What is the brake? The brake is what we mean by the brake. Of course, the brake is widely used. The general movable mechanical equipment can be applied to the brake. There are many types of brakes, one of which is the pneumatic caliper brake. People who have applied the pneumatic caliper disc brake may encounter the disc brake with noise. What should we do? If there is "squeaky, squeaky" noise during the braking of the pneumatic caliper disc brake, the following methods can be used to remove it: 1. Add a noise prevention plate between the brake caliper piston and the brake lining to make the piston form an inclination. Then ensure that the brake pads and brake discs touch flexibly during braking, so that the brake pads do not exhibit abnormal noise under normal wear and tear conditions. 2. Select brake pad materials with softer and lower density for the brake. 3. When the pneumatic caliper disc brake is braking, the brake pad moves to one side, which can show the impact dynamic and static. This is because the gap between the brake pad and the caliper body is too large, which can be eliminated by soldering. However, it should be noted that the solder should be coated on the side opposite to the direction of travel to avoid failure under the effect of braking force. After reading the relevant introduction above, do you have the right response measures for the noise of the pneumatic caliper disc brake?

time:2023-06-21

More

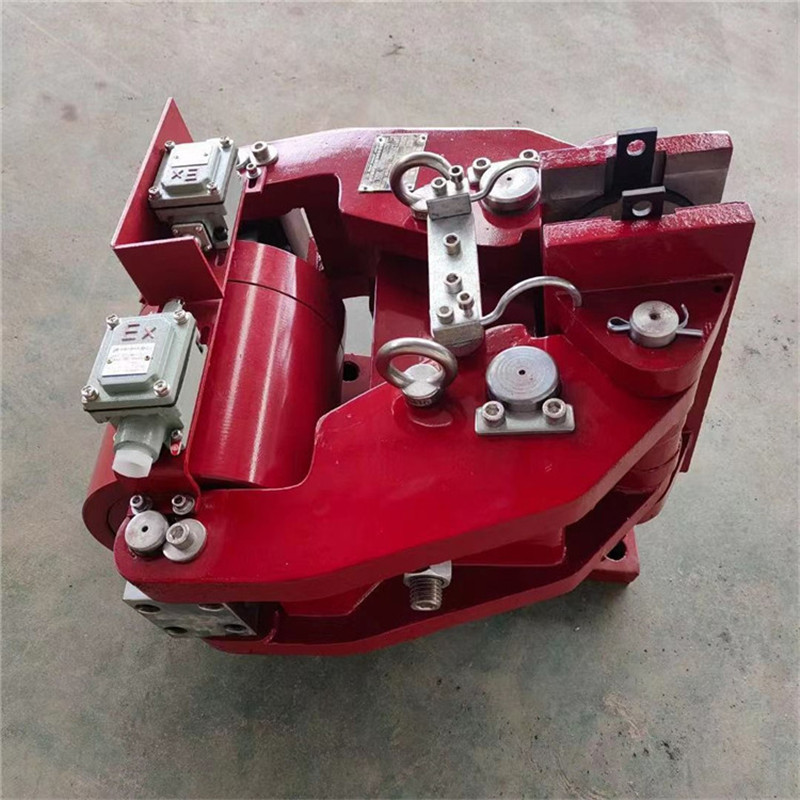

Pneumatic caliper disc brakes are widely used in the braking and deceleration of various mechanisms in hoisting, transportation, metallurgy, mining, port, construction and other machinery, as well as in the tension control field of cable, paper making, copper plate and other machinery. Usage conditions: Environmental temperature: -5 ℃ -40 ℃ Working pressure: ≤ 7bar; Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products. The air source should not contain oil, water, or other impurities. Main features of pneumatic caliper disc brake: pneumatic braking, spring release. The overall structure is simple, small in size, and lightweight. Asbestos free brake pads, green and environmentally friendly. The installation and replacement of brake pads are convenient and fast. The brake pad is easy to adjust after being worn. The automatic brake block following device ensures that the brake block has equal clearance with the main engine brake disc during the opening and closing operation of the entire machine. All power sources do not need to be set separately and can be used in conjunction with existing air compression stations. Speed control valves are installed in the gas supply line, and the braking time can be adjusted steplessly.

time:2023-06-21

More

Working principle and conclusion of the brake1) The total transmission ratio of the entire brake system is not related to the structural form of the brake, but rather to factors such as the thrust utilization coefficient, friction coefficient, and structural transmission efficiency of the thruster.2) The leverage ratio of the mechanism is not related to mechanical transmission efficiency, braking force, thruster thrust, brake wheel diameter, friction coefficient, etc., but only to the structural form.3) Due to the difference in the meaning and calculation formula between the total transmission ratio of the system and the lever ratio of the mechanism, the total transmission ratio of a system with a large lever ratio of the mechanism must be higher; Customization power may not necessarily be high for a large leverage ratio.4) The total transmission ratio of the system is directly proportional to the rated power.5) The energy consumption during the start-up process of the electric hydraulic thruster is basically the same as that during the rated operating stage.6) Thrusters with the same rated thrust are used on different types of brakes, and different braking torques can be obtained by varying the total transmission ratio of the system.7) A brake with the same driving force and a rated braking torque has a higher energy efficiency value.8) The energy efficiency of the brake is related to the total transmission ratio of the system, friction coefficient, mechanical transmission efficiency, thruster thrust utilization coefficient, and thruster energy efficiency.

time:2023-06-21

More

The difference between a normally closed brake and a normally open brake is that a normally open brake is often in a released state and only brakes when needed under the driver's control. It generates a holding brake force by manpower, hydraulic pressure, or air pressure. Once the holding brake force stops working, the brake releases under the action of gravity or spring. The normally closed brake is used to hold the brake when the machinery is not rotating, and to release the brake when the mechanical equipment is rotating. This type of brake usually uses a spring to generate the holding brake force, which is released by a specialized brake release device.The main swing hinge points of the brake are equipped with self-lubricating bearings, which have high transmission efficiency, flexible operation, safety and reliability, long service life, and no need for lubrication during use;

time:2023-06-21

More

The voltage of the electromagnetic drum brake can be AC 380V, DC 220V, DC 24V (customized according to on-site conditions). It is an automated execution component formed by merging the input shaft and output shaft. The space between the two axes is filled with granular magnetic particles. When the magnetic coil conducts electricity, magnetic force and magnetic particle production hardening phenomenon occur, transmitting torque between continuous sliding. When the magnetic coil is not conductive, torque will not be transmitted from the input shaft to the output shaft. JZ200 Electromagnetic Drum BrakeJZ300 electromagnetic iron block brakeJZ400 electromagnetic iron block brakeMWZ200 Electromagnet BrakeMWZ315-630 Electromagnetic Block BrakeMWZ250 Electromagnetic Drum BrakeMWZ315 Electromagnetic BrakeZWZ3-250 Electromagnetic Drum BrakeZWZ3-315 Electromagnetic BrakeThe current usage status and fault problems of the electromagnetic braking system of ZWZA electromagnetic brake. In order to overcome the serious impact of voltage and harmonics on the circuit board of the original electromagnetic brake, a hydraulic centralized control method was adopted to replace the original electromagnetic control. A hydraulic system schematic diagram was designed according to the specific working conditions, and the specific design parameters of the hydraulic cylinder were calculated. The required hydraulic components were selected In the article, the static analysis and optimization design module of finite element analysis software was used to conduct static analysis on the hydraulic cylinder barrel, and the wall thickness of the cylinder barrel was optimized. The electromagnetic brake reduces the quality of the cylinder barrel while meeting the stress and deformation conditions of the cylinder barrel. Compared with traditional empirical design, the design method based on analysis software improves the utilization rate of materials and reduces the production cost of the product, This provides an effective and feasible approach for the design and optimization of hydraulic cylinders Using AMESim simulation software, the electromagnetic drum brake simulated and analyzed the system under two different feedback signals: system pressure and piston rod displacement. Through analysis, it was found that the hydraulic system performance of the pressure feedback signal was good, and the deviation from theoretical derivation was small. The displacement feedback hydraulic system was analyzed based on the principle of the positioning vehicle hydraulic system, Simulation calculations were conducted using software to identify the drawbacks of the hydraulic system and propose solutions

time:2023-06-21

More

Track unit brake TZD-1-840-T-X tread brake1. TZD series, TZD series tread brake, is an integrated brake shoe tread brake that integrates brake cylinder, brake shoe stroke adjustment mechanism, brake shoe anti eccentric wear mechanism, and brake force amplification mechanism. It is used nationwide. Models: TZD-1-1050, TZD-1-840, TZD-1-660, TZD-1-710, etc., are brakes used in conjunction with railway vehicles. It has the characteristics of easy installation and maintenance, sensitive operation, and long service life. TZD-2 is a parking brake with manual release function, while TZD-3 is a brake with manual assisted braking.2. DZD series and DZD series unit brakes are used for Internal combustion locomotive brakes and are used in China. Model: DZD-1, DZD-2, DZD-33. TTD series, TTD series brakes are heavy-duty, anti eccentric wear brakes developed in the TZD series tread brakes. Model: TTD-1, TTD-2, TTD-34. The DT series brake is a heavy-duty and anti eccentric wear brake developed on the basis of the DZD series tread brake. Models: DT-1, DT-2, DT-3Unit 12、 Brake shoeA brake shoe is a shoe shaped brake block made of cast iron or other materials, which holds the wheel tread tightly during braking and stops the wheel from rotating through friction.Train brake shoes (synthetic brake shoes, composite brake shoes, high friction and low friction brake shoes)(1) Overview of Train Brake ShoeIn railway terminology, brake pads are called brake shoes, which are located on the tread of the wheels. When braking, the two brake shoes at the front and rear of the wheels clamp the wheels tightly through the action of the brake pedal, achieving the purpose of stopping. During the operation of a train, braking is required to generate friction in contact with the wheel tread, which converts the kinetic energy of the train into thermal energy and dissipates it into the atmosphere, achieving deceleration or stopping of the train. The braking component that directly rubs the wheels to stop the train is the brake shoe. A tile shaped brake block made of cast iron or other materials that holds the wheel tread tightly during braking and stops the wheel from rotating through friction.In the era of high-tech development, trains, as one of the main modes of transportation, make us increasingly demanding for their safety. Due to the harsh operating environment of trains, the safety of their braking system is particularly important. Among them, the friction performance of train brake pads plays a crucial role in relation to driving safety and operational reliability. At present, China's brake pad detection technology is relatively backward, with low work efficiency and the inability to quickly and accurately grasp the status of tires, which seriously restricts the acceleration of railway vehicles in China. The testing methods used abroad are expensive and technically challenging. Transplantation has never been seen in China. So the quality of brake pads has become the top priority for the survival of enterprises. The braking device is an important device for safe deceleration or parking of trains. For the safety of trains, the braking performance of trains must be ensured under various conditions. With the continuous improvement of train operation speed, the requirements for braking performance of braking devices are also higher, and traditional brake shoe braking cannot adapt to the development of high-speed trains. At present, the Passenger railroad car in our country basically adopt the disc brake, and the train brake pad is an important component of the disc brake device, which plays an important role in braking performance. The train brake pad testing system is based on the brake pad braking experimental platform, which tests the friction performance of train brake pads. The train brake pad testing system tests multiple performance parameters such as bearing pressure, surface temperature, and wheel running speed of the brake pads through assembly experiments. The brake pads of train disc brakes mainly use synthetic brake pads. The characteristics of synthetic brake pads are:1. Good thermal stability. The resin decomposition temperature is high, and the actual measured temperature is 377 degrees Celsius.2. Low compression elasticity, low noise, and uniform temperature distribution.3. Strong adhesion, with both resin aging resistance and rubber toughness, low heat decay rate, and good recovery.4. Good production performance and good surface reproducibility.

time:2023-06-17

More

Jiaozuo Golden Band Brake Product Sales Phone 15838971872, electric hydraulic block brake, electric hydraulic drum brake, hydraulic failure protection brake manufacturer, Jiaozuo brake manufacturer, electric hydraulic thruster, electromagnetic drum brake, safety brake, hydraulic disc brake, pneumatic brake, electromagnetic disc brakeMatching hydraulic thruster Ed-23/5YWZ8-200/E30 matching thruster Ed-30/5YWZ8-300/E30 matching thruster ED-30/5YWZ9-300/E50 matching thruster ED-50/6YWZ8-300/E80 matching thruster Ed-80/6YWZ8-400/E50 matching thruster Ed-50/6YWZ8-400/E80 matching thruster Ed-80/6YWZ8-400/E121 matching thruster Ed-121/6YWZ8-500/E121 matching thruster Ed-121/6YWZ8-500/E201 matching thruster Ed-201/6YWZ8-600/E121 matching thruster Ed-121/6YWZ8-600/E201 matching thruster Ed-201/6YWZ8-600/E301 matching thruster ED-301/6YWZ8-700/E201 matching thruster Ed-201/6YWZ8-700/E301 matching thruster Ed-301/6YWZ8-800/E301/12 matching thruster Ed-301/12The company has a huge marketing and comprehensive market service network system, with nearly 100 sales personnel, 6 distributors, and 36 offices forming a sound sales network and after-sales service system. The sales network is spread throughout the country, and the after-sales service is in place, providing users with high-quality pre-sales, in sales, and after-sales services in a timely and comprehensive manner.The company operates in accordance with modern enterprise systems and adheres to management innovation, creating an internal market-oriented management model and a corporate culture system that creates value for customers, wealth for society, profits for enterprises, and benefits for employees. It is a banner for the development of national industry in the industry, and is following the path of new industrialization and sustainable development in domestic and foreign market competition, Striving towards the goal of "Century Golden Hoop, World Golden Hoop", and making unremitting efforts to build a powerful and internationally operated first-class enterprise.

time:2023-06-17

More

YP11.YP21.YP31.YP32 series electric hydraulic disc brake is an advanced product with high performance and multi-function. Due to its advanced functions such as automatic equalization of tile setback and automatic compensation for pad wear, it is easy to maintain during use. By adding various limit switches, the required interlocking protection signals can be provided to the host PLC. Suitable for deceleration and maintenance (parking) braking of various modern large-scale specialized loading and unloading machinery, lifting and transportation machinery, metallurgical equipment, mining equipment, and engineering machinery.Main features:The interlocking equal distance device and automatic tile following device can always maintain equal distance between the two tile blocks during use without adjustment, completely avoiding the phenomenon of brake pads floating against the brake disc.The main swing hinge points are equipped with self-lubricating bearings, which do not require lubrication during use; High transmission efficiency, sensitive operation, and brake closing (up) time of 0.25~0.4 seconds.The stepless lining friction automatic compensation device can maintain a constant distance between the pads and the braking torque during use, avoiding the trouble of frequent adjustment.Adjustable torque built-in spring with torque scale.The brake pad is plug-in and easy to replace. Provide various materials such as semi metal and powder metallurgy liners to adapt to different working conditions. Equipped with our company's new thruster, it is sensitive in operation and has a long service life.Basic parameters:Product models: YP11, YP21, YP31, YP32Applicable disc diameter: 355-1100mmBraking torque: 935-21200Nm0.25~0.4S.QQ Image 20220922083048

time:2023-06-17

More

Daily maintenance and upkeep should be carried out when using the brake1. Maintain the cleanliness of the caliper disc hydraulic brake assembly, especially the surface of the brake disc and brake lining, to ensure that the entire brake operates freely, flexibly, reliably, and cleanly.2. Regularly observe the stock of brake fluid in the oil pool. When the liquid level is below the marking line, clean brake fluid of the original brand should be added in a timely manner, so that its height is millimeters higher than the marking line. Never mix other brands of brake fluid. After adding, the air nozzle should be opened for exhaust before tightening for use.3. Regularly check the thickness of the brake disc. When the thickness of the worn brake disc is less than the specified value, the brake disc must be replaced.4. During use, the surface of the brake lining should not be contaminated with grease or brake fluid, and the thickness of the lining should be checked regularly. If the thickness is less than the specified value, the dynamic lining should be replaced.When there is oil leakage at the piston of the master cylinder and slave cylinder, the sealing ring must be replaced. Special attention should be paid to the fact that new sealing rings must be soaked in brake fluid for at least an hour before being replaced. They cannot be assembled and used after being taken out. When cleaning the oil cylinder or piston, it is necessary to use a sprinkling solution, and gasoline or other mineral oils are not allowed.

time:2023-06-17

More

There are various models of electric hydraulic thrusters, but the working principle is similar, and the structure is shown in the following figure. After being powered on, the motor inside the hydraulic brake drives the centrifugal oil pump inside the hydraulic brake head, increasing the hydraulic oil pressure. Hydraulic oil transfers pressure to the piston in the oil cylinder, and the hydraulic push rod moves upwards driven by the piston to open the brake shoe of the brake.Technical data of the hydraulic holding brake (taking the technical data of MYTl-90 electric hydraulic thruster as an example): thrust 900N, stroke 80mm, rising time 0.8s, Fall time 0.5s, power 0.25kW, 20 # engine oil, oil weight, 720 operations per hour, and the model of the supporting brake (the combination of thruster and brake can form a hydraulic holding brake).

time:2023-06-17

More

The performance characteristics of the pneumatic hydraulic disc brake. Compared with the drum brake, the working surface of the disc brake is flat and heat transfer occurs on both sides. When the disc rotates, it is easy to cool and is not prone to large deformation. The braking efficiency is relatively stable. After a long time of use, the brake disc has enhanced its braking effect due to high temperature expansion; The drum brake has a single side heat transfer and a large temperature difference between the inner and outer sides, which makes the brake drum prone to deformation. At the same time, after prolonged braking, the brake drum expands due to high temperature, and the braking efficiency is weakened. In addition, the disc brake is simple in structure, convenient in maintenance, and easy to realize automatic adjustment of brake clearance. The disadvantage of the disc brake is that the friction plate acts directly on the disc, without automatic friction amplification, and the braking efficiency is low. Therefore, if the brake actuating pipeline pressure required for the hydraulic braking system is high, additional power auxiliary devices must be installed; When also used for parking brake, the added parking brake transmission device is more complex than the drum brake, so it is applied on the rear wheels.

time:2023-06-17

More

Working principle of electric hydraulic thruster:The electric hydraulic thruster consists of two parts, driving the electric motor and the body (centrifugal pump). The body part is composed of a cover, cylinder, piston, impeller, and rotor.When energized, the electric motor drives the transmission shaft and the impeller on the shaft to rotate, causing pressure to occur inside the piston. Under this pressure, oil is sucked from the upper part of the piston to the lower part of the piston, forcing the piston and the push rod and crossbeam fixed on it to rise rapidly. Mechanical movement occurs by mechanically tightening the load tension spring through a lever (if the thruster or brake is equipped with a load tension spring).When the power is cut off, the impeller stops rotating, and the piston rapidly decreases under the force of the tension spring and its own gravity, forcing oil to flow into the upper part of the piston from the beginning. At this time, it still recovers through the lever tissue.Electric hydraulic thrusters are often used in cooperation with brake frames and are widely used for braking various transmission equipment.Characteristics of electric hydraulic brakes:With the continuous use of various electrical equipment in daily life, it has brought many conveniences to everyone, especially for some machine equipment equipped with drive and control devices, which are not only widely used, but also very convenient in the application process. The electric hydraulic thruster is a compact layout driving and control equipment that integrates electric motors, centrifugal pumps, and oil cylinders, and is widely used. Therefore, the main characteristics of the electric hydraulic thruster are as follows:1. The layout of the electric hydraulic thruster is simple and the volume is relatively small, which will reduce the occupied area of the thruster. Therefore, there are many categories and professions to use, and the application is sensitive.2. Electric hydraulic thrusters typically

time:2023-06-17

More