adjustment convenient and intuitive.The asbestos free brake pad and brake pad adopt a plug-in type, which is safe and reliable, and easy and fast to replace.Additional devices can be added according to customer requirements, as shown in the Additional Function Table.Usage conditions: Environmental temperature: -20 ℃~50 ℃. The relative humidity of the air shall not exceed 90%. The surrounding working environment must not contain flammable, explosive, or corrosive gases. The altitude of the location of use complies with GB755-2000. Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products.3、 Prospects for the Promotion and Application of YWZ9 Electric Hydraulic Block BrakeThe successful development of YWZ9 electric hydraulic block brake has changed the situation where brake products in China do not have auxiliary performance, greatly improving the overall performance of the machine, reducing the labor intensity of manual installation, adjustment, and maintenance. It is an ideal replacement product for the domestic brake industry. In terms of replacing imports and exporting supporting hosts to earn foreign exchange, the demand for them is also increasing day by day, and the market prospects are broad.In short, the YWZ9 electric hydraulic block brake technology has driven the forward development of China's brake history, driven technological progress in the same industry, and greatly improved the level of the main engine, with significant economic and social benefits. On the other hand, the brake technology not only keeps pace with the Vanguard International Semiconductor Corporation's advanced brakes, but also has some international structures and performances, which has far-reaching historical significance and good promotion and application value.

time:2021-05-17

More

What is a disc hydraulic brake? The disc hydraulic brake is controlled by hydraulic pressure, and its main components include brake discs, wheel cylinders, brake calipers, oil pipes, etc. The disc brake is characterized by simple structure, convenient adjustment, good high temperature resistance, fast heat dissipation, light weight but stable braking effect. After the cylinder oil pipe joint of the disc hydraulic brake is removed, air will enter the oil pipe and wheel cylinder. After reinstallation, there will be air in the braking system, causing the braking effect to fail. Therefore, after the joint is removed, the air must be discharged before it can be used normally. So how to bleed the disc hydraulic brake? What are the methods? The editor is here to answer everyone's questions one by one:The method for bleeding the disc hydraulic brake is:1. Add sufficient hydraulic oil to the main cylinder, grip the brake grip tightly, allow the air to exhaust, and then immediately connect the connector to the wheel cylinder.2. Firmly grip the handle of the disc electric hydraulic brake to generate oil pressure in the master cylinder, then loosen the bleed screw to release the air.3. When no more bubbles are generated at the bleed screw, immediately tighten the bleed screw, loosen the brake grip, and allow the master cylinder to return oil.4. Repeat the second and third steps multiple times until the air is completely discharged. The action during bleeding must be coordinated to avoid operational errors that may cause air to enter the hydraulic system, causing the work to start over. It is also important to note that during the bleeding process, the hydraulic oil should be adjusted to the master cylinder at any time. The brake caliper is fixed together with the front fork guide column and is a fixed part of the braking device. The hydraulic brake disc is fixed to the wheel and rotates with the wheel. When holding the brake handle tightly, push the piston to move. Due to the non Compressibility of the brake fluid, the piston pushes the oil in the master cylinder to flow into the cylinder of the slave cylinder along the hose, and pushes the piston and friction plate to clamp the brake disc from both sides, producing great friction resistance and forcing the wheels to stop rotating

time:2021-05-17

More

The company mainly produces:Electric hydraulic block brake, electric hydraulic thruster, explosion-proof electric hydraulic thruster, explosion-proof electric hydraulic brake, electromagnetic power loss brake, electromagnetic power on brake, motor brake, electromagnetic brake, wind power yaw brake, hydraulic direct disc brake, yaw brake pad, PZ series disc brake, QP12.7 series disc brake, wind iron wedge series brake, wind power generator brake Wind power brake friction lining, disc brake lining, hydraulic failure protection disc brake, pneumatic failure protection disc brake, electric failure protection disc brake, explosion-proof brake, YT series thruster, ED series thruster, explosion-proof thruster and other series of products are developed, manufactured, sold and served as a chemical industrial brake manufacturer. Electric hydraulic double caliper disc brake pads YP11, YP21, YP31, YP41 Electric hydraulic double caliper disc brake padsThe Disc brake system of the brake factory is mainly composed of mechanical disc brake and hydraulic control station. Its working principle is to generate braking torque by applying frictional braking force to the brake disc through the brake. The hydraulic station can adjust the size of the oil pressure in the brake and the positive pressure of the brake, thereby adjusting the size of the braking torque. The hydraulic station adopts electro-hydraulic proportional control technology, which has advantages such as high braking torque, sensitive action, good heat dissipation performance, and convenient use and maintenance. When the ambient temperature of the disc brake reaches 40 ℃, brake for 10 times/h, and the high temperature of the disc surface is far less than 150 ℃, so no spark will be generated. It meets the requirements for safe use in mines.The company produces dozens of series, more than 800 varieties and specifications, and various non-standard products, such as electric hydraulic block brake, electromagnetic block brake, hydraulic, electromagnetic, pneumatic caliper disc brake, hydraulic wind proof iron wedge brake, electro-hydraulic push rod, electric hydraulic thruster, etc., with the advantages of smooth braking, safety and reliability, easy maintenance, low power consumption, long life, no noise, high frequency, etcThere are many types of disc brake. According to the brake type, the service brake is usually used as the foot brake of the car, while the parking brake is used as the hand brake of the car. Our common service brakes are bicycles and motorcycles. These two wheeled vehicles, whether they are handbrake or foot brake, are all service brakes. The reasons for brake failure without a parking brake are as follows:(1) The disc brake control mechanism is improperly adjusted. After applying braking force, the brake cam of the drum brake does not rotate properly, and the angle of the brake shoe opening is not large enough to tightly press the friction plate onto the inner surface of the brake drum, resulting in brake failure; Or the plunger valve stroke of the disc brake is not enough, and the brake pad cannot clamp the brake disc, which makes the brake system lose its function.(2) Wear of friction plates (or brake pads). Due to prolonged use of the brake, especially during continuous downhill operations, the surface temperature of the friction plate can rise, leading to phenomena such as erosion, aging, or severe wear, resulting in a significant decrease in the friction coefficient and an impact on braking performance.(3) There is oil and water in the brake. If the wheel bearing is filled with too much lubricating grease, it will leak into the brake drum when the seal is worn or damaged after melting at high temperature. Make the friction surface slip. When the motorcycle is wading or washed with water, if there is water in the brake, it will also slip, leading to brake failure.(4) The friction plate of disc brake falls off. The friction plate and brake shoe are generally bonded together with adhesive (also fixed with rivets) and cured at a certain constant temperature. If the adhesion is not firm or due to wear, the friction plate may partially or completely detach from the brake shoe, causing brake failure.

time:2021-05-17

More