Jiaozuo Brake, subordinate to Jiaozuo Hongqi Brake Co., Ltd., is a company integrating brake, actuator, development and manufacturing, sales and service.

time:2021-06-07

More

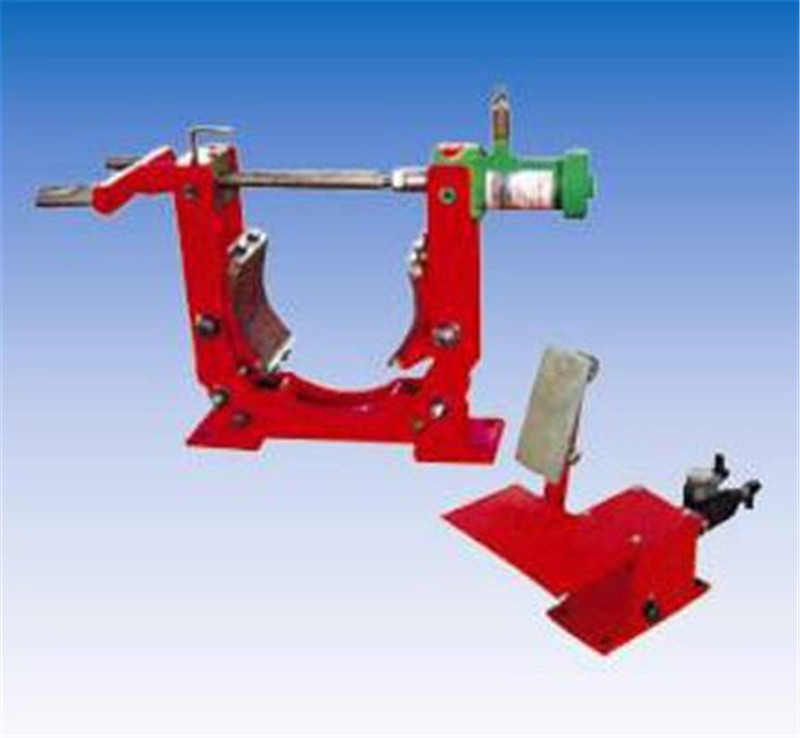

TYW series hydraulic block brake is a normally open, hydraulically driven brake, which is horizontally installed (horizontally installed relative to the brake wheel axis), mainly used for deceleration braking of slewing mechanisms such as portal cranes and Tower crane. The TYW series brakes are controlled by a foot operated hydraulic pump, allowing for arbitrary braking.Main features:The interlocking back distance equalization device and automatic tile following device can always maintain equal back distance of both sides of the tiles without adjustment, completely avoiding the phenomenon of one side of the brake pad floating against the brake wheel due to uneven back distance.The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use.The brake pad is a card mounted integral shaped structure, which is very convenient and fast to replace. There are different materials of brake pads available for users to choose from, such as semi metal (asbestos free) hard and semi hard, soft (asbestos containing, asbestos free).TYW is equipped with a manual closing (upper brake) device, which can be used to maintain braking when necessary in non working conditions.TYWZ real image large oil cylinder

time:2021-06-07

More

The structural purpose of electric hydraulic brakes is to stop or decelerate the moving parts in machinery. Commonly known as brakes or brakes. The brake mainly consists of a brake frame, brake components, and control devices.1. Although the axial size of the compact and power-off brake is small, the braking torque is sufficient.2. The quick response and power loss brake uses a spring device to form braking torque, and the spring reset time is the braking response time3. The use of new friction materials in life loss braking determines the performance of high life.

time:2021-06-07

More

Durable electric hydraulic thruster Ed121/6 Ed201/6 Ed301/6, including motor, hydraulic cylinder, impeller, push rod, and piston; The motor is located below the hydraulic cylinder, which is divided into a lower impeller chamber and an upper working chamber. The impeller is located in the impeller chamber and is connected to the motor rotor shaft. The push rod and the piston connected to the push rod are located in the working chamber. The piston is externally equipped with a cylinder liner, which is combined with the hydraulic cylinder body as a whole; The front and back of the impeller are equipped with blades, and the upper end of the impeller is equipped with valve blocks. The valve blocks are located on both sides of the impeller, forming a double oil inlet with the upper wall of the impeller chamber, and the cylinder liner and hydraulic cylinder form a double oil return port. The electric hydraulic thruster of this utility model adopts a dual circuit structure, which reduces the blade diameter, reduces shaft power, increases the service life of the motor and blades, reduces the power of the motor, and achieves energy-saving purposes. Durable electric hydraulic thruster Ed121/6 Ed201/6 Ed301/6 Electric hydraulic thruster Ed50/6 Ed80/6 Ed30/6 23/51-ED121 Workshop DrawingIt is also a common fault that the brake cannot be opened. Firstly, check whether the coil of the brake is burnt out. If the coil is burnt out, it needs to be replaced and wired again. Secondly, check if the friction plate of the brake has experienced excessive surface temperature and brake wheel adhesion due to frequent braking. If this is the case, the brake wheels should be cleaned with gasoline and the friction plates should be replaced. The ED model parameters and appearance diagram should be provided

time:2021-06-07

More

The brake disc uses the peripheral surface as the friction surface, which greatly increases the brake surface and effectively shortens the Braking distance, evenly distributes the force strength of the brake components, prolongs the brake service life, reduces friction plate wear, and avoids brake heating. Circumferential disc brake is a braking system independently innovated and developed by Chinese people. It has a number of invention patents and utility model patents, which is more than five times larger than the caliper disc brake and full disc brake, in line with the Chinese road.As a developing country, there is still a certain gap between China's caliper disc brake industry and that of developed countries. However, in developing countries, China is a country with complete caliper disc brake industry and strong comprehensive strength. When foreign well-known caliper disc brake enterprises slowly take root in China, even with the continuous progress of new technologies and processes, caliper disc brakes are also constantly developing, constantly pushing through the old to bring forth the new, and constantly improving the intelligent level, Chinese enterprises are still facing more and more challenges. When the domestic caliper disc brake market is becoming more and more saturated, it is urgent for domestic caliper disc brake enterprises to find a larger and broader international market and a new market breakthrough. The globalization and integration of the world economy are developing rapidly, and international market competition is becoming increasingly fierce. It has become an inevitable trend for our caliper disc brake enterprises to enter the international market. However, in the last century, the era where one computer and one translation software could travel the world has disappeared forever. Nowadays, the internationalization path of enterprises needs to be more systematic and standardized. It is necessary to carefully study the international market, understand the development trends of the international market, identify their position in the market, and promote product and branding. Only in this way can we actively and steadily explore the international market. Disc brake is adopted. Disc brake is also called disc brake, which is named after its shape as its name implies. The disc brake is hydraulic type and controlled by hydraulic pressure. The main parts include brake disc, wheel cylinder, brake caliper, oil pipe, etc. The brake disc is made of alloy steel and fixed to the wheels, rotating with the wheels. The wheel cylinder is fixed on the bottom plate of the brake and remains stationary. The two friction plates on the brake caliper are installed on both sides of the brake disc. The piston of the wheel cylinder is driven by hydraulic pressure from the oil pipe to press the friction plates against the brake disc, causing friction braking. The action is like using pliers to clamp the rotating plate and force it to stop.QP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof Brakes

time:2021-06-07

More

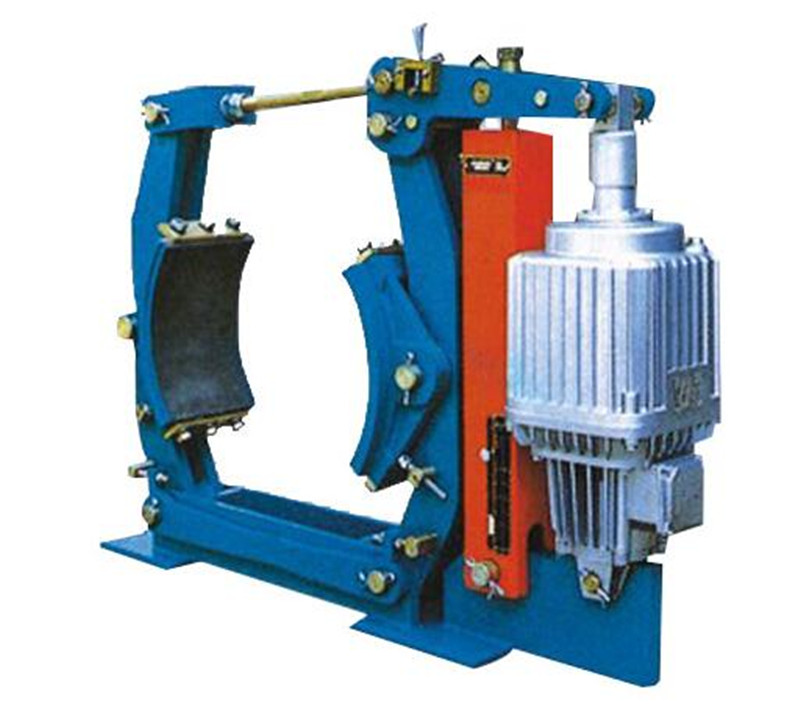

YWZE Product IntroductionHydraulic brakes are widely used for deceleration and parking (maintenance) braking of various mechanisms in various lifting transportation, port loading and unloading, metallurgical equipment, mining machinery, and engineering machinery.Compliant with standards:The connection dimensions and braking torque parameters of YWZE series brakes comply with GB6333-86 standard, and the technical requirements comply with JB/T6406-2006 standard; The YWZEE series is equipped with Ed series thrusters that meet the DIN15430 standard.Main features:Interlocking type equal back distance device (patented technology) and automatic tile following device can always maintain equal back distance of both sides of the tiles without adjustment, completely avoiding the phenomenon of one brake pad floating against the brake wheel due to uneven back distance.The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use.The brake spring is arranged inside the square tube and equipped with a ruler, making it very convenient for users to read the braking torque value, eliminating the trouble of measurement and calculation.The brake pad is a card mounted integral molding structure, which is very convenient and fast to replace. There are different materials of brake pads available for users to choose from, such as semi metal (asbestos free) hard and semi hard, soft (asbestos containing, asbestos free).It can be matched with our company's new thruster, with sensitive action and long service life.Additional devices:● Manual release device● Release (open) limit switch, which can display whether the brake is released normally.● Automatic compensation device for brake pad wear, which can achieve stepless automatic compensation for pad setback and braking torque when pad wear occurs.● Pad wear limit switch, which can display the signal when the brake pad is worn to the limit (note: applied to brakes that require automatic compensation device).Using a thruster with a lowering delay valve to drive, it can achieve delayed closure of the brake.Brake Additional Function TableAdditional Function CodeAdditional MenuWLPad wear limit switchRLOpening limit switchWCLiner wear compensation deviceCPAnticorrosive typeHLLeft hand operated deviceHRRight hand operated deviceYWZE series electric hydraulic block brakes:YWZE160-E23 Electric Hydraulic Drum Brake Brake ShoeYWZE-200/23; YWZE-200/30; YWZE-250/23; YWZE-250/30; YWZE-250/50; YWZE-300/30; YWZE-300/50; YWZE-300/80; YWZE9-315/30; YWZE-315/50; YWZE-315/80; YWZE-400/50; YWZE-400/80; YWZE-400/121; YWZE-500/80; YWZE-500/121; YWZE-500/201; YWZE-600/121; YWZE9-600/201; YWZE9-600/301; YWZE-630/121; YWZE-630/201; YWZE-630/301; YWZE-700/201; YWZE-700/301; YWZE-710/201; YWZE-710/301; YWZE-800/301/12Specific production model:YT1, ED, YTD. series electric hydraulic thrustersJZ, MW, TJ2, ZWZA, ZWZ3 series electromagnetic brakesYWZE, YWZE3, YWZE4, YWZE5, YWZE8, YWZE10, YWZE9, YWZE13, YW series electric hydraulic brakesQP, CQP series pneumatic caliper disc brakeDCPZ series electromagnetic caliper disc brakeYPZ series arm disc brakeSBD series safety brakeSH, ST series hydraulic failure protection brakeDADH series hydraulic direct acting brakeSE series electromagnetic failure protection brakeSP series pneumatic failure protection brakeYFX, YDGZ, YLBZ, Series Windproof Brakes

time:2021-06-07

More

The hydraulic brake has the characteristics of compact structure, fast response speed, and long service life. The fluid provided can be continuously circulated in the brake, which has greatly improved the environmental protection. A variety of technical means have also been adopted to effectively protect the brake while reducing the occurrence of faults. It is undoubtedly beneficial for the guarantee of tires and vehicle loads, with low cost and strong functions. The disc brake is mainly composed of the brake master cylinder, brake hose, brake wheel cylinder, brake disc, etc. The brake master cylinder is fixed on the steering handle and consists of a main hydraulic cylinder, a manual brake handle (or brake pedal), a housing, a plunger, and a leather cup. One end of the brake hose is connected to the brake master cylinder, and the other end is connected to the brake wheel cylinder. The pipe is filled with hydraulic oil. The brake wheel cylinder is connected to the front shock absorber and is a fixed part of the brake, consisting of an oil cylinder and a piston, with each piston facing a friction plate at the front end. The brake disc is fixed to the front wheel and rotates with the wheel, which is the rotating part of the brake. A series of specialized devices that can forcibly reduce the driving speed of a car. The braking system mainly consists of four parts: energy supply device, control device, transmission device, and brake. The main function of the braking system is to slow down or even stop a moving car, maintain a stable speed when driving downhill, and keep a stopped car stationary. As the brake friction pads are vulnerable parts, they need to be replaced regularly. The friction plates of drum brakes are connected by rivets, and when replacing the friction plates, the rivets need to be removed and replaced, resulting in a particularly long maintenance time; The installation and connection of the friction lining of the Disc brake is relatively simple. The friction lining on the brake caliper can be easily taken out with an ordinary box wrench, which can greatly shorten the working hours and increase the attendance rate. The main reason is that the brake disc is prone to high temperature after a long time of braking, while the brake disc after high temperature should not be drenched with water, which is easy to crack and cause brake failure. Driving is very dangerous. The road conditions in China are very complex, and it is inevitable to encounter long and steep slopes. If there is no auxiliary braking technology such as in cylinder braking, continuous braking for a long time will cause significant damage to the brake discs, which is also an unbearable loss for users. On the contrary, if the Disc brake axle is installed and the engine with the in cylinder brake technology is installed, the vehicle will have a very high driving safety. The brake system is a series of special devices YWZ13 outline drawings used on the vehicle to make the outside world (mainly the road surface) exert a certain force on some parts of the vehicle (mainly the wheels), so as to carry out a certain degree of forced braking

time:2021-06-07

More

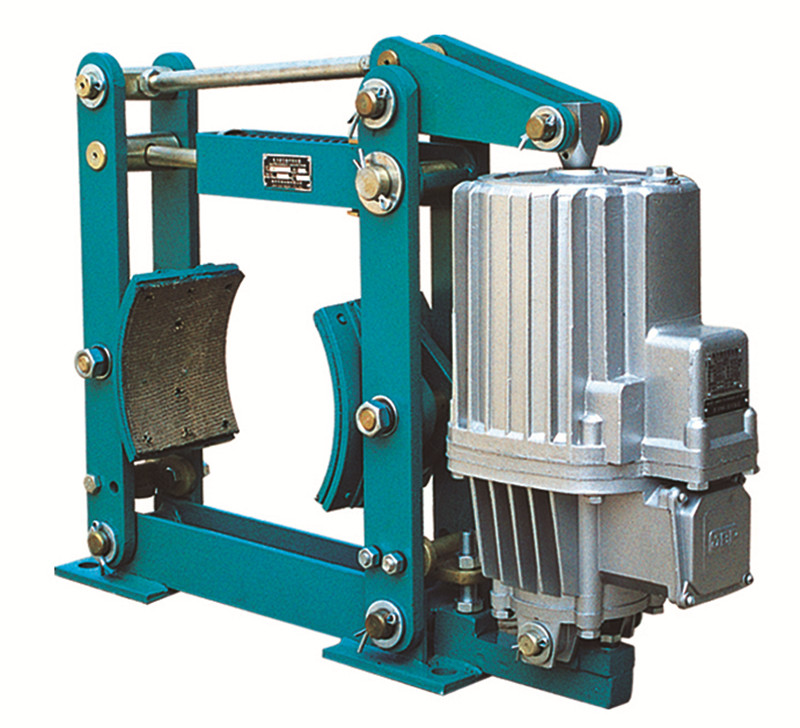

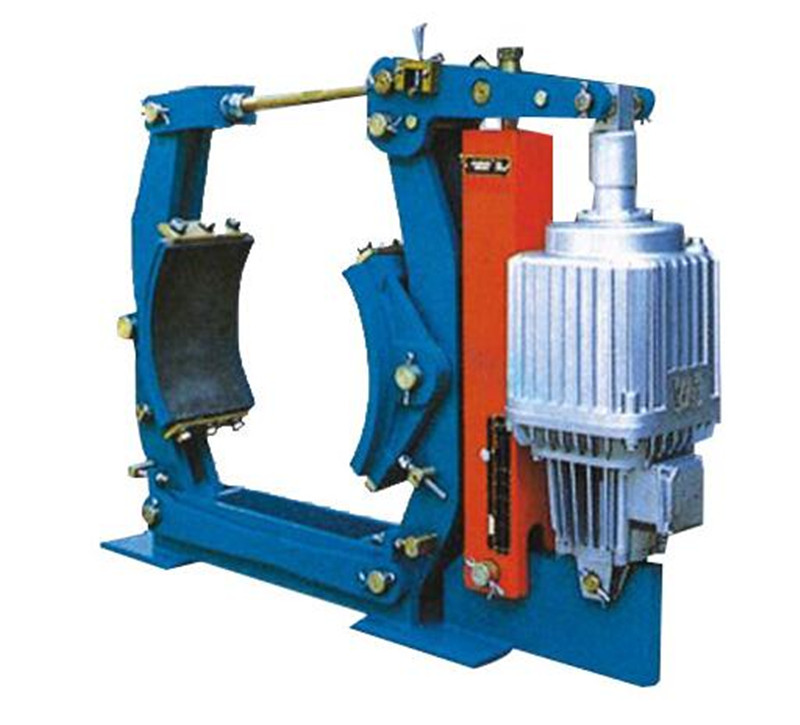

The connection dimensions and braking torque parameters of the electric hydraulic brake comply with the JB/ZQ4388-86 standard, and the technical requirements comply with the JB/T6406-2006 standard; YWZF is equipped with Ed series thrusters that comply with DIN15430 standard;Main features:Interlocking type equal back distance device (patented technology) and automatic tile following device can always maintain equal back distance of both sides of the tiles without adjustment, completely avoiding the phenomenon of one brake pad floating against the brake wheel due to uneven back distance.The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use.The brake spring is arranged inside the square tube and equipped with a ruler, making it very convenient for users to read the braking torque value, eliminating the trouble of measurement and calculation.The brake pad is a card mounted integral molding structure, which is very convenient and fast to replace. There are different materials of brake pads available for users to choose from, such as semi metal (asbestos free) hard and semi hard, soft (asbestos containing, asbestos free).It can be matched with our company's new thruster, with sensitive action and long service life.We can adjust the input power of the push rod by controlling its speed through a switch, thereby achieving speed control.Obviously, if the electric speed regulators configured in the electro-hydraulic push rod are different, the actual control modes that can be achieved will also be different. If distinguished from the perspectives of structure, working principle, and power supply mode, it can be divided into explosion-proof electric push rod, DC mode, AC mode, step mode, permanent magnet electromagnetic synchronous mode, three-phase asynchronous induction mode, and so on. As a key component of automobile safety performance, brakes have always been the focus of attention and research by domestic and foreign experts and scholars. The quality and efficiency of their braking performance will directly affect the safety of transportation. Therefore, it is necessary to pay attention to the selection of brake accessoriesAccording to the actual application, in fact, single-phase electric speed governor and three-phase electric speed governor are common in electro-hydraulic push rod products, which are distinguished according to the different working power modes; According to different forms of protection, electric speed regulators can be divided into three levels: first level, second level, and third level.In addition to the above classification methods, the operating speed and insulation level can also serve as the classification basis for electric speed regulators in electro-hydraulic push rod products. The former can be divided into constant speed motors, high-speed motors, low-speed motors, and speed regulating motors; The latter can be divided into local insulation mode, full insulation mode, and semi insulation modeElectric hydraulic brake, electric hydraulic thruster, electric hydraulic block brake, explosion-proof electric hydraulic thruster, explosion-proof electric hydraulic brake, explosion-proof electric hydraulic thruster, ED electric hydraulic thruster, YT1 electric hydraulic thruster, BED explosion-proof electric hydraulic thruster, BYT1 explosion-proof electric hydraulic thruster, hydraulic disc brake, electromagnetic disc brake, wind power yaw brake pad, wind power yaw brake, Wind power brake, pneumatic disc brake, pneumatic caliper disc brake, electromagnetic power loss brake, disc brake pad, electric hydraulic brake pad, YWZ electric hydraulic brake, YWZB electric hydraulic brake, YWZ2 electric hydraulic brake, YWZ3 electric hydraulic brake, YWZ4 electric hydraulic brake, YWZ4B electric hydraulic brake, YWZ5 electric hydraulic brake, YWZ8 electric hydraulic brake, hydraulic block brake, The YTD series thruster is used as the driving device for the brake. Mainly used for mechanical braking of driving devices in lifting, transportation, metallurgy, mining, ports, and construction machinery.The installation dimensions comply with JB/ZQ4388-97 standard. The technical conditions comply with the JB/T6406-2006 standard.

time:2021-06-07

More

Crane winch disc brake manufacturerResearch level and current status of noise inside and outside of service brakesThe early research on brake noise focused on the drum brake which was widely used at that time. Now the disk brake has become the focus of research because of its wide application. The systematic research on brake vibration and noise from both theoretical and technical perspectives began in the 1950s. So far, many practical engineering methods and various mechanical models have been accumulated to solve specific problems. But so far, there has been no consistent conclusion on the research of this problem from the mechanism to the analysis method. The measures used in engineering to suppress the generation of screams are basically empirical and do not have universality.The frequency range of braking noise of winch disc brake of crane is very wide. It can range from tens of hertz to tens of thousands of hertz. During a braking session, the braking noise is mostly a single tone, with occasional occurrences of two or three tones simultaneously. In the perception of the human ear, the high-frequency components generally within a few million hertz are harsh and difficult to eliminate. They are the main component of braking noise and are also the focus that manufacturers need to study and solve. Throughout the 1950s, the characteristics of friction materials themselves were considered the fundamental cause of brake squealing. There are two main theories at this stage. The theory attributes the brake squeal to the frictional characteristics of the friction pair. Based on this theory, the study can simply attribute the brake squeal to the self-excited vibration problem of the braking system when the static friction coefficient is greater than the dynamic friction coefficient or the change rate of the dynamic friction coefficient f with the relative sliding speed v. Caliper disc brakes were used only as central brakes in the past, but now they are increasingly used as wheel brakes by various cars and trucks. The full disc brake is only used for a few vehicles, mainly heavy vehicles as wheel brakes, and can also be used as a retarder in some cases.The winch disc brake of crane, especially the floating caliper disc brake, is widely used because it has the following advantages:A. The output torque of the disc brake is less affected by the temperature change, and the performance is stable and reliable;B. Most of the brake discs of the disc brake are exposed to the air, so the heat dissipation capacity is strong, and the temperature change of the brake disc is small during braking;C. After the temperature of the brake disc rises, the variation along the thickness direction is much smaller than the radial variation of the brake drum, resulting in smaller changes in pedal travel and brake air conditioning, and a relatively stable time for the brake to function;D. The braking performance of the disc brake recovers quickly after wading, and it only needs one or two times of braking to return to normal;E. When the output braking torque is the same, the size and mass are generally smaller;F. It is easier to achieve clearance action adjustment, and other maintenance and repair operations are also simpler.The theory of friction characteristics of winch disc brake of crane can explain some phenomena of brake squeal, but it is inconsistent with many test results. Even with the same friction pair, the tendency to squeal varies greatly for brakes with different structures. R. The research results of TSpur indicate that sometimes unrelated braking screams still occur, and even if they are large, braking screams may not necessarily occur, leading to the emergence of a second theory, the Sprag slip theory. The Sprag Slip theory explains that when the friction coefficient is constant (that is, f is independent of), the self-excited vibration of the system can be caused only by the improper selection of the geometric characteristics of the friction pair. The further development of this theory has led to the formation of the geometric characteristic coupling theory. The coupling theory of geometric characteristics emphasizes the influence of structural coupling characteristics (friction coupling between friction surfaces and elastic coupling between various components) on brake squeal. The f-characteristic of friction materials is not a necessary condition for generating brake squeal, and f itself is also an important factor affecting brake squeal. For driving, brakes are not only working devices but also safety devices. With the development of technology and the improvement of energy-saving and environmental protection requirements, more and more permanent magnet synchronous gearless traction machines will replace traditional worm gear and worm type traction machines. Therefore, there may be no need to install a separate upstream overspeed protection device. The brake of this type of permanent magnet synchronous gearless traction machine (which should undergo type testing) has an upstream overspeed protection function. The disc brake uses the end face of the disc as the contact surface of the friction pair. Crane winch disc brakeDisc brake is also called disc brake, which is named after its shape as its name implies. It is controlled by hydraulic pressure and its main components include brake discs, wheel cylinders, brake calipers, oil pipes, etc. The brake disc is made of alloy steel and fixed on the wheel. It rotates with the wheel. The friction brake can be divided into disc brake, external holding block brake, internal expanding shoe brake, band brake, comprehensive band brake, double shoe brake, multi shoe brake, simple single band brake, single disc brake, multi disc brake, fixed caliper brake, floating brake, etc. In 1991, it was awarded the Henan Province High Quality Product Award. In 1993, it was awarded the Brake Product Quality Approval Certificate by the National Center for Quality Supervision and Inspection of Lifting and Transportation Machinery. In 1994, it was awarded the Contract and Credit Enterprise by the Provincial Administration for Industry and Commerce. In 2002, it was the first to pass the International ISO9001:2000 Standard Quality Approval Certificate. In 2006, it was awarded the National "Special Equipment Type Test and Verification Certificate". Passed the international "Coal Mine Safety Certification" and "Explosion Proof Certificate" in 2011; Our company's products are now widely used and highly praised in industries such as metallurgy, ports, construction, hydraulic engineering, and lifting transportation nationwide. Our company aims to provide high-quality products, reasonable product prices, and comprehensive pre-sales and after-sales services. We are willing to sincerely cooperate with new and old friends for common development.Crane winch disc brakeHydraulic disc brakeSB50, SB100, SB160, SB250, SB315, SB400, YQP50, YQP100, YQP160, YQP250, YQP315, YQP400SBD100-A, SBD125-A, SBD160-A, SBD200-A, SBD250-ASBD80-B, SBD160-B, SBD250-C, SBD365-C, SBD425-C, SBD120-D, SBD240-D,ST1SH, ST2SH, ST3SH, ST4SH, ST5SH, ST10SH, ST16SH, ST25SH, ST25SH-A, ST25SH-C, ST40SH, ST1SH-A450SH, 4SH, 3SH, 5SH, 904SHST, SBD, SH images

time:2021-05-26

More

YLBZ series wheel brake/Henan disc brake manufacturer/Jiaozuo Hongqiao Brake Co., LtdThe hydraulic system of the wheel brake is specially designed for the hydraulic control equipment of the wheel brake. This hydraulic station consists of a set of horizontal oil pumps, motor sets, and control components. The control components are made of high-quality domestic components, which are composed of integrated oil circuit blocks to form a system. The system has stable commutation, reliable performance, convenient operation, compact equipment, neat and beautiful appearance, and convenient use and maintenance.Main technical parameters of hydraulic system1. System rated pressure: 8Mpa2. Peak pressure: 12Mpa3. Working pressure: 4~6Mpa (During debugging, as long as the working pressure of the brake can be opened, an additional 1Mpa can be added.)4. Working flow rate: 3.7L/min5. Motor: YB2 or YBK2-90L-4, 1.5KW 380V/660V or 660/1140V6. Normal operating temperature range of system oil: 5-70 ℃YLBZ hydraulic wheel brake:YLBZ25-160; YLBZ40-150; YLBZ40-160; YLBZ40-180; YLBZ40-200; YLBZ63-180; YLBZ63-200;YLBZ63-210; YLBZ100-200Performance Description of Hydraulic System1. Level sensor: an element that displays the liquid level in the oil tank.2. Air filter: Maintain a balance of air pressure inside and outside the closed fuel tank and prevent debris from entering the tank.3. Mesh oil filter: Used to clean the hydraulic oil entering the oil pump.4. Overflow valve: used to regulate system pressure.5. Air cooler (optional): used for cooling the system oil temperature. According to the size of the oil cylinder, it is optional for larger cylinder diameters and smaller system pressures.6. Explosion proof electromagnetic directional valve: mainly used for the movement of oil cylinders. When the solenoid valve is energized, the oil cylinder begins to move and the brake brake opens; When the solenoid valve loses power, the oil cylinder resets and the brake brake closes.7. Explosion proof temperature transmitter (optional): Used in conjunction with temperature measuring elements to convert temperature or temperature difference signals into standard unified signals.8. Explosion proof pressure transmitter (optional): It can convert the physical pressure parameters sensed by the pressure measuring element sensor into standard electrical signals for supply to secondary instruments such as indicator alarms, recorders, regulators, etc. for measurement, indication, and process adjustment.The main feature can be equipped with an interlocking backhaul equal device, which can always maintain equal backhaul of both sides of the pads during use, completely avoiding the phenomenon of one side of the brake pad sticking to the brake disc due to uneven backhaul, and equipped with an automatic tile following device.The main swing hinge points are equipped with self-lubricating bearings, which have high transmission efficiency and long service life, and do not require lubrication during use.The brake spring is arranged inside a square spring tube and is equipped with a brake torque scale on one side. The brake torque is directly displayed, making adjustment convenient and intuitive.The asbestos free brake pad is plug-in type, making it easy and fast to replace.The automatic compensation device for brake pad wear can maintain a constant distance between the pads and the brake torque during use.Some additional functions can be achieved by adding additional devices.It is a global enterprise in the fields of construction machinery, mining equipment, diesel and natural gas engines, industrial gas turbines, and diesel electric hybrid power units.Three types of waiting pictures for new wheels

time:2021-05-26

More

The electric hydraulic brake adopts advanced AC braking technology, which is directly powered by 3-phase 380V power supply. Without rectifier device, it has a wide range of braking torque adjustment, and can achieve two-stage speed regulation. It has the advantages of fast braking and reliable braking, and is suitable for spindle transmission and auxiliary transmission in various machines that require fast stop, accurate positioning, reciprocating operation, and prevent sliding. Such as lifting machinery, transportation machinery, packaging machinery, food machinery, printing machinery, woodworking machinery, deceleration machinery, metallurgical machinery, forging machinery, construction machinery, etc.Electric hydraulic brakes typically brake in worm gear transmission, where the worm is the active component and the worm gear is the passive component.(1) Features of Worm driveA single stage transmission can achieve a large transmission ratio, with a compact structure, stable transmission, and no noise, but low transmission efficiency.(2) Judgment of Turbine Steering in Worm driveIn Worm drive, the relationship between the worm and the turbine steering depends on the relative position between them, the rotation direction of the worm and its rotation direction.The left or right hand rule is used to determine the direction of the turbine relative to the worm, the right hand rule is used when the gear shift worm is right-handed (the worm is also divided into left and right rotation and the judgment method is the same as that of the helical gear direction), and the left hand rule is used when the worm is left-handed. Bend the four fingers to point to the rotation direction of the worm (the straight arrow indicates the Circular motion direction of the visible side of the worm), and the opposite direction of the thumb is the movement direction of the worm relative to the worm. The performance of the materials and components used in the brake should comply with relevant standards and regulations, undergo factory inspection, and be able to pass corresponding tests on the product.The magnetic material of the brake should be low-carbon high-quality carbon steel with good magnetic conductivity, electrical pure iron, and other magnetic materials with magnetic conductivity not lower than the above materials.The soft magnetic magnetic powder used in the brake should undergo stability treatment, and its physical and magnetic properties should comply with the provisions of relevant specialized technical conditions and standards.The insulation level of the excitation coil shall not be lower than level E.The outlet wire of the brake adopts high-temperature resistant, high-strength, and well insulated wires.The brake power supply device must be reliable.Electric hydraulic brakes generally have some symptoms before the brake malfunctions, such as shaking of the steering wheel during braking or a fine scream during braking. This all reflects a problem with the brake system, and it is time to replace or repair the brake discs or pads. Because the brake disc is damaged, it will cause uneven force on the brake disc during braking, causing the steering wheel to shake. A very thin and sharp metal friction sound is emitted, indicating that the electric hydraulic brake pads have been worn very thin and need to be replaced in a timely mannerSpiral transmission uses a pair of screws and nuts to achieve transmission requirements, mainly used to convert rotary motion into linear motion, while transmitting motion and power.Classification of screw drives for electric hydraulic brakes:1) Transmission screw: Mainly used to transmit power, requiring a smaller torque to generate a larger axial thrust to overcome working resistance. Such as the spiral of various lifting or pressure devices. This type of transmission screw mainly bears a large axial force, usually abbreviated as work, with short working time and low working speed each time.2) Conduction spiral: Mainly used for transmitting motion, sometimes also subjected to significant axial loads. For example, the screw of the machine tool feed mechanism. The conductive spiral mainly operates continuously for a long time and has a high working speed, therefore requiring high transmission accuracy.3) Adjusting the screw: to adjust and fix the relative position of the parts. Spiral of fine adjustment mechanisms in machine tools, instruments, and testing devices. The adjustment screw does not rotate frequently and is usually adjusted under no load.The characteristics of spiral transmission include high transmission accuracy, stable operation without noise, easy self-locking, and the ability to transmit large amounts of power.Brakes Co., Ltd. has taken the lead in passing the ISO-9001:2000 quality management system certification in the same industry, possessing electric hydraulic brake actuators YWZ2 electric hydraulic brake, YWZ3 electric hydraulic brake, YWZ4 electric hydraulic brake, YWZ4B electric hydraulic brake, YWZ5 electric hydraulic brake, YWZ8 electric hydraulic brake, YWZ9 electric hydraulic brake, YWZ10 electric hydraulic brake, and YWZ13 electric hydraulic brake, YWZ12 electric hydraulic brake, YW electric hydraulic brake, YW-L electric hydraulic brake, YW-E electric hydraulic brake, YW-P electric hydraulic brake, YW-K electric hydraulic brake, TYWZ2 foot hydraulic drum brake. YWZ4 type test certificate of special equipment, YWZ9 type test certificate of special equipment, YWZ8 type test certificate of special equipment, YW type test certificate of special equipment, and domestic product inspection test bench, enterprise technology center and various new product patents, among which the output and performance of disc brake rank first in China. It is currently one of the few brake production enterprises in the brake industry that has obtained recognition certificates, and one of the enterprises recognized by the Quality Supervision and Inspection Center for Lifting and Transportation Machinery for product quality. The company has developed over 200 varieties and specifications of products, including electric hydraulic block brakes, disc electromagnetic brakes, electric hydraulic thrusters, various single-phase and three-phase AC/DC electromagnets, and an annual production capacity of over 100000 sets of various brake, thruster, and electromagnetic products. It is a domestic manufacturer that integrates the research, development, and manufacturing of a series of electric hydraulic brakes and various electric hydraulic thrustersYWZ4BZ4Z5Z9 diagram

time:2021-05-26

More

Pneumatic caliper disc brake QP12.7 QP15 QP20 CQP25.4-D QP30-DBy changing the air pressure, subtle torque adjustment of the machinery becomes possible.(1) Prevention of overload of the gate (2) Tension control (3) Soft start, smooth stop, etc., with good accuracy implementation3. Pneumatic safetyNo electrical sparks generatedDue to not using electrical equipment, there is no electrical spark generated, which is reassuringNon asbestos friction plateGrinding edges does not use asbestos at all, achieving good wear resistance and heat resistance.4. Be slow and at easeHigh-speed actuationCompared to electromagnetic type, the response speed is 20% fasterSmooth combined brakingThe adjustment of the communication bureau is very simple, allowing for smooth power connection and braking.The smooth operation enhances the durability of the machinery and generates great value.5. Long service life and simple maintenanceLong lifespanThe heat release effect is good, and the thickness of the friction plate is very generous. Compared with the electromagnetic type, the lifespan is 2.5 to 5 times longer.Easy installation and operationDue to its simple and integrated construction, installation and operation are both simpleThe exchange of friction plates is simpleTwo parallel long tracks are formed by overlapping movable arms on both sides of the car, which are unloaded one by one onto the mining car by a warehouse type trolley with four rollers, which is filled with minerals. The capacity of a warehouse type trolley can be equal to or half of the capacity of a mining car; Every time a mining truck is fully stored, the warehouse type trolley will make one or two round-trip trips. Using this type of train in the excavation of single track single end tunnels can save a lot of shunting time. A fully steel structure mining car with two sleeve connected cylinders installed on both sides of the lower part of the pneumatic self dumping car body; There are two types: narrow gauge and quasi gauge. When using this type of mining truck. The bucket type transfer train must be equipped with an air compressor when connecting several mining cars in series on the traction locomotive or at the unloading site. When the cargo needs to be overturned, compressed air is introduced into the cylinder. For mines with unified compressed air pipeline networks, pipeline compressed air can also be used for unloading work. This type of mining car has a long service life and a small maintenance workloadDue to the obvious advantages of the disc brake, there is a trend to replace the block brake on some equipment. Former West German companies such as BUBENZER, KRUPP, and DEMAG all have a series of production crystals for this type of brake. For example, BUBENZER has multiple series such as SKP, SKD, and SB. In 1980, the former West Germany formulated a draft of relevant standards for disc brakes, which was revised in 1989 to gradually standardize the design and manufacture of disc brakes. Several companies in Japan also produce disc brakes, such as Sumitomo Electric, which uses British technology to produce MK series disc brakes, and Japan Co., Ltd. and BUBEN.ZER jointly produce sB series disc brakes. The former Soviet Union, the United States and France also produced disc brakes. In recent years, many of the various hoisting machinery, metallurgical machinery, ship unloaders, large excavators and other equipment imported from China use disk brakes. For example, the crane running mechanism of the Overhead crane imported from Japan by the hot rolling plant of WISCO uses a normally open pedal hydraulic disk brake, The Overhead crane introduced from France by Qinshan Nuclear Power Station uses the disc brake as the safety brake. The working principle of the pneumatic brake is to input pressurized gas into the air chamber of the pneumatic brake, so as to drive the piston to move in a straight line, so that the friction block of the brake can lower the brake and press the brake wheel to produce friction and brake. The pneumatic brake is connected by air pressure, released by a reset spring, and the disc slides along the axis with air pressure to contact the friction plate. Discs, friction plates, etc. are assembled onto the wheel hub to form an integrated structure. The friction plate can be disassembled by unscrewing the adjusting nut, and the exchange is simple. Pneumatic brakes are constructed by installing a tapered shaft sleeve with a wedge onto the shaft, with friction plates that can be exchanged while maintaining the mechanical equipment in its original state. The heat generated by friction is dissipated by a cooling plate installed on a disc with a hub. The friction plate is a double cut split type, which can be exchanged by using a screwdriver to remove the countersunk screw through the hole of the hub disc. Pneumatic brakes have good heat dissipation and can be widely used in industries such as packaging machinery, wire and cable equipment, thin paper, and corrugated paper.Pneumatic brakes, also known as ventilated brakes, mean that there is a fully inflated air that applies pressure to the socket to achieve braking effect, which is widely used in industry. When it comes to pneumatic brakes, they are also divided into normally closed brakes and normally open brakes. Normally closed brakes keep their sockets open when they are not working, and when they are ventilated during operation, they brake and form a brake.The products are widely used in lifting, mining, mechanical metallurgy, electricity, railways, water conservancy, ports, chemical engineering, and docks. Our factory has obtained the special equipment type test certificate issued by the National Lifting Machinery Quality Supervision and Inspection Center. It was rated as a contract abiding and credit worthy enterprise in Henan Province and a contract abiding and credit worthy enterprise in Jiaozuo City. Our factory adheres to the principle of quality and customer satisfaction. Think about the user's thoughts, be anxious about the user's anxietiesMain features:The QP series adopts spring braking and pneumatic release; The CQP series is pneumatic braking with spring release.2. The overall structure is simple, small in size, and lightweight.3 asbestos free brake pads, green and environmentally friendly. The arrangement of the brake pad adopts a spring clamp type, which is convenient and fast to replace.4 The brake pad is easy to adjust after being worn.Each disc diameter of the 5 QP series brake can be adjusted for four levels of braking torque.All power sources do not need to be set separately and can be connected to the existing air compression station for grid use. A speed regulating valve is installed in the gas supply line, and the braking time can be infinitely adjusted.7 brake block automatic follow-up device to ensure equal clearance between the brake block and the host brake disc during the opening and closing operation of the entire machine.Usage conditions:Environmental temperature -5 ° C to 40 ° C; Working pressure: 5-7bar for QP series and 7bar for CQP series; Outdoor rain and snow erosion or corrosive gases and media should be corrosion-resistant products; The air source should not contain oil, water, or other impurities.The altitude of the location where the DCPZ series is used shall not exceed 2000mThe power supply voltage is AC380V/50HZ. If the user has special requirements, please negotiate and confirm when placing an order.Consultation orderingModel of pneumatic caliper disc brake:QP12.7-A QP12.7-BQPL12.7A-A QPL12.7A-BQPL12.7-BCQP12.7-A CQP12.7-BCQPL12.7-A CQPL12.7A-A CQPL12.7A-BCQPL12.7-BQP12.7 Pneumatic caliper disc brake:Usage conditions:Environmental temperature -40 ° to+60 °Working air pressure 5-7Main performance and structural features:The overall structure is simple, with small volume and light weight.Asbestos free brake pads, green and environmentally friendly.The installation of the brake pad adopts a spring clamp type, which is convenient and fast to replace.The brake pad is easy to adjust after being worn.Each brake disc diameter of each specification can be adjusted for four levels of braking torque.All power sources do not need to be set separately and can be connected to the existing air compression station for grid use. A speed regulating valve is installed in the gas supply line, and the braking time can be infinitely adjusted.QPL12.7-A Pneumatic Caliper Disc Brake:Usage conditions:Environmental temperature -40 ° to+60 °Working air pressure 5-7Main performance and structural features:The overall structure is simple, with small volume and light weight.Asbestos free brake pads, green and environmentally friendly.The brake pad is easy to adjust after being worn.Each brake disc diameter of each specification can be adjusted for four levels of braking torque.QP12 series multi real graphs

time:2021-05-26

More