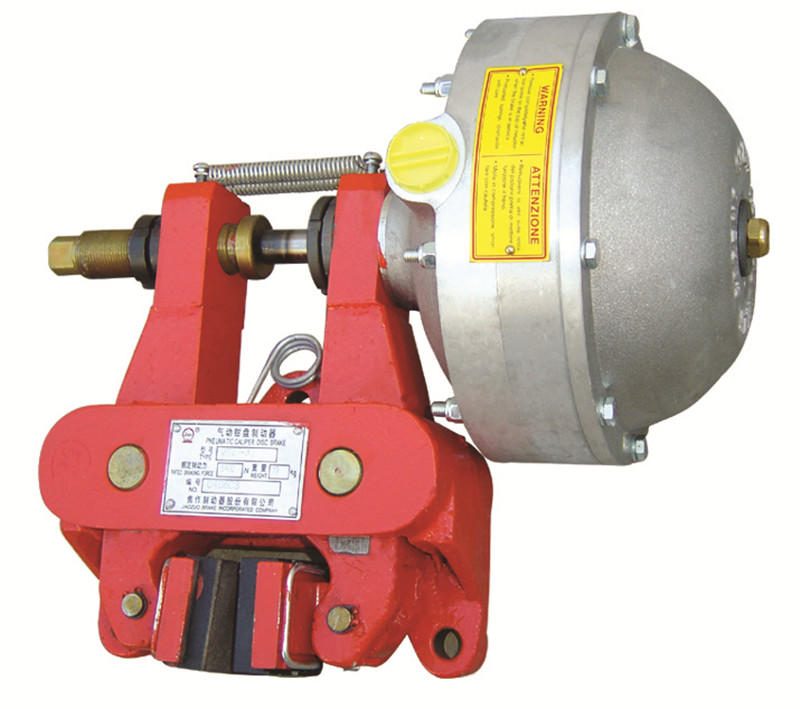

PDA series pneumatic disc brakes are widely used for parking brake or deceleration brake of small and medium-sized driving mechanisms. The tension braking of the winding mechanism, such as the tension control of the Paper mill, the tension control of newsprint during news printing, the unwinding and tensioning of steel plate (steel wire), the paying off of wires and cables, the paying off and tensioning control of cables, etcFeatures:The main swing hinge point is equipped with self-lubricating bearings, which have high transmission efficiency and long service life.Automatic compensation device.Automatic torque display directly.Manual brake release for easy maintenance.Usage conditions:Environmental temperature -20 ° -+50Features:The main swing hinge point is equipped with self-lubricating bearings, which have high transmission efficiency and long service lifeManual brake release for easy maintenance.Model Meaning:Brake model, brake wheel diameter, cylinder code, cylinder inner diameter, cylinder stroke, and brake additional function code.When the PDA5 pneumatic caliper brake utilizes the impact or rotation effect to generate pressure air in cylinder 1, the piston rod 5 quickly contracts into the cylinder under the pressure. The left and right brake arms, under the action of the reset spring 4, drive the friction block 12 to quickly open (i.e. release the brake). When the cylinder stops supplying air and quickly deflates through the control valve, the piston rod 5 quickly extends under the spring inside the cylinder, pushing the left and right brake arms to drive the friction block 12 to close (i.e., the holding brake). The air pressure causes the pneumatic PDA5 pneumatic caliper brake to use compressed air as the power source for movement or work, so it can only be applied to? Technical advantages: 1. Super long service life of disc spring group, 2 million times. 2. Single set of brake with large braking force of 440kN adjustable. 3. Patent product with single sealing ring research and invention, braking force is not easily transmitted to the piston, completely solving the problem of oil leakage. 4. The contact area between the friction plate and the brake disc is large, and the friction plate is made of asbestos free copper based powder metallurgy material, which can adapt to high temperature, high load and heavy load conditions, ensuring stable friction coefficient during brakingOur factory produces pneumatic brakes, which are well sold in Jiaozuo, Henan. Our products have good quality and low prices. Color: blue, red, green, low order price, good quality, fast delivery, Cash on delivery. Packaging: Customized packaging in wooden boxes.Pneumatic caliper disc brakeCQPL12.7A-A; CQPL12.7A-B; CQPL12.7B; QPL12.7A-A; QPL12.7A-B; QPL12.7-A; QPL12.7-B;QP30-D; QP25.4-D; CQP30-D; CQP25.4-D; PDA5; PDA10; PDB5; PDB10; PDB19; PDC5; PDC10QP30-D; QP25.4-D; CQP30-D; CQP25.4-D; PDA5; PDA10; PDB5; PDB10; PDB19; PDC5; PDC10

time:2021-04-26

More

Warning: The thruster should be reliably grounded according to electrical specifications! Attention: When wiring, cut off the power supply and erect a sign at the power switch that reads "Someone is working, do not switch on",Until the wiring is completed.When wiring, remove the cover of the thruster junction box (there is a wiring diagram on the reverse side), and connect the three-phase power line (phase sequence is not required) and grounding wire as required. Then cover the junction box cover and tighten the screwsED electric hydraulic thrusterEd23/5, Ed30/5, Ed50/6, Ed80/6, Ed121/6, Ed201/6, Ed23/5, Ed30/5, Ed50/6, Ed80/6, Ed121/6, Ed201/6, Ed301/6Mainly used as an operating component for the YWZ4, YWZ5, YWZ8, YWZ9, YWL.YW.YWZP series electric hydraulic block brakes. It is widely used in industries such as lifting transportation, metallurgy, mining, port electric hydraulic block brake ports, and construction.Usage conditions:Environmental temperature: DB-25 hydraulic oil should be used at -20 ℃ -50 ℃, and YH-10 aviation hydraulic oil should be used below -20 ℃, without installing a heater; When using DB-25 hydraulic oil, a heater must be installed. Continuous operation S1, intermittent operation S3-60%.Voltage and frequency: three-phase AC 380V/50 (60) Hz. Our company can also provide other products with different frequencies and voltages. Please negotiate and order if needed.Three-phase AC asynchronous motor, in accordance with the regulations of (G8755-2000), with detailed performance in the "Technical Data". Insulation level: F level, electrical protection level: IP65.Cable: The cross-sectional area of the wire can reach 4X2.5mm ²。Efficient anti-corrosion products: Used in situations where there are corrosive media and high relative humidity in the air, which may result in condensation. The motor adopts vacuum injection molded stator and is painted with special anti-corrosion paint. The series of products can be provided with anti-corrosion products, and users can contact the company if they need themspecial requirementsAccording to requirements, different voltage and frequency levels of thrusters can be provided. The special treated three proof motor is suitable for "TH" type, "AH" type, and hybrid type requirements.Selection of installation methodVertical installation: The piston rod connecting block faces upwards. Horizontal installation and any position in the middle: The installation form is shown in the following figure.All push rods and connecting blocks of the thrusters can rotate. The Ed50-Ed301 mounting base can be used for 90. Rotate. The Ed23 and Ed30 mounting bases can also provide 900 rotations, but the installation height dimension A is increased by 8mm (specify when ordering). Regardless of the installation position, the piston rod cannot withstand radial forces to avoid affecting its effectiveness and lifespan.

time:2021-04-26

More

The Ed series electric hydraulic thrusters are mainly made of cast aluminum alloy for the outer shell, so their appearance is very beautiful and their quality is also very lightweight. The motor is mainly made of a non immersed structure.2. The surface of the motor shaft and push rod of the Ed series electric hydraulic thruster are treated with hard chromium plating, which has excellent sealing performance and can effectively extend the service life of the sealing components.We mainly produce YWZB, YWZ2, YWZ3, YWZ4, YWZ5, YWZ6, YWZ8, YWZ9, YWZ10, YWZ12, and YWZ13 series electric hydraulic block brakes. All kinds of explosion-proof brakes, TJ2 series new energy-saving electromagnet brakes, electric hydraulic arm disc brakes, mine explosion-proof electromagnetic starters and mine vacuum feed switches have complete specifications, reliable performance and superior quality. 13803910788 is popular throughout the country and highly praised by users. YT1 series electric hydraulic thrusters: YT1-18Z/2, YT1-18ZB/2, YT1-25Z/4, YT1-25ZB/4, YT1-45Z/4, YT1-45Z/5, YT1-45Z/6, YT1-90Z/6, YT1-90Z/8, YT1-125Z/10, YT1-180Z/8, YT1-180Z/10, YT1-180Z/12, YT1-320Z/12, YT1-320Z/20, YT1-25/4, YT1-45/6, YT1-90/9-8, YT1-125/10. YT1-180/12 MYT1 series electric hydraulic thrusters: MYT1-25/4, MYT1-45/6, MYT1-90/8, MYT1-180/12, MYT1-18Z/2, MYT1-25Z/4 MYT1-45Z/6, MYT1-90Z/8, MYT1-125Z/10, MYT1-180Z/12, MYT1-320Z/12 MYT3 series electric hydraulic thrusters: MYT3-22/4, MYT3-40/4, MYT3-70/5, MYT3-125/5, MYT3-125E/5, MYT3-200/8, MYT3-200E/8, MYT3-315/8 YWZ series electric hydraulic block brakes: YWZ-100/18, YWZ-200/25, YWZ-300/25, YWZ-300/45, YWZ-300/90, YWZ-400/45, YWZ-400/90, YWZ-500/125 YWZ-600/180 YWZ2 series electric hydraulic block brakes: YWZ2-100/23, YWZ2-200/23, YWZ2-200/30, YWZ2-200/40, YWZ2-300/30, YWZ2-300/50, YWZ2-300/70, YWZ2-400/50, YWZ2-400/80, YWZ2-400/125, YWZ2-500/125, YWZ2-600/125 YWZ3 series electric hydraulic block brakes: YWZ3-160/18, YWZ3-200/25, YWZ3-250/25, YWZ3-250/25 Z3-250/45, YWZ3-315/45, YWZ3-315/90, YWZ3-400/45, YWZ3-400/90 YWZ3-500/12 YWZ4 series electric hydraulic block brakes: YWZ4-200/23, YWZ4-200/30, YWZ4-300/30, YWZ4-300/50, YWZ4-400/80, YWZ4-400/121, YWZ4-500/121, YWZ4-600/201 YZW5 series hydraulic block brakes: YWZ5-200/23, YWZ5-200/30, YWZ5-250/23, YWZ5-250/30, YWZ5-315/50, YWZ5-400/80, YWZ5-400/121 JCZ series Brakes: JCZ-200A, JCZ-300A, JCZ-400A, JCZ-200/15, JCZ-300/15, JCZ-300/25H JCZ-400/45HA, JCZ-500/45H, JCZ-500/80H, JCZ-600/100H ED series electric hydraulic thrusters: ED-23/5, ED-30/5, ED50/6, ED-80/6, ED-121/6, ED-201/6, ED-301/6 TJ2 series brakes: TJ2-100, TJ2-200, TJ2-300 YTD2 series electric hydraulic thrusters: YTD2-230/50, YTD2-300/50, YTD2-500/60, YTD2-800/60, YTD2-1250/60, YTD2-2000/60, YTD2-300/60, YTD2-600 500/120, YTD2-800/120, YTD2-1250/120 YTD2-2000/120, YTD2-3000/120Usage conditions:Environmental temperature: DB-25 hydraulic oil should be used at -20 ℃ -50 ℃, and YH-10 aviation hydraulic oil should be used below -20 ℃, without installing a heater; When using DB-25 hydraulic oil, a heater must be installed. Continuous operation S1, intermittent operation S3-60%.Voltage and frequency: three-phase AC 380V/50 (60) Hz. Our company can also provide other products with different frequencies and voltages. Please negotiate and order if needed.Three-phase AC asynchronous motor, in accordance with the regulations of (G8755-2000), with detailed performance in the "Technical Data". Insulation level: F level, electrical protection level: IP65.Cable: The cross-sectional area of the wire can reach 4X2.5mm ²。Efficient anti-corrosion products: Used in situations where there are corrosive media and high relative humidity in the air, which may result in condensation. The motor adopts vacuum injection molded stator and is painted with special anti-corrosion paint. The series of products can be provided with anti-corrosion products, and users can contact the company if they need themElectric hydraulic thrusterWarning: The thruster should be reliably grounded according to electrical specifications! Attention: When wiring, cut off the power supply and erect a sign at the power switch that reads "Someone is working, do not switch on",Until the wiring is completed.When wiring, remove the cover of the thruster junction box (there is a wiring diagram on the reverse side), and connect the three-phase power line (phase sequence is not required) and grounding wire as required. Then cover the junction box cover and tighten the screwsED electric hydraulic thrusterEd23/5, Ed30/5, Ed50/6, Ed80/6, Ed121/6, Ed201/6, Ed23/5, Ed30/5, Ed50/6, Ed80/6, Ed121/6, Ed201/6, Ed301/6Mainly used as an operating component for the YWZ4, YWZ5, YWZ8, YWZ9, YWL.YW.YWZP series electric hydraulic block brakes. It is widely used in industries such as lifting transportation, metallurgy, mining, port electric hydraulic block brake ports, and construction.YWZ9-250 cleaning

time:2021-04-26

More

The braking device usually consists of a crane brake, a braking wheel, and a braking drive device. This includes adjustment work in three aspects: adjusting the working stroke, adjusting the braking force, and adjusting the brake clearance. It achieves mechanism braking through the principle of friction. When the friction part of the brake set on the stationary base presses against the friction part on a running shaft of the mechanism with a certain force, the friction force generated between the two contact surfaces produces Friction torque on the rotating axis, which is usually called braking torque. When the braking torque is balanced with the torque generated by the torsional force of the lifting object or during operation, the braking requirement YPZ2 is metSince the emergence of power machinery and motor vehicles in the world, brake pads have been used in their transmission and braking mechanisms. In the early stages of brake pad friction material development, cotton, cotton cloth, leather, etc. were used as substrates for brake pads. For example, cotton fibers or their fabrics were soaked in rubber slurry and processed to form brake pads or bands. Its disadvantage: poor heat resistance, when the friction surface temperature exceeds 120 ℃, cotton and cotton cloth will gradually coking or even burn. As the speed and load of the vehicle increase, its braking temperature also correspondingly increases, and this type of friction material can no longer meet the usage requirementsBrake pads are a polymer ternary composite material that is a physical and chemical composite. It is a product made from three major categories of polymer binders (resin and rubber), reinforcing fibers, and friction performance modifiers, as well as other additives, through a series of production and processing. The characteristics of hydraulic brake pads are good friction coefficient and wear resistance, as well as certain heat resistance and mechanical strength, which can meet the performance requirements of mechanical transmission and braking. They are widely used in various mechanical equipment such as lifting, metallurgy, ports, docks, water conservancy, wind turbines, oil drilling rigs, etc.Carbon fiber friction materials. It is a type of friction material made of carbon fiber as a reinforcing material. Carbon fiber has high modulus brittleness and high dual wear. Carbon fiber friction materials have the characteristics of good thermal conductivity and heat resistance, and are one of the best performance friction materials among various types. They are powder metallurgy friction materials. Also known as sintered friction materials, it is made by mixing iron based and copper based powder materials, pressing them, and sintering them at high temperatures. Suitable for braking and transmission conditions at higher temperatures. For example, the braking and transmission of aircraft, trucks, and heavy construction machinery. Advantages: Long service life; Disadvantages: High product price and high braking noiseYPZ Big Red ImageYPZ2 series electric hydraulic arm disc brake:YPZ2-315I/23; YPZ2-315I/30; YPZ2-315I/50; YPZ2-315I/80; YPZ2-355I/23; YPZ2-355I/30; YPZ2-355I/50; YPZ2-355I/80; YPZ2-400I/30; YPZ2-400I/50; YPZ2-400I/80; YPZ2-450I/50; YPZ2-450I/80; YPZ2-450 II/50; YPZ2-450 II/121; YPZ2-450 II/201; YPZ2-500 II/50; YPZ2-500 II/80; YPZ2-500 II/121; YPZ2-500 II/201; YPZ2-560 II/50; YPZ2-560 II/80; YPZ2-560 II/121; YPZ2-560 II/201; YPZ2-630 II/80; YPZ2-630 II/121; YPZ2-630 II/201; YPZ2-710 II/121; YPZ2-710 II/201; YPZ2-630 III/201; YPZ2-630 III/301; YPZ2-710 III/201; YPZ2-710 III/301; YPZ2-800 III/201; YPZ2-800 III/301; YPZ2-900 III/201; YPZ2-900 III/301; YPZ2-1000 III/201; YPZ2-1000 III/301; YPZ2-1250 III/201; YPZ2-1250 III/301

time:2021-04-26

More

Brake lining is generally composed of steel plate, adhesive insulation layer and friction block. Steel plate shall be coated to prevent rust. SMT-4 furnace temperature tracker is used to detect the temperature distribution during coating to ensure quality. The insulation layer is composed of non heat transfer materials, with the purpose of insulation. The friction block is composed of friction materials and adhesives, which are squeezed onto the brake disc or drum during braking to generate friction, thereby achieving the goal of vehicle deceleration and braking. Due to friction, the friction blocks will gradually wear out, and generally speaking, brake pads with lower costs will wear out faster.1. Under normal usage conditions, check the brake shoes every month or kilometer. Not only should the remaining thickness be checked, but also the wear status of the shoes should be checked, whether the degree of wear on both sides is the same, whether the return is smooth, etc. Any abnormal situations must be dealt with immediately.2. The brake shoe is generally composed of two parts: an iron lining plate and a friction material. It is important not to wait until the friction material is completely worn out before replacing the shoe. For example, the front brake shoes of Jetta have a new thickness of 14 millimeters, while the maximum thickness for replacement is 7 millimeters, including a thickness of over 3 millimeters of iron lining plate and nearly 4 millimeters of friction material. Some vehicles have a brake shoe alarm function, and once the wear limit is reached, the instrument panel will give an alarm to prompt for shoe replacement. The shoes that have reached the limit of use must be replaced. Even if they can still be used for a period of time, it will reduce the braking effect and affect the safety of driving. Picture of grooved brake pads3. When replacing, it is necessary to replace the brake pads provided by the original spare parts. Only in this way can the braking effect between the brake pads and the brake discs be good and the wear is minimal.When replacing the shoes, special tools must be used to push the brake wheel cylinder back. Do not use other crowbars to forcefully press back, as this can easily cause the brake caliper guide screw to bend and cause the brake pads to jam.5. After replacement, it is necessary to apply a few foot brakes to eliminate the gap between the shoe and brake disc, which may cause foot failure to brake and lead to accidents.After replacing the brake shoes, it is necessary to run in for 200 kilometers to achieve optimal braking effect. The newly replaced shoes must be driven carefullyIs the braking system ultimately made of brake pads (brake discs) or brake shoes (drum type)? Regularly check the thickness of the brake pads or brake shoes. When the thickness of the manufacturer is close to or less than the small thickness specified by the manufacturer, it should be replaced immediately. While checking the brake pads, it is also necessary to check the wear of the brake disc and drum, such as dents on the contact surface, timely brake disc or drum lights, to ensure the contact area with the brake disc and braking force.Check the brake oil on the car. Before checking the brakes, carefully wipe the dirt on the master cylinder to prevent it from falling into the storage tank. Remove the fasteners (usually pins) and cover. For cylinders that are not calibrated, maintain the top of the tank at 6 millimeters. If there is a scale, keep the liquid level higher than the scale.If the oil level is found to be falling, immediately check if there is a leak in the brake oil circuit. If the brake fluid is dirty, release and flush the entire system, then fill the master cylinder with new fluid. Brake oil should not be reused. All brake fluid released from the system should be discarded.SBD friction plate image

time:2021-04-26

More

BYWZ5 explosion-proof electric hydraulic brakeConsulting and ordering model: BYWZ5-160/23 BYWZ5-200/23BYWZ5-250/23 BYWZ5-250/50BYWZ5-315/23 BYWZ5-315/50 BYWZ5-315/50 BYWZ5-315/80BYWZ5-400/50 BYWZ5-400/80 BYWZ5-400/121BYWZ5-500/80 BYWZ5-500/121 BYWZ5-500/201BYWZ5-630/121 BYWZ5-630/201 BYWZ5-630/301BYWZ5-710/201 BYWZ5-710/301 BYWZ5-800/301/2011YWZ5 explosion-proof typeBYWZ9 explosion-proof electric hydraulic brakeConsulting and ordering model: BYWZ9-160/23 BYWZ9-200/23BYWZ9-250/23 BYWZ9-250/50BYWZ9-315/23 BYWZ9-315/50 BYWZ9-315/50 BYWZ5-315/80BYWZ9-400/50 BYWZ9-400/80 BYWZ9-400/121BYWZ9-500/80 BYWZ9-500/121 BYWZ9-500/201BYWZ9-630/121 BYWZ9-630/201 BYWZ9-630/301BYWZ9-710/201 BYWZ9-710/301 BYWZ9-800/301/201Dedicated to coal mines, cranes, and mining machineryBEd-121/12, BEd-201/12, BEd-301/12Manufacturer's prices for BEd30/5, BEd50/6, BEd80/6, BEd80/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd121/6, BEd201/6, BEd301/6, BEd30/5 explosion-proof electric hydraulic thrustersManufacturer prices for BEd121/12, BEd201/12, BEd301/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd-30/5, BEd-50/6, BEd-80/6, BEd-80/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd-121/6, BEd-201/6, BEd-301/6, BEd-30/5 explosion-proof electric hydraulic thrustersBEd-121/12, BEd-201/12, BEd-301/12 Flameproof electric hydraulic thruster manufacturer prices. The brake "Product Quality Approval Certificate", "Type Test Approval Certificate", and "Special Equipment Type Test Qualification Certificate" issued by the National Lifting and Transportation Machinery Product Quality Supervision, Inspection and Testing Center. And passed the ISO: 9000 and GB/T19001-2000 Quality Management System Certification of the China Fangyuan Certification Committee. In 2004, it was awarded the title of High Quality Product in Henan Province. Obtained the National Industrial Product Production License in April 2008 (For explosion-proof electrical appliances, Jiaozuo Hydraulic Brake Factory, brake manufacturer, crane brake, thruster brake, YT1 thruster, explosion-proof brake, wind brake, electromagnetic brake mainly produces YWZB, YWZ2, YWZ3, YWZ4, YWZ5, YWZ6, YWZ8, YWZ9, YWZ10, YWZ12, YWZ13 series electric hydraulic block brakes. All kinds of explosion-proof brakes, TJ2 series new energy-saving electromagnet brakes, electric hydraulic boom disk system The actuator, mining explosion-proof electromagnetic starter, and mining vacuum feed switch have complete product specifications, reliable performance, and high-qualityOur company is guided by the principle of "market orientation, technology guarantee, quality survival, reputation development". Advanced production equipment and processes, strong technical strength, comprehensive testing methods, a complete quality assurance system, reasonable product prices, and reputable after-sales service are reliable guarantees for our company's products to quickly enter the market and win users1. Implement the GB/T19001ISO9000 series standards, improve and improve the quality management system, and ensure timely provision of safe and reliable products according to national and industry standards to users;2. Strictly implement the "Three Guarantees" policy. During the "Three Guarantees" period, any product quality issues are guaranteed to be repaired, replaced, or returned. Beyond the "three guarantees" period, ensure the provision of maintenance accessories and provide good service work;3. Upon receiving notification from the user regarding product quality issues, a response shall be given within 24 hours. If on-site problem-solving is required, technical service personnel shall be dispatched within 48 hours to ensure that the problem is not resolved and service work is not stopped;4. According to user requirements, serve as a good advisor, assist in selection, and proactively provide pre-sales and after-sales service.

time:2021-04-26

More

BYWZ5 explosion-proof electric hydraulic brakeConsulting and ordering model: BYWZ5-160/23 BYWZ5-200/23BYWZ5-250/23 BYWZ5-250/50BYWZ5-315/23 BYWZ5-315/50 BYWZ5-315/50 BYWZ5-315/80BYWZ5-400/50 BYWZ5-400/80 BYWZ5-400/121BYWZ5-500/80 BYWZ5-500/121 BYWZ5-500/201BYWZ5-630/121 BYWZ5-630/201 BYWZ5-630/301BYWZ5-710/201 BYWZ5-710/301 BYWZ5-800/301/201BYWZ9 explosion-proof electric hydraulic brakeConsulting and ordering model: BYWZ9-160/23 BYWZ9-200/23BYWZ9-250/23 BYWZ9-250/50BYWZ9-315/23 BYWZ9-315/50 BYWZ9-315/50 BYWZ5-315/80BYWZ9-400/50 BYWZ9-400/80 BYWZ9-400/121BYWZ9-500/80 BYWZ9-500/121 BYWZ9-500/201BYWZ9-630/121 BYWZ9-630/201 BYWZ9-630/301BYWZ9-710/201 BYWZ9-710/301 BYWZ9-800/301/201Dedicated to coal mines, cranes, and mining machineryBEd-121/12, BEd-201/12, BEd-301/12Manufacturer's prices for BEd30/5, BEd50/6, BEd80/6, BEd80/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd121/6, BEd201/6, BEd301/6, BEd30/5 explosion-proof electric hydraulic thrustersManufacturer prices for BEd121/12, BEd201/12, BEd301/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd-30/5, BEd-50/6, BEd-80/6, BEd-80/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd-121/6, BEd-201/6, BEd-301/6, BEd-30/5 explosion-proof electric hydraulic thrustersBEd-121/12, BEd-201/12, BEd-301/12 Flameproof electric hydraulic thruster manufacturer prices. The brake "Product Quality Approval Certificate", "Type Test Approval Certificate", and "Special Equipment Type Test Qualification Certificate" issued by the National Lifting and Transportation Machinery Product Quality Supervision, Inspection and Testing Center. And passed the ISO: 9000 and GB/T19001-2000 Quality Management System Certification of the China Fangyuan Certification Committee. In 2004, it was awarded the title of High Quality Product in Henan Province. Obtained the National Industrial Product Production License in April 2008 (For explosion-proof electrical appliances, Jiaozuo Hydraulic Brake Factory, brake manufacturer, crane brake, thruster brake, YT1 thruster, explosion-proof brake, wind brake, electromagnetic brake mainly produces YWZB, YWZ2, YWZ3, YWZ4, YWZ5, YWZ6, YWZ8, YWZ9, YWZ10, YWZ12, YWZ13 series electric hydraulic block brakes. All kinds of explosion-proof brakes, TJ2 series new energy-saving electromagnet brakes, electric hydraulic boom disk system The actuator, mining explosion-proof electromagnetic starter, and mining vacuum feed switch have complete product specifications, reliable performance, and high-qualityOur company is guided by the principle of "market orientation, technology guarantee, quality survival, reputation development". Advanced production equipment and processes, strong technical strength, comprehensive testing methods, a complete quality assurance system, reasonable product prices, and reputable after-sales service are reliable guarantees for our company's products to quickly enter the market and win users1. Implement the GB/T19001ISO9000 series standards, improve and improve the quality management system, and ensure timely provision of safe and reliable products according to national and industry standards to users;2. Strictly implement the "Three Guarantees" policy. During the "Three Guarantees" period, any product quality issues are guaranteed to be repaired, replaced, or returned. Beyond the "three guarantees" period, ensure the provision of maintenance accessories and provide good service work;3. Upon receiving notification from the user regarding product quality issues, a response shall be given within 24 hours. If on-site problem-solving is required, technical service personnel shall be dispatched within 48 hours to ensure that the problem is not resolved and service work is not stopped;4. According to user requirements, serve as a good advisor, assist in selection, and proactively provide pre-sales and after-sales service.

time:2021-04-26

More

BYWZ5 explosion-proof electric hydraulic brakeConsulting and ordering model: BYWZ5-160/23 BYWZ5-200/23BYWZ5-250/23 BYWZ5-250/50BYWZ5-315/23 BYWZ5-315/50 BYWZ5-315/50 BYWZ5-315/80BYWZ5-400/50 BYWZ5-400/80 BYWZ5-400/121BYWZ5-500/80 BYWZ5-500/121 BYWZ5-500/201BYWZ5-630/121 BYWZ5-630/201 BYWZ5-630/301BYWZ5-710/201 BYWZ5-710/301 BYWZ5-800/301/201 New BYWZ5 Explosion-proof Blue MeshBYWZ9 explosion-proof electric hydraulic brakeConsulting and ordering model: BYWZ9-160/23 BYWZ9-200/23BYWZ9-250/23 BYWZ9-250/50BYWZ9-315/23 BYWZ9-315/50 BYWZ9-315/50 BYWZ5-315/80BYWZ9-400/50 BYWZ9-400/80 BYWZ9-400/121BYWZ9-500/80 BYWZ9-500/121 BYWZ9-500/201BYWZ9-630/121 BYWZ9-630/201 BYWZ9-630/301BYWZ9-710/201 BYWZ9-710/301 BYWZ9-800/301/201Dedicated to coal mines, cranes, and mining machineryBEd-121/12, BEd-201/12, BEd-301/12Manufacturer's prices for BEd30/5, BEd50/6, BEd80/6, BEd80/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd121/6, BEd201/6, BEd301/6, BEd30/5 explosion-proof electric hydraulic thrustersManufacturer prices for BEd121/12, BEd201/12, BEd301/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd-30/5, BEd-50/6, BEd-80/6, BEd-80/12 explosion-proof electric hydraulic thrustersManufacturer's prices for BEd-121/6, BEd-201/6, BEd-301/6, BEd-30/5 explosion-proof electric hydraulic thrustersBEd-121/12, BEd-201/12, BEd-301/12 Flameproof electric hydraulic thruster manufacturer prices. The brake "Product Quality Approval Certificate", "Type Test Approval Certificate", and "Special Equipment Type Test Qualification Certificate" issued by the National Lifting and Transportation Machinery Product Quality Supervision, Inspection and Testing Center. And passed the ISO: 9000 and GB/T19001-2000 Quality Management System Certification of the China Fangyuan Certification Committee. In 2004, it was awarded the title of High Quality Product in Henan Province. Obtained the National Industrial Product Production License in April 2008 (For explosion-proof electrical appliances, Jiaozuo Hydraulic Brake Factory, brake manufacturer, crane brake, thruster brake, YT1 thruster, explosion-proof brake, wind brake, electromagnetic brake mainly produces YWZB, YWZ2, YWZ3, YWZ4, YWZ5, YWZ6, YWZ8, YWZ9, YWZ10, YWZ12, YWZ13 series electric hydraulic block brakes. All kinds of explosion-proof brakes, TJ2 series new energy-saving electromagnet brakes, electric hydraulic boom disk system The actuator, mining explosion-proof electromagnetic starter, and mining vacuum feed switch have complete product specifications, reliable performance, and high-qualityOur company is guided by the principle of "market orientation, technology guarantee, quality survival, reputation development". Advanced production equipment and processes, strong technical strength, comprehensive testing methods, a complete quality assurance system, reasonable product prices, and reputable after-sales service are reliable guarantees for our company's products to quickly enter the market and win users1. Implement the GB/T19001ISO9000 series standards, improve and improve the quality management system, and ensure timely provision of safe and reliable products according to national and industry standards to users;2. Strictly implement the "Three Guarantees" policy. During the "Three Guarantees" period, any product quality issues are guaranteed to be repaired, replaced, or returned. Beyond the "three guarantees" period, ensure the provision of maintenance accessories and provide good service work;3. Upon receiving notification from the user regarding product quality issues, a response shall be given within 24 hours. If on-site problem-solving is required, technical service personnel shall be dispatched within 48 hours to ensure that the problem is not resolved and service work is not stopped;4. According to user requirements, serve as a good advisor, assist in selection, and proactively provide pre-sales and after-sales service.

time:2021-04-26

More

The electric hydraulic thruster has been equipped with hydraulic oil according to regulations when leaving the factory. If the thruster has been stored for a long time (more than 6 months), screw out the plug (see Figure 1) before use to check whether the oil level is normal. If the oil level does not reach the specified level, hydraulic oil should be added to the specified level (see Figure 1), otherwise the thruster cannot work properly. The hydraulic oil grade can be found in Table 2 (Mobil, Shell, and other hydraulic oils equivalent to the grade in the table can also be used), and the hydraulic oil filled must not contain impurities or dirt (it should be filtered). When adding hydraulic oil, the push rod should be slowly pulled up and down several times to remove air from the hydraulic cylinder and ensure sufficient oil is added. The electric motor of the electric hydraulic thruster is connected to the middle of the body with a cover. There is a piston with two push rods inside the body, and a blade wheel is connected to the rotating shaft. The rotating shaft is supported by a support plate equipped with rolling bearings, which is fastened to the piston and is sturdy with screws. The upper end of the body is connected to the crossbeam through the push rod, and the crossbeam is equipped with a connecting rod for connecting the pin shaft and the matching hydraulic push rod brake. The pin holes under the body of the ED panoramic camera are also used for connection. When energized, the main shaft of the electric motor drives the slide to rotate the shaft and the impeller on the shaft at high speed. Under the action of centrifugal force, the oil in the oil pipeline generates a pressure difference, which causes the oil to be sucked from the upper part of the piston to the lower part, forming high pressure at the lower part of the piston, forcing the piston and the push rod and crossbeam fixed on it to rise rapidly. When the piston rises to the top position, the lower part of the piston maintains a constant pressure. At the same time, mechanical motion is generated by compressing the load spring through a lever mechanism (if the thruster or brake has a load spring). (If matched with the YWZ series hydraulic push rod brake, release the brake) When the power is cut off, the impeller stops rotating, and the piston rapidly drops under the force of the load spring and its own gravity, forcing oil to flow back into the upper part of the piston. At this time, it still returns to its original position through the lever mechanism. (If matched with the YWZ series brake, hold the brake).YT1-18Z/2 YT125ZB/4 YT125ZC/4 YT1-45Z/4 YT1-45Z/5 YT1-45Z/6 YT1-90Z/6 YT1-90Z/8 YT1-125Z/10 YT1-180Z/8 YT1-180Z/10 YT1-180Z/12 YT1-320Z/12 (B) YT1-320Z/20 (A) YT1-320Z/35 YT1-350Z/12 YT1-350Z/20 YT1-350Z/3545 Pusher Multi Solid Figure 4. Instructions for Use:1. Installation test: First, check whether the thrust on the nameplate of the electric hydraulic thruster product matches the required force: remove oil stains on the motor and body surface, and check whether the push rod lifting is smooth. Unscrew the oil filling plug 5 (Figure 3) and oil level plug 3, and inject suitable and pure hydraulic oil until the screw hole 3 is reached. Then tighten plug 3 and plug 5. According to different ambient medium temperatures, it is recommended to follow Table 6 for hydraulic oil. The temperature of the surrounding medium is+45 ℃~+21 ℃+20 ℃~+0 ℃+0 ℃~-15 ℃~-15 ℃~-30 ℃ - below 30 ℃. 20 # mechanical oil GB443-64, 10 # transformer oil (freezing point -10 ℃) SYB1351-62, 25 # transformer oil (freezing point -25 ℃) SYB1351-62, instrument oil (freezing point -60 ℃), GB487-65, a mixture of alcohol and glycerol. It is recommended to use oil to connect the lower part of the hydraulic thruster with a pin, and connect the connecting rod of the crossbeam with a lever device with a pin. After testing whether the external power supply matches the motor nameplate, correctly connect the motor terminal to the external power supply. Connect the power supply and check whether the impeller operates flexibly and whether the push rod lifts smoothly. 2. Use and maintenance: check whether the electric hydraulic thruster works normally and whether there is oil leakage or oil seepage. A constant amount of oil should be maintained. But note that the oil level cannot be higher than the oil level plug. If it is higher than the oil level plug, there may be oil leakage at the push rod, motor, and cylinder head. Check the oil at least every six months. When the oil deteriorates or mixes with impurities, the oil should be changed when the viscosity increases. If the oil selection is not appropriate, a separate selection should be made. Check if the motor wiring is in good condition and if the protective device is appropriate and reliable.Oil leakage at the push rod. During installation, the push rod was burned by welding current and the sealing element was worn. When refueling, the pusher should be upright. When adding to the flat oil injection port, the connecting bolt may become loose during use, and the motor bearing may be worn. The sealing element may be damaged and the hydraulic oil may be discharged. Tighten the bolt and replace the pusher. Replace the pusher. Choose a suitable product, check the power parameters, adjust the mechanism travel, and replace the pusher. Replace the pusherPusher does not operate, motor respondsWhen refueling, the thruster should be firm and filled up to the oil port position for refueling. Replace the thruster and select a suitable inlet culvert to replace the thruster. Replace the thruster and ground it as requiredWater ingress into the poorly sealed junction boxThe thruster leaks oil from the middle flangeOil leakage from the motor and damage to the motor shaft sealED electric hydraulic thrusterEd23/5, Ed30/5, Ed50/6, Ed80/6, Ed121/6, Ed201/6, Ed23/5, Ed30/5, Ed50/6, Ed80/6, Ed121/6, Ed201/6, Ed301/6The brake pusher is mainly used as an operating component for the YWZ4, YWZ5, YWZ8, YWZ9, YWL.YW.YWZP series electric hydraulic block brakes. It is widely used in industries such as lifting transportation, metallurgy, mining, port electric hydraulic block brake ports, and construction.

time:2021-04-26

More

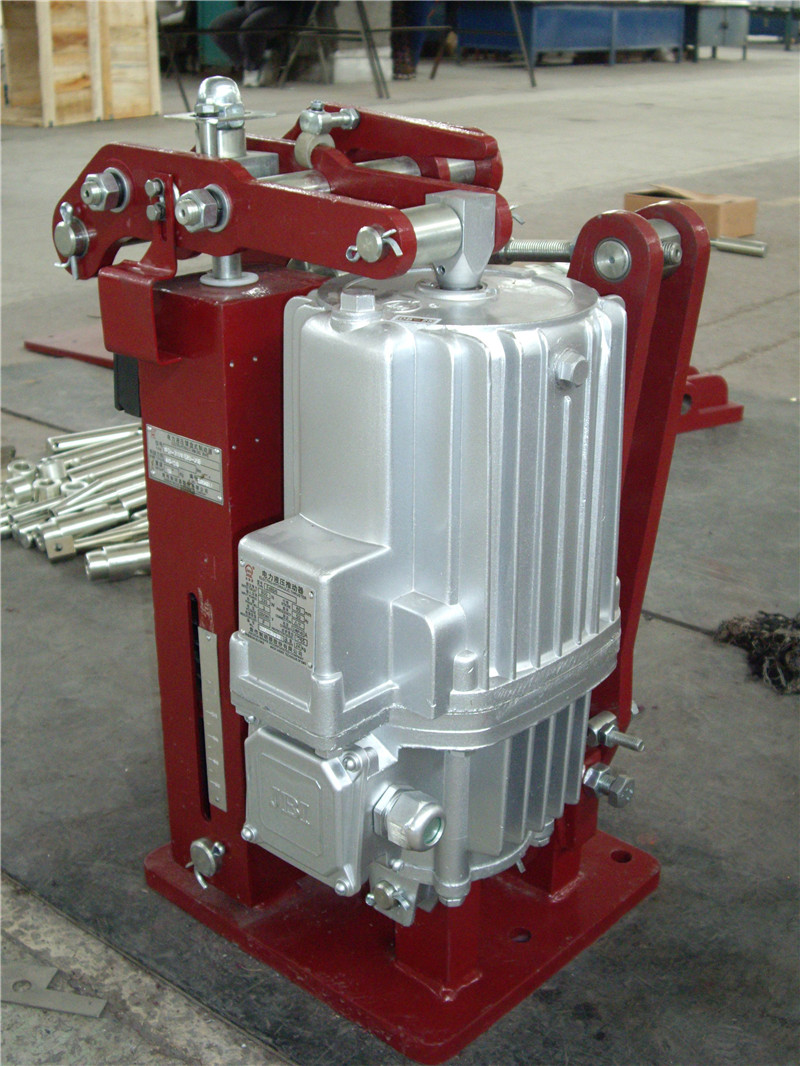

Electric hydraulic brake model: YWZ5-315/50Composition: brake pads, brake arms, brake wheels, brake release devices, etcPurpose: Mainly used for mechanical braking of driving devices in lifting, transportation, metallurgy, mining, ports, and construction machineryModel classification: YWZ, YWZ2, YWZ3, YWZ4, YWZ5, YWZ9, etcWorking principle of the new YWZ5 with manual workshop diagramThis series of hydraulic push rod brakes consists of two main parts: a brake frame and a matching ED type electric hydraulic thruster. When powered on, the electric hydraulic thruster acts, its push rod quickly rises, and the brake shoe is opened (released) through the action of a lever; When the power is cut off, the push rod of the electric hydraulic thruster rapidly descends under the action of spring force and closes the brake shoe (holding brake) through lever actionUsage This product is widely used in lifting and transportation, metallurgy, mining, port, construction, building materials and other work as a driving device for mechanical braking of external holding brake, and can also be used as a power source for other methods of motion, such as reciprocating, shaking, Circular motion, etc.The motor is a three-phase AC asynchronous motor that complies with the regulations of GB755-87, and has an insulation level of E. Application conditions:1. Continuous operation S1, continuous operation S3, with a load duration rate of FC=40%2. The rated frequency is 50Hz, and the rated voltage is 380V (three-phase AC voltage)3. The altitude of the application address meets the standard (GB755-87)4. The ambient temperature should be within the range of -20 ℃ to 40 ℃, and the relative humidity of the air should not exceed 90%. 5. It is generally suitable for vertical equipment, piston rod connection blocks facing upwards, and the inclination should not exceed ± 15 °.The MYT3 series electric hydraulic thruster is a new type of single push rod thruster based on the national conditions of our country and taking into account the planning of domestic and foreign leading products. It has the advantages of safe and reliable operation, sensitive and stable upward and downward movements, convenient repair, and low quotation. Its practicality and versatility are superior, and the product meets the requirements of DQ4516. The protection level of the thruster shell is IP54 (GB4208-84)This product is widely used in lifting and transportation, metallurgy, mining, port, construction, building materials and other work as the driving equipment of the external holding brake for mechanical braking, as well as as the power source for other methods of motion, such as reciprocating, rocking, Circular motion, etc.The motor is a three-phase AC asynchronous motor that complies with the regulations of GB755-87, and has an insulation level of E. Application conditions:1. Continuous operation S1, continuous operation S3, with a load duration rate of FC=40%2. The rated frequency is 50Hz, and the rated voltage is 380V (three-phase AC voltage)3. The altitude of the application address meets the standard (GB755-87)4. The ambient temperature should be within the range of -20 ℃ to 40 ℃, and the relative humidity of the air should not exceed 90%. 5. It is generally suitable for vertical equipment, piston rod connection blocks facing upwards, and the inclination should not exceed ± 15 °.The ED.YTI.MYT3 series electric hydraulic thrusters are a new type of single push rod thruster based on China's national conditions and taking into account domestic and international product planning. They have the advantages of safe and reliable operation, sensitive and stable upward and downward movements, easy repair, and low quotation. They have excellent practicality and versatility, and meet the requirements of DQ4516. The thruster shell protection level is IP54 (GB4208-84)The interlocking back distance equalization device (patented technology) and the automatic tile following device can always maintain equal back distance of both sides of the tiles without adjustment, completely avoiding the phenomenon of one brake pad floating against the brake wheel due to uneven back distance.The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use.The brake spring is arranged inside the square tube and equipped with a ruler, making it very convenient for users to read the braking torque value, eliminating the trouble of measurement and calculation.The brake pad is a card mounted integral shaped structure, which is very convenient and fast to replace. There are different materials of brake pads available for users to choose from, such as semi metal (asbestos free) hard and semi hard, soft (asbestos containing, asbestos free).It can be matched with our company's new thruster, with sensitive action and long service life.Additional devices:Manual release deviceReleasing (opening) limit switch can display whether the brake is released normally.The automatic compensation device for brake pad wear can achieve stepless automatic compensation for pad backoff and braking torque when pad wear occurs.The limit switch for pad wear can achieve signal display when the brake pad is worn to its limit (note: applied to brakes that require automatic compensation devices).Using a thruster with a lowering delay valve to drive, the delayed closure of the brake can be achieved.

time:2021-04-26

More

The ED.YTI.MYT1.YTD series electric hydraulic thrusters are a new type of single push rod thruster designed based on China's national conditions and with reference to domestic and international leading product plans. They have the advantages of safe and reliable operation, sensitive and stable upward and downward movements, easy repair, and low quotation. They have excellent practicality and versatility, and the product meets the requirements of DQ4516. The protection level of the thruster shell is IP54 (GB4208-84)The interlocking back distance equalization device (patented technology) and the automatic tile following device can always maintain equal back distance of both sides of the tiles without adjustment, completely avoiding the phenomenon of one brake pad floating against the brake wheel due to uneven back distance.The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use.The brake spring is arranged inside the square tube and equipped with a ruler, making it very convenient for users to read the braking torque value, eliminating the trouble of measurement and calculation.The brake pad is a card mounted integral shaped structure, which is very convenient and fast to replace. There are different materials of brake pads available for users to choose from, such as semi metal (asbestos free) hard and semi hard, soft (asbestos containing, asbestos free).It can be matched with our company's new thruster, with sensitive action and long service life.ED50 detection imageAdditional devices:Manual release deviceReleasing (opening) limit switch can display whether the brake is released normally.The automatic compensation device for brake pad wear can achieve stepless automatic compensation for pad backoff and braking torque when pad wear occurs.The limit switch for pad wear can achieve signal display when the brake pad is worn to its limit (note: applied to brakes that require automatic compensation devices).Using a thruster with a lowering delay valve to drive, the delayed closure of the brake can be achieved.Electric hydraulic brake modelComposition: brake pads, brake arms, brake wheels, brake release devices, etcPurpose: Mainly used for mechanical braking of driving devices in lifting, transportation, metallurgy, mining, ports, and construction machineryModel classification: YWZ, YWZ2, YWZ3, YWZ4, YWZ5, YWZ9, etcoperational principleThis series of hydraulic push rod brakes consists of two main parts: a brake frame and a matching ED type electric hydraulic thruster. When powered on, the electric hydraulic thruster acts, its push rod quickly rises, and the brake shoe is opened (released) through the action of a lever; When the power is cut off, the push rod of the electric hydraulic thruster rapidly descends under the action of spring force and closes the brake shoe (holding brake) through lever actionUsage This product is widely used in lifting and transportation, metallurgy, mining, port, construction, building materials and other work as a driving device for mechanical braking of external holding brake, and can also be used as a power source for other methods of motion, such as reciprocating, shaking, Circular motion, etc.The motor is a three-phase AC asynchronous motor that complies with the regulations of GB755-87, and has an insulation level of E. Application conditions:1. Continuous operation S1, continuous operation S3, with a load duration rate of FC=40%2. The rated frequency is 50Hz, and the rated voltage is 380V (three-phase AC voltage)3. The altitude of the application address meets the standard (GB755-87)4. The ambient temperature should be within the range of -20 ℃ to 40 ℃, and the relative humidity of the air should not exceed 90%. 5. It is generally suitable for vertical equipment, piston rod connection blocks facing upwards, and the inclination should not exceed ± 15 °.45 Pusher Multi Real ImageThe MYT3 series electric hydraulic thruster is a new type of single push rod thruster based on the national conditions of our country and taking into account the planning of domestic and foreign leading products. It has the advantages of safe and reliable operation, sensitive and stable upward and downward movements, convenient repair, and low quotation. Its practicality and versatility are superior, and the product meets the requirements of DQ4516. The protection level of the thruster shell is IP54 (GB4208-84)This product is widely used in lifting and transportation, metallurgy, mining, port, construction, building materials and other work as the driving equipment of the external holding brake for mechanical braking, as well as as the power source for other methods of motion, such as reciprocating, rocking, Circular motion, etc.The motor is a three-phase AC asynchronous motor that complies with the regulations of GB755-87, and has an insulation level of E. Application conditions:1. Continuous operation S1, continuous operation S3, with a load duration rate of FC=40%2. The rated frequency is 50Hz, and the rated voltage is 380V (three-phase AC voltage)3. The altitude of the application address meets the standard (GB755-87)4. The ambient temperature should be within the range of -20 ℃ to 40 ℃, and the relative humidity of the air should not exceed 90%. 5. It is generally suitable for vertical equipment, piston rod connection blocks facing upwards, and the inclination should not exceed ± 15 °.

time:2021-04-26

More

Metallurgical brakes are based on this design concept. The friction required for water-cooled brakes should mainly come from the friction between polymers, rather than the direct friction between the metal dual surface and the friction material. The friction of polymers can be seen as two parts: the adhesion component and the deformation component. The adhesion component is the frictional resistance generated by the adhesion between polymers, which is easy to understand, The frictional deformation component of polymer materials refers to the strain that occurs in the surface material during elastic or viscoelastic contact, and positive work is done on the friction system. After unloading, some of the energy released is consumed in the form of vibration energy and thermal energy. Pneumatic brake usage diagramFor friction material products with copper as a friction dual component, metallurgical brakes need to design a new formula system to achieve this. The new formula system should not contain metal materials and hard friction enhancers, but should use more organic polymer materials, including fibers and particles as reinforcement materials, matrix binders, and friction performance regulators. However, for high-temperature working conditions above 250 ℃, such formula systems are not recommended, Due to the poor heat resistance of organic compounds, the friction and wear performance will be reduced under the action of frictional heatThe Metallurgical Crane Brake Zone provides us with metallurgical crane brakes, metallurgical crane safety brakes, metallurgical crane safety brakes, metallurgical crane lifting low-speed brakes, and other contents. The content about metallurgical crane brakes is comprehensive, and various models of specialized brakes for the metallurgical industry have a long service life to choose from. It is an information integration platform for the construction machinery industry, With the development of modern industrial machinery, brakes have emerged many new structural types, among which caliper disc brakes, magnetic powder brakes and electromagnetic brakes are widely used. The specific classification of various disc drum brakes is as follows:Friction brake can be divided into disc brake, external block brake, internal expansion shoe brake, belt brake, integrated belt brake, double shoe brake, multi shoe brake, simple belt brake, single disc brake, multi disc brake, fixed caliper brake, floating brake, etc. Non friction brake, which can be divided into magnetic powder brake, magnetic eddy current brake, water eddy current brake, etc.In particular, under high load, it has good heat resistance, stable braking effect, and is not afraid of mud and water. When driving in winter and under bad road conditions, many cars use flat brake discs, perforated brake discs, and scoring brake discs. Among them, scoring brake discs have good braking effect and ventilation and heat dissipation capacity.The diameter of the brake disc and the diameter D of the brake disc of the metallurgical brake should be as large as possible. At this time, the Galaxy effective radius of the brake disc is increased, which can reduce the clamping force of the brake caliper, and reduce the unit pressure and working temperature of the pad. The diameter of the brake disc is usually chosen to be 70% to 79% of the rim diameter, depending on the rim diameter. Vehicles with a total mass greater than 2 tons should have an upper limit.Z-Z9 series brakeThe thickness of the brake disc has an impact on the quality of the brake disc and the temperature rise during operation. To reduce the mass, the thickness of the brake disc should not be too large; In order to reduce temperature, the thickness of the brake disc should not be too small. The brake disc can be made solid, or a ventilation hole can be cast in the middle of the brake disc for heat dissipation and ventilation. When designing friction materials, apart from graphite and metal sulfides that serve as solid lubricants and have thermal conductivity, no metals, metal oxides, or metal salt inorganic substances are added. Instead, they rely on the weight of the polymer, whether they are fibers and particles used as reinforcement materials, matrix binders, or friction performance modifiers. These materials will not cause furrows or scratches on copper pairs, The organic matter is easy to transfer to the metal dual surface to form a transfer film to protect the dual surface. For example, the cashew nut shell oil friction powder we are familiar with has this effect. It is hoped that the friction will occur between the transfer film on the copper dual surface and the facial mask on the friction material surface.

time:2021-04-26

More